Furnace body of cupola furnace

A cupola and furnace body technology, applied in furnaces, vertical furnaces, furnace types, etc., can solve problems such as coke crushing, large investment in cupolas, and flue gas entering the workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

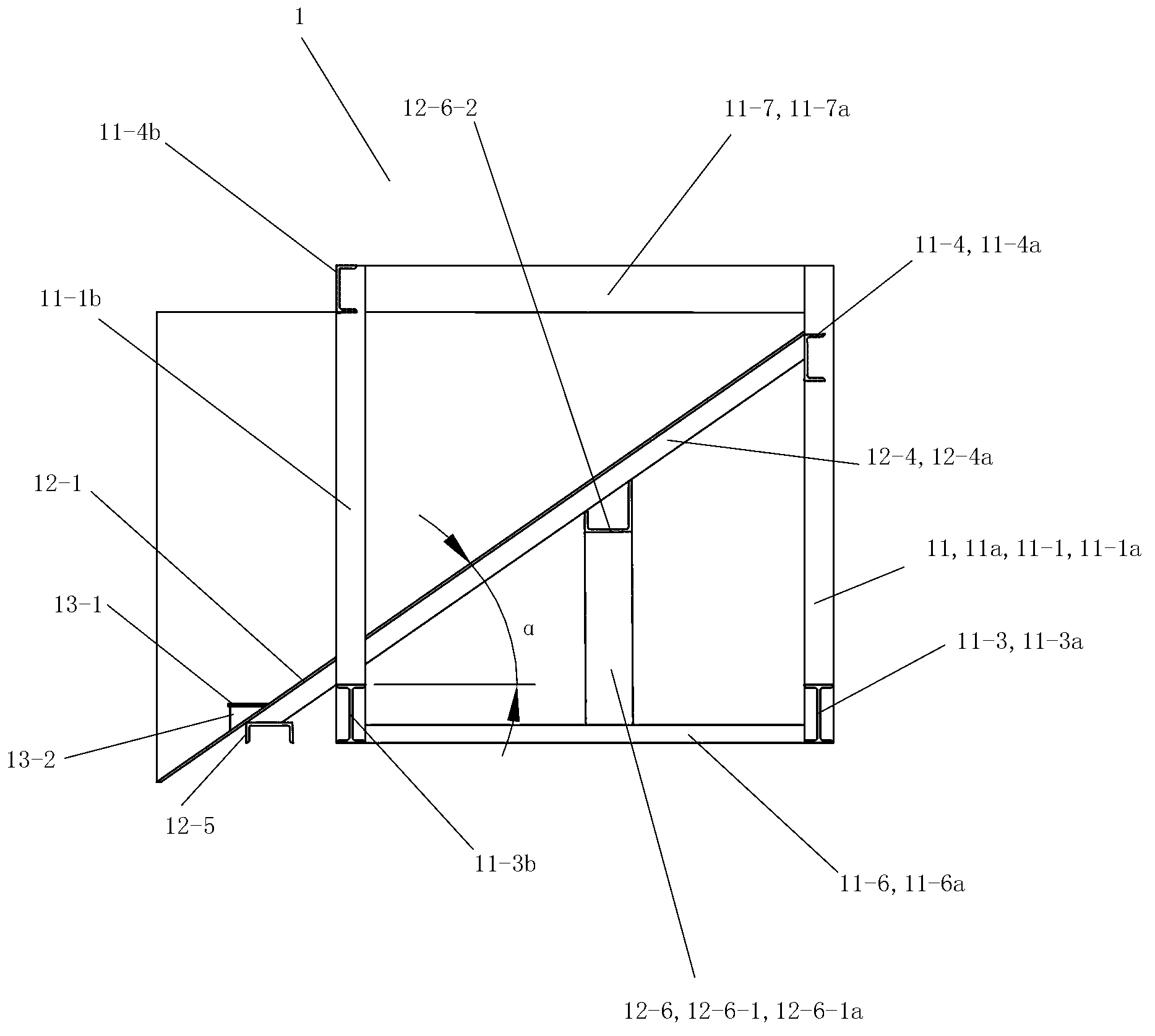

[0095] (Embodiment 1, material guide device)

[0096] See Figure 1 to Figure 3 , The material guide device 1 of this embodiment includes a support structure, a material guide structure 12 and a buffer device 13 . The support structure is a wedge-shaped support base or steel structure support frame made of cement and bricks (this embodiment is a support frame composed of straight steel components fixedly connected to each other in sequence, and the straight Steel components are I-beams or / and channel steels or / and angle steels).

[0097] The supporting structure of the material guiding device 1 includes a steel main frame body 11 a as a frame 11 . The main frame body 11a is a structural member in the form of a rectangular parallelepiped frame, and its upper part is open. The material guide structure 12 is fixed on the main frame body 11a in an inclined manner with the front high and the rear low.

[0098] The main frame body 11a includes two left vertical beams 11-1 and tw...

Embodiment 2

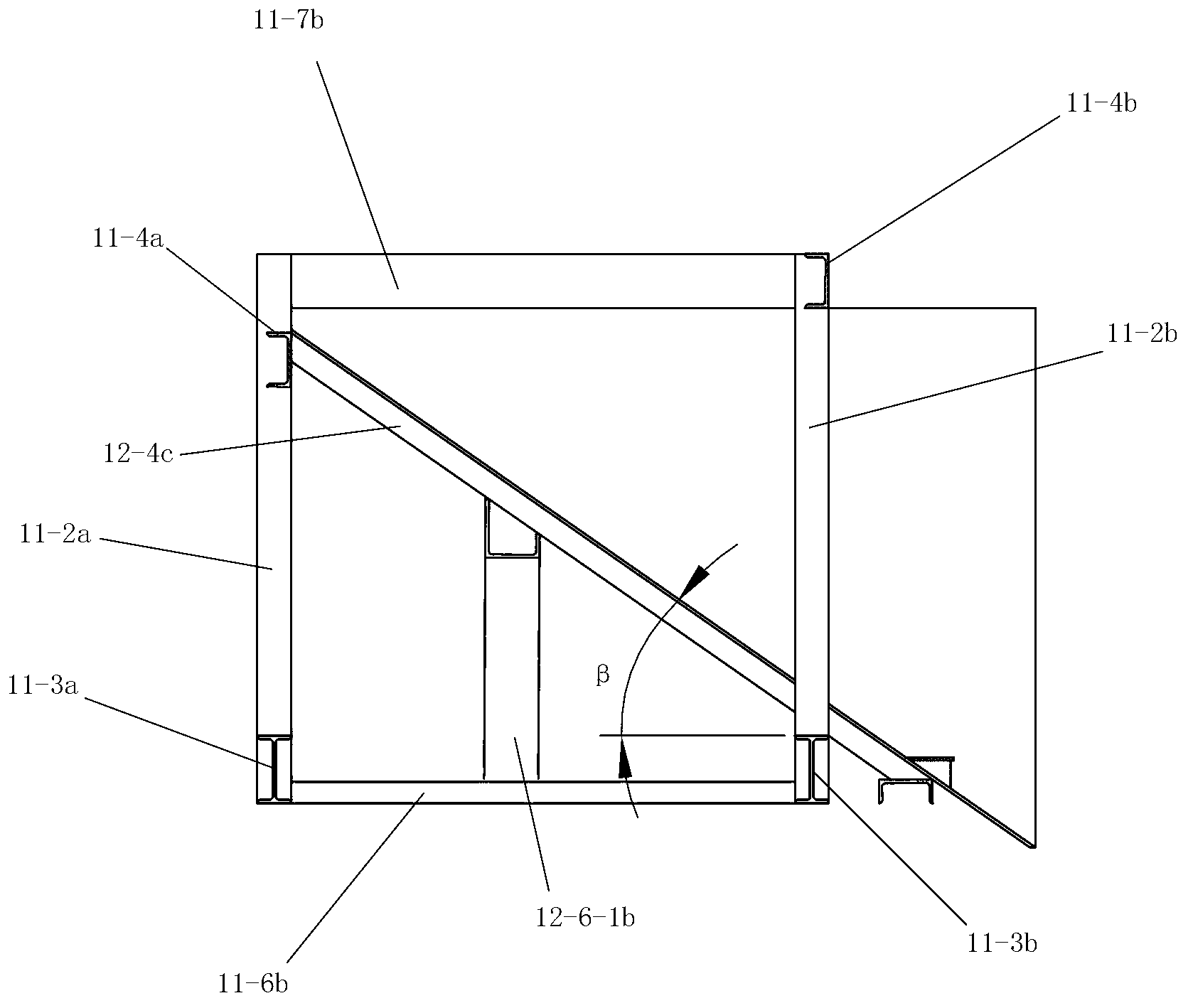

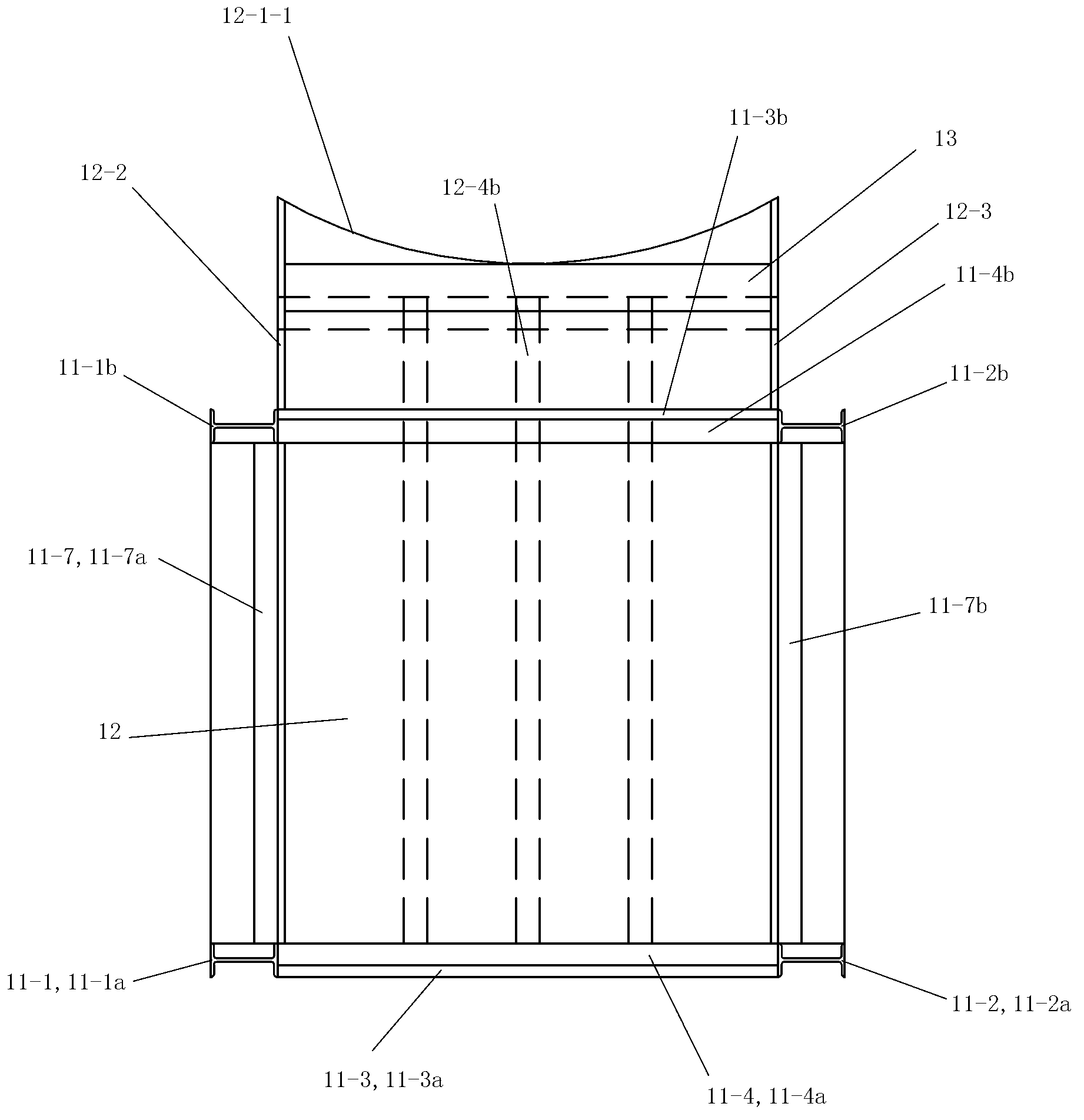

[0114] (Embodiment 2, material guide device)

[0115] See Figure 4 to Figure 6 , The material guide device 1 of this embodiment includes a support structure, a material guide structure 12 and a buffer device 13 . The material guide structure 12 , the buffer device 13 and the connection relationship between the material guide structure 12 and the buffer device 13 in this embodiment are the same as those in the first embodiment. The supporting structure of the material guiding device 1 includes a bracket 11 . The difference between this embodiment and Embodiment 1 lies in that the length of each vertical beam of the bracket 11 in this embodiment is twice the length of each vertical beam in Embodiment 1. The support 11 of the present embodiment is made up of two parts of the main frame body 11a and the barrel support frame 11b, and the lower half of each vertical beam is used as the vertical beam of the main frame body 11a, so that the main frame body 11a of the present embodi...

Embodiment 3

[0124] (embodiment 3, the furnace body of cupola)

[0125] See Figure 7 to Figure 9 and Figure 11 , the furnace body of the cupola of the present invention is a side-feeding type furnace body 2, which includes a furnace bottom part 2a, a hearth part 2b, a furnace body part 2c and a chimney part 2d in order from bottom to top. The supporting part 20 of the cupola includes a foundation, pillars, a furnace floor and a furnace door. The body of furnace 2 is basically in the shape of a circular column, and is the part of the cupola that is located on the furnace floor of the cupola supporting part 20. The upper material is the furnace lining 22 of refractory material, wherein, the part of the furnace lining 22 from the furnace floor to the lower edge of the feeding port is the furnace body 22-1.

[0126] See Figure 12 to Figure 16 , The furnace body 2 also includes a collision protection ring 23 . The collision protection ring 23 is formed by welding and fixing a cylindrica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com