Device for blending combustion of sludge in medium-speed coal mill and method

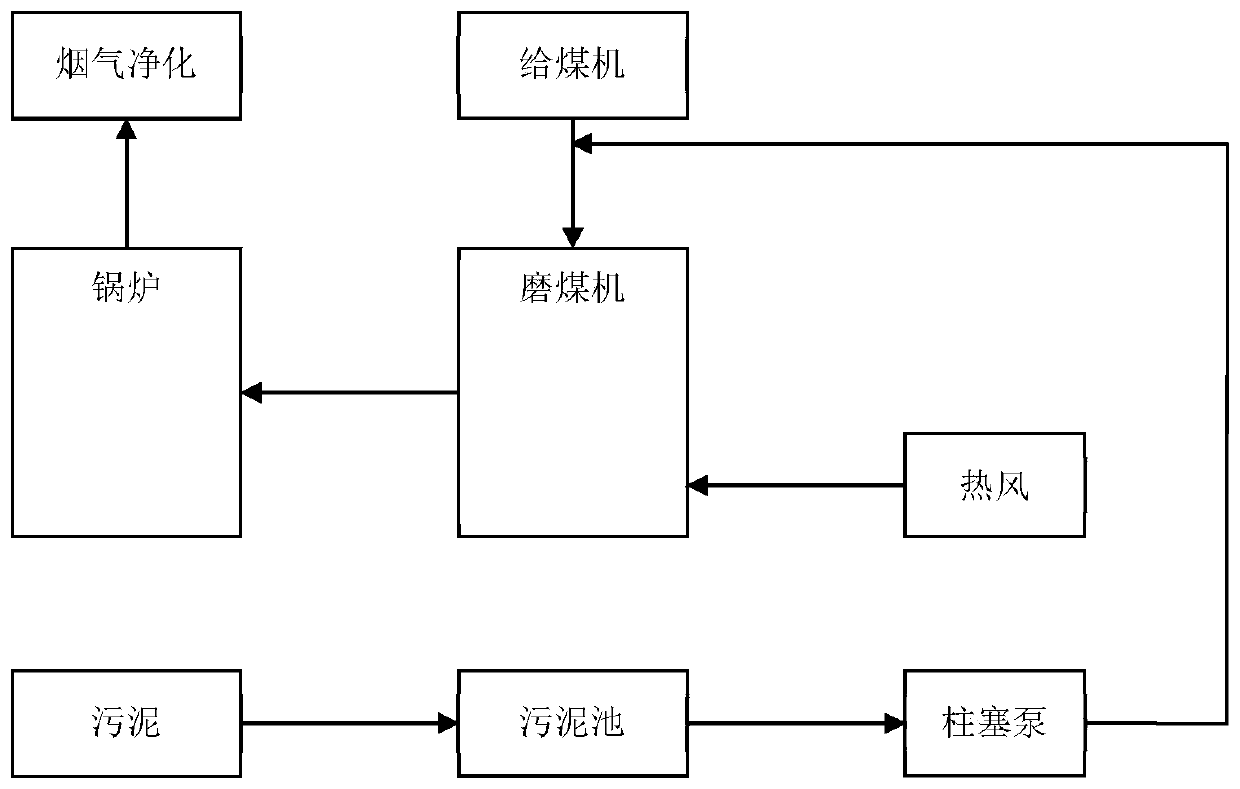

A coal mill and sludge technology, applied in combustion methods, dehydration/drying/concentrated sludge treatment, combustion types, etc., can solve the problems of large investment and high operation and maintenance costs, and achieve low investment, low operating costs, and savings effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

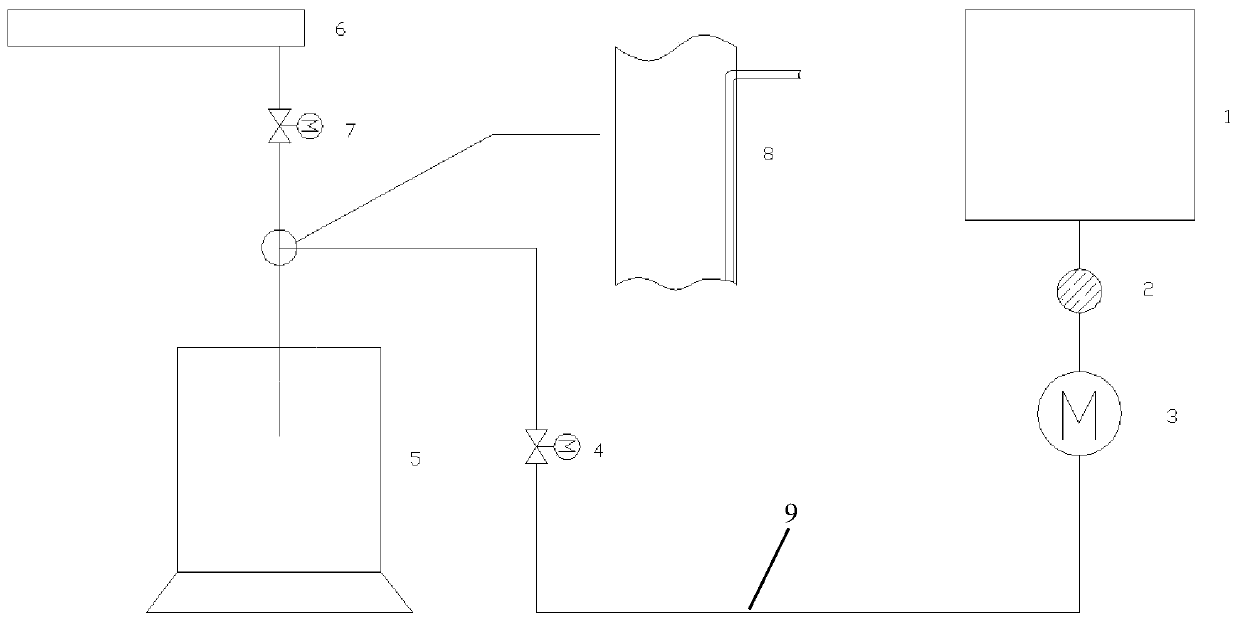

[0040]For a power plant with an installed capacity of 1000MW, when the load of the unit is 1000MW, 5 coal mills are running and 1 is standby. The maximum continuous output of a single coal mill is 80t / h. Due to the mixing of wet sludge, the coal mill Low load stable combustion and coal mill drying output limitation. Make the following assumptions:

[0041] 1) Select a single coal mill to run 60t / h of coal, and mix with 10% of sludge.

[0042] 2) Assuming that the water content of the sludge is 85%, according to the sludge water content-density relationship diagram, the corresponding sludge theoretical density d=1.1017g / ml.

[0043] 3) Select the S pendulum plunger pump produced by a certain company. The maximum conveying capacity is 10m 3 / h. The pumping volume can be adjusted steplessly according to requirements, assuming that the pumping volume is D=6t / h (slightly less than 6m 3 / h)

[0044] 4) The conveying speed is v=0.5m / s.

[0045] According to πr 2 =D÷v÷3600

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com