Molten steel flow divider bracket

The technology of a molten steel diverter and an angle steel is applied to the structure of the bracket and the structure field of the bracket of the molten steel diverter. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

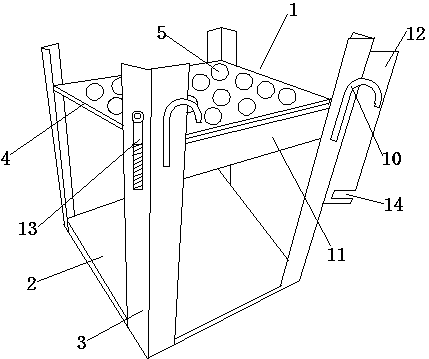

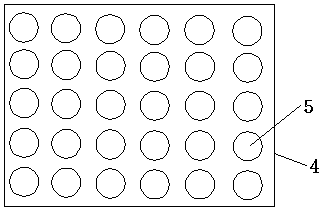

[0025] The support of the molten steel diverter, the support 1 is composed of a base plate 2 and support columns 3 respectively arranged on the four corners of the base plate. The upper part of the bracket is provided with a positioning plate 4 parallel to the bottom plate, the positioning plate is provided with a positioning hole 5 for placing the ingot mould, a connecting beam 11 is provided between two adjacent support columns, and insulation cotton baffles are provided on the four sides of the support Board, the middle and upper part of the outer surface of the bracket is provided with a hook 10.

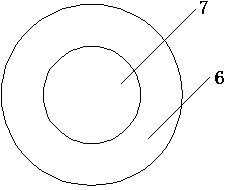

[0026] The positioning holes on the positioning plate are distributed in a dot matrix, and the ingot mold 17 is placed in the positioning holes. The ingot mold is cylindrical and has a cavity 18 inside. The aperture of the positioning holes is equal to the outer diameter of the ingot mold, and the ingot mold is inserted and fixed. in the positioning hole. Positioning strip 15 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com