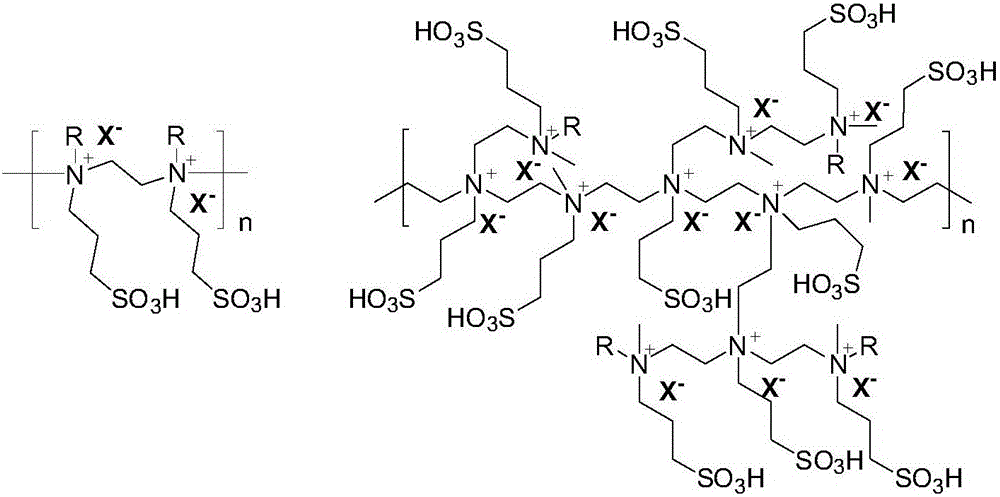

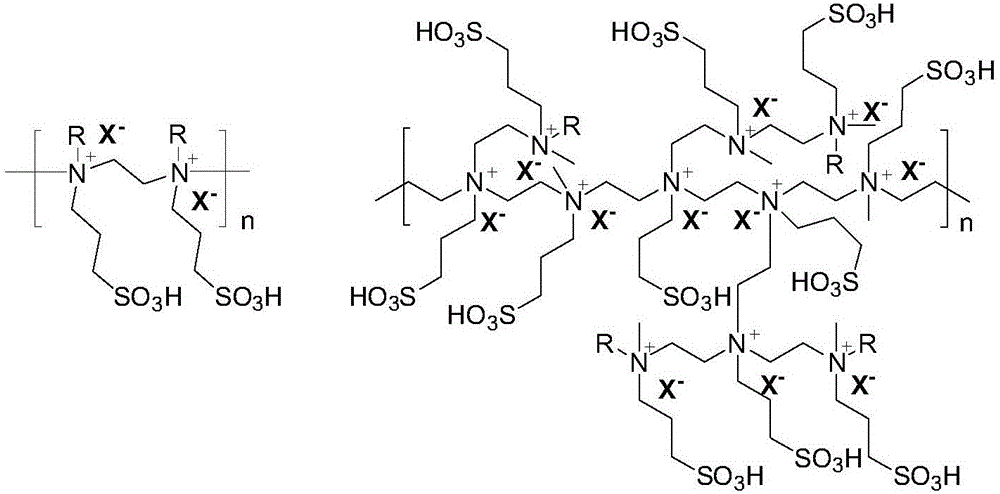

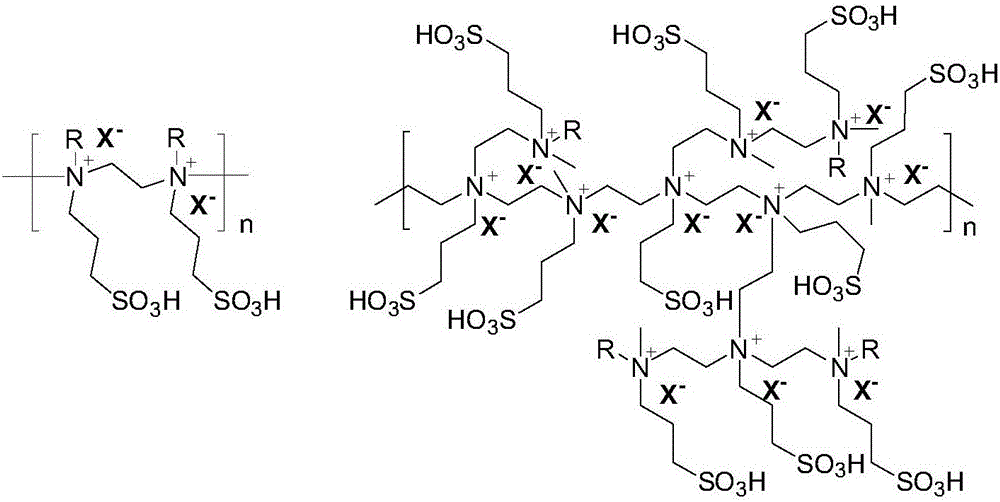

Polymerized ionic liquid catalysis method for preparing biodiesel

A technology for polymerizing ionic liquids and biodiesel, applied in chemical instruments and methods, biofuels, catalytic reactions, etc., can solve the problems of long post-processing process and complicated operation, and achieve convenient synthesis, good atomic economy, and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Put 0.284 gram of sulfonic acid group functionalized dodecyl polyethylene diammonium p-toluene sulfonate (average molecular weight 7700), 11.2 gram of oleic acid, and 2.6 gram of methanol into the reaction flask, stir, heat, The esterification temperature is 40-65°C. After reacting for 6 hours, the reaction solution was allowed to stand still and separated into layers, the upper layer of the reaction solution was poured out, methanol was distilled off, and the conversion rate of oleic acid was 51.4%.

Embodiment 2

[0038] Embodiment 2: Put 0.295 grams of sulfonic acid functionalized cetyl polyethylene diammonium p-toluene sulfonate (average molecular weight 8000), 11.2 grams of oleic acid, and 2.6 grams of methanol into the reaction flask, stir, heat, The esterification temperature is 40-65°C. After reacting for 6 hours, the reaction solution was allowed to stand and separated into layers, the upper layer of the reaction solution was poured out, methanol was distilled off, and the conversion rate of oleic acid was 53.4%.

Embodiment 3

[0039] Embodiment 3: Put 0.295 grams of sulfonic acid functionalized cetyl polyethylene diammonium p-toluene sulfonate (average molecular weight 24000), 11.2 grams of oleic acid, and 2.6 grams of methanol into the reaction flask, stir, heat, The esterification temperature is 40-65°C. After reacting for 6 hours, the reaction solution was allowed to stand still and separated into layers, the upper layer of the reaction solution was poured out, methanol was evaporated, and the conversion rate of oleic acid was 77.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com