Sediment removal machine for removing sediment at bottom of pile and working method thereof

A slag cleaning machine and slag sedimentation technology, applied in sheet pile walls, infrastructure engineering, construction, etc., to overcome incomplete slag cleaning, high degree of automation, avoid the risk of hole collapse, and use a large amount of mud to pollute the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing of description and specific embodiment:

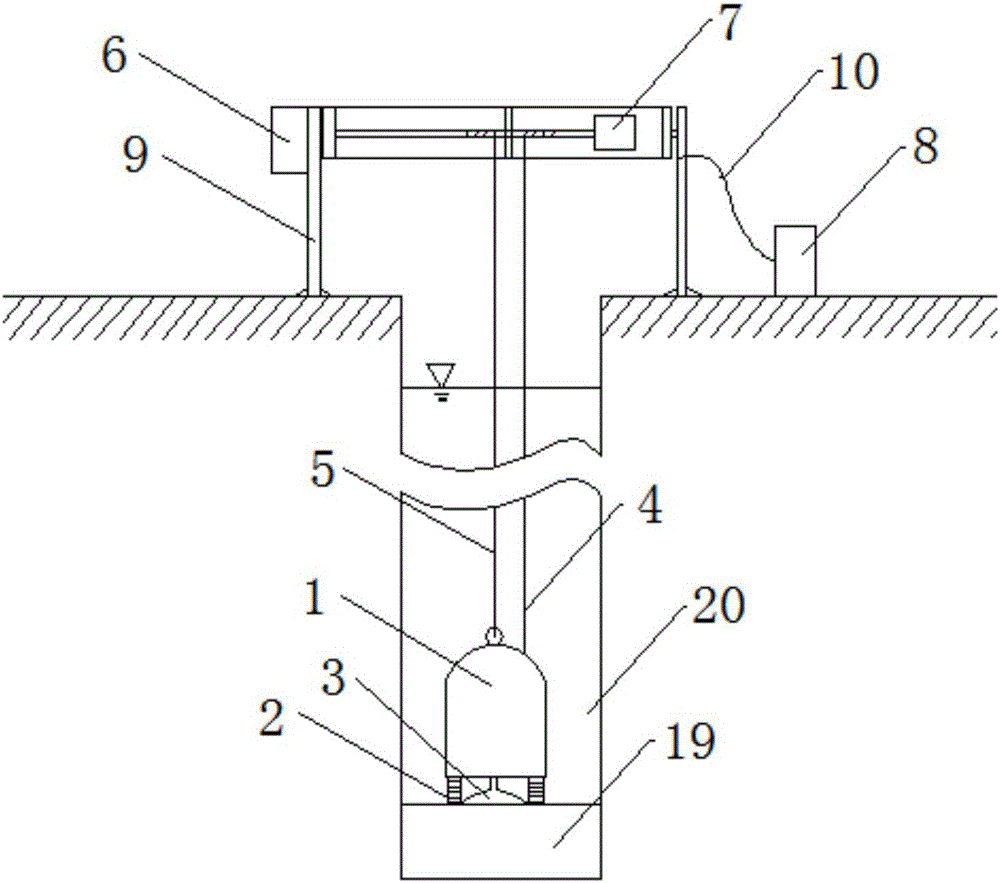

[0036] Such as figure 1 shown. The slag cleaning machine used for pile bottom sediment cleaning includes slag cleaning device 1, main controller 6, bracket 9, distribution box 8, lifting device, horizontal moving device, floating water cable 4, etc.

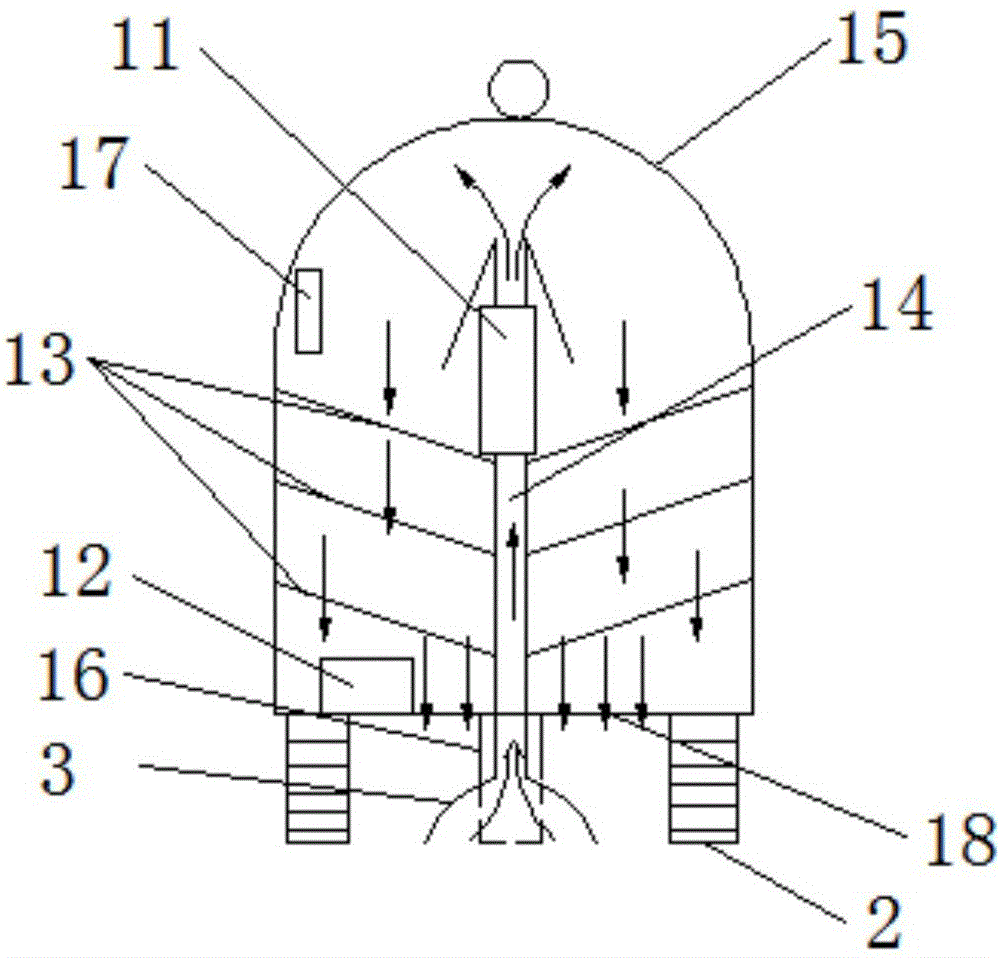

[0037] The structure of the slag removal device 1 is as figure 2 As shown, the slag removal device includes an outer cover 15, and the outer cover 15 is provided with a slag suction pipe 14 for absorbing sediment. 15, the slag suction pipe inlet 3 at the bottom of the slag suction pipe 14 spreads outwards in a trumpet shape; at least three layers of sediment filter screens 13 are arranged between the outer cover 15 and the slag suction pipe 14, and the sediment filter screen 13 The diameters of the mesh holes decrease sequentially from top to bottom, the height of the position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com