Patents

Literature

42results about How to "Improve slag cleaning efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

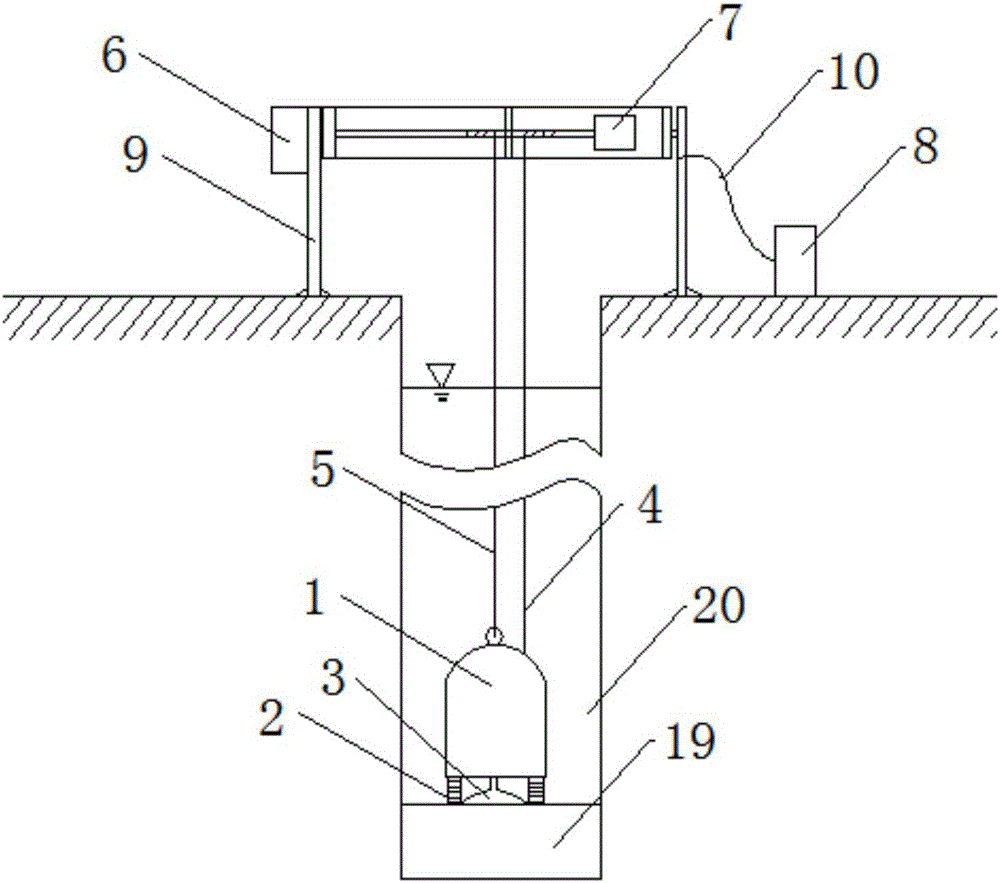

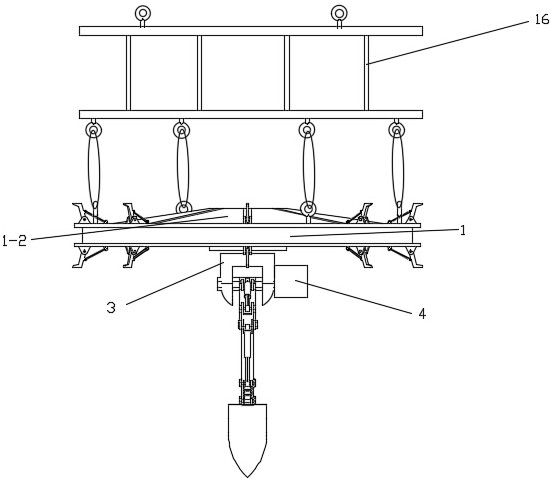

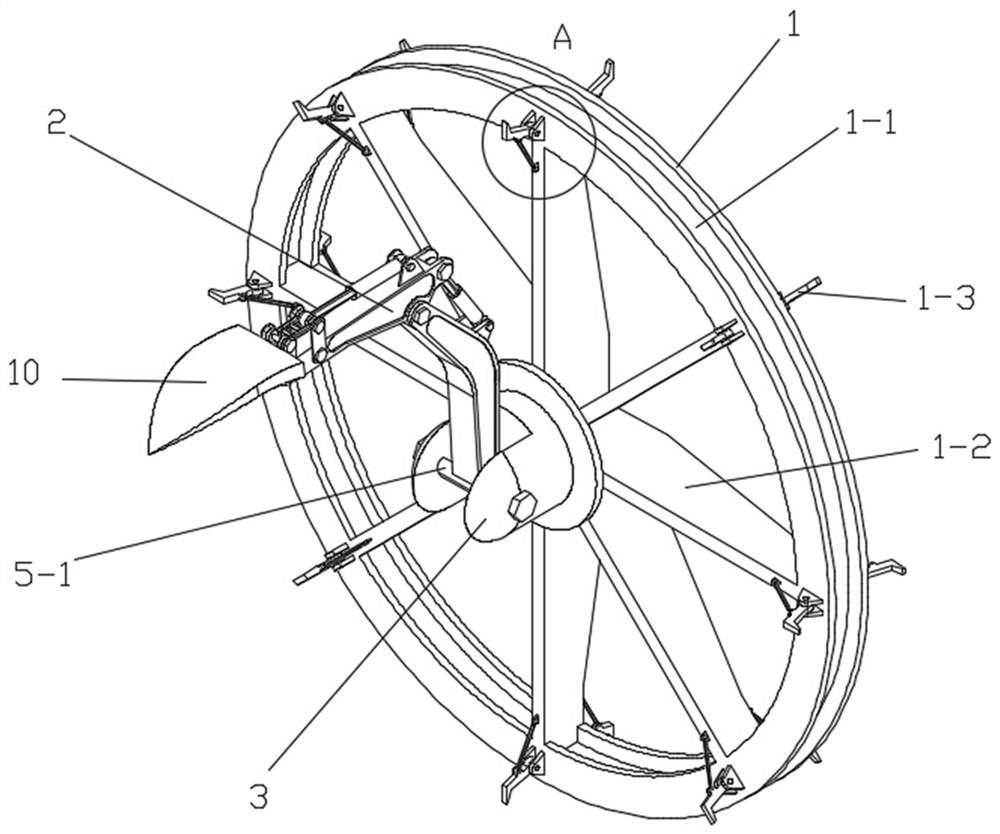

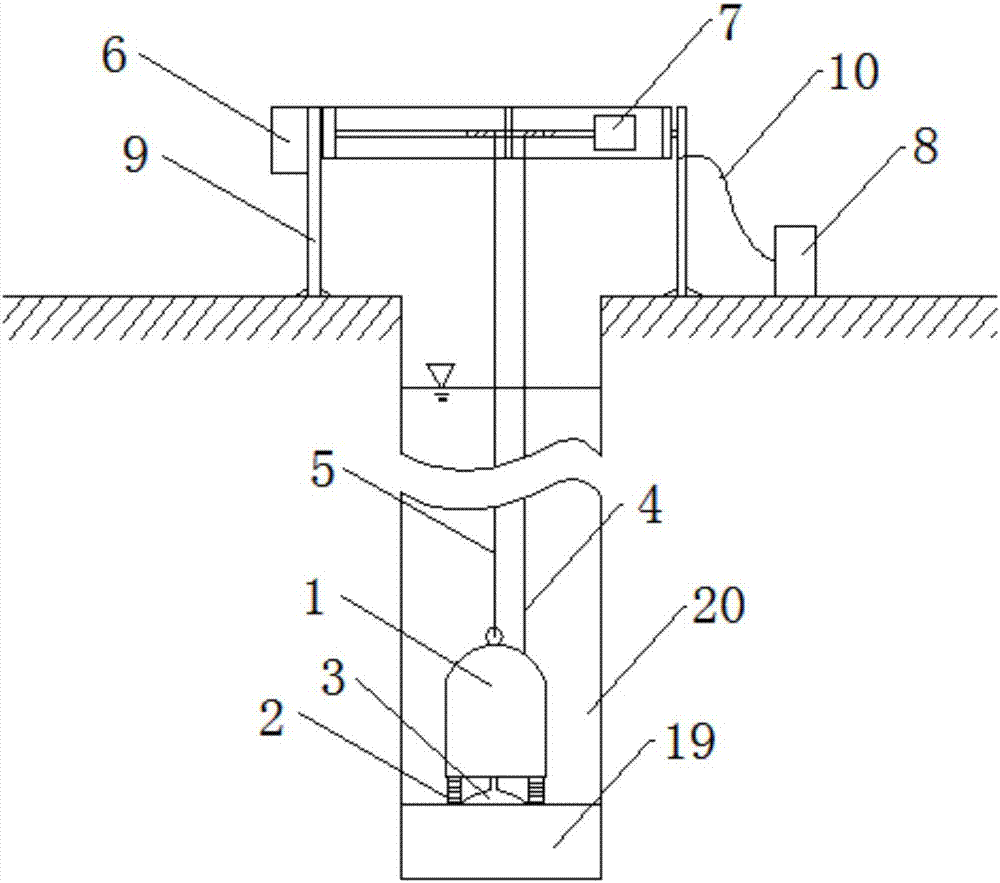

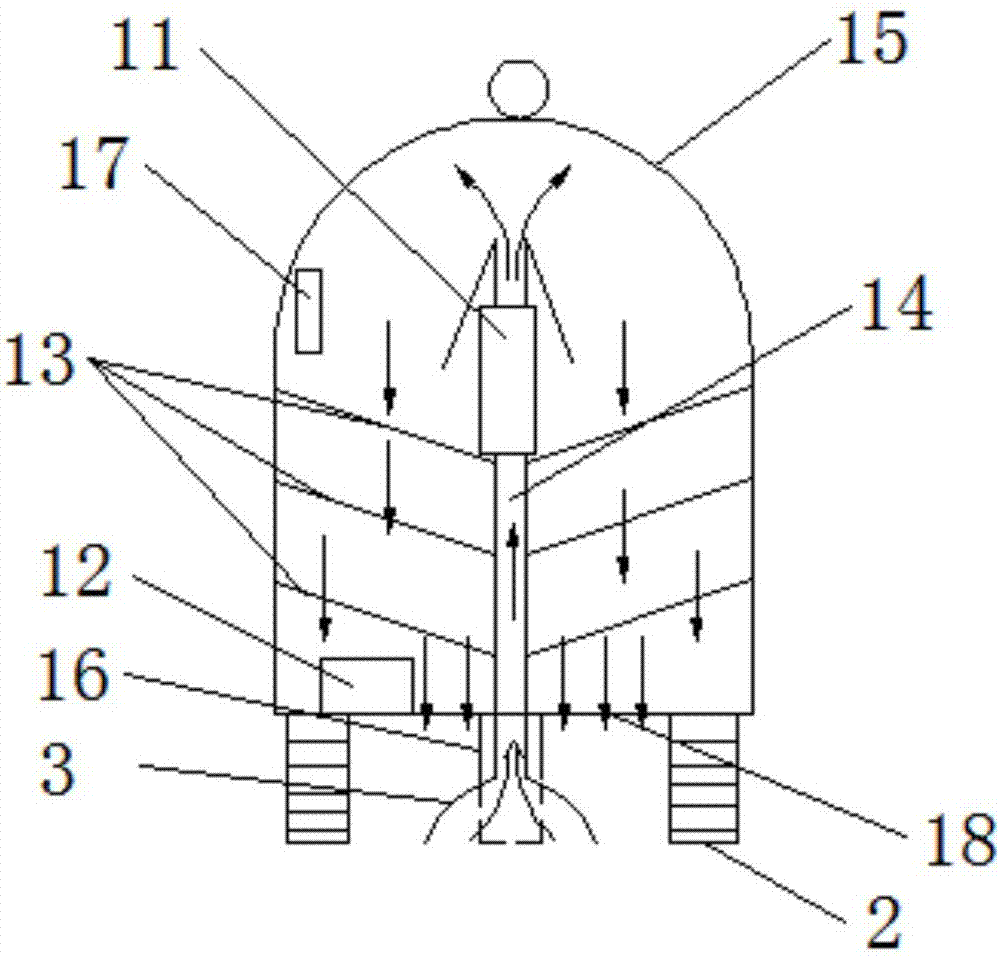

Sediment removal machine for removing sediment at bottom of pile and working method thereof

ActiveCN105821881AThorough slag removalAvoid the risk of hole collapseBulkheads/pilesSediment FilterDischarge return

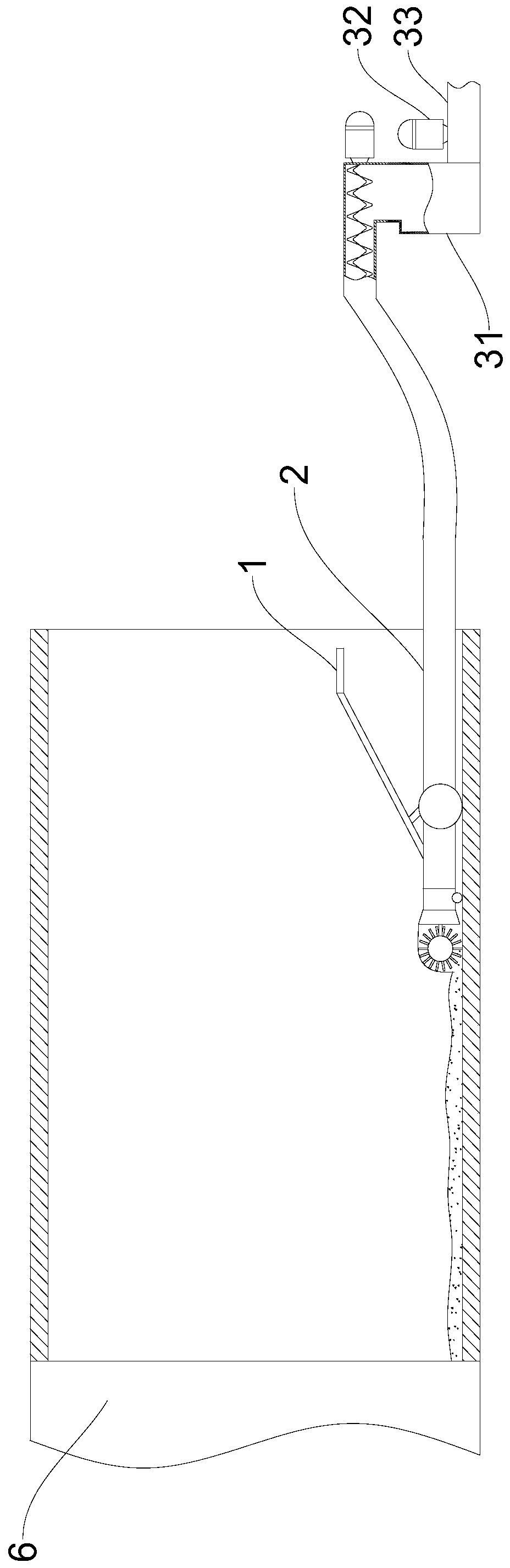

The invention discloses a sediment removal machine for removing sediment at the bottom of a pile and a working method thereof. The sediment removal machine comprises a sediment removal device and a main controller for controlling work of the sediment removal device. The sediment removal device comprises an outer cover, a sediment suction tube for sucking the sediment is arranged in the outer cover, and the bottom end of the sediment suction tube extends out of the outer cover so that the sediment at the bottom of the pile can be sucked into the outer cover. At least one layer of sediment filter screen is arranged between the outer cover and the sediment suction tube. The positions where the sediment filter screens are located are lower than an outlet of the sediment suction tube. A water outlet is formed in the bottom surface of the outer cover so as to discharge return mud flowing down the sediment filter screens. A sediment amount sensor is arranged on the upper portion of the inner side face of the outer cover and connected with the main controller. Mud displacement does not exist, mud pouring is not needed, the automation degree is high, operability is high, the sediment removal efficiency and effect are improved, the hole collapse risk caused by mud displacement is avoided, and the problem that the environment is polluted because a large amount of mud is used is solved.

Owner:SHANDONG UNIV

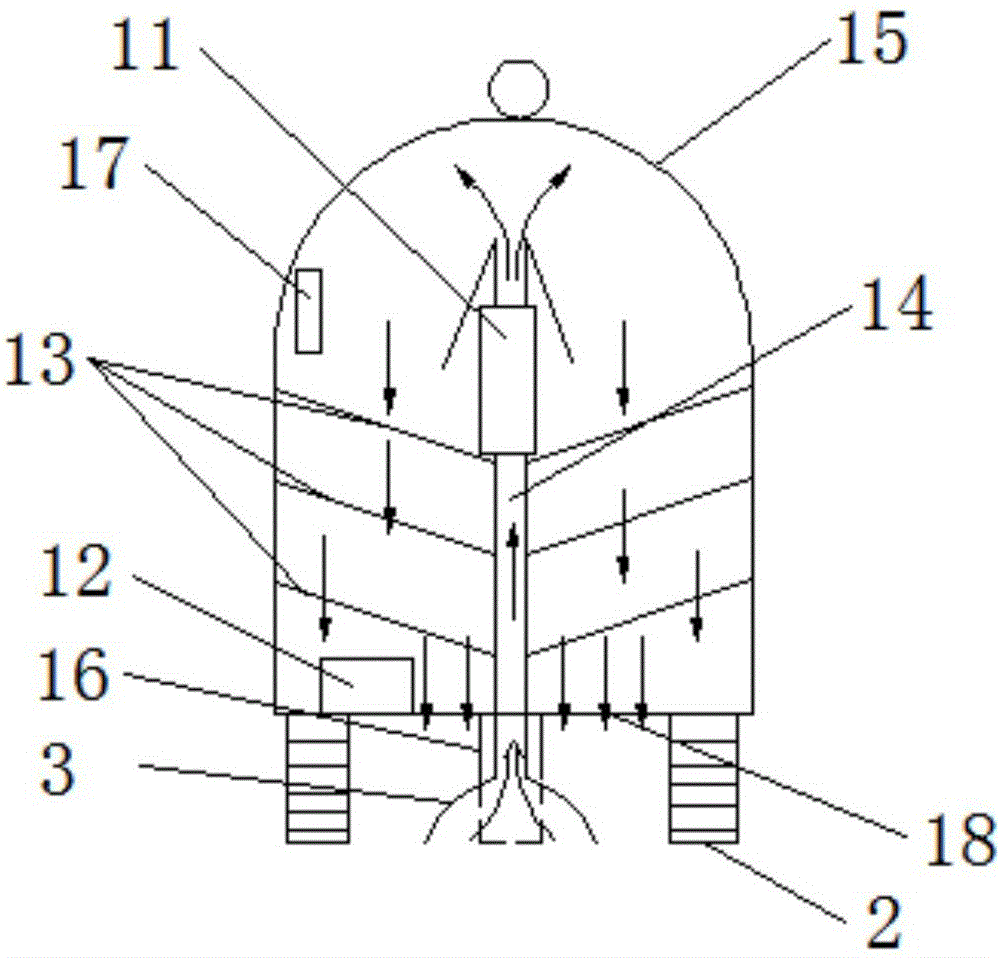

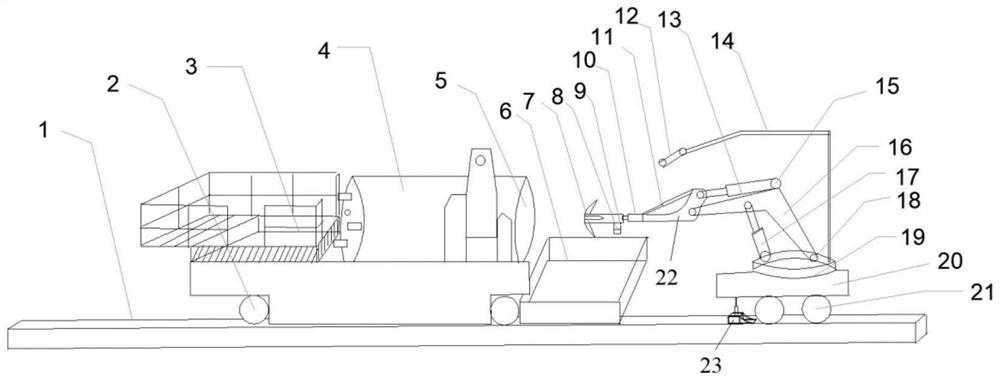

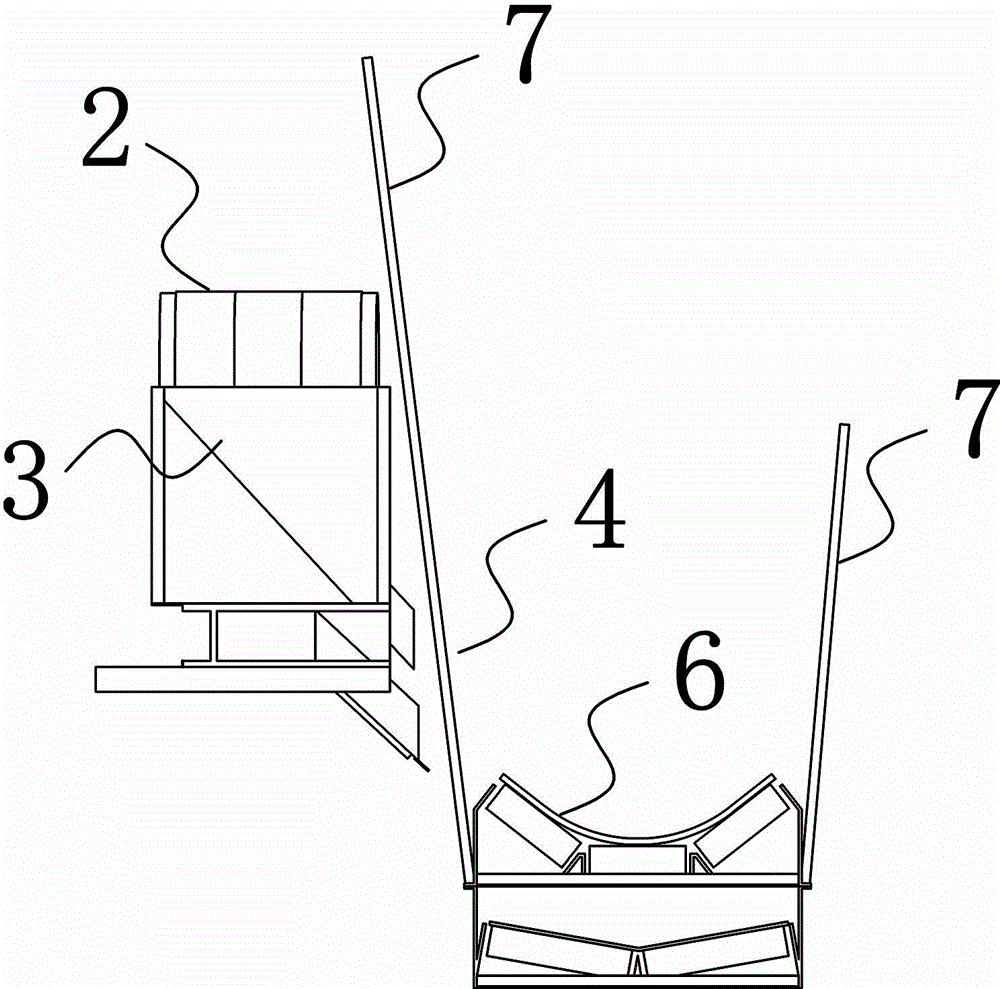

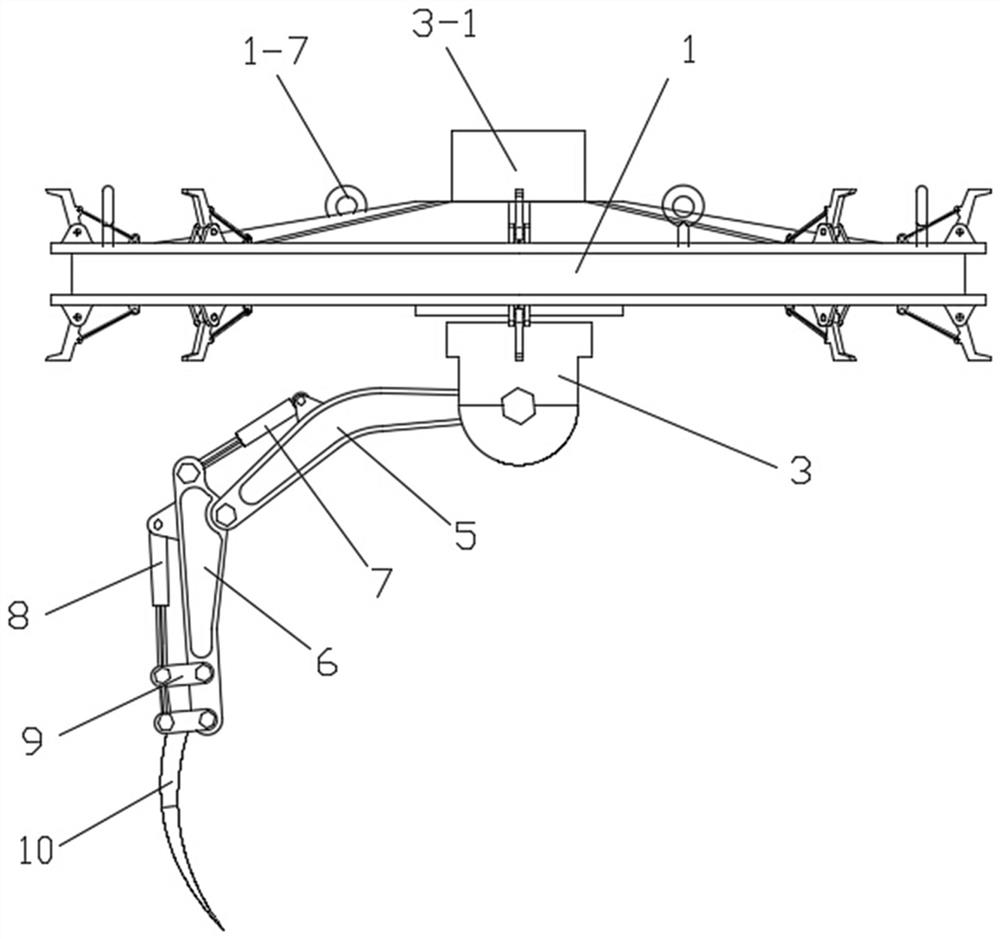

Multi-mode tunnel bottom slag removing robot suitable for tunnel boring machine (TBM)

The invention discloses a multi-mode tunnel bottom slag removing robot suitable for a tunnel boring machine (TBM). The technical problems that slag at the bottom of a tunnel is manually removed, the cleaning efficiency is low, the construction progress is affected, and the construction cost is increased are solved. The robot includes a TBM host and a main beam, wherein the main beam is arranged atthe back of the TBM host; the main beam is provided with a tunnel bottom slag removing robot system; the tunnel bottom slag removing robot system includes a driving system and tail-end slag-removingactuators; and mechanical arms are arranged between the driving system and the tail-end slag-removing actuators. According to the robot, a slag removing system is arranged at the bottom of the main beam; the appropriate tail-end slag-removing actuator is selected for removing the slag according to the slag characteristics and the slag amounts at the bottom of the tunnel; and the slag at the bottomof the tunnel is automatically removed, so that the slag removing efficiency is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

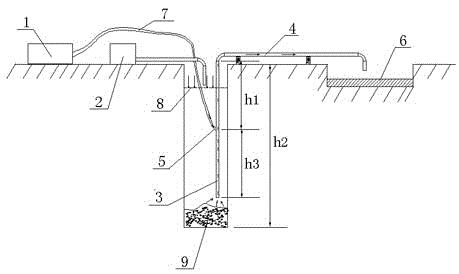

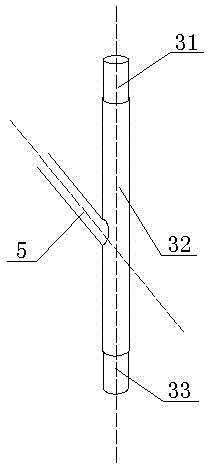

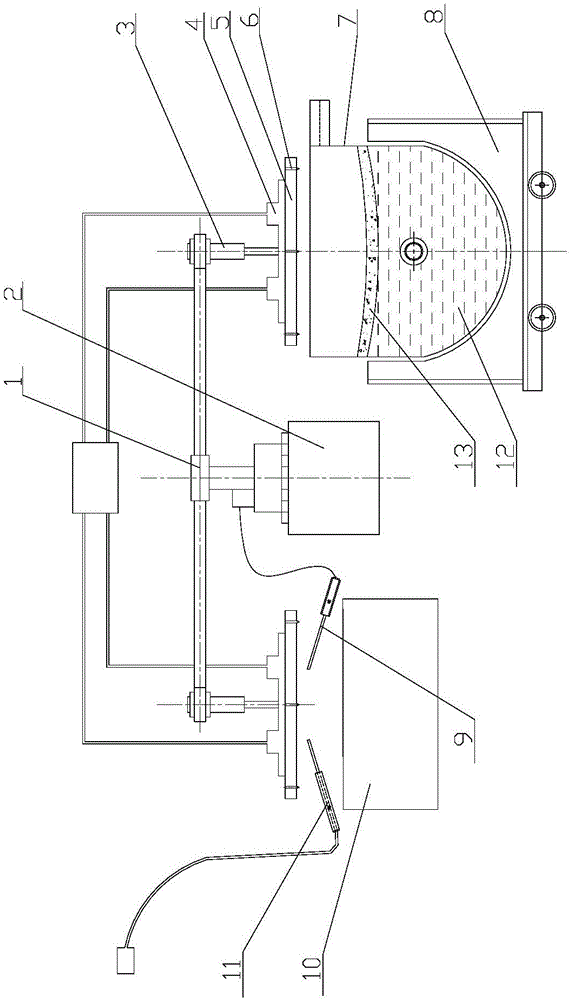

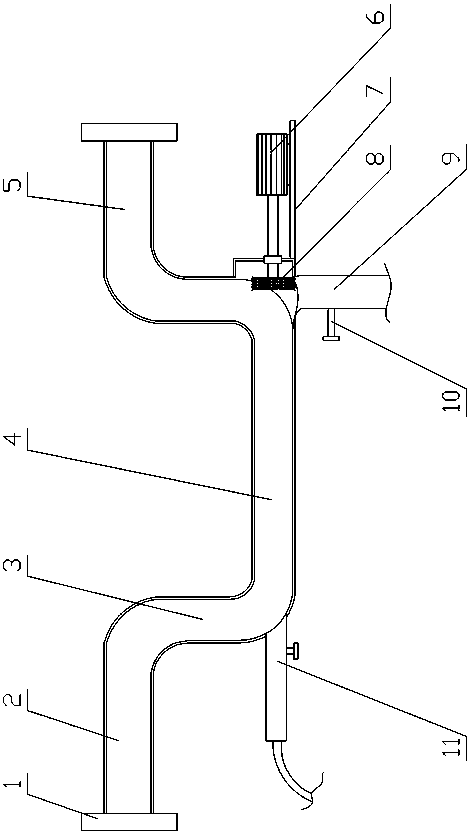

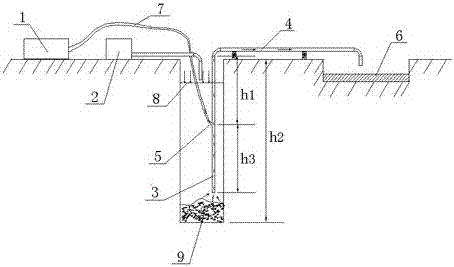

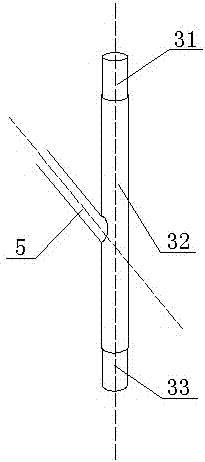

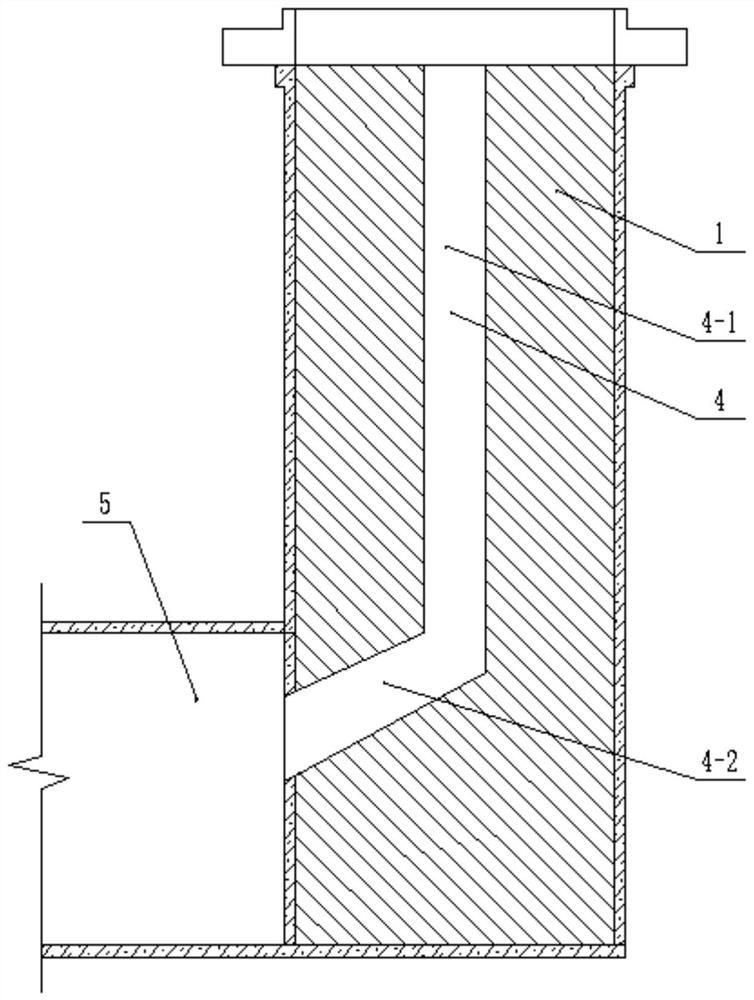

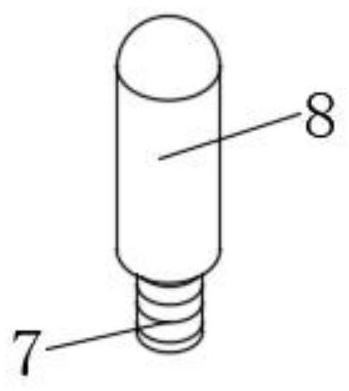

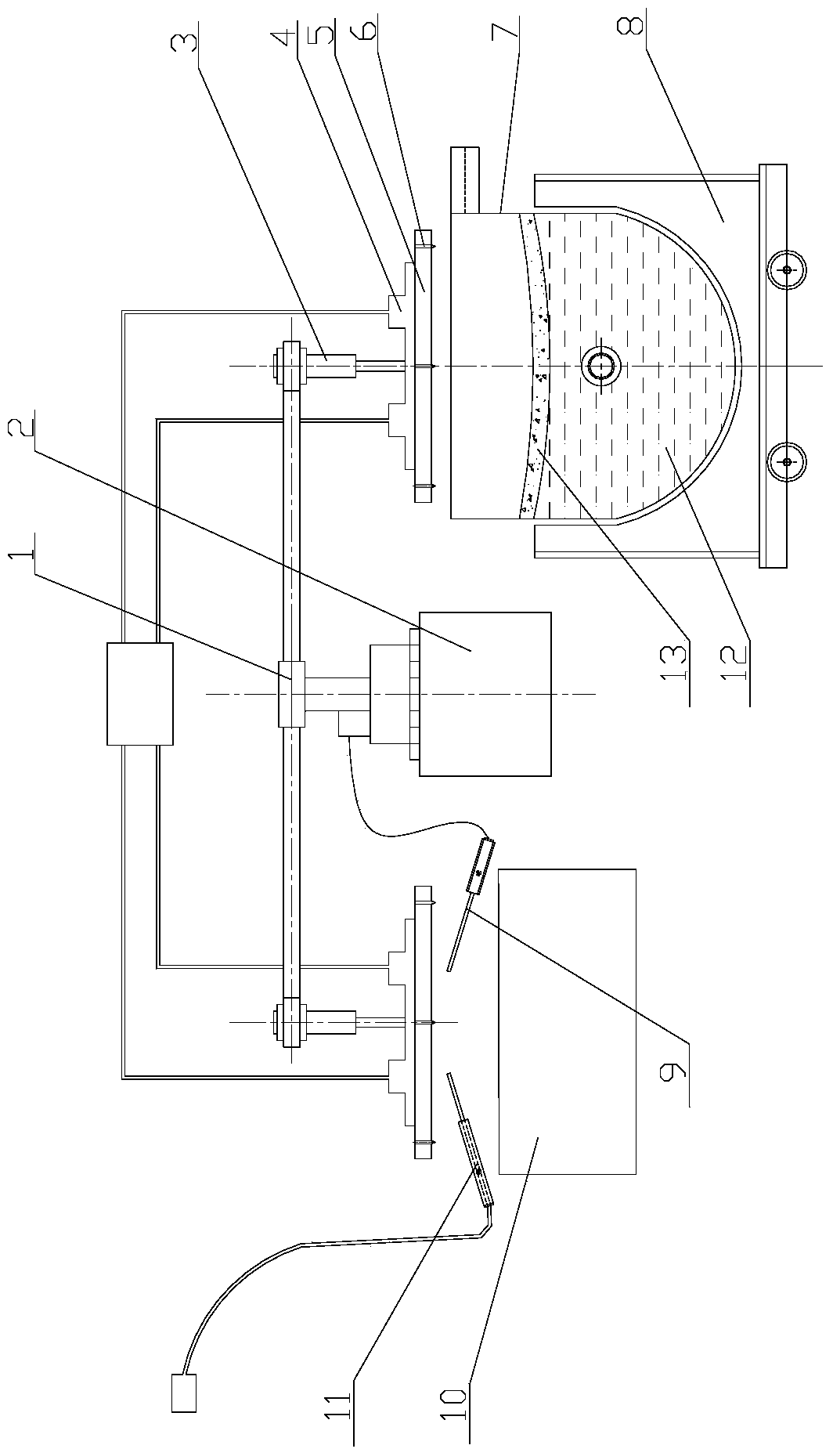

Device and method for removing hole bottom sediment of pore-forming pouring pile

The invention discloses a device and a method for removing hole bottom sediment of a pore-forming pouring pile. The device comprises an air supply mechanism, a liquid supply mechanism, a hose, a sediment discharging pipe and an inclined pipe; the sediment discharging pipe comprises a vertical sediment discharging pipe part and a horizontal sediment discharging pipe part; the vertical sediment discharging pipe part is communicated with the air supply mechanism through the hose, and comprises an upper pipe, a middle pipe and a lower pipe; the middle pipe comprises an outer pipe and an inner pipe of which the central axes are overlapped; the upper pipe is connected with the outer pipe or the inner pipe through screw threads; the lower pipe is also connected with the outer pipe or the inner pipe through screw threads; the inclined pipe penetrates through the inner pipe and the outer pipe downwards; an air outlet of the air supply mechanism is communicated with the inner pipe through the hose and the inclined pipe in sequence. By adoption of the structure, the sediment removal efficiency is improved effectively, but energy consumption is not increased obviously.

Owner:CHINA MCC5 GROUP CORP

Dam trash rack solid trash removing device

PendingCN107859006AIncrease the dirt insertion forceAvoid leaning stuckArtificial water canalsElectric machineryElectrical and Electronics engineering

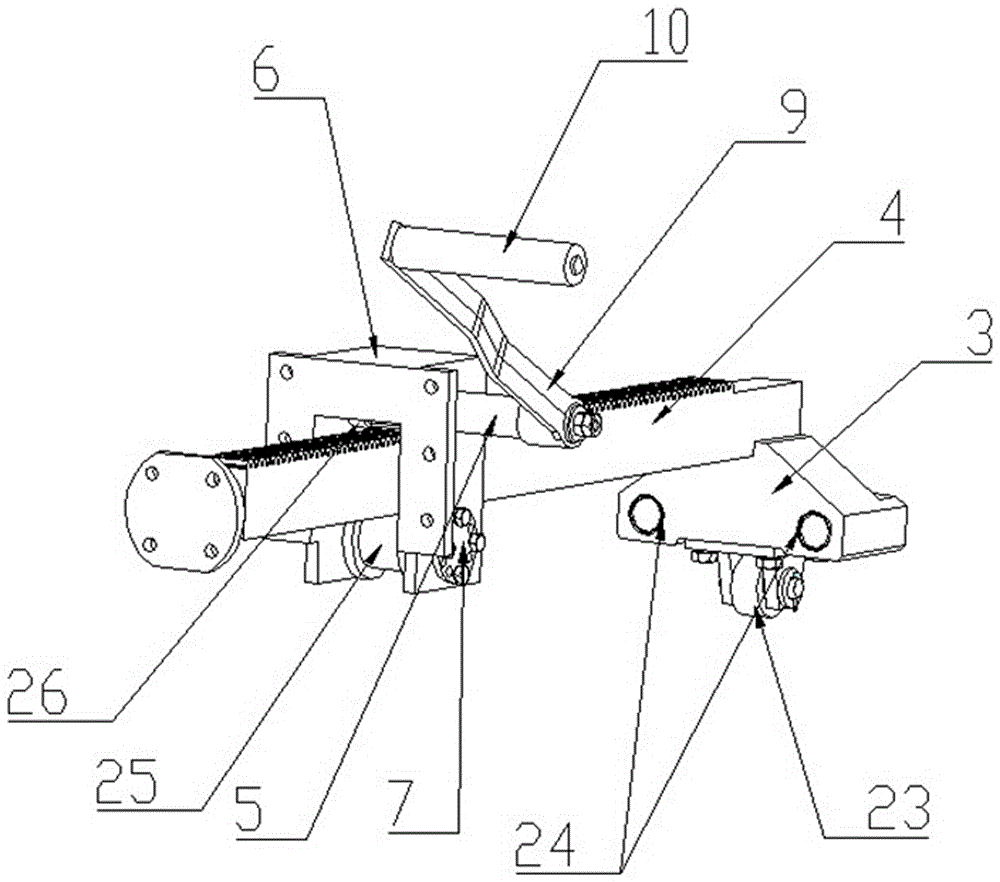

The invention discloses a dam trash rack solid trash removing device. The dam trash rack solid trash removing device comprises a trash removing rake arranged on the water inlet side of a trash rack, acounterweight car arranged above the trash rack in a hinged mode, a traction mechanism for driving the counterweight car to move and turning over the trash removing rake, a base fixedly arranged above the trash rack, rails parallel to the trash rack, and a traveling mechanism which is arranged at the bottom of the traction mechanism and matched with the rails; the counterweight car is in rollingfit with guide rails arranged on the two sides of the trash rack, or with rack strips through guide wheels on the two sides; the trash removing rake inversely covers the trash rack in a C shape, the upper portion of the trash removing rake is hinged to the counterweight car, the lower middle portion of the trash removing rake is connected with a rack turning cable of the traction mechanism, and the trash removing rake is provided with rack teeth inserted into the trash rack; and the traction mechanism comprises a machine frame of which the bottom is fixedly provided with the traveling mechanism, and a spindle arranged on the upper portion of the machine frame, the spindle connected with an output shaft of a speed reducer driven by a motor and wound with a lifting cable and the rake turningcable, the lifting cable is connected with the counterweight car, and the machine frame is provided with a hydraulic rake turning mechanism for enabling the rake turning cable to go up and down. Thedam trash rack solid trash removing device has the characteristics of being simple in structure, stable and reliable in work and high in slag removing efficiency.

Owner:戴娇

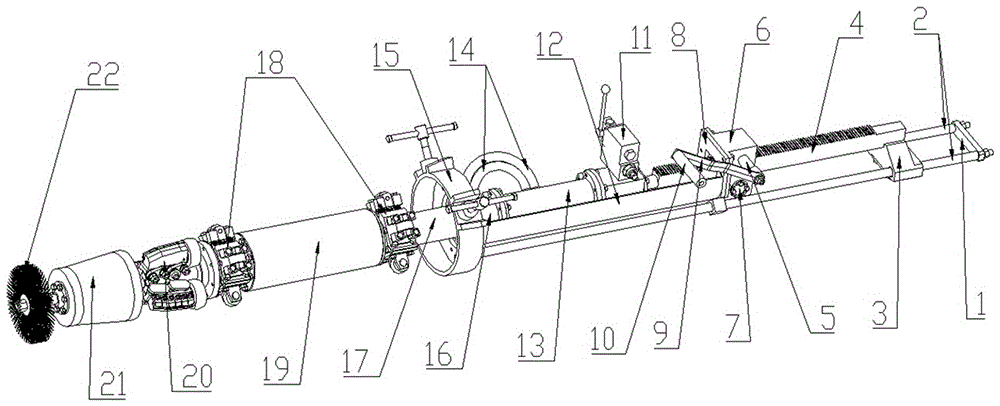

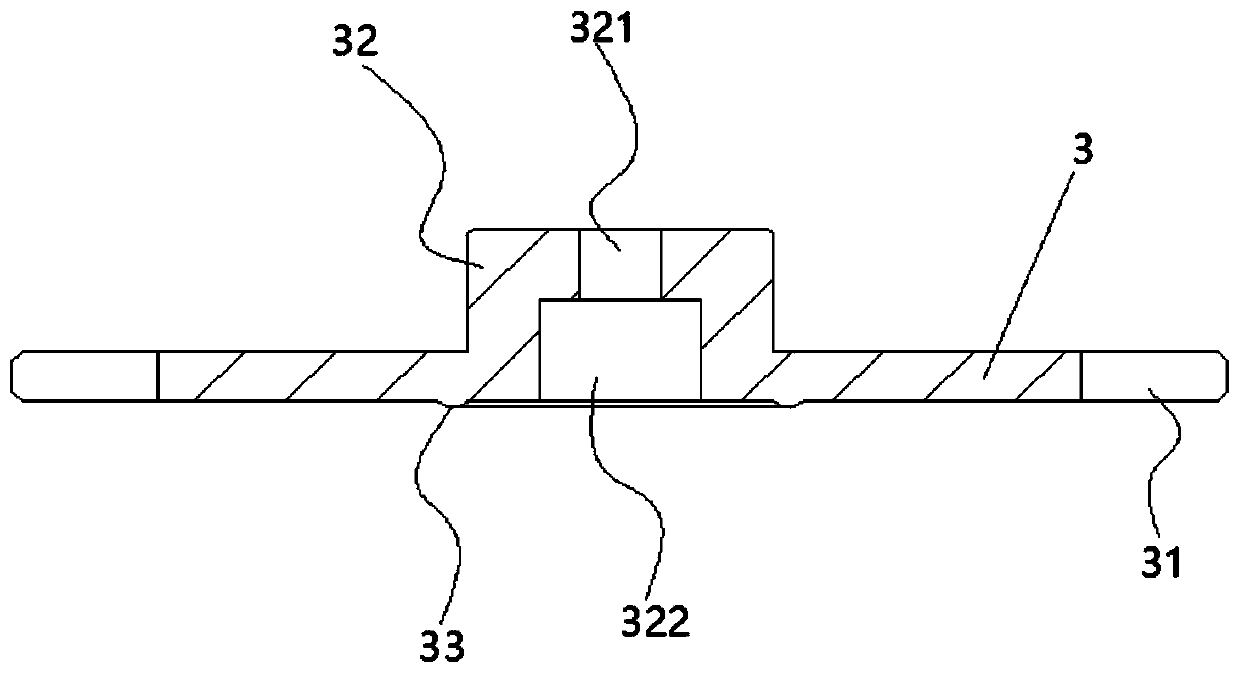

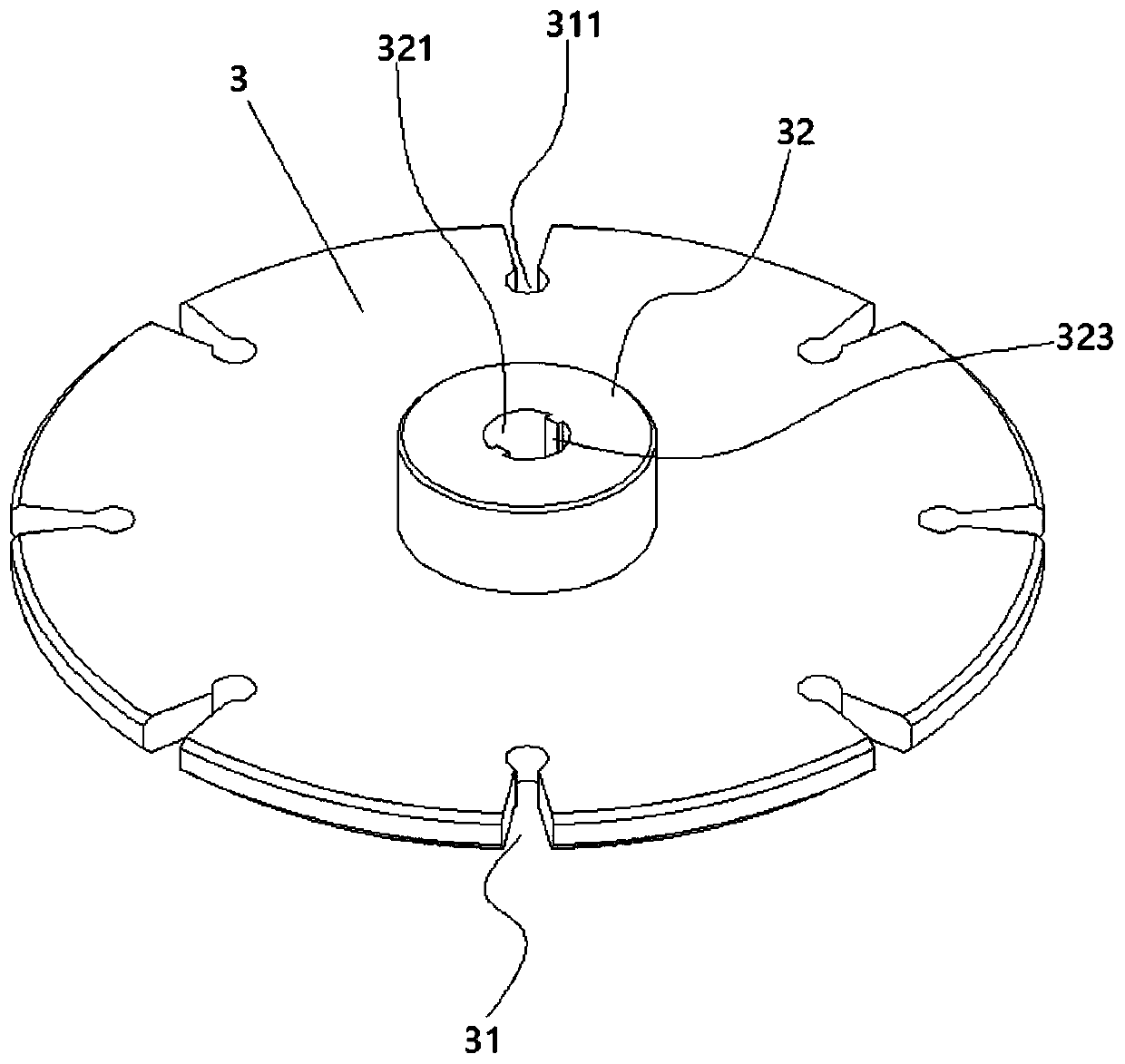

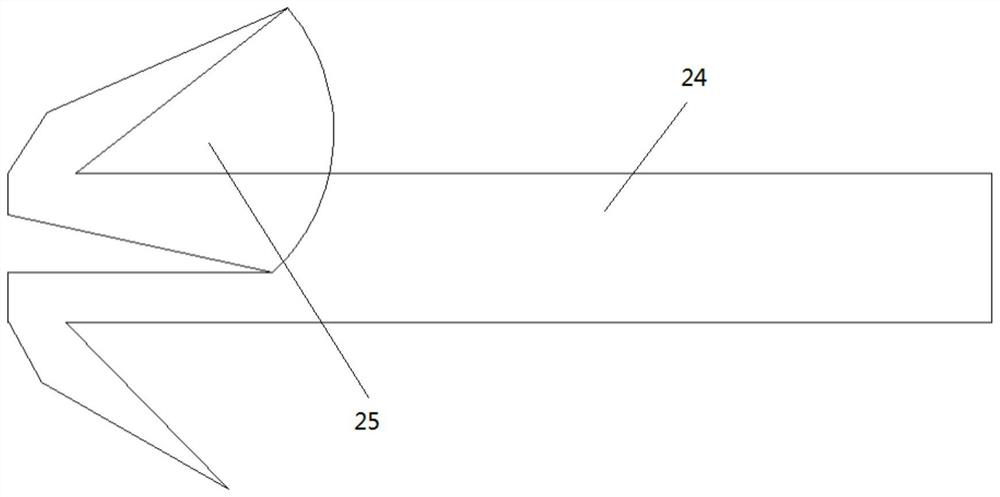

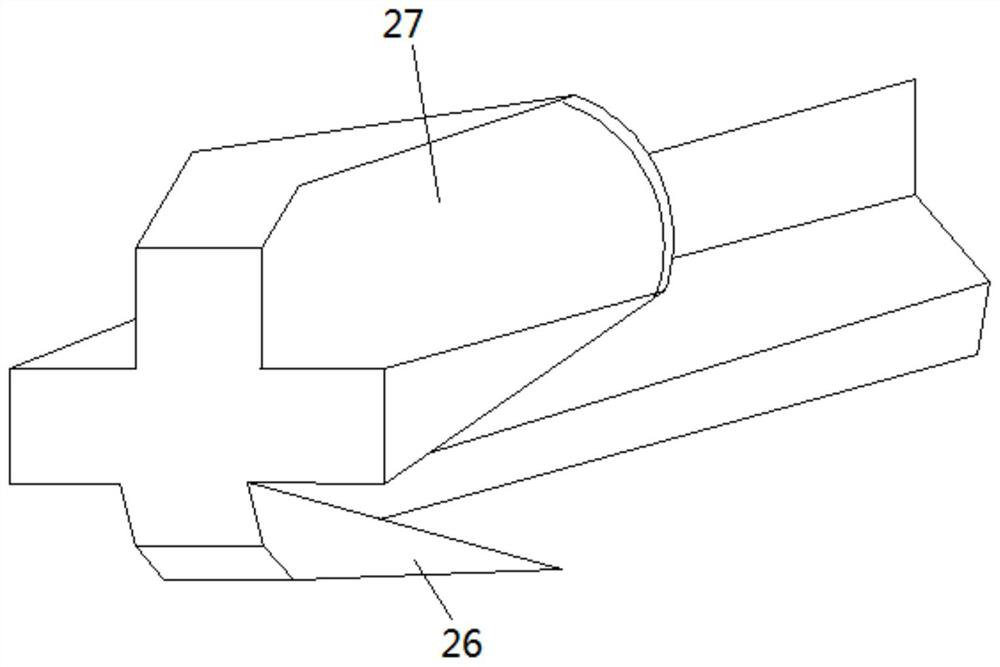

Pipeline flash butt welding rotation mechanical internal slag removing system

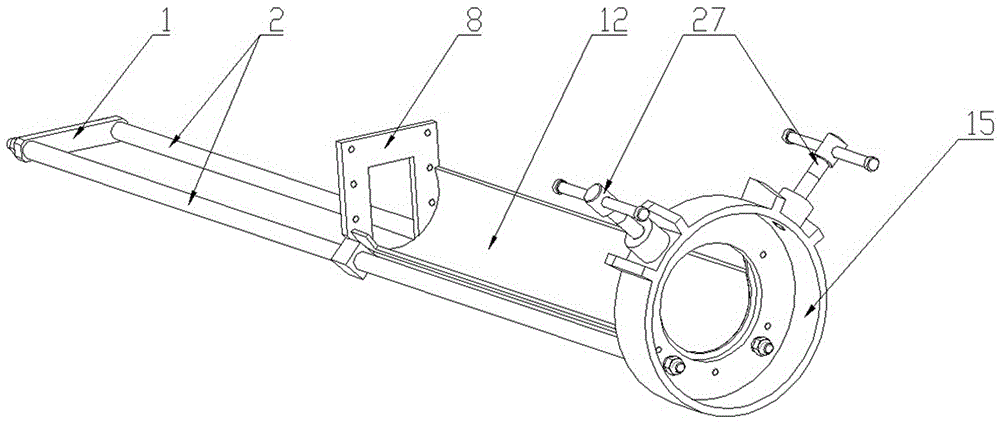

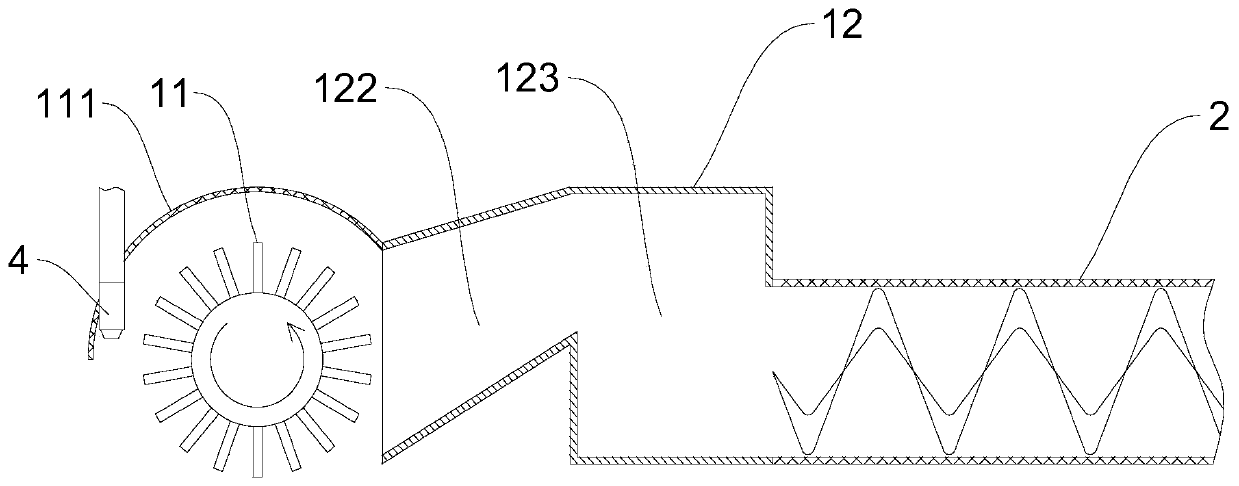

ActiveCN106238895ASolve the problem of welding slag removalAdaptableFeeding apparatusTurning machinesButt weldingSlag

The invention relates to a pipeline flash butt welding rotation mechanical internal slag removing system. The pipeline flash butt welding rotation mechanical internal slag removing system mainly comprises a pushing mechanism, a hydraulic power system and a slag removing knife set; the slag removing knife set is driven by the hydraulic power system to rotate and is driven by the pushing mechanism to move inside a pipeline, and therefore removing of slag in welding lines of the inner wall of the pipeline can be achieved. The pipeline flash butt welding rotation mechanical internal slag removing system is compact in structure and low in manufacturing cost, and the complete machine miniaturization is easily achieved; the pipeline flash butt welding rotation mechanical internal slag removing system is used in cooperation with a pipeline flash butt welding device, the slag in the welding lines of the inner wall of the pipeline can be removed, the slag removing efficiency is high, and the quality of the surfaces of the welding lines is good; and the pipeline flash butt welding rotation mechanical internal slag removing system is high in adaptive capacity, can be suitable for inner wall slag removing of the welding lines of the metal pipeline with the nominal diameter being 219 mm and the wall thickness ranging from 8 mm to 20 mm.

Owner:阳江市中乌巴顿技术研究院

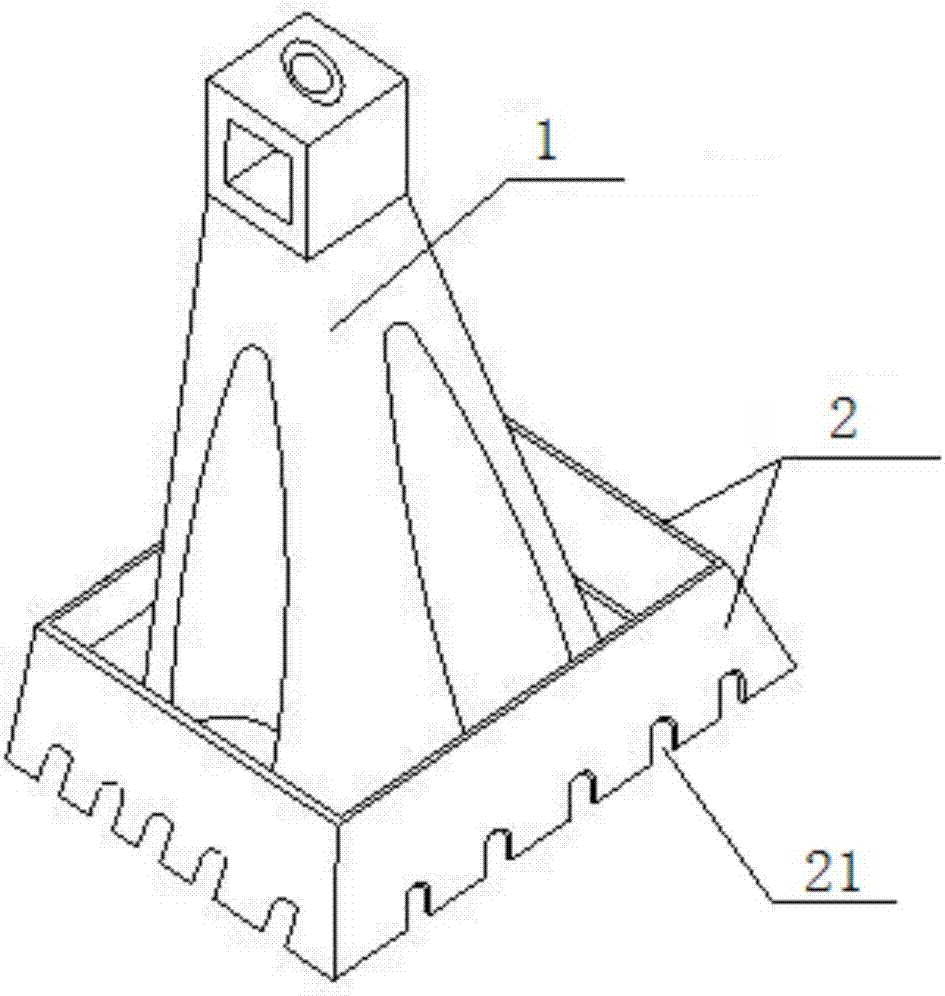

Rectangular impact drill bit for declined rock groove segment during diaphragm wall construction and construction method

PendingCN107120065AImprove slag cleaning efficiencyReduce dosageDrill bitsBulkheads/pilesDrill bitBuilding construction

The invention discloses a rectangular impact drill bit for a declined rock groove segment during diaphragm wall construction and a construction method and belongs to the field of diaphragm wall construction. The drill bit comprises a star-shaped impact drill, side plates, conical hammer teeth and a hammer plate, wherein the side plates are flat plates with sawtooth sides, the four side plates form a rectangle around side surfaces of a drill hammer impact surface of the star-shaped impact drill, a plurality of conical hammer teeth are distributed on half impact surface of the drill hammer impact surface of the star-shaped impact drill, and the other half impact surface is covered and fixed with the hammer plate which is a flat plate. The grooving construction method comprises steps as follows: the drill hammer impact surface of the star-shaped impact drill impacts the declined rock groove segment, so that grooves are formed, and groove impacting operation is performed with the side with the conical hammer teeth corresponding to the protruding side of rock in the groove segment and the hammer plate corresponding to the soft soil side in the groove segment. The rectangular impact drill bit and the construction method are suitable for a drill hammer to impact declined rocks in the grooves, so that the grooving dimension and perpendicularity are guaranteed.

Owner:KUNMING RAILWAY CONSTR COMPANY OF CHINA RAILWAY NO 8 ENG GRP

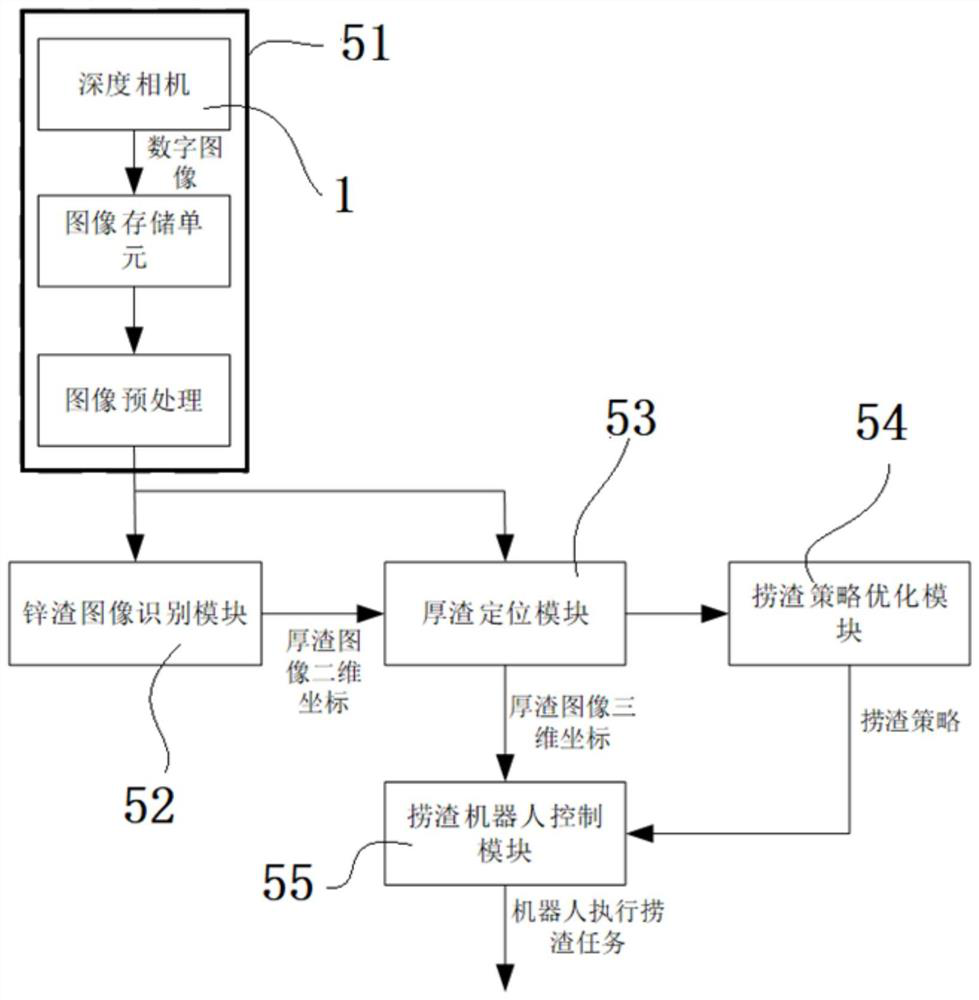

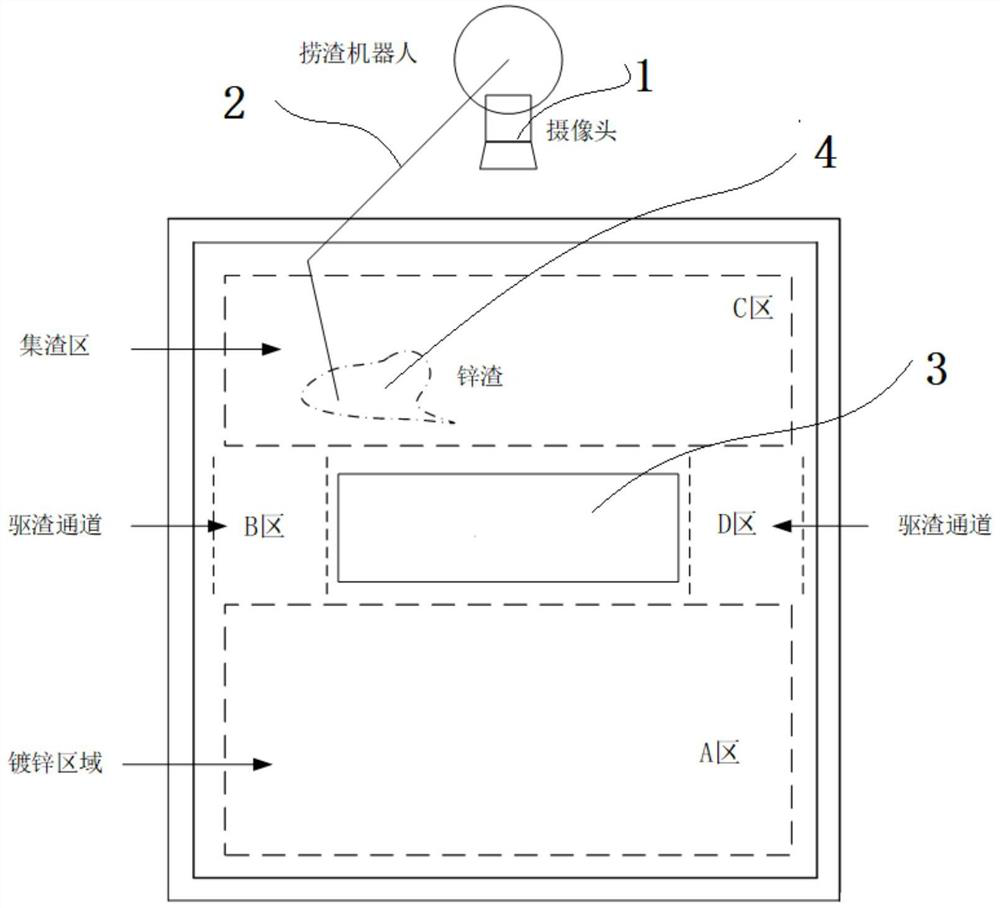

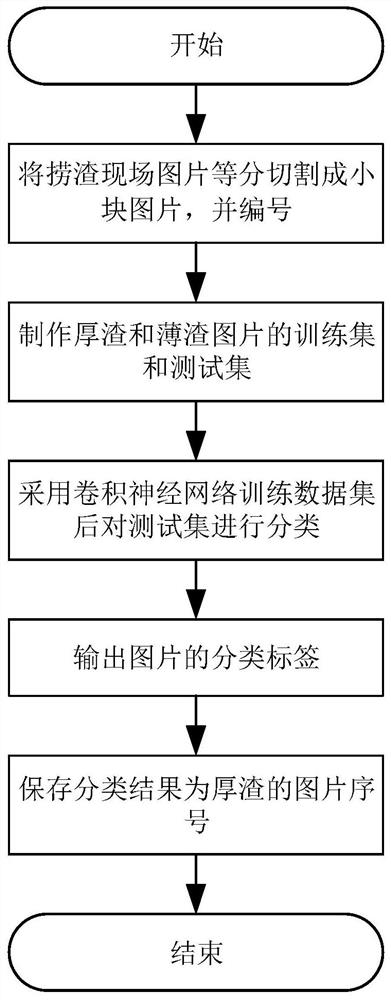

Machine vision-based slag salvaging method and robot system

ActiveCN112011750AIncrease autonomyReduce fishing frequencyHot-dipping/immersion processesProgramme-controlled manipulatorRobotic systemsMachine vision

The invention discloses a machine vision-based slag salvaging method and robot system. A thick slag area influencing the quality of a galvanized plate is identified and positioned through a vision technology, then, a slag salvaging sequence is obtained according to a slag salvaging area priority rule, and finally, a slag salvaging robot is controlled to salvage all thick slag and pour the thick slag into a nearby slag hopper. Compared with a traditional robot slag salvaging system, the machine vision-based slag salvaging scheme is provided, the optimal slag salvaging sequence is optimized anddetermined according to zinc slag distribution characteristics and a slag salvaging strategy, zinc consumption and power consumption caused by unnecessary slag salvaging times are reduced, the autonomy of the slag salvaging robot is remarkably improved, and the operation efficiency is improved.

Owner:WUHAN UNIV OF SCI & TECH

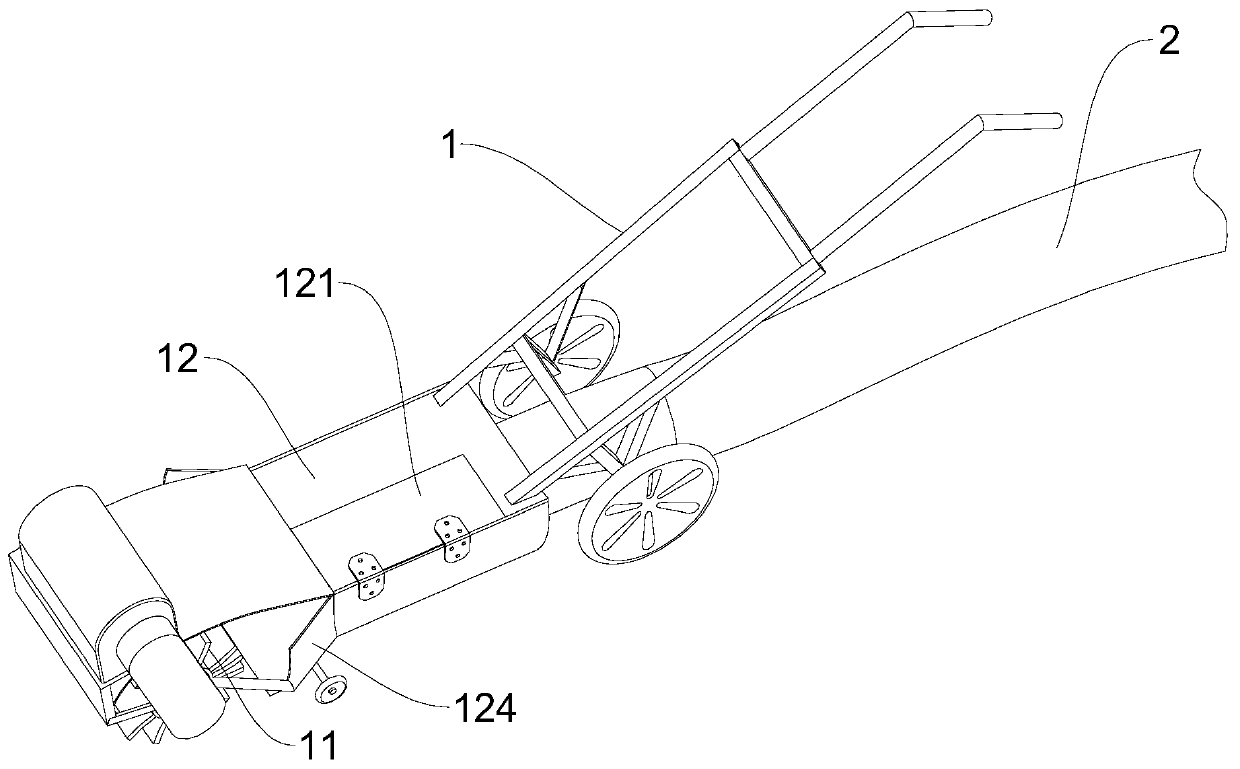

Soil pressure balance shield machine shield tail quick slag removal device

The invention provides a soil pressure balance shield machine shield tail quick slag removal device, and belongs to the technical field of shield machines. The soil pressure balance shield machine shield tail quick slag removal device includes a vehicle, a spiral conveying hose and a conveying system, the vehicle is provided with a ground brush and a slag collection bin, the ground brush is used for drawing in and throwing out sludge, the slag collection bin is used for gathering the sludge thrown out by the ground brush, the vehicle is used for moving and collecting the sludge at the tail ofthe shield machine, the inlet end of the spiral conveying hose is connected with the slag collection bin, the spiral conveying hose is used for transporting the sludge collected by the vehicle to theoutside of the tail of the shield machine, and the conveying system is used for transporting the sludge from the outlet end of the spiral conveying hose to a slag outlet of the shield machine. According to the soil pressure balance shield machine shield tail quick slag removal device, the problem of inconvenient sludge removal at the tail of the shield machine is solved, the efficiency of slag removal is improved, and continuous driving of the shield machine is ensured.

Owner:CHINA RAILWAY SIXTH GRP CO LTD

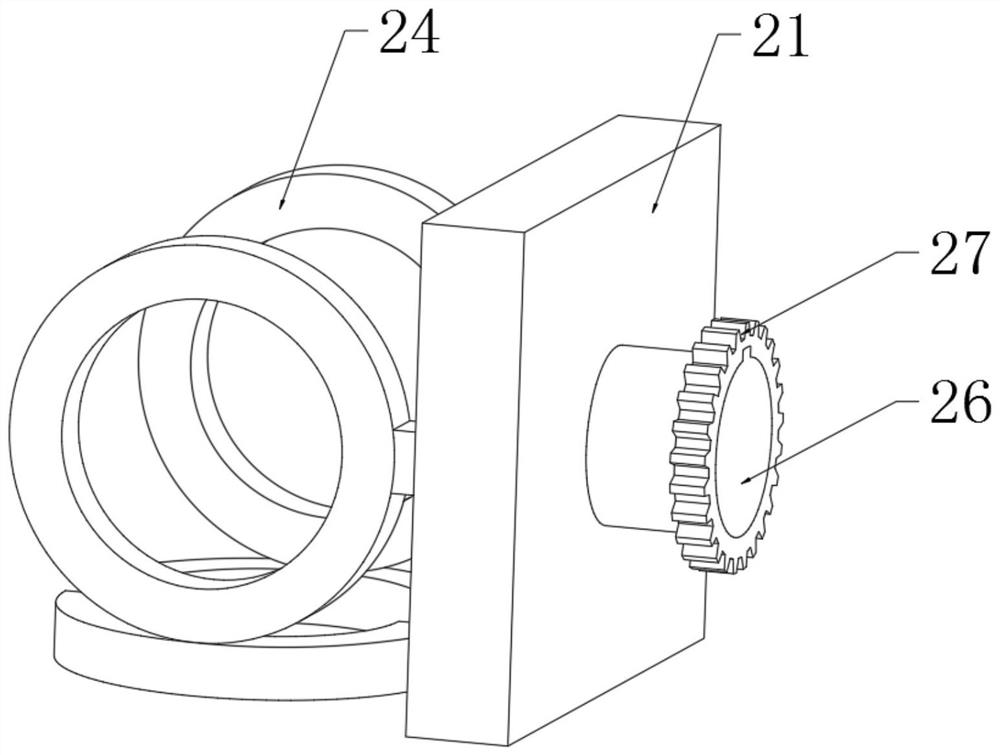

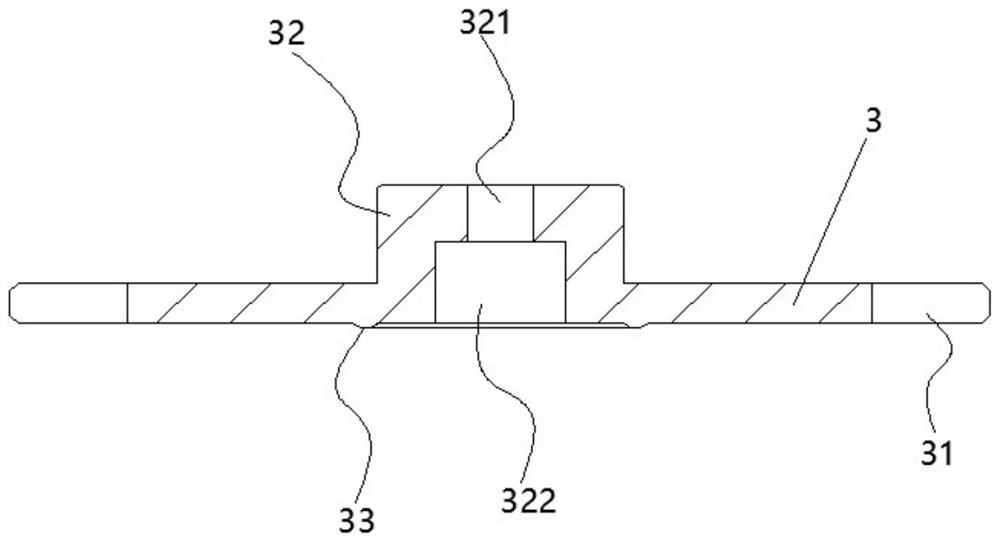

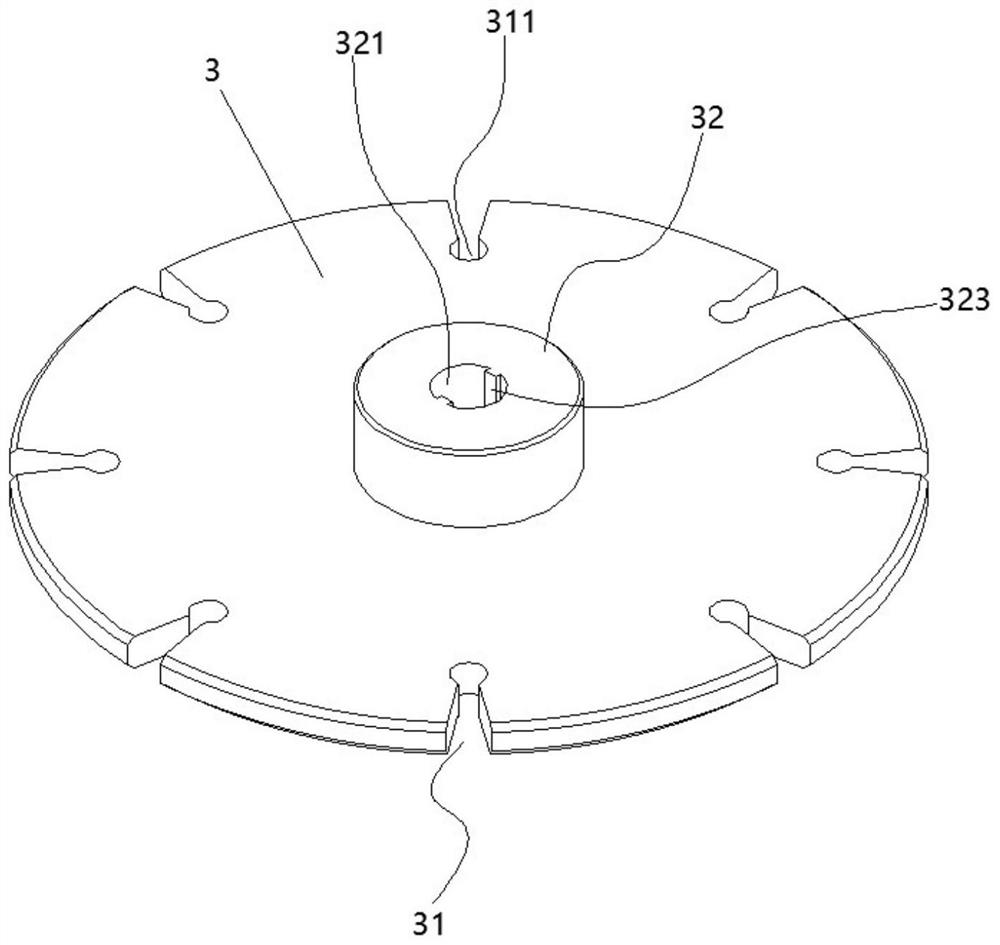

Molten iron pretreatment adhering type slag removing technology and device

ActiveCN106541124ALight weightReduce iron lossCasting cleaning apparatusProcess efficiency improvementSlagPre treatment

The invention relates to a molten iron pretreatment adhering type slag removing technology and device. A molten iron tank is conveyed to a slag removing station, slag adhering discs are lowered into the molten iron tank, and the slag adhering discs are cooled through a water cooling system; temperature measuring devices arranged on the slag adhering discs are used for controlling the immersion depth of the slag adhering discs, water cooling of adhering slag is conducted after the slag adhering discs stay in a slag layer for 60-120 s, and then the slag adhering discs are elevated to the position above the tank edge of the molten iron tank; the slag adhering discs are rotated to the slag removing station through a rotation mechanism, and solid slag on the slag adhering discs is removed; and the above slag adhering and removing processes are repeatedly conducted till all desulfurized slag in the molten iron tank is completely removed. The adhering type slag removing manner is adopted, the characters that the desulfurized slag is low in specific gravity and high in cooling speed are utilized, the desulfurized slag is rapidly solidified in a chilling condition and adheres to the slag adhering discs, and then the slag adhering discs are cleaned. The molten iron pretreatment adhering type slag removing technology and device have the beneficial effects that the slag removal rate is high, iron losses are small, and the slag removing efficiency is high.

Owner:ANGANG STEEL CO LTD

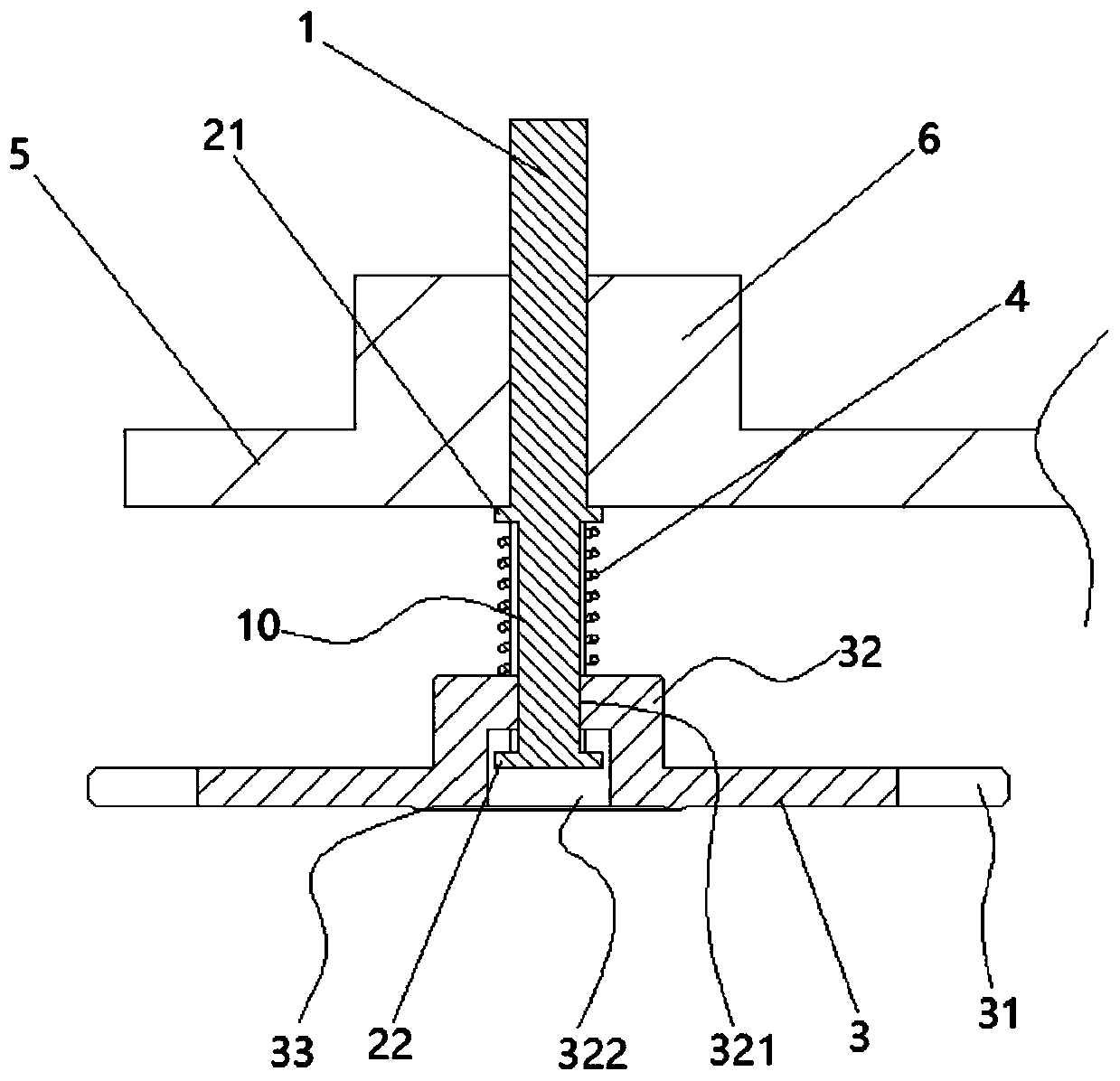

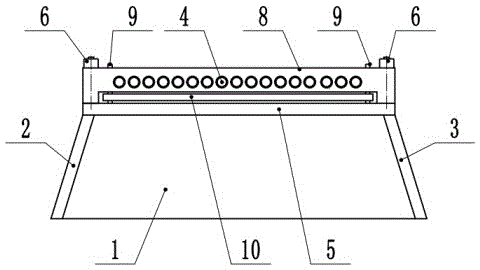

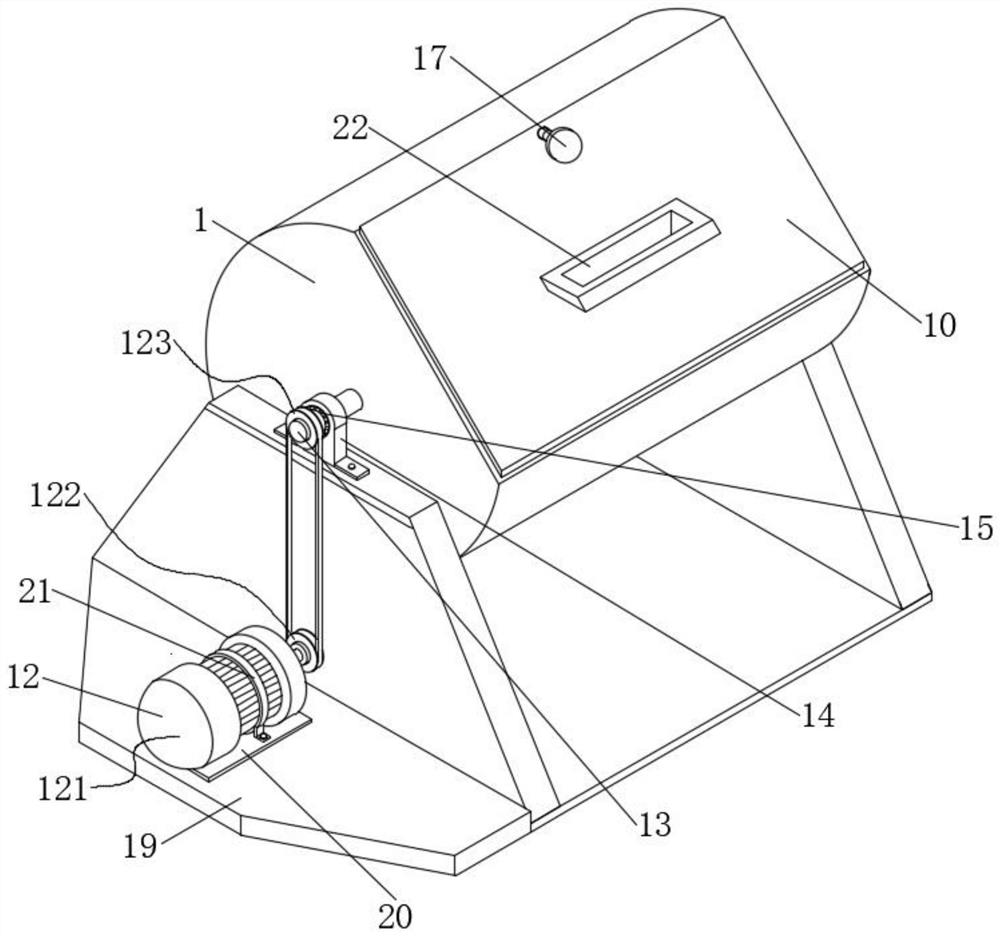

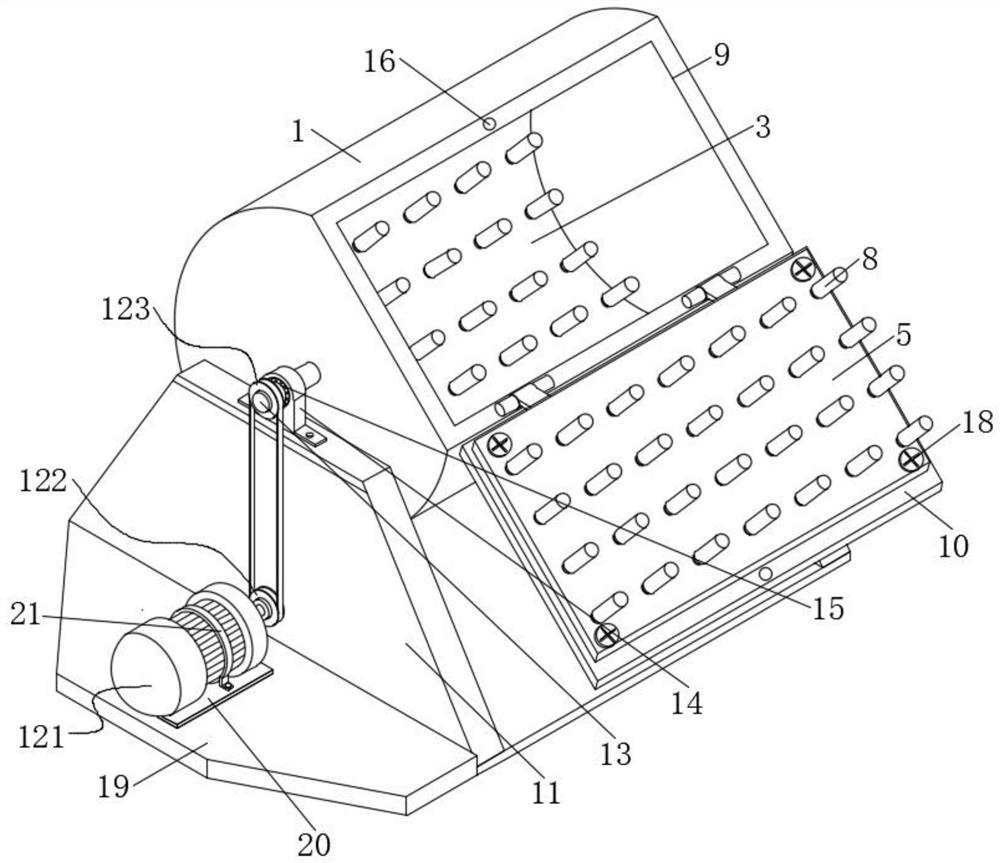

Efficient aluminum template slag removing mechanism

ActiveCN110711725AFast and effective slag removalImprove slag cleaning efficiencyCleaning using toolsMetallurgyDrive shaft

The invention discloses an efficient aluminum template slag removing mechanism. The mechanism comprises a rotating shaft, a slag removing cutter, a first limiting piece, a second limiting piece and anelastic piece; the first limiting piece and the second limiting piece both fixedly sleeve one end position of the rotating shaft, and are arranged at an interval; a shaft section of the rotating shaft between the first limiting piece and the second limiting piece forms a transmission shaft section matched with the slag removing cutter; the slag removing cutter movably sleeves the transmission shaft section, and is in synchronous rotating fit with the rotating shaft; the elastic piece movably sleeves the transmission shaft section; a first end is contacted with and abuts against the first limiting piece; and a second end is contacted with and abuts against the slag removing cutter. The slag removing cutter can be bonded with aluminum templates by using the elastic piece, and can be finelyadjusted to move on the transmission shaft section in the axial direction of the rotating shaft, so that the quick and effective slag removing operation is realized, and the slag removing efficiency is high.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Alcohol-based fuel conveying pipeline deslagging piping assembly

The invention relates to an alcohol-based fuel conveying pipeline deslagging piping assembly. The assembly is provided with a transverse pipe A and a transverse pipe B which are arranged coaxially. Aneccentric transverse pipe is further arranged between the transverse pipe A and the transverse pipe B. The two ends of the eccentric transverse pipe communicate with the transverse pipe A and the transverse pipe B through vertical pipes correspondingly. The outer ends of the transverse pipe A and the transverse pipe B are provided with flanges connected with fuel conveying pipelines correspondingly. A high-pressure flush hydraulic giant is arranged on the side portion of one end of the eccentric transverse pipe. A deslagging pipeline is downwards arranged at the other end of the eccentric transverse pipe. A throttle valve is arranged on the deslagging pipeline. A transverse base plate is arranged on the outer side of the upper portion of the deslagging pipeline. A deslagging cylinder is mounted on the transverse base plate. The front end of a piston rod of the deslagging cylinder penetrates through the pipe wall of one vertical pipe and stretches into the eccentric transverse pipe. Adeslagging head is further mounted at the front end of the piston rod of the deslagging cylinder. After the piping assembly is additionally arranged, the deslagging efficiency of the conveying pipelines is greatly improved, and smooth operation of the conveying pipelines is effectively guaranteed.

Owner:湖北恒泰新能源开发有限公司

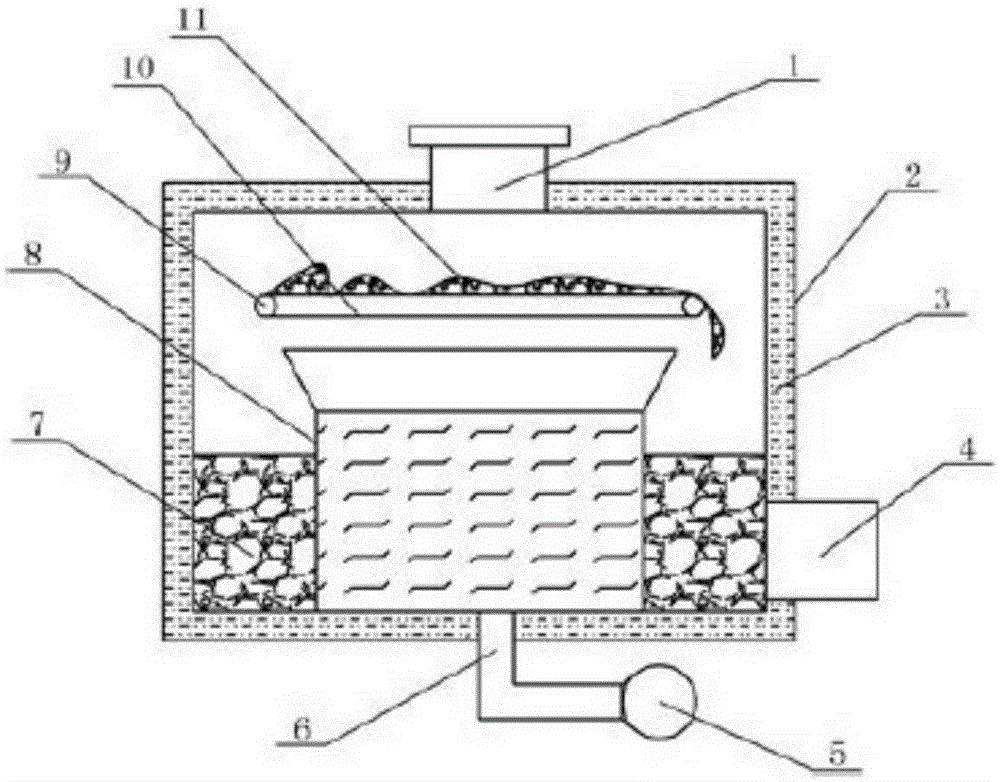

Chemical plant sewage pool decontamination apparatus

InactiveCN106390573AAvoid the hassle of re-cleaningAvoid pollutionMoving filtering element filtersWater storageWater discharge

The present invention provides a chemical plant sewage pool decontamination apparatus, which comprises a sewage pool, wherein the bottom portion of the sewage pool is provided with a water discharging port, the top portion of the sewage pool is provided with a sewage inlet, a conveying belt is arranged inside the sewage pool and is connected to a rotation shaft, the rotation shaft is fixed on the inner wall of the sewage pool, the conveying belt is provided with a filtration hole, a water storage box is arranged just below the conveying belt, a garbage storage zone is arranged between the water storage box and the sewage pool, and a garbage discharging port is arranged on one side of the lower portion of the sewage pool. According to the present invention, with the chemical plant sewage pool decontamination apparatus, the decontamination is convenient, the problem that the residue cleaning requires the complete draining of the sewage in the pool is avoided, the condition that the solid garbage and the sewage are subjected to long-term deposition so as to cause the malodor can be prevented, and the environment pollution can be avoided.

Owner:JIANGSU JIHUA CHEMICAL CO LTD

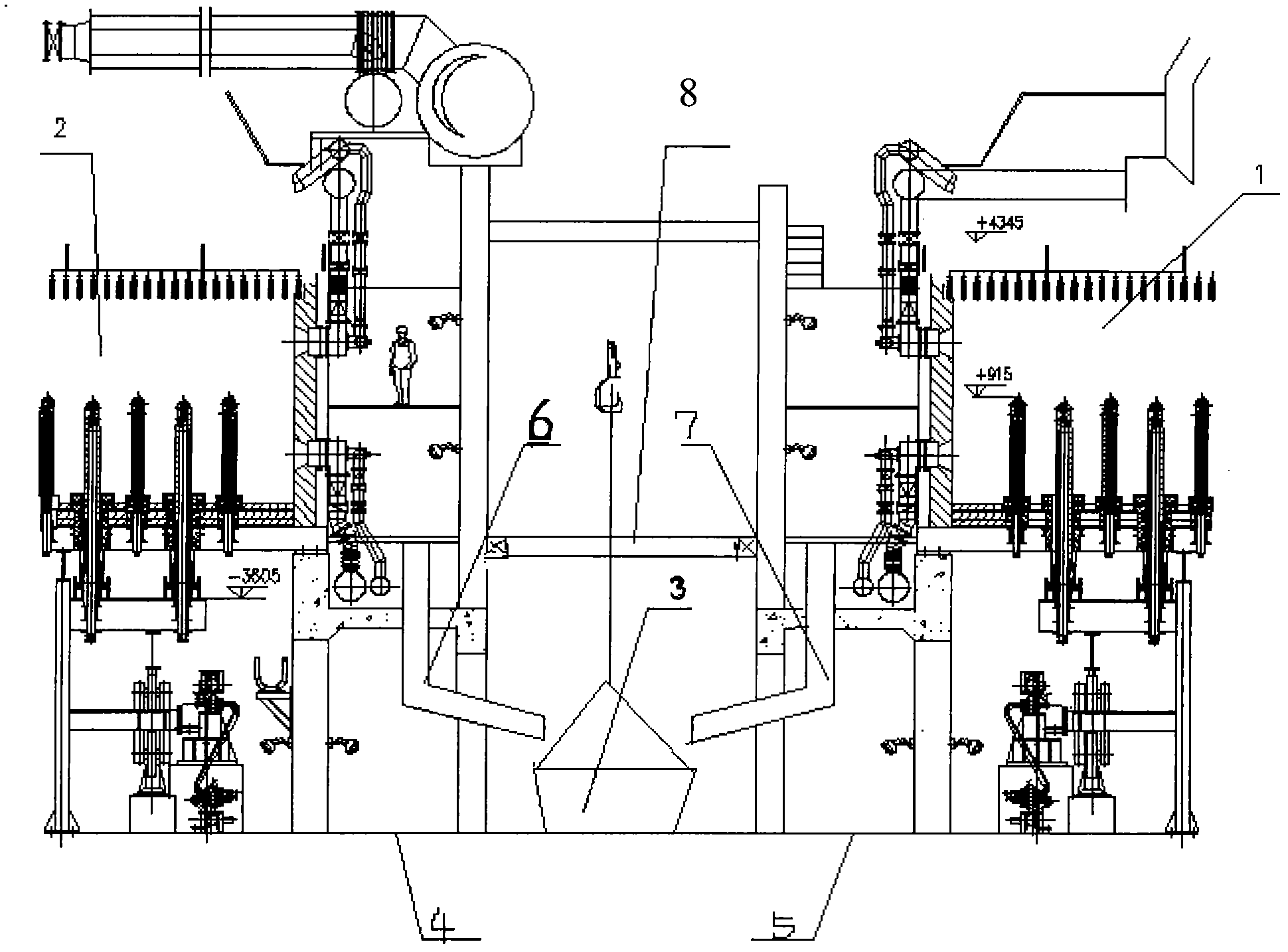

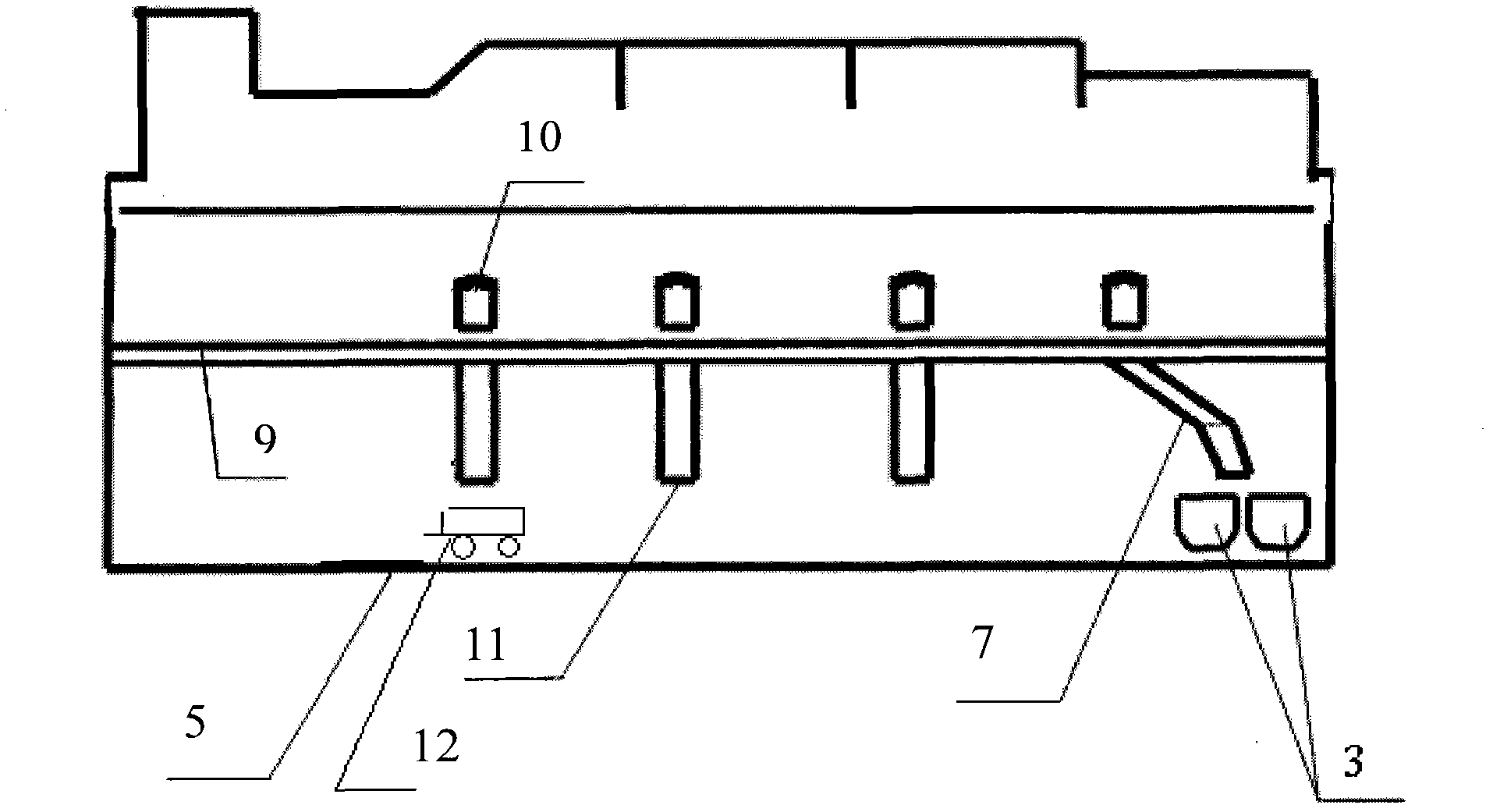

Rapid slag removing method of heating furnace

ActiveCN102538476AImprove slag cleaning efficiencyPut into productionCharge manipulationSlagWorking environment

A rapid slag removing method of a heating furnace is disclosed, which aims at alleviating the labor intensity, improving the working environment and improving the slag removing efficiency. In the invention, four mounting holes are respectively arranged in slag discharging furnace doors corresponding to a steel platform channel outside the four slag discharging furnace doors on each side of the heating furnace, and two slag sliding grooves communicated to the bottom of the furnace are installed on each mounting hole, namely eight slag sliding grooves are arranged; two of the slag sliding grooves can change the slag sliding direction; these two slag sliding grooves enable half of the high-temperature steel slag in the furnace to directly and alternately slide in two slag hoppers which are arranged at the new slag hoisting points on the bottom of the furnace and are arranged in parallel, the other six slag sliding grooves enable the residual steel slag to slide in a slag transporting trolley arranged on the ground of the bottom of the furnace, the residual steel slag is transported to the new slag hoisting point and fed in the slag hoppers for hoisting, the two slag hoppers are hoisted by turns to work continuously, so that the slag removing efficiency of the heating furnace is improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Steel ladle slag clearing device and steel ladle slag clearing method

ActiveCN113182509AEfficient removalImprove slag cleaning efficiencyMelt-holding vesselsHydraulic cylinderMotor drive

The invention provides steel ladle slag clearing device and a steel ladle slag clearing method. Through arrangement of a hydraulic cylinder driving module consisting of a rotatable support base, a hydraulic cylinder and a connecting rib plate in the slag clearing device and a motor driving module consisting of a rotary motor and a gear connecting disc, cooperating with a remote high-definition camera, steel slags of a ladle mouth can be effectively cleared by driving a slag clearer. Through uniform arrangement of a plurality of gas spraying guns, a plurality of hooks and a slag raking plate, larger chunks of stacked slag can be hooked through the hooks, and slag chips also can be gathered through the slag raking plate, and therefore, different slag stacking situations can be effectively solved.

Owner:SGIS SONGSHAN CO LTD

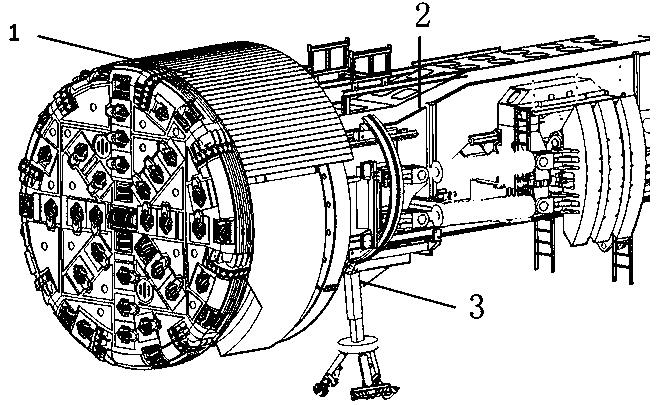

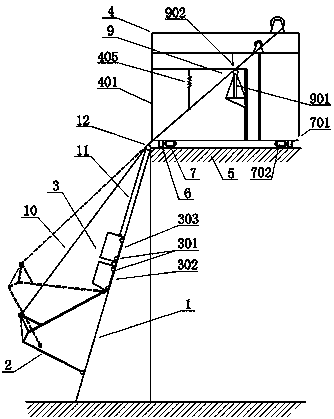

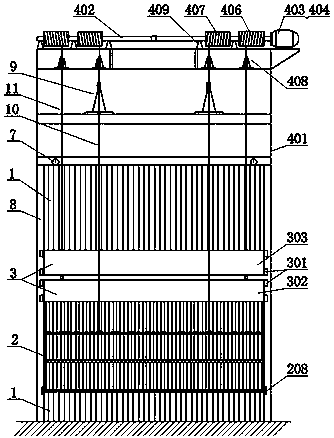

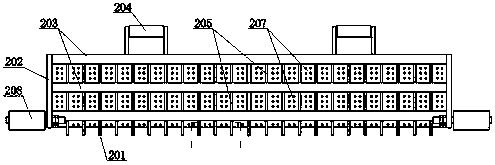

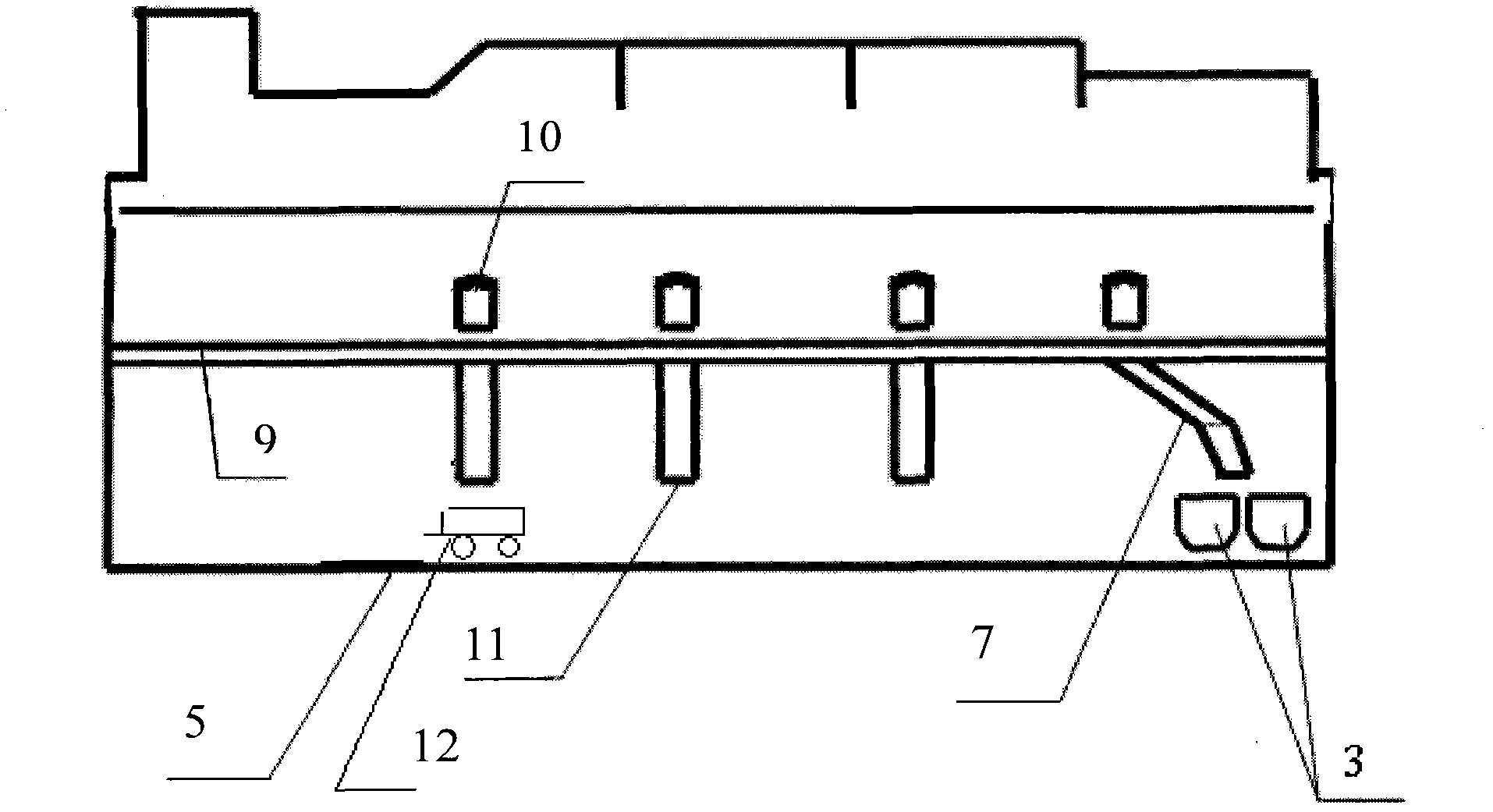

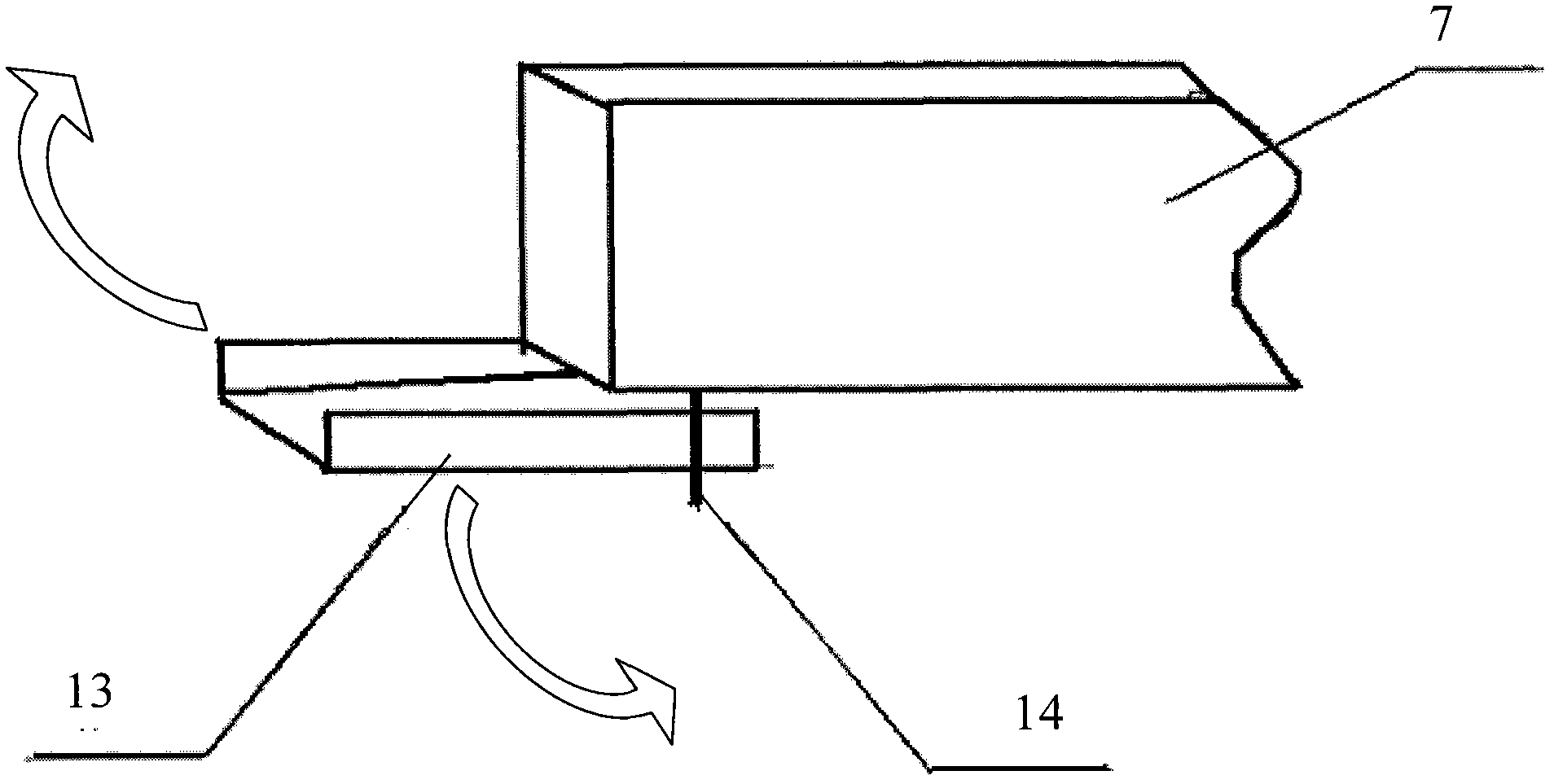

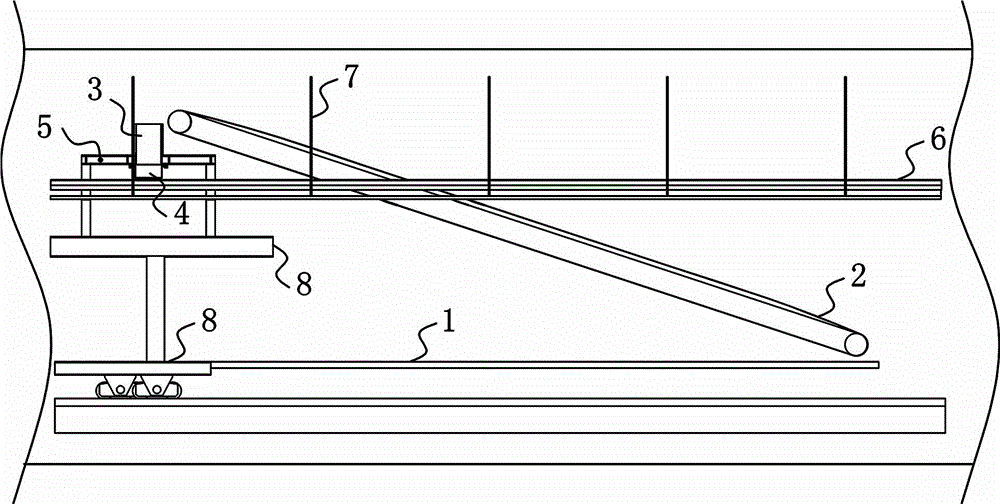

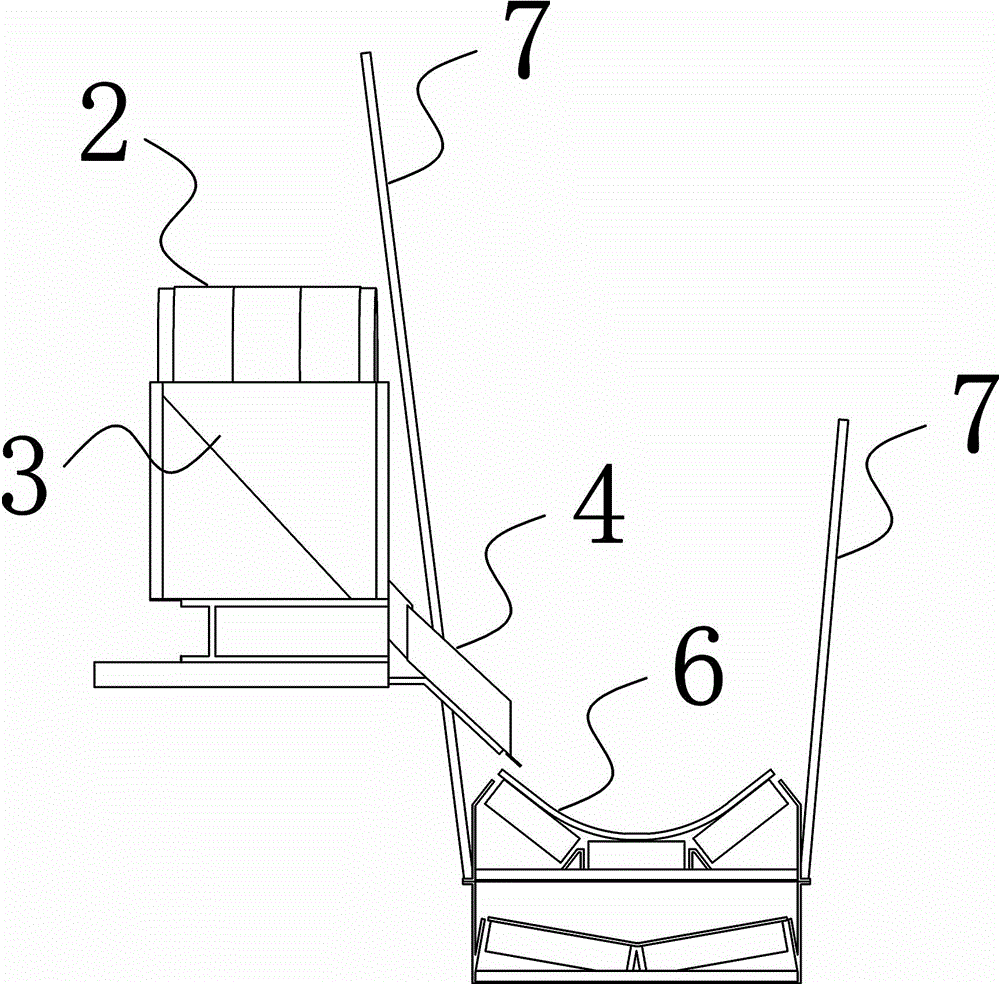

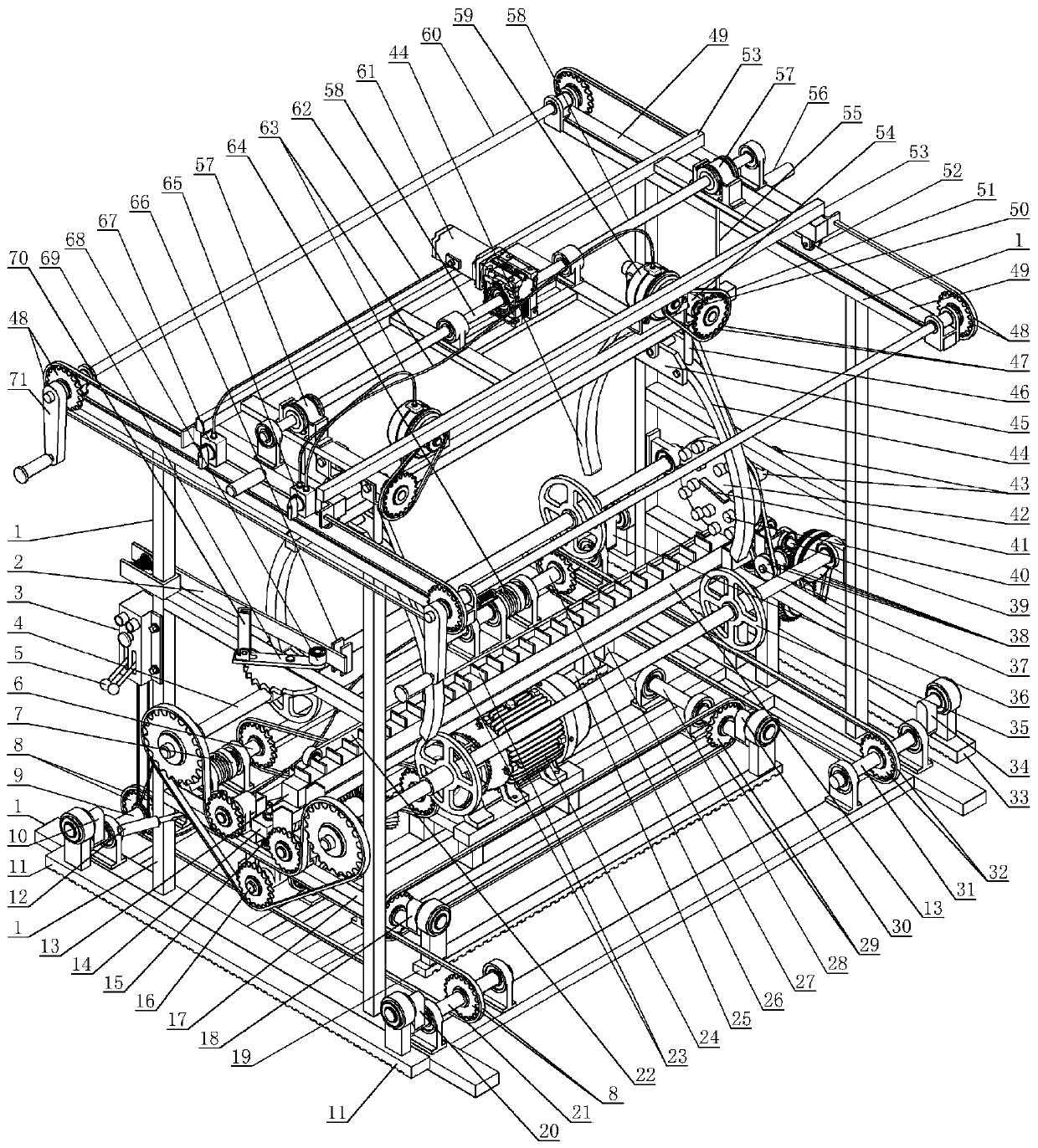

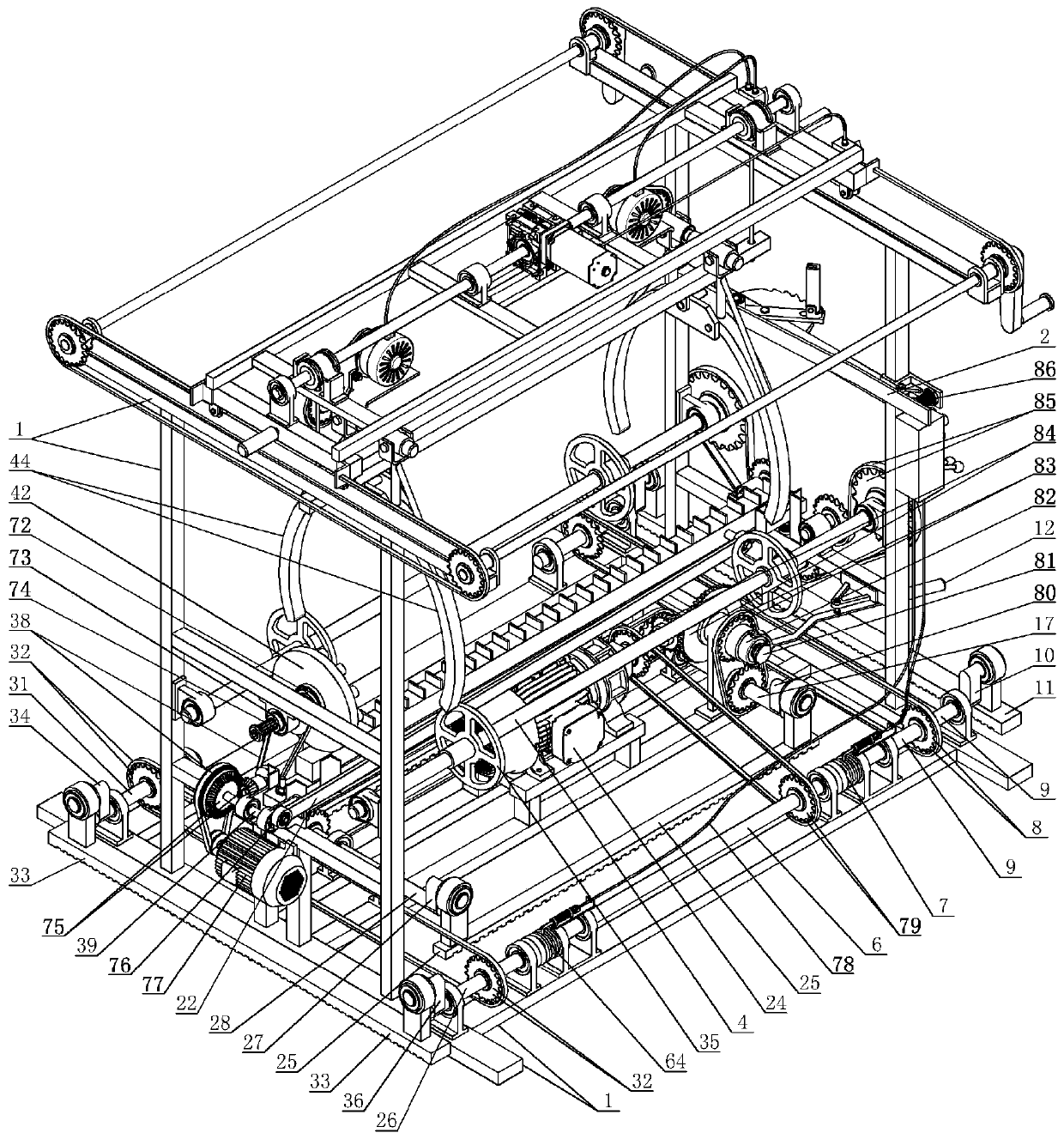

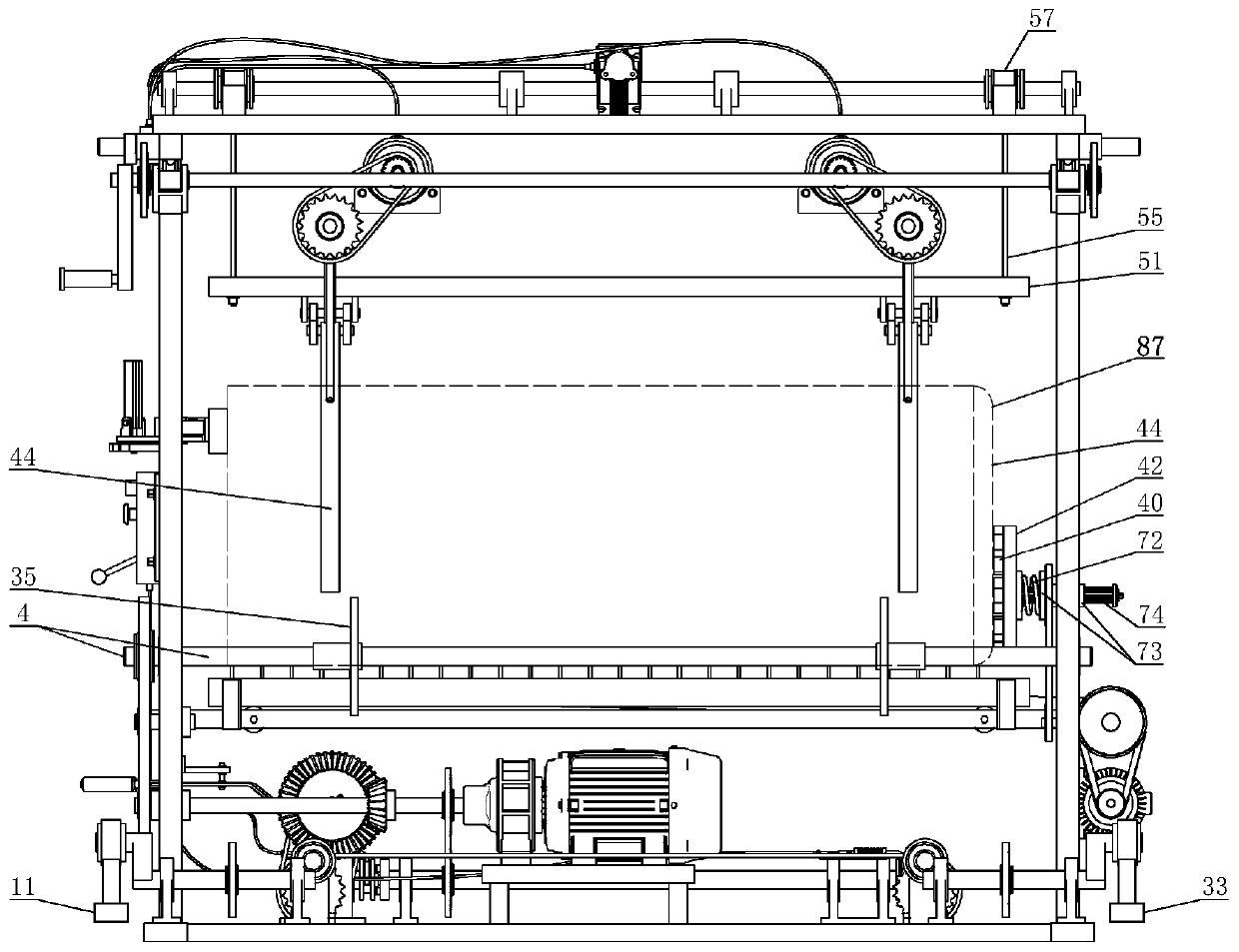

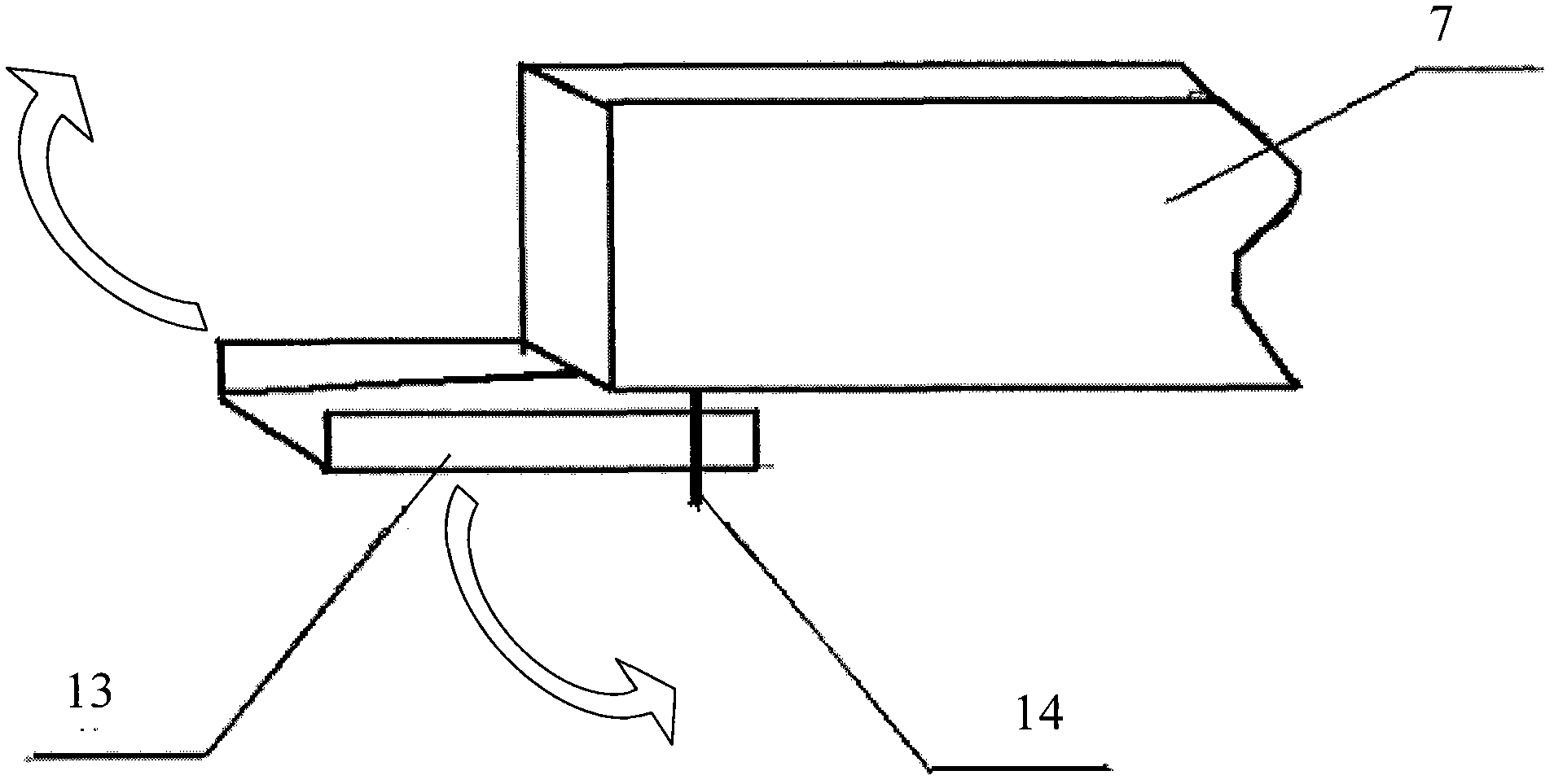

Construction waste slag removing system and method for open type heading machine

ActiveCN104632243AImprove slag cleaning efficiencyShorten the construction periodTunnelsUnderground transportSlagConstruction waste

The invention provides a construction waste slag removing system for an open type heading machine. A slag removing belt is arranged in a tail area of the heading machine in an inclined mode. The head end of the slag removing belt is located on the lower side and fixedly installed on a support. The support is connected with a trailer of the heading machine. The tail end of the slag removing belt is fixedly installed on the top of the trailer of the heading machine. A slag discharging hopper is arranged at the tail end of the slag removing belt and is in lap joint with a movable chute. The movable chute is in lap joint with a continuous belt of a tunnel. The invention further provides a construction waste slag removing method for the open type heading machine, wherein the construction waste slag removing system is adopted. The construction waste slag removing method comprises the steps that firstly, construction waste slag is piled close to the head end of the slag removing belt; secondly, when the heading machine starts heading and the continuous belt of the tunnel is started, the slag removing belt is started; thirdly, the waste slag is manually shoveled to the slag removing belt, and the waste slag is conveyed to the continuous belt of the tunnel from the slag hopper and the movable chute; finally, construction waste slag is removed. By the adoption of the construction waste slag removing system and method for the open type heading machine, construction waste slag can be completely removed, and the slag removing efficiency is high; the problem that a train occupies a rail is avoided, and the construction period can be effectively shortened.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG

A device and method for removing sediment at the bottom of hole-forming cast-in-place piles

The invention discloses a device and a method for removing hole bottom sediment of a pore-forming pouring pile. The device comprises an air supply mechanism, a liquid supply mechanism, a hose, a sediment discharging pipe and an inclined pipe; the sediment discharging pipe comprises a vertical sediment discharging pipe part and a horizontal sediment discharging pipe part; the vertical sediment discharging pipe part is communicated with the air supply mechanism through the hose, and comprises an upper pipe, a middle pipe and a lower pipe; the middle pipe comprises an outer pipe and an inner pipe of which the central axes are overlapped; the upper pipe is connected with the outer pipe or the inner pipe through screw threads; the lower pipe is also connected with the outer pipe or the inner pipe through screw threads; the inclined pipe penetrates through the inner pipe and the outer pipe downwards; an air outlet of the air supply mechanism is communicated with the inner pipe through the hose and the inclined pipe in sequence. By adoption of the structure, the sediment removal efficiency is improved effectively, but energy consumption is not increased obviously.

Owner:CHINA MCC5 GROUP CORP

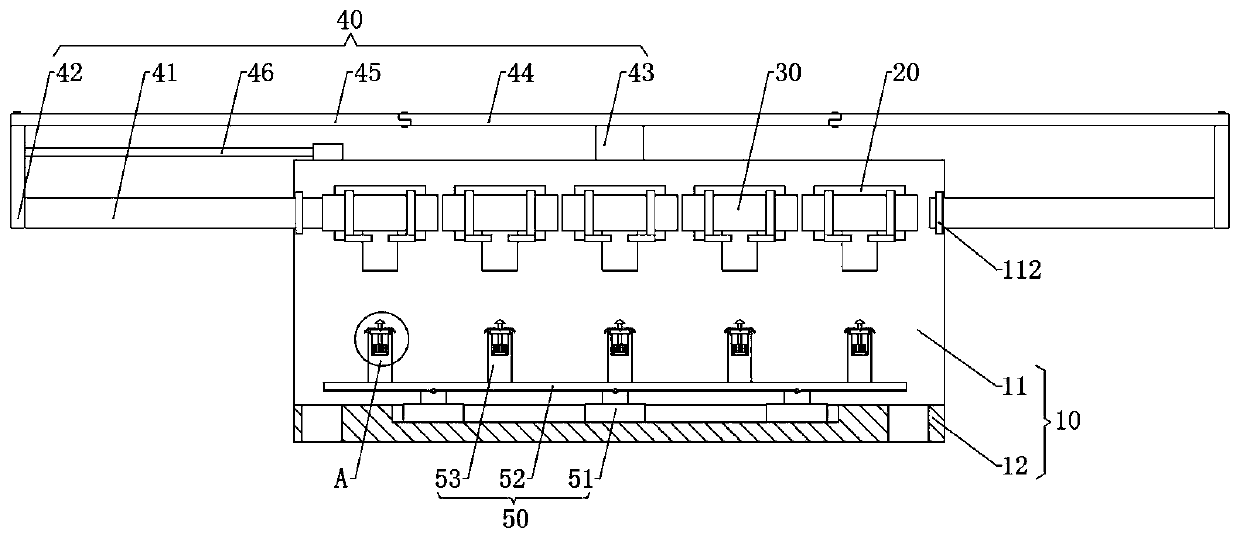

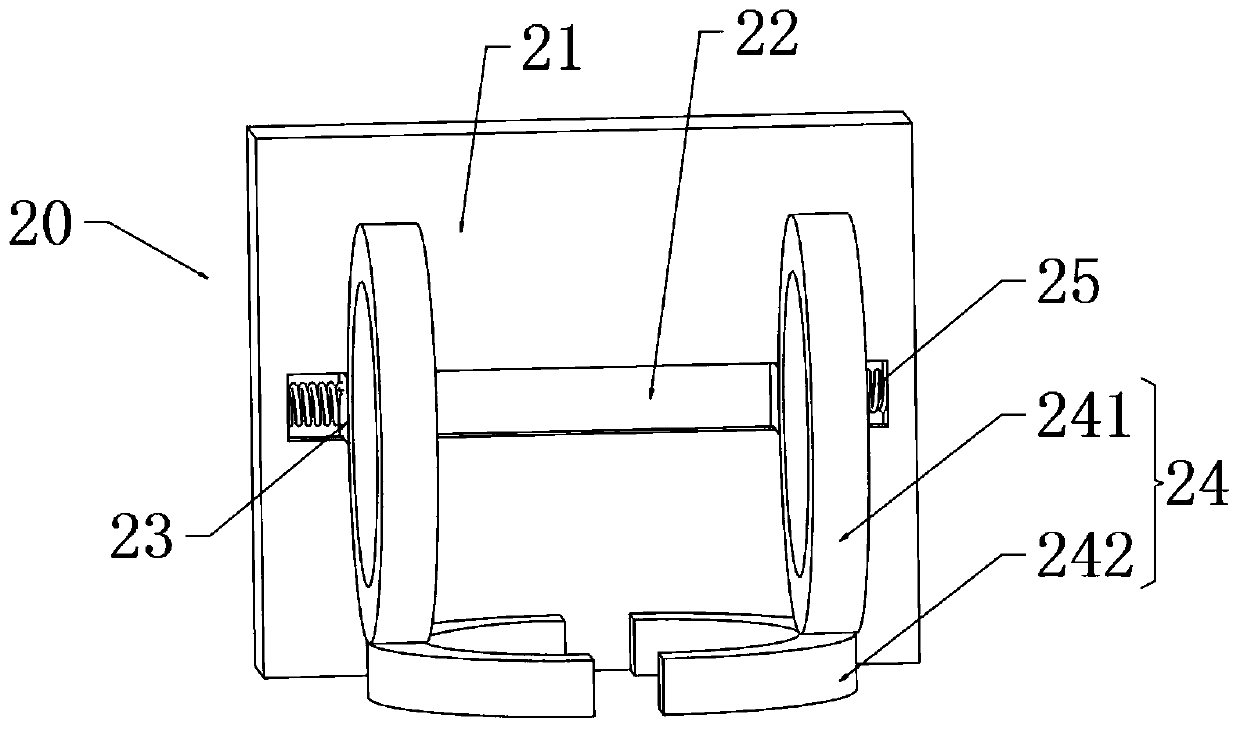

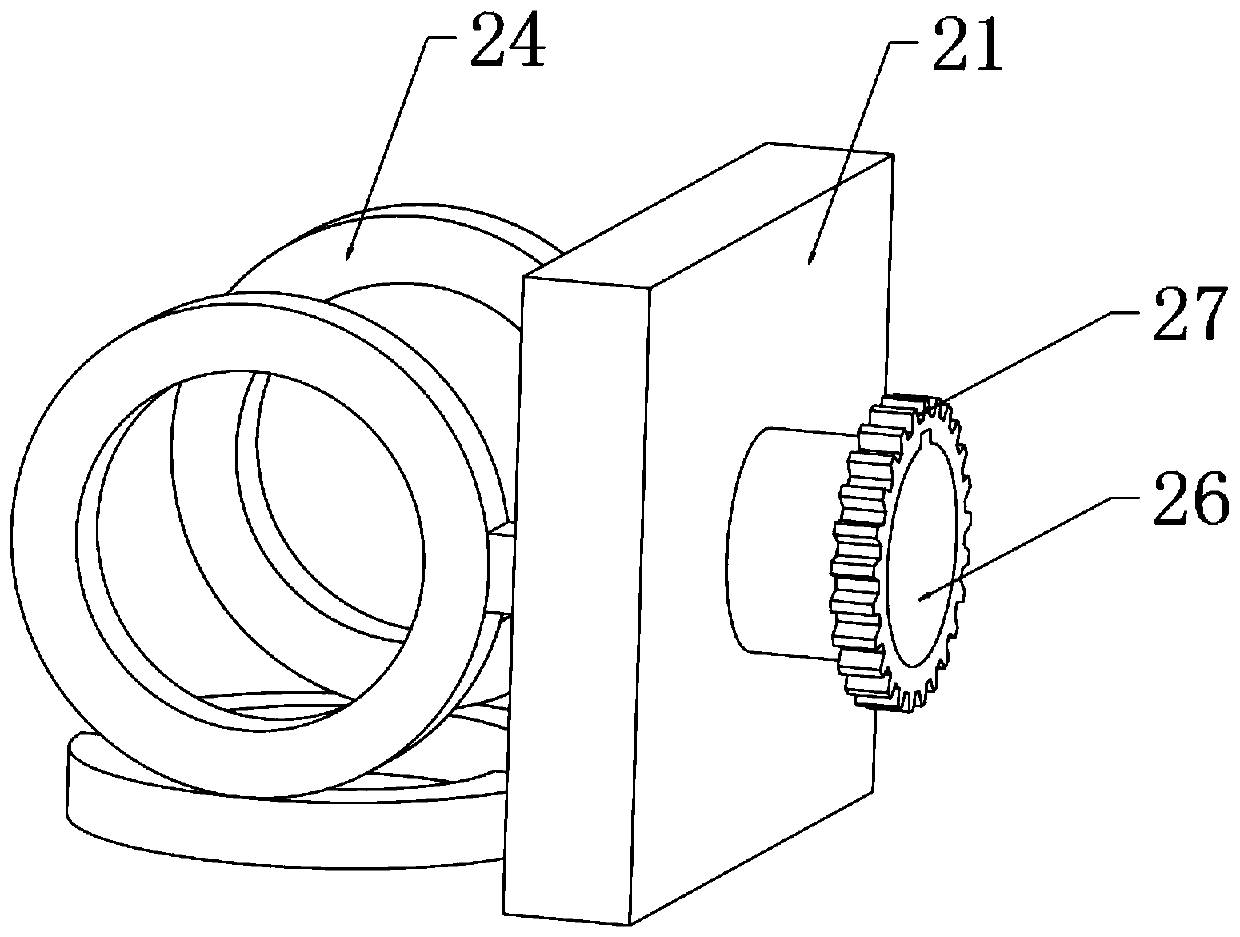

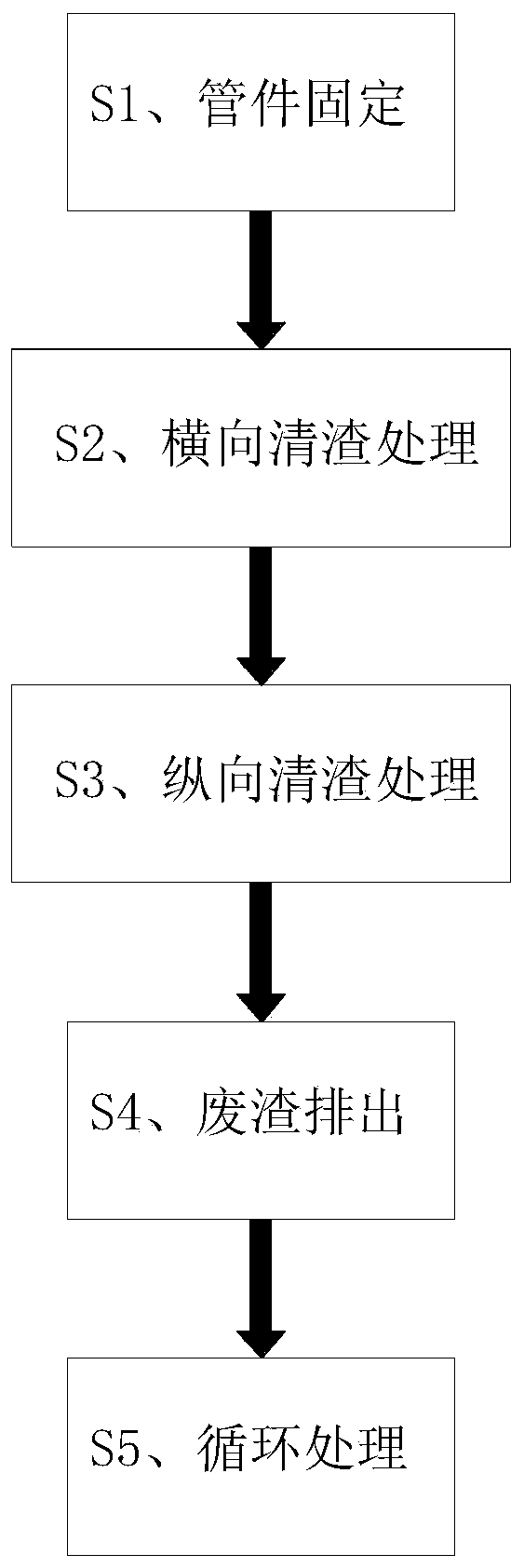

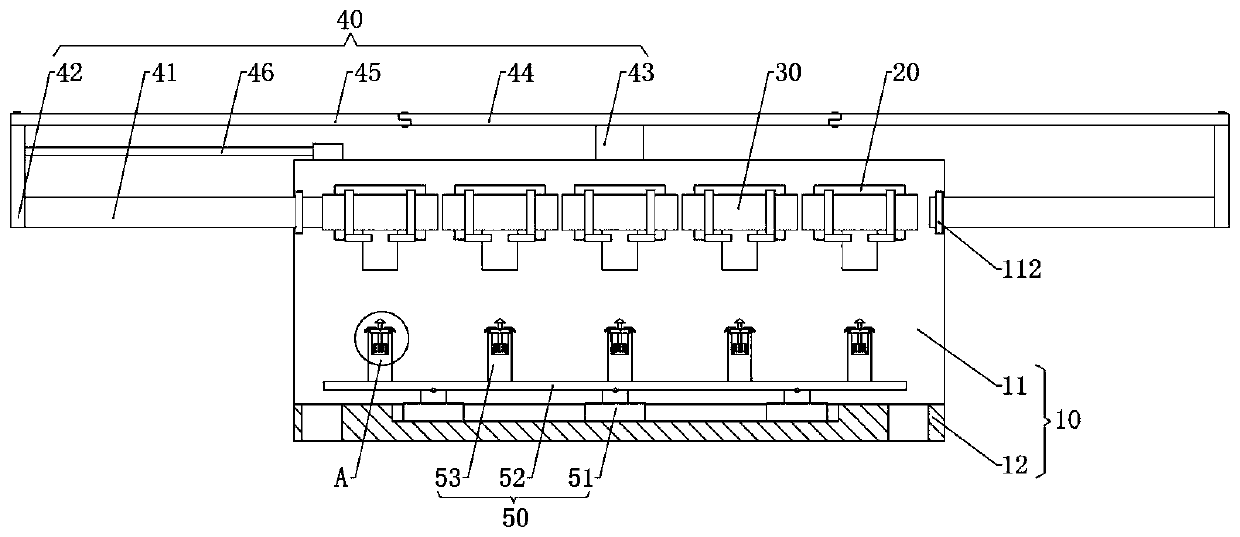

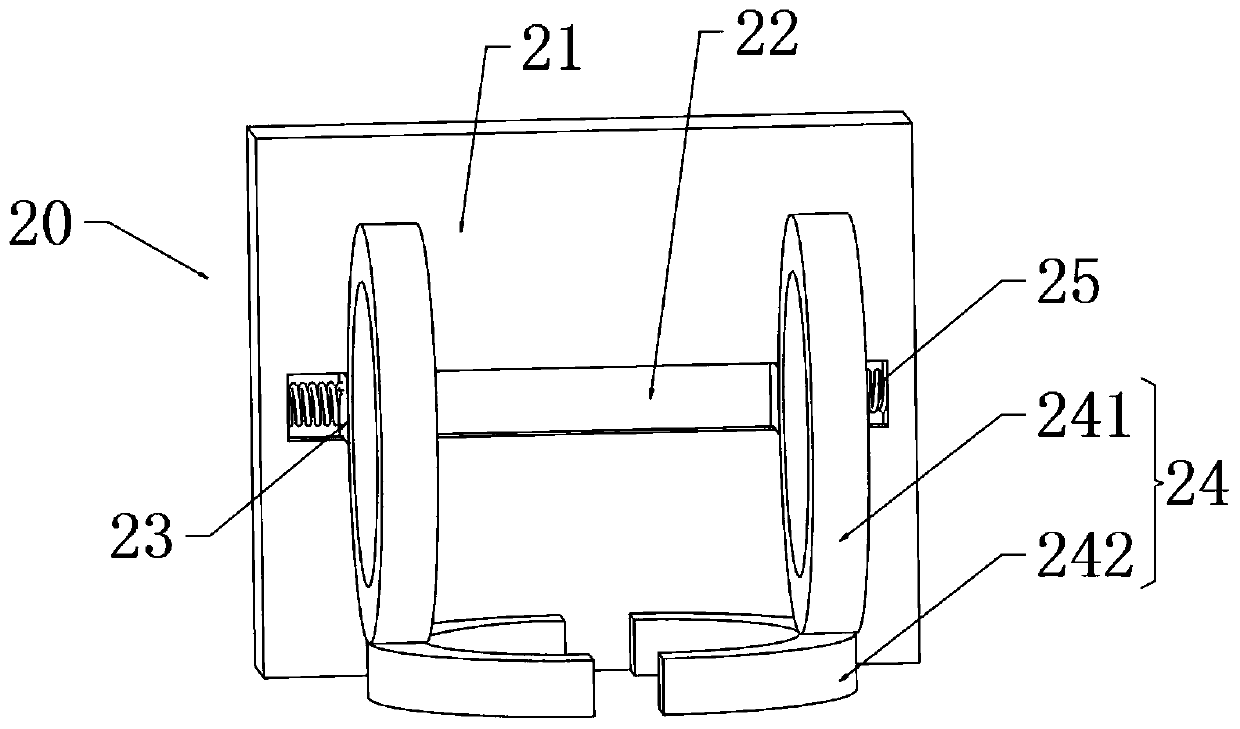

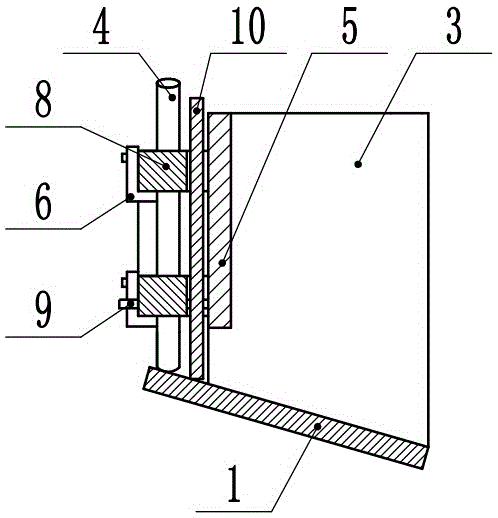

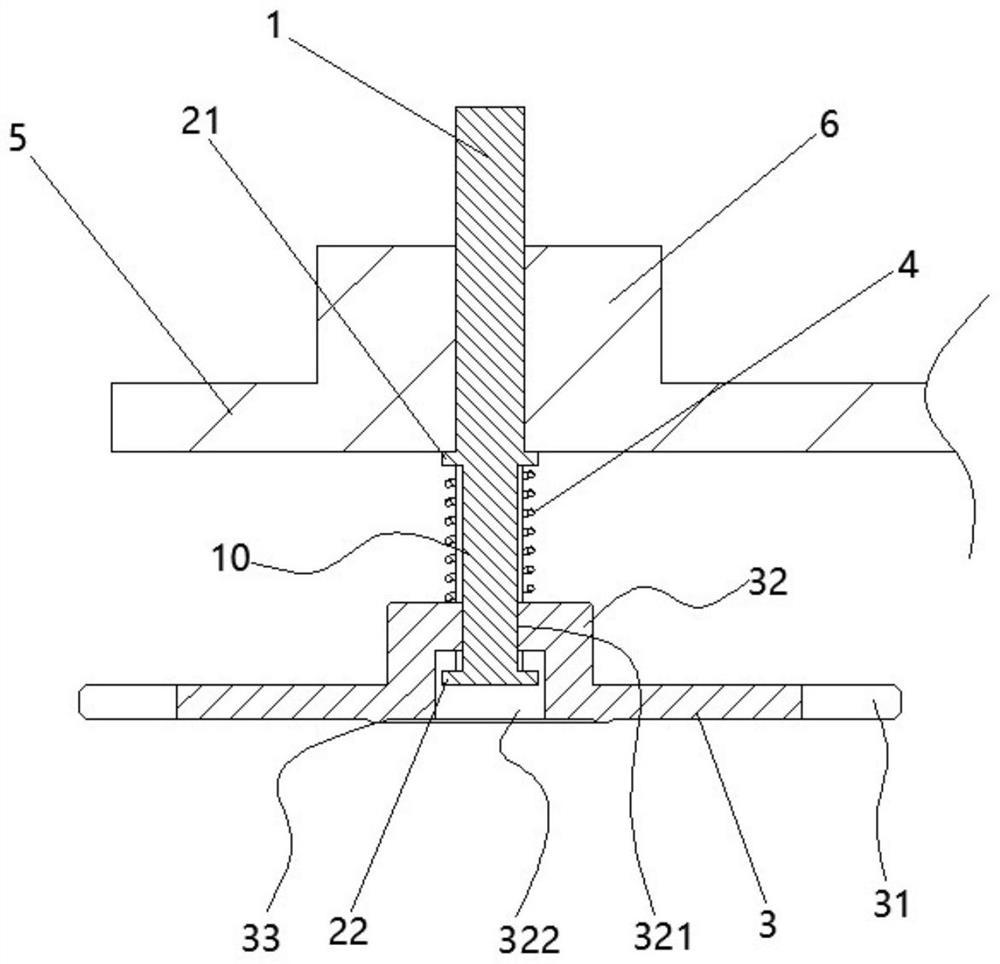

Metal pipe three-way connector casting molding demolding post-treatment system

ActiveCN111360236AEasy to clean slagReduce work intensityStructural engineeringMechanical engineering

The invention relates to a metal pipe three-way connector casting molding demolding post-treatment system. The system comprises a mounting frame and three-way connectors, wherein the mounting frame iscomposed of a vertical plate and a horizontal plate arranged at the bottom of the vertical plate, multiple sets of clamping mechanisms are arranged on the front face of the vertical plate, and the three-way connectors are fixed in the clamping mechanisms; and a transverse slag removing mechanism is arranged at the top of the vertical plate, and a longitudinal slag removing mechanism is arranged at the top of the horizontal plate. According to the system, the three-way connectors are fixed through the multiple sets of clamping mechanisms so that the transverse slag removing mechanism and the longitudinal slag removing mechanism can conveniently remove slag in inner cavities of the multiple three-way connectors at the same time, the slag removing efficiency is improved, and meanwhile the working intensity of workers is reduced; through meshing transmission of racks and gears, the direction of the three-way connectors is adjusted, and sand can fall down from the three-way connectors conveniently; and one end of a lifting plate is lifted through three sets of air cylinders, so that sand slides into rectangular through holes from the lifting plate conveniently.

Owner:临沂美华精密铸造有限公司

Metal pipe fitting casting molding demolding post-treatment process

The invention relates to a metal pipe fitting casting molding demolding post-treatment process. The metal pipe fitting casting molding demolding post-treatment process is mainly completed by matchinga metal pipe fitting tee joint casting molding demolding post-treatment device. The metal pipe fitting tee joint casting molding demolding post-treatment device comprises a mounting frame and tee joints, the mounting frame consists of a vertical plate and a horizontal plate arranged at the bottom of the vertical plate, a plurality of groups of clamping mechanisms are arranged on the front surfaceof the vertical plate, the tee joints are fixed in the clamping mechanisms, the top of the vertical plate is provided with a transverse slag removing mechanism, and the top of the horizontal plate isprovided with a longitudinal slag removing mechanism. According to the metal pipe fitting casting molding demolding post-treatment process, the tee joints are fixed by the multiple groups of clampingmechanisms, so that the transverse slag removing mechanism and the longitudinal slag removing mechanism can simultaneously remove slag from inner cavities of the multiple tee joints, the slag removingefficiency is improved, and meanwhile the working strength of workers is reduced.

Owner:深圳市宝田精工科技有限公司

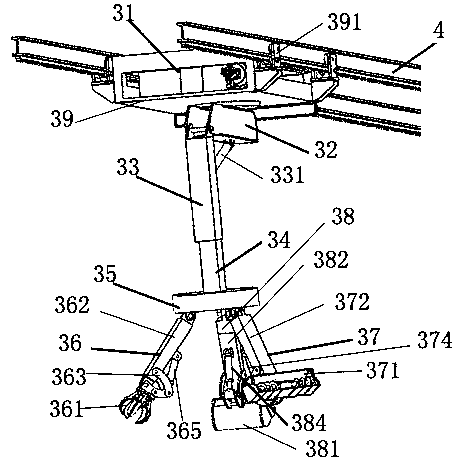

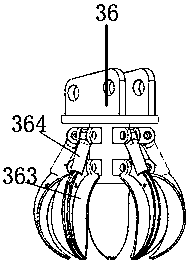

Hoisting mechanical arm for vertical shaft slag removal and using method of hoisting mechanical arm

PendingCN114320306AAchieve double rotational accelerationEasy to clean slagDrilling rodsDerricks/mastsElectric machineryEngineering

A hoisting mechanical arm for vertical shaft slag removal comprises a chuck and a rotating arm which are connected, a rotating base matched with the rotating arm is formed in the middle of the chuck, the rotating arm is rotationally connected to the rotating base, and the rotating base is rotationally connected to the chuck; the rotating arm comprises a first supporting arm and a second supporting arm which are rotationally connected, the first supporting arm is provided with a first driving piece connected with the end of the second supporting arm, and the rotating seat is provided with a driving motor connected with the first supporting arm; a rotary connecting piece is arranged at the end part of the second support arm, and a second driving piece connected with the rotary connecting piece is arranged on the second support arm; a slag removing shovel or a drill rod is arranged on the rotary connecting piece; compared with the prior art, by arranging the hoisting type mechanical arm, mechanical slag removal operation can be conducted in the vertical shaft, a slag removal shovel or a drill rod can be arranged on the rotating connecting piece according to needs, the mechanical arm can ascend and replace, descend to remove slag or drill holes, and better safety is achieved.

Owner:XIANGTAN UNIV +1

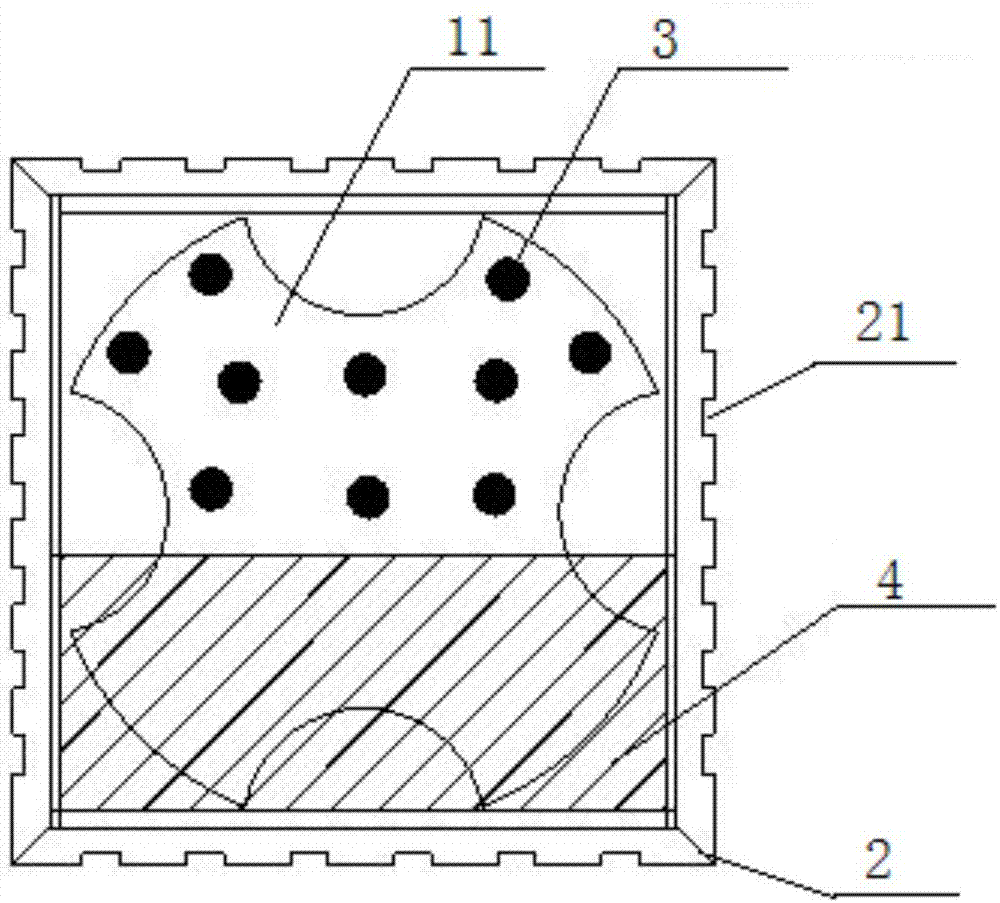

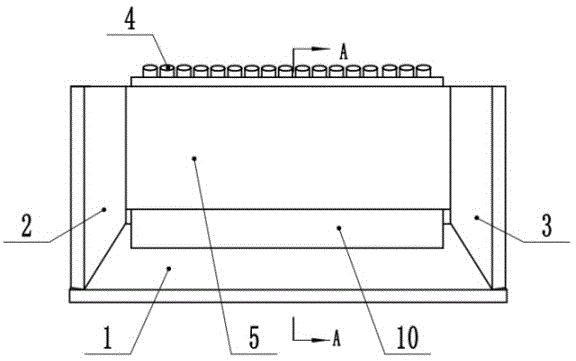

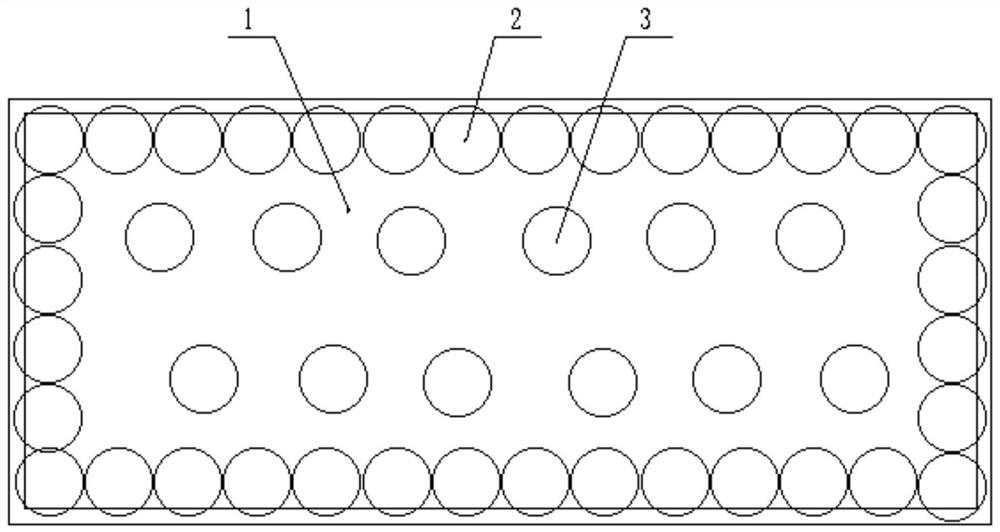

Self-sinking type slag filtering device of slag conveyor

ActiveCN105033239AImprove filter residue efficiencyGood effectCasting cleaning apparatusSlagEngineering

The invention provides a self-sinking type slag filtering device of a slag conveyor. The self-sinking type slag filtering device mainly comprises a bottom plate (1), a front end plate and a rear end plate (3), wherein the front end plate and the rear end plate (3) are fixedly connected to the front end and the rear end of the bottom plate (1) respectively. The self-sinking type slag filtering device further comprises a grid located above the bottom plate (1) and between the front end plate and the rear end plate (3). The grid comprises a grid support (8) and a plurality of vertical strips (4). The vertical strips (4) are independently and movably installed in positioning grooves of the grid support (8). The side faces of the vertical strips (4) are coated with a fireproof and slag bonding preventing coating. By means of the device for slag filtering, molten iron can be filtered through gaps of the grid, the slag filtering efficiency is high, and the effect is good. Meanwhile, after the lower ends of the vertical strips (4) are molten, the vertical strips (4) can automatically sink under the effect of gravity and impact vibration, and it is ensured that the bottoms of the vertical strips (4) make contact with the bottom plate (1) all the time. The slag filtering effect is stable, and reliability is high. The slag filtering device does not need to be frequently replaced, and the maintaining workload is small.

Owner:YANTAI SHENGLIDA ENG TECH

Carbon crucible outer wall slag remover

The invention discloses a carbon crucible outer wall slag remover. The carbon crucible outer wall slag remover is a special machine for producing a carbon crucible and is used to remove sand slag on the outer wall of the carbon crucible; the carbon crucible outer wall slag remover is provided with a frame; the frame is provided with two carrier rollers rotationally connected with each other for supporting the carbon crucible; at least one of the two carrier rollers is a power roller for rotating the carbon crucible; the two carrier rollers are arranged in parallel at an interval; the gap between the two carrier rollers is provided with a knife holder; the knife holder is supported by the frame and slidably and reciprocally connected with the frame in the axial direction of the carrier rollers; a plurality of outer wall scrapers are fixedly arranged on the top surface of the knife holder; the outer wall scrapers are arranged at intervals in the axial direction of the carrier rollers; aknife holder driving device is arranged on the knife holder or the frame; the carrier rollers drive the carbon crucible to rotate after rotating, at the moment, the sand slag in contact with the outerwall scrapers is removed by the outer wall scrapers under the pressure of the self weight of the carbon crucible, and then the knife holder is pushed and pulled reciprocally, so that the sand dregs on the outer wall of the carbon crucible are removed by using the displacement of each outer wall scraper, and the process of slag removal is labor-saving and effort-saving.

Owner:刘盼盼

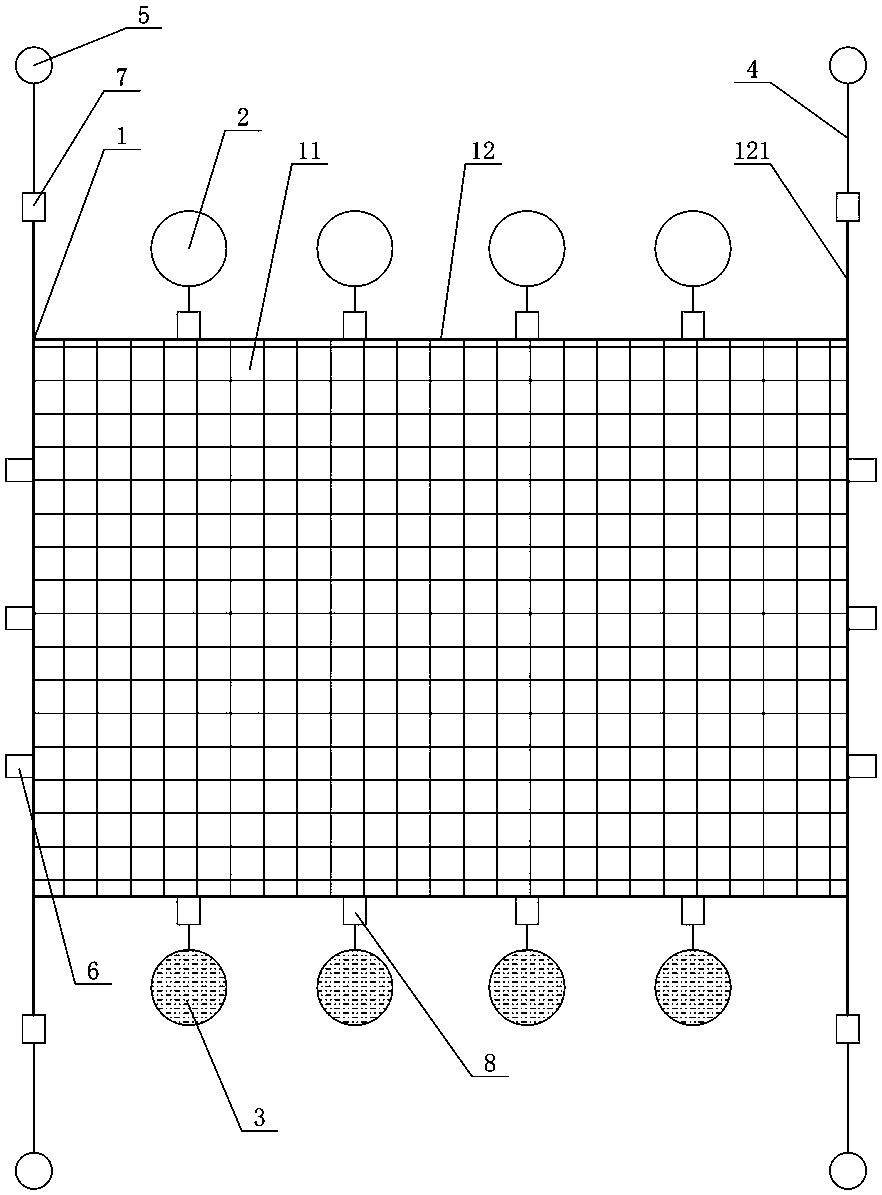

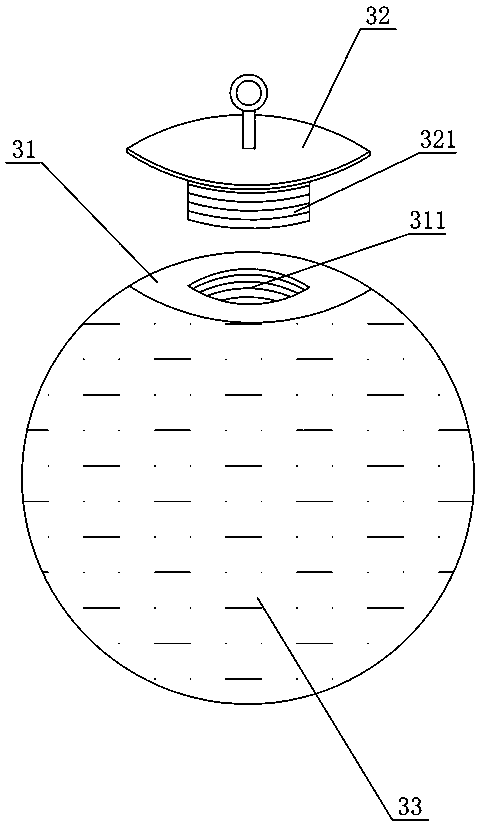

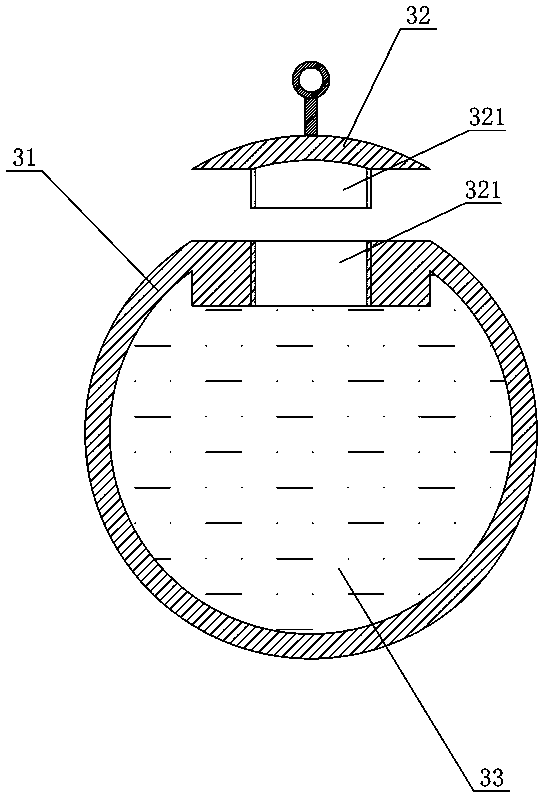

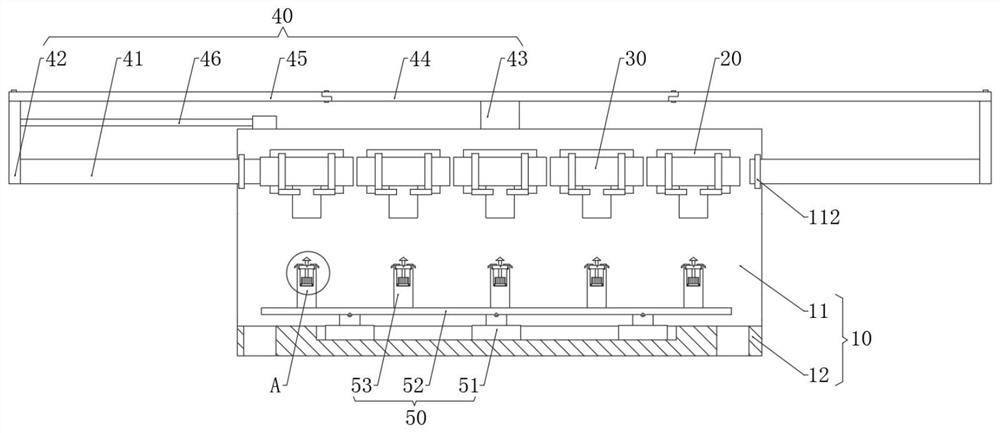

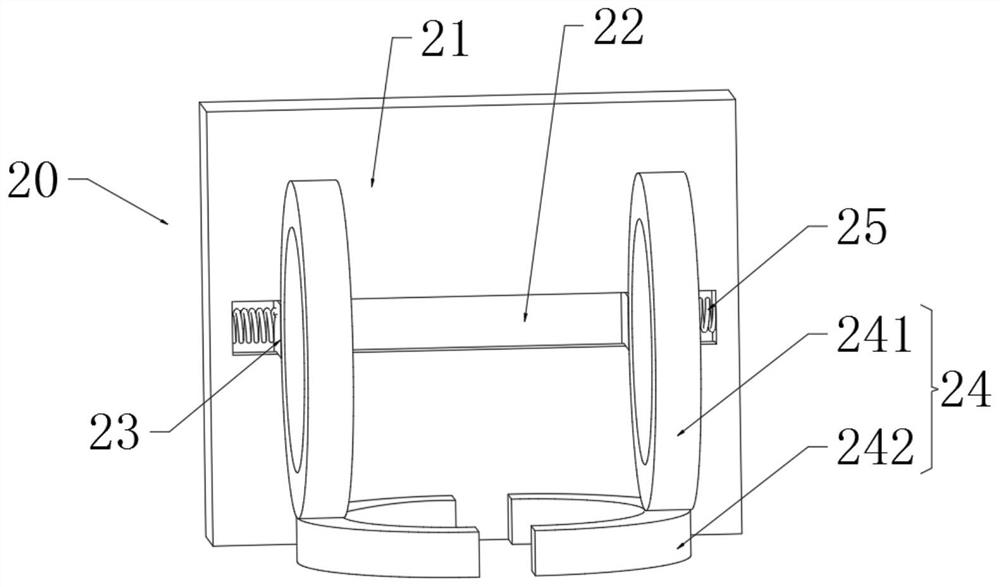

Combined water surface slag catch net and slag catch method

The invention discloses a combined water surface slag capturing net and a slag capturing method. The slag capturing net comprises at least one net body; multiple first float balls are arranged on the top edges of the net bodies at intervals; all the first float balls are detachably connected with the top edges of the net bodies; multiple sinking balls are arranged at the bottom edges of the net bodies at intervals; all the sinking balls are detachably connected with the bottom edges of the net bodies; two ends of two side edges of the net bodies are detachably connected with traction ropes; second float balls are respectively mounted at the ends of all the traction ropes; and multiple first unloading buckles are arranged at two side edges of the net bodies at intervals. The slag capturing method comprises the steps of: (S1) assembly of the slag capturing net; (S2) sinking of the slag capturing net into water; (S3) fixation of the slag capturing net; (S4) traction for slag capturing; (S5) slag packing; and (S6) taking of slag ashore. The combined water surface slag capturing net and the slag capturing method have the advantages of low cost, wide application range, capability of recycling and high slag removing efficiency.

Owner:钟永

A post-processing system for casting and demolding of tee joints of metal pipe fittings

Owner:临沂美华精密铸造有限公司

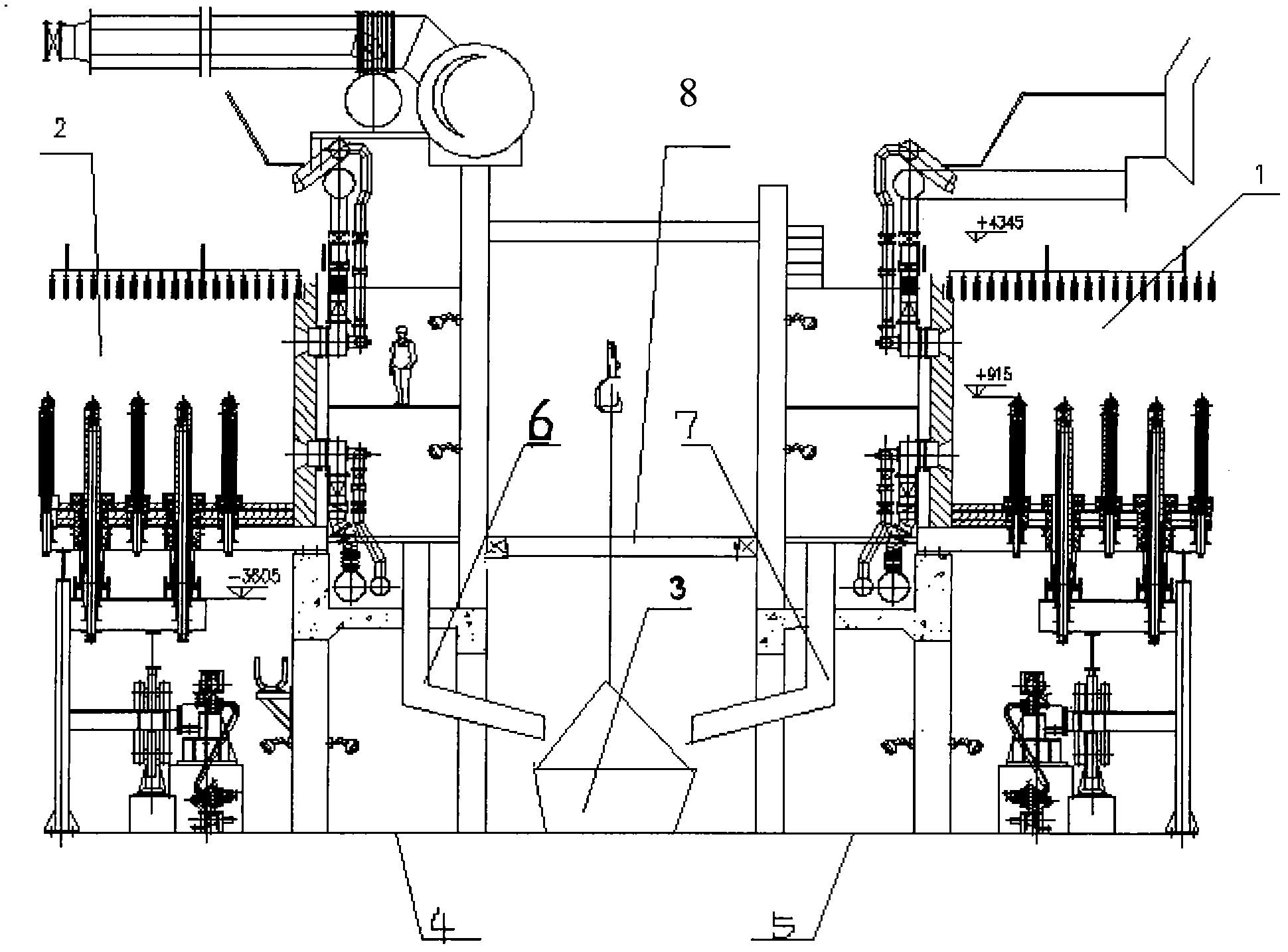

Construction method for ultra-deep vertical shaft in limited space

ActiveCN113404496AImprove excavation efficiencyFlexible operationConstructionsHydro energy generationMode of transportDrill hole

The invention discloses a construction method for an ultra-deep vertical shaft in limited space a limited space. The construction method comprises the following steps: S1, a preset vertical shaft position is determined, and surrounding rock in the range of the preset vertical shaft is pre-destroyed by drilling a hole through a rotary excavating drill; S2, a transverse channel is excavated at the bottom of the preset vertical shaft position; S3, a muck leakage hole is drilled in the preset vertical shaft, and the lower end of the muck leakage hole communicates with the transverse channel; S4, the vertical shaft is excavated, and muck generated by excavation is conveyed into the transverse channel through the muck leakage hole till the vertical shaft is excavated to the base; and S5, a muck conveying vehicle enters the transverse channel, and outwards conveys the muck conveyed into the transverse channel to a specified storage point. By optimizing the excavation mode and the muck transportation mode, the adverse effect that the muck cannot be effectively discharged due to the narrow construction site and the complex external environment is solved, and the construction efficiency is greatly improved.

Owner:CHINA CONSTR EIGHTH ENG DIV

A high-efficiency aluminum formwork slag removal mechanism

ActiveCN110711725BFast and effective slag removalImprove slag cleaning efficiencyCleaning using toolsDrive shaftSlag

The application discloses a high-efficiency aluminum template slag removal mechanism, including: a rotating shaft, a slag removal knife, a first limiter, a second limiter, and an elastic member; both the first limiter and the second limiter are fixed It is located at one end of the rotating shaft and arranged at intervals; the shaft section between the first limiter and the second limiter on the rotating shaft forms a transmission shaft section that cooperates with the slag cleaning knife; the slag cleaning knife is movably sleeved on the transmission on the shaft section, and synchronously rotate with the rotating shaft; the elastic member is movably sleeved on the transmission shaft section, and the first end is in contact with the first limiter, and the second end is in contact with the slag cleaning knife. Not only the elastic parts can be used to make the slag cleaning knife close to the aluminum template, but also the slag cleaning knife can be fine-tuned and moved along the axial direction of the rotating shaft on the transmission shaft section, so as to realize fast and effective slag cleaning operation and high slag cleaning efficiency.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Steel plate slag removal equipment

PendingCN113843697APrevent accidental injury to staffImprove securityGrinding machinesGrinding feedersSlagIndustrial engineering

The invention relates to the technical field of slag removal equipment, and discloses steel plate slag removal equipment which comprises a slag removal rotary drum, a feeding groove is formed in the surface of the slag removal rotary drum, and a cover plate is hinged to one side of the feeding groove through a hinge. By forming the feeding groove in the surface of the slag removal rotary drum and shielding the feeding groove with the cover plate, the equipment can prevent steel plates and steel slag in the slag removal rotary drum from splashing out to accidentally injure workers, the safety performance of the equipment during use is improved, and the workers can complete discharging at a time. The repeated discharging process is avoided. A mounting arc-shaped plate I, a mounting arc-shaped plate II, a mounting arc-shaped plate III and a mounting plate which are internally provided with a plurality of slag removal nails are arranged in the slag removal rotary drum, so that the contact area between the slag removal nails in the equipment and the steel plates is increased, the equipment can carry out slag removal on the steel plates in all directions, and the slag removal time of the equipment is shortened. And the slag removal efficiency of the equipment is improved.

Owner:GUANGZHOU ZENGLI STEEL STRUCTURE

Slag cleaner for cleaning pile bottom sediment and its working method

ActiveCN105821881BThorough slag removalAvoid the risk of hole collapseBulkheads/pilesSediment FilterSlag

The invention discloses a sediment removal machine for removing sediment at the bottom of a pile and a working method thereof. The sediment removal machine comprises a sediment removal device and a main controller for controlling work of the sediment removal device. The sediment removal device comprises an outer cover, a sediment suction tube for sucking the sediment is arranged in the outer cover, and the bottom end of the sediment suction tube extends out of the outer cover so that the sediment at the bottom of the pile can be sucked into the outer cover. At least one layer of sediment filter screen is arranged between the outer cover and the sediment suction tube. The positions where the sediment filter screens are located are lower than an outlet of the sediment suction tube. A water outlet is formed in the bottom surface of the outer cover so as to discharge return mud flowing down the sediment filter screens. A sediment amount sensor is arranged on the upper portion of the inner side face of the outer cover and connected with the main controller. Mud displacement does not exist, mud pouring is not needed, the automation degree is high, operability is high, the sediment removal efficiency and effect are improved, the hole collapse risk caused by mud displacement is avoided, and the problem that the environment is polluted because a large amount of mud is used is solved.

Owner:SHANDONG UNIV

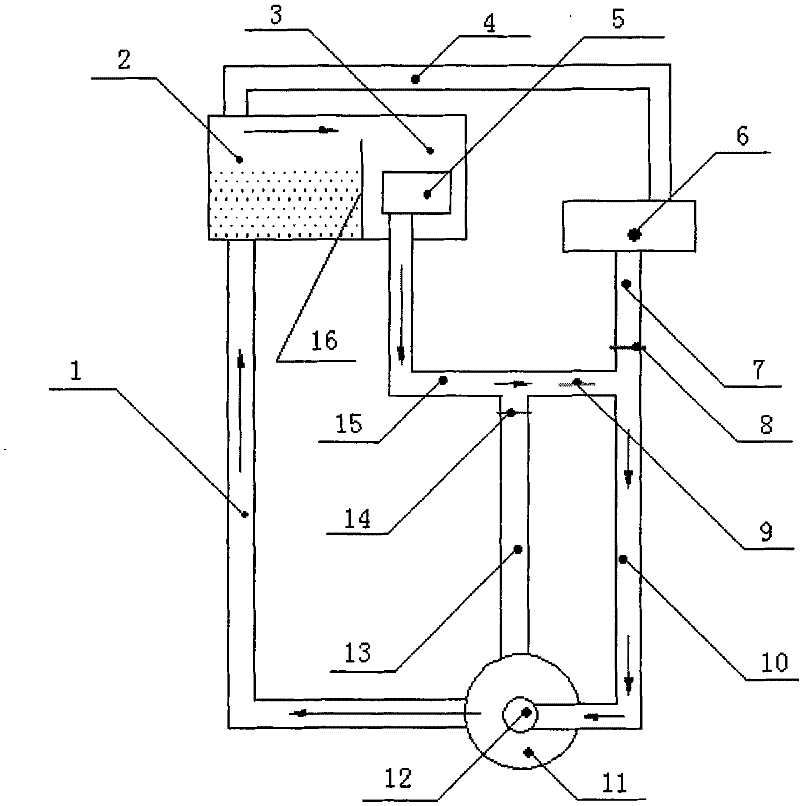

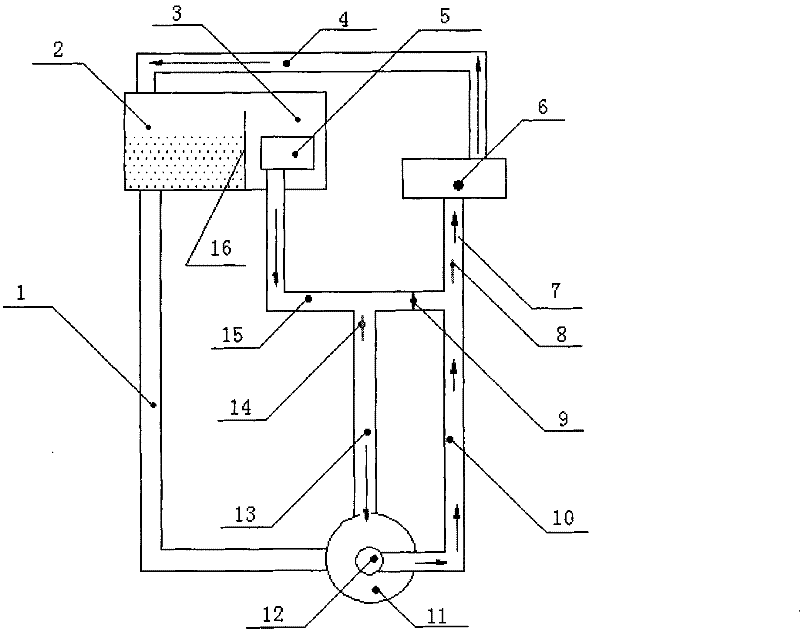

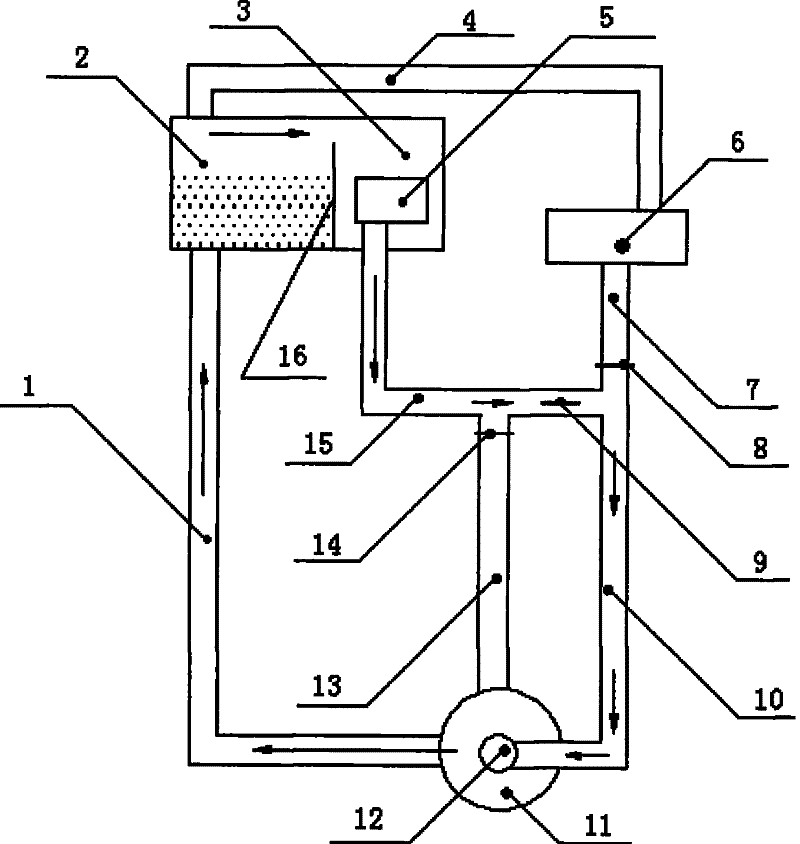

Pile bottom hole clearing system and process of pile bottom hole clearing

The invention relates to a pile-bottom borehole-cleaning system and a pile-bottom borehole-cleaning technique, adopting a direct-reverse circulation-combined borehole cleaning technique for carrying out pile-bottom borehole cleaning. The pile-bottom borehole cleaning system comprises a reverse circulation pump, a mud pump, a valve switch, a pipeline, a mud ditch or a mud pipeline, a sedimentationbasin and a conduit; the conduit is communicated with a pipeline at the right side and connected with the reverse circulation pump, the mud pump and a three-way valve switch; the interconversion of the direct-reverse circulation borehole cleaning is realized by controlling the valve switch. Compared with the prior art, the pile-bottom borehole cleaning system and technique can carry out fast slagremoval cleanly and thoroughly, thereby increasing the slag removal efficiency by 3 to 5 times, and ensuring the quality of the pile basement; the used borehole cleaning device has simple and functional installment and operation, easily accessible materials, low price and convenient process.

Owner:CSCEC STRAIT CONSTR & DEV

Adhesion-type slag removal process and device for molten iron pretreatment

ActiveCN106541124BLight weightReduce iron lossCasting cleaning apparatusProcess efficiency improvementSlagWater cooling

The invention relates to a molten iron pretreatment adhering type slag removing technology and device. A molten iron tank is conveyed to a slag removing station, slag adhering discs are lowered into the molten iron tank, and the slag adhering discs are cooled through a water cooling system; temperature measuring devices arranged on the slag adhering discs are used for controlling the immersion depth of the slag adhering discs, water cooling of adhering slag is conducted after the slag adhering discs stay in a slag layer for 60-120 s, and then the slag adhering discs are elevated to the position above the tank edge of the molten iron tank; the slag adhering discs are rotated to the slag removing station through a rotation mechanism, and solid slag on the slag adhering discs is removed; and the above slag adhering and removing processes are repeatedly conducted till all desulfurized slag in the molten iron tank is completely removed. The adhering type slag removing manner is adopted, the characters that the desulfurized slag is low in specific gravity and high in cooling speed are utilized, the desulfurized slag is rapidly solidified in a chilling condition and adheres to the slag adhering discs, and then the slag adhering discs are cleaned. The molten iron pretreatment adhering type slag removing technology and device have the beneficial effects that the slag removal rate is high, iron losses are small, and the slag removing efficiency is high.

Owner:ANGANG STEEL CO LTD

Rapid slag removing method of heating furnace

ActiveCN102538476BImprove slag cleaning efficiencyPut into productionCharge manipulationDischarge devicesSlagWorking environment

A rapid slag removing method of a heating furnace is disclosed, which aims at alleviating the labor intensity, improving the working environment and improving the slag removing efficiency. In the invention, four mounting holes are respectively arranged in slag discharging furnace doors corresponding to a steel platform channel outside the four slag discharging furnace doors on each side of the heating furnace, and two slag sliding grooves communicated to the bottom of the furnace are installed on each mounting hole, namely eight slag sliding grooves are arranged; two of the slag sliding grooves can change the slag sliding direction; these two slag sliding grooves enable half of the high-temperature steel slag in the furnace to directly and alternately slide in two slag hoppers which are arranged at the new slag hoisting points on the bottom of the furnace and are arranged in parallel, the other six slag sliding grooves enable the residual steel slag to slide in a slag transporting trolley arranged on the ground of the bottom of the furnace, the residual steel slag is transported to the new slag hoisting point and fed in the slag hoppers for hoisting, the two slag hoppers are hoisted by turns to work continuously, so that the slag removing efficiency of the heating furnace is improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com