Alcohol-based fuel conveying pipeline deslagging piping assembly

A technology for conveying pipelines and alcohol-based fuels, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve problems such as affecting the smoothness of fuel transportation, large cleaning workload, and labor and material resource consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

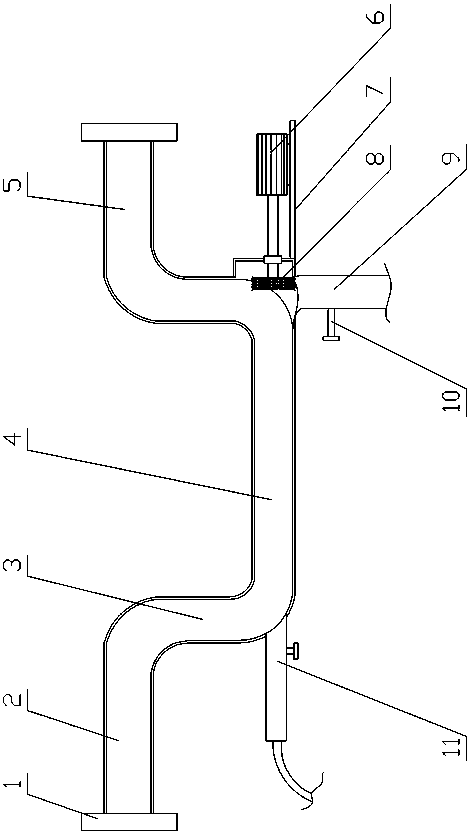

[0010] see figure 1 , the present invention is an auxiliary component added later, which relates to a slag removal piping assembly for an alcohol-based fuel delivery pipeline, which has a coaxially arranged horizontal tube A2 and a horizontal tube B5, and between the horizontal tube A and the horizontal tube B is also An eccentric horizontal tube 4 is provided, and the two ends of the eccentric horizontal tube communicate with the horizontal tube A and the horizontal tube B respectively through the vertical tube 3, and the outer ends of the horizontal tube A and the horizontal tube B are provided with flanges connected with the fuel delivery pipeline 1. A high-pressure flushing water gun 11 is provided at one end of the eccentric horizontal pipe, and a downwardly arranged slag discharge pipe 9 is provided at the other end of the eccentric horizontal pipe. A shut-off valve 10 is provided on the slag discharge pipe. The outer side is provided with a transverse seat plate 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com