Combined water surface slag catch net and slag catch method

A combined and net-based technology, which is applied to the cleaning of open water surfaces, water conservancy projects, construction, etc., can solve the problems of high cost and low efficiency of slag removal, and achieve the effects of low cost, improved efficiency of slag removal, and convenient recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

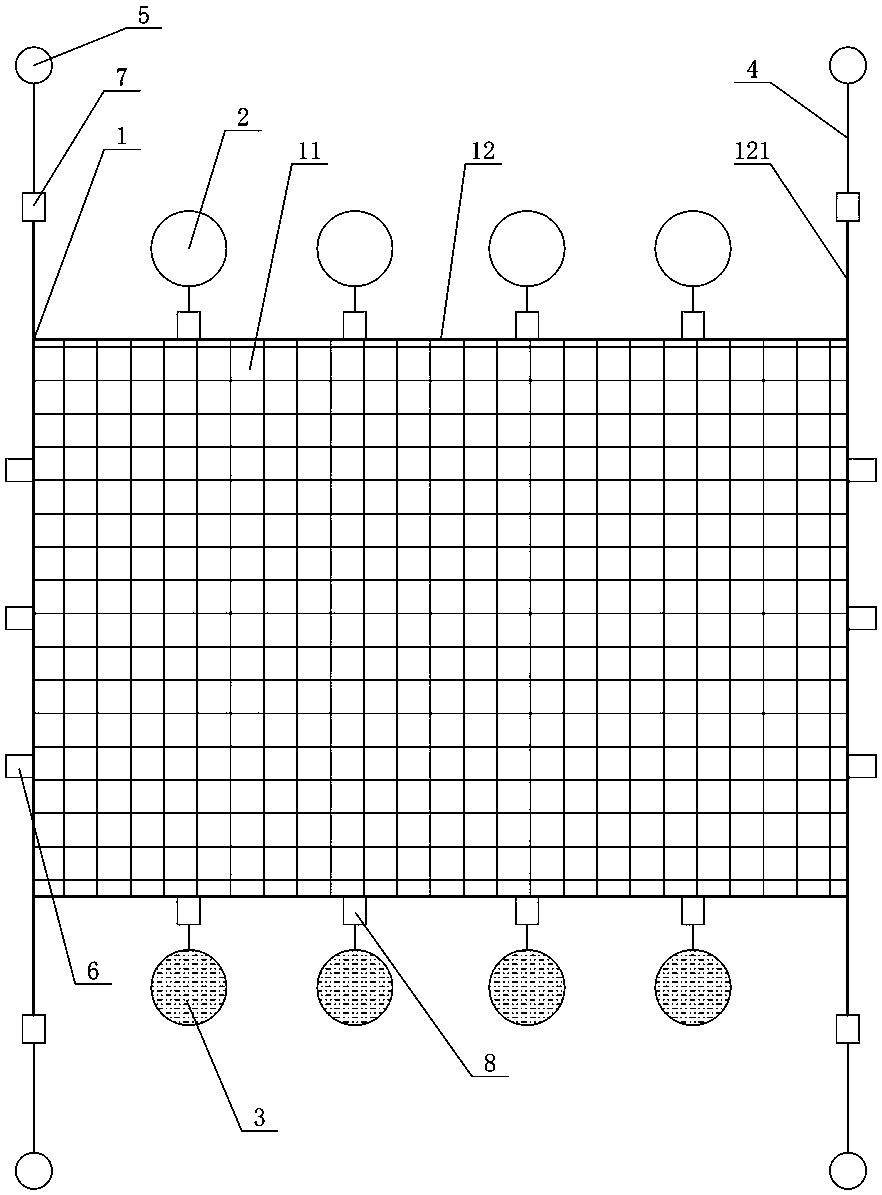

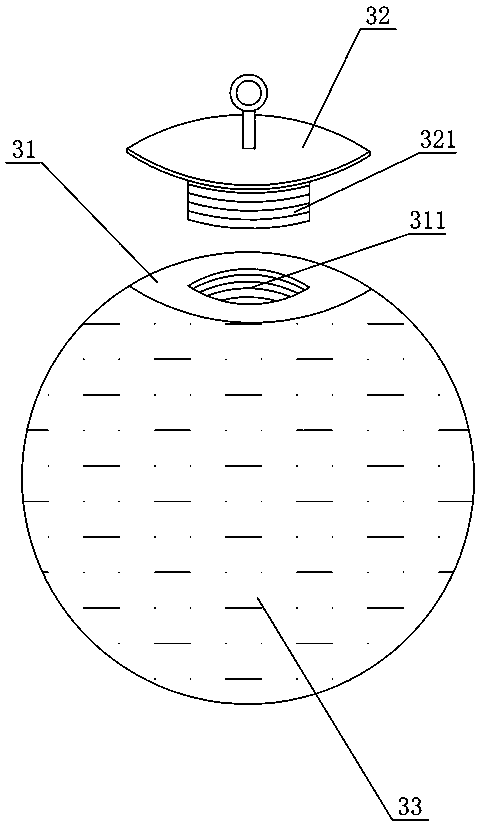

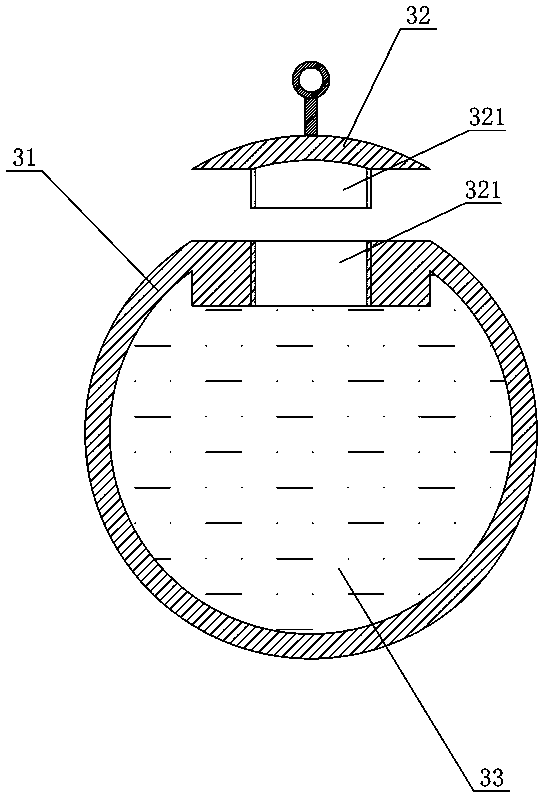

[0034] Figure 1 to Figure 5 It shows the first embodiment of the combined water surface slag catcher net of the present invention, the slag catcher net includes at least one net body 1, and the net body 1 is arranged with a plurality of first floating balls 2 at intervals on the top edge, each first The floating ball 2 is detachably connected to the top edge of the net body 1, and the bottom edge of the net body 1 is arranged with a plurality of sinking balls 3 at intervals, each sinking ball 3 is detachably connected to the bottom edge of the net body 1, and the net body 1 is placed Both ends of the side are detachably connected with traction ropes 4 , and the ends of each traction rope 4 are equipped with second floating balls 5 , and a plurality of first shackles 6 are arranged at intervals on both sides of the net body 1 . When using, calculate the area of the required net body 1 according to the area of one slag catcher. When the slag catcher area is smaller than the...

Embodiment 2

[0043] Such as Figure 6 As shown, the second embodiment of the combined water surface slag-catching net of the present invention is basically the same as that of Embodiment 1, the only difference being that the slag-catching net is formed by connecting two net bodies 1 through the first shackle 6 , can be applied to the situation where the slag catch area is large at one time.

[0044] In other embodiments, the first shackles 6 are arranged at the ends of both sides of the mesh body 1. When two mesh bodies 1 are connected, a rope body is used to alternately pass through the sides of the two mesh bodies 1 in an S shape. Bundling is formed, and then secondary fastening is formed through the first shackle 6 at the end, which further improves the connection strength on the one hand and facilitates disassembly on the other hand.

[0045] Such as Figure 7As shown, the flow chart of the slag-catching method of the present invention is carried out with the above-mentioned combined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com