Steel plate slag removal equipment

A technology for cleaning slag and equipment, applied in metal processing equipment, grinding/polishing equipment, grinding feed motion, etc., can solve the problems of inability to replace the slag cleaning alone, inability to protect operators, inconvenient loading and unloading, etc. The effect of cleaning slag time, easy loading and unloading, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

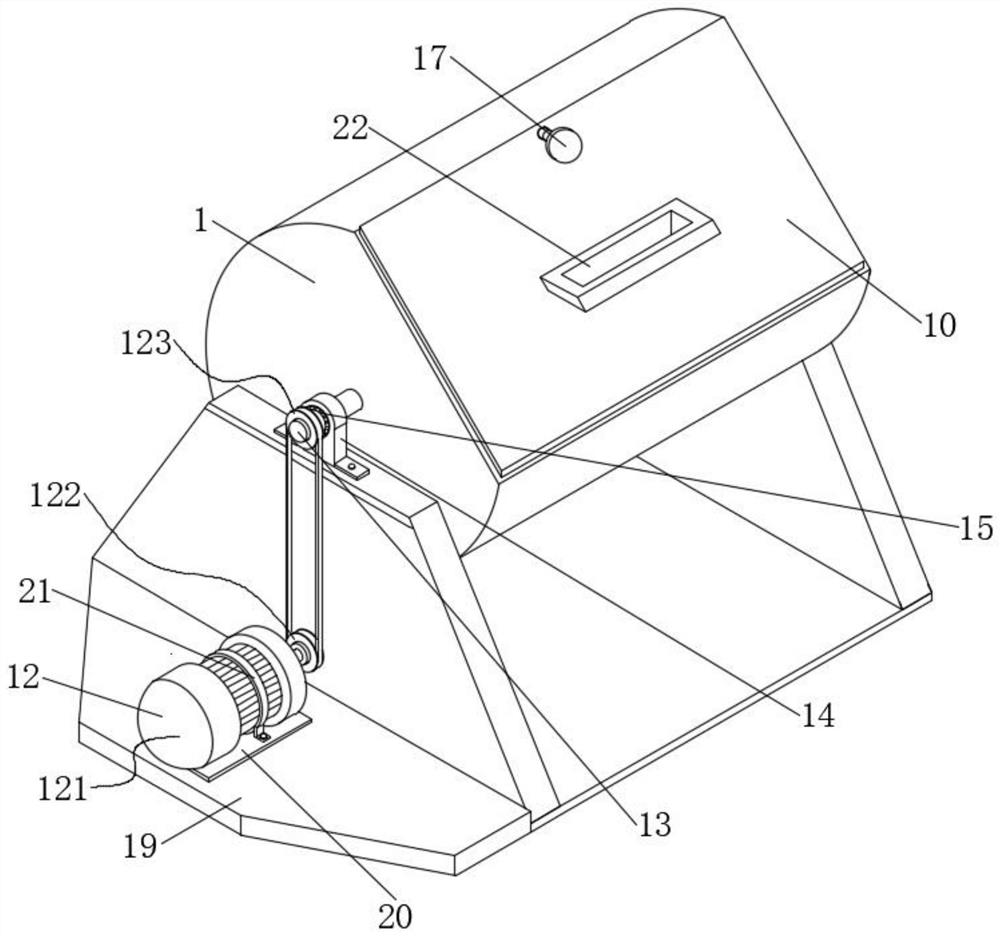

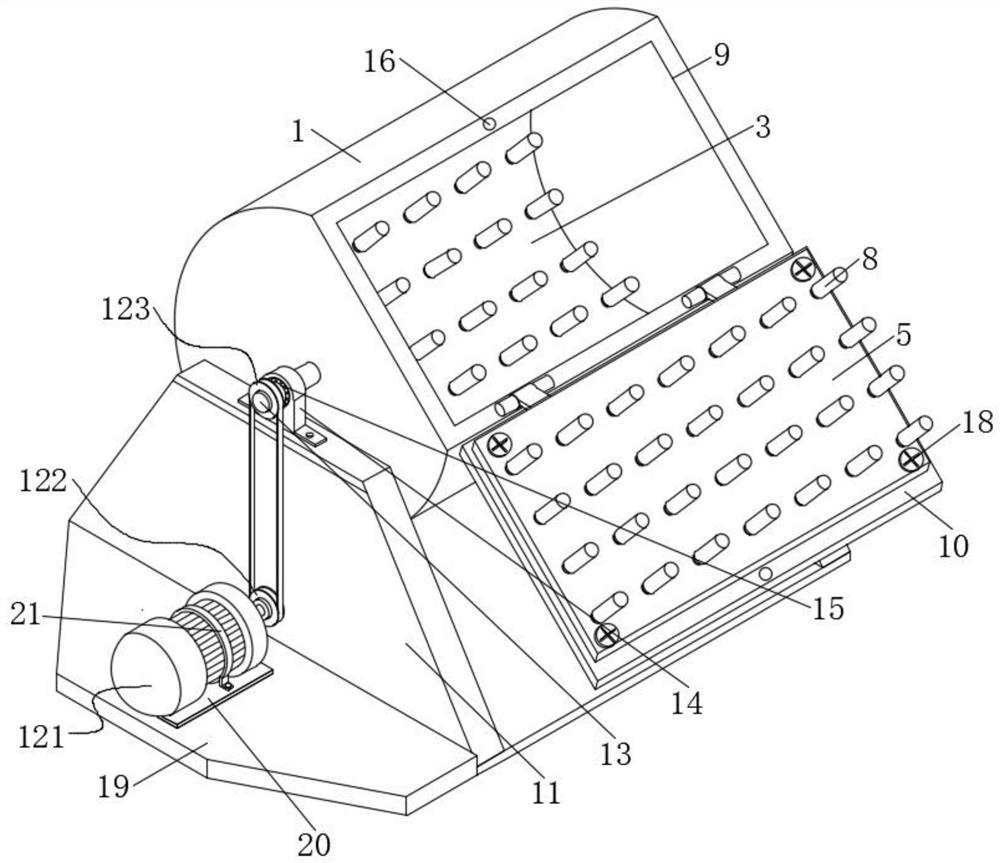

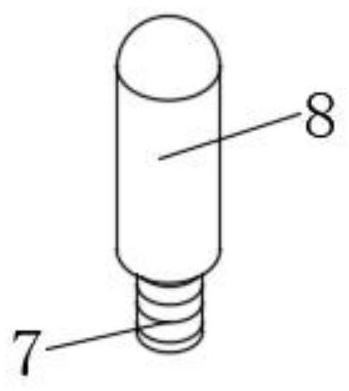

Embodiment 1

[0027] see Figure 1-2 As shown, a steel plate slag removal equipment includes a slag removal drum 1, the surface of the slag removal drum 1 is provided with a feeding groove 9, and through the setting of the feeding groove 9, the user can directly pass through the feeding groove 9. The material is put into the inside of the slag cleaning drum 1, and one side of the feeding chute 9 is hinged with a cover plate 10 through a hinge. Prevent external impurities from entering the inside of the slag cleaning drum 1 when not in use, and at the same time prevent the steel plates and steel slag inside the slag cleaning drum 1 from splashing out, install the arc plate 1, install the arc plate 2 3, There are four installation screws 23 connected with the internal thread of the slag cleaning drum 1, and the inside of the installation arc plate three 4 is threaded. By setting the limit bolt 17, it is convenient for the operator to install the arc plate one 2, The installation and disassem...

Embodiment 2

[0029] see Figure 1-4As shown, a steel plate slag removal equipment includes a slag removal drum 1, the surface of the slag removal drum 1 is provided with a feeding groove 9, and through the setting of the feeding groove 9, the user can directly pass through the feeding groove 9. The material is put into the inside of the slag cleaning drum 1, and one side of the feeding chute 9 is hinged with a cover plate 10 through a hinge. Prevent external impurities from entering the inside of the slag cleaning drum 1 when not in use, and at the same time prevent the steel plates and steel slag inside the slag cleaning drum 1 from splashing out, install the arc plate 1, install the arc plate 2 3, There are four installation screws 23 connected with the internal thread of the slag cleaning drum 1, and the inside of the installation arc plate three 4 is threaded. By setting the limit bolt 17, it is convenient for the operator to install the arc plate one 2, The installation and disassemb...

Embodiment 3

[0031] see Figure 1-5 As shown, a steel plate slag removal equipment includes a slag removal drum 1, the surface of the slag removal drum 1 is provided with a feeding groove 9, and through the setting of the feeding groove 9, the user can directly pass through the feeding groove 9. The material is put into the inside of the slag cleaning drum 1, and one side of the feeding chute 9 is hinged with a cover plate 10 through a hinge. Prevent external impurities from entering the inside of the slag cleaning drum 1 when not in use, and at the same time prevent the steel plates and steel slag inside the slag cleaning drum 1 from splashing out, install the arc plate 1, install the arc plate 2 3, There are four installation screws 23 connected with the internal thread of the slag cleaning drum 1, and the inside of the installation arc plate three 4 is threaded. By setting the limit bolt 17, it is convenient for the operator to install the arc plate one 2, The installation and disassem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com