Adhesion-type slag removal process and device for molten iron pretreatment

A technology of molten iron pretreatment and slag staining, which is applied to the improvement of process efficiency, mechanical cleaning, and tool manufacturing. Small, high clearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

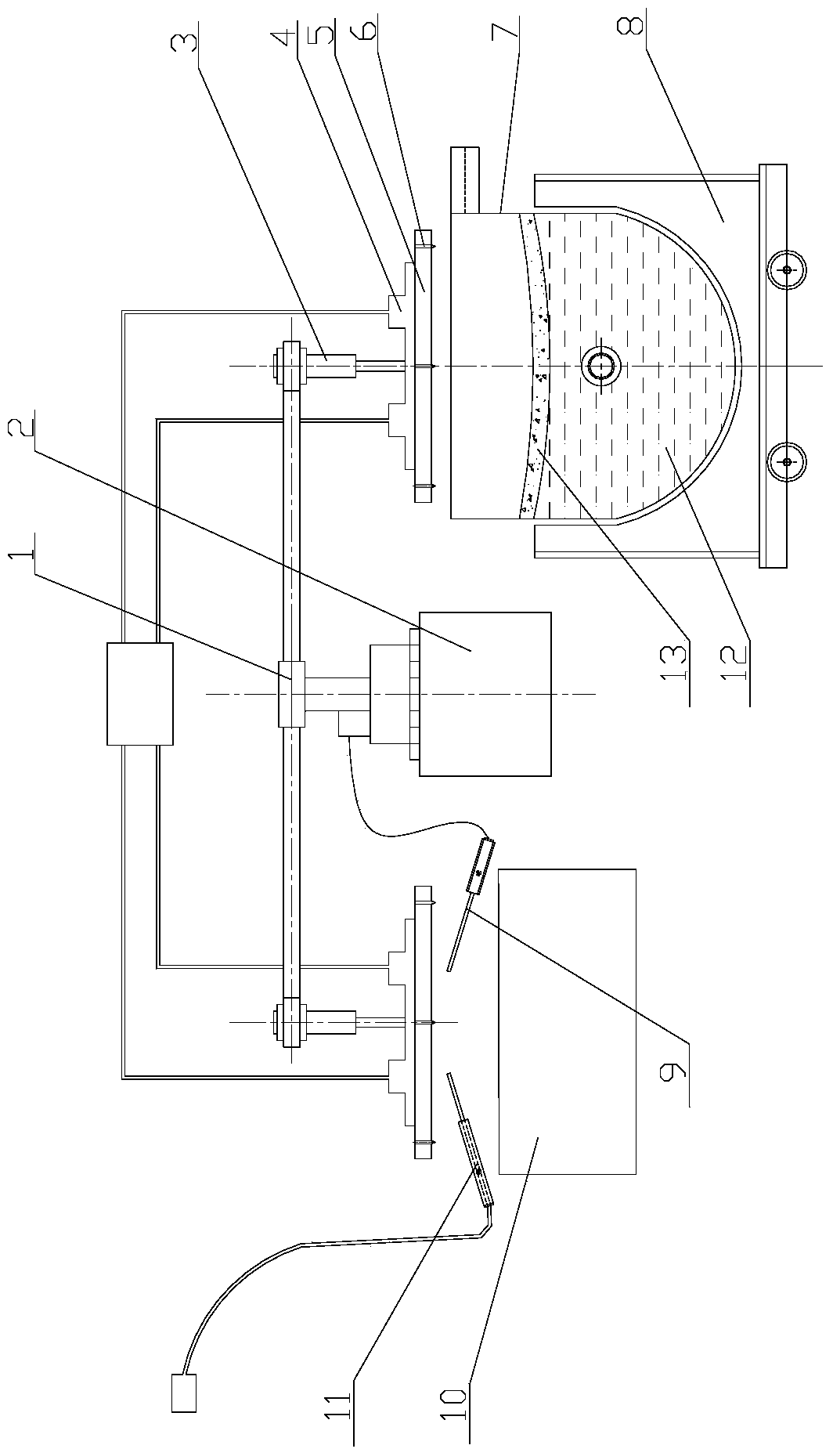

[0047] In the smelting laboratory, a "500kg multifunctional experimental furnace" was used to simulate the molten iron tank 7, and the adhesion type slag removal device of the present invention was used to perform a slag removal experiment on the molten iron tank 7 with a capacity of 400 kg. The diameter of the slag pan 5 that is used is 80% of the diameter of the mouth of the molten iron tank 7, the cooling water pressure of the water cooling system 4 is 0.5MPa, and the temperature measurement system 6 is 4 thermocouples installed on the slag pan 5. 4 high-pressure water guns 11 and 4 mechanical wind shovels 9 are installed above the 10; adopt once to dip slag during the slag removal operation, and the slag-stick pan 5 stays in the slag layer 13 for 60 seconds, and the high-pressure water gun 11 spray processing time is In 30 seconds, the residue can be cleaned up without the need for a mechanical wind shovel 9 to remove the residue.

Embodiment 2

[0049] In the smelting laboratory, a "500kg multifunctional experimental furnace" was used to simulate the molten iron tank 7, and the adhesion type slag removal device of the present invention was used to perform a slag removal experiment on the molten iron tank 7 with a capacity of 400 kg. The diameter of the slag pan 5 that is used is 85% of the diameter of the 7 tank mouths of the molten iron tank, the cooling water pressure of the water cooling system 4 is 0.8MPa, and the temperature measurement system 6 is 6 thermocouples installed on the slag pan 5. 5 high-pressure water guns 11 and 3 mechanical air shovels 9 are installed above the 10; the slag removal operation adopts secondary slag dipping, and the slag-sticking tray 5 stays in the slag layer 13 for 90 seconds each time the slag is stained; 11 The spray treatment time is 45 seconds, and the remaining small amount of residue is cleaned by mechanical air shovel 9.

Embodiment 3

[0051] In the smelting laboratory, a "500kg multifunctional experimental furnace" was used to simulate the molten iron tank 7, and the adhesion type slag removal device of the present invention was used to perform a slag removal experiment on the molten iron tank 7 with a capacity of 400 kg. The diameter of the slag pan 5 that is used is 90% of the diameter of the mouth of the molten iron tank 7, the cooling water pressure of the water cooling system 4 is 1.0MPa, and the temperature measurement system 6 is 8 thermocouples installed on the slag pan 5, and the slag pan is installed on the slag pan. 6 high-pressure water guns 11 and 2 mechanical wind shovels 9 are installed above the 10; adopt once to dip slag during the slag removal operation, and the slag-stick pan 5 stays in the slag layer 13 for 120 seconds, and the high-pressure water gun 11 spraying treatment time is For 60 seconds, the remaining small amount of residue is cleaned by mechanical wind shovel 9.

[0052] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com