Pile bottom hole clearing system and process of pile bottom hole clearing

A hole cleaning and process technology, applied in sheet pile walls, infrastructure engineering, wellbore/well components, etc., can solve the problem of difficulty in controlling the quality of hole cleaning at the bottom of the pile, and achieve clean and thorough slag cleaning, easy access to materials, and significant economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

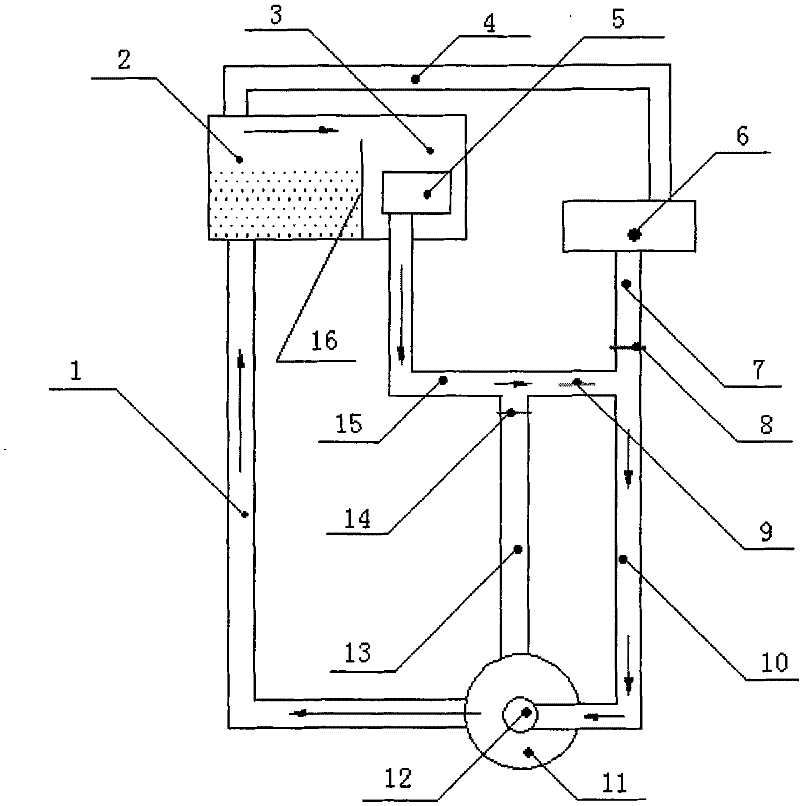

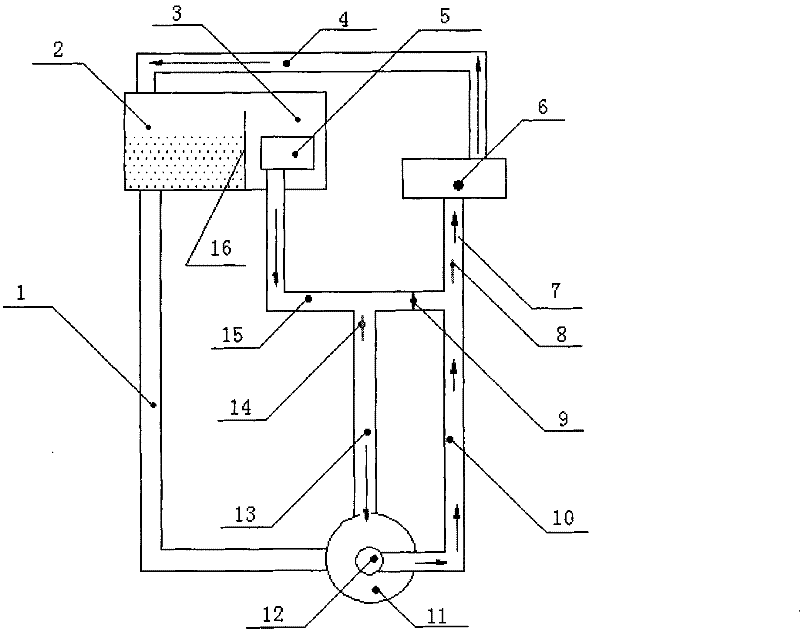

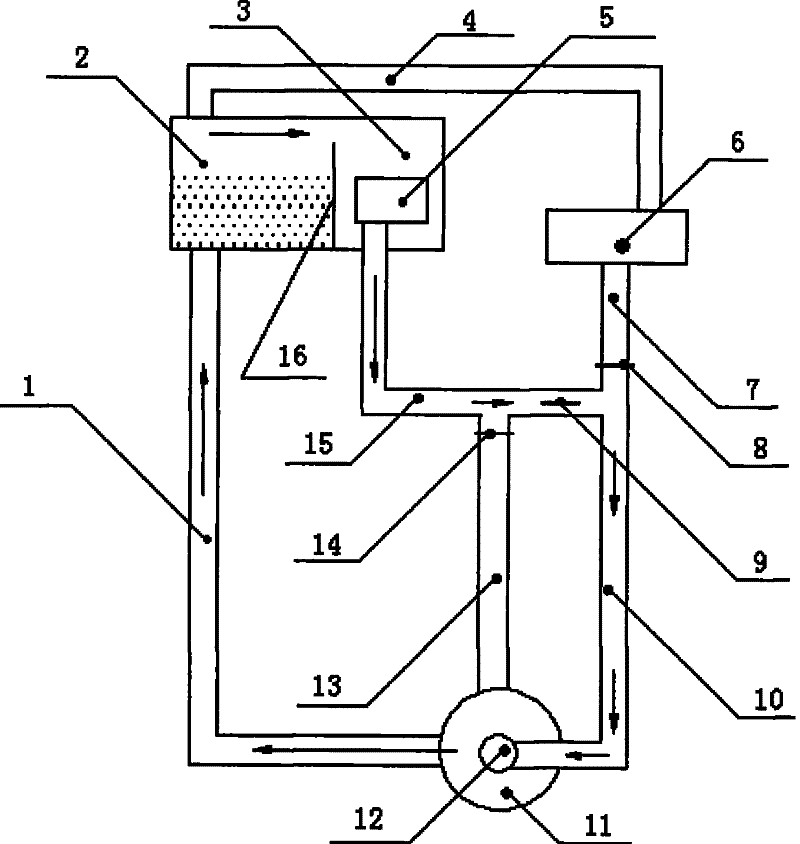

[0023] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments:

[0024] as attached figure 1 , 2 As shown, the present invention includes reverse circulation pump 6, mud pump 5, valve switch 14, valve switch 8, valve switch 9, pipeline 4, pipeline 7, pipeline 10, pipeline 13, pipeline 15, mud ditch or pipeline 1, sedimentation tank 2 and conduit 12; the bottom of pile position 11 places reinforcement cage, and the height of reinforcement cage is determined according to pile length, is generally about 30-50 meters, conduit 12 is put into from the top of pile, puts into the middle of reinforcement cage to the bottom of conduit and distances The bottom of the pile position 11 is 30-50 cm away, and the bottom of the conduit 12 communicates with the pile position 11. Because the pile is filled with mud, the conduit 12 is also filled with mud at this time; the mud ditch or pipeline 1 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com