Patents

Literature

53results about How to "Fast slag removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Refractory materials and refractory equipment for aluminum alloy melt casting, and method for preparing refractory equipment

The invention discloses a fire-resisting material used for aluminum alloy fusion casting, and a fire-resisting apparatus made of the fire-resisting material and a method for preparing the fire-resisting apparatus, wherein the fire-resisting material comprises aluminum silicate fiber powder, talcum powder, mullite powder, zirconite powder and a silica sol solution. The fire-resisting material has the advantages of no aluminum adhesion and no chemical reaction with an aluminum liquid, no addition of asbestos, rapid deslagging and no damage after using a prefabricated molding assembling part, better thermal-shock resistance, durability, controllable concentration, intensity and thermal-shock resistance, and small shrinkage mass of a cooling process after use to effectively prevent the assembling joint of the prefabricated molding part from cracking. The corresponding fire-resisting apparatus has the advantages of heat shock resistance, washing resistance, corrosion resistance, and small heat expansion coefficient.

Owner:SOUTHWEST ALUMINUM GRP +1

Method for removing ladle dross

ActiveCN1806964AFast slag removalEfficient slag removalCasting cleaning apparatusLiquid slagMolten steel

The invention provides the method of removing liquid steel scum, comprising the following steps: dragging the scum from liquid steel liquid level with harrow rotary dragging method, at the same time, adding the anti-oxidization agent on the clean liquid steel surface. Because of adopting the harrow rotary dragging method, the invention solves the problems of big loss of scarfing cinder, hard operation and heavy labor strength. Adding the anti-oxidization agent avoids the secondary oxidization of liquid steel. The method uses the freezing slag agent to solidify the liquid slag. It strengthens the effect of removing slag.

Owner:YANTAI SHENGLIDA ENG TECH

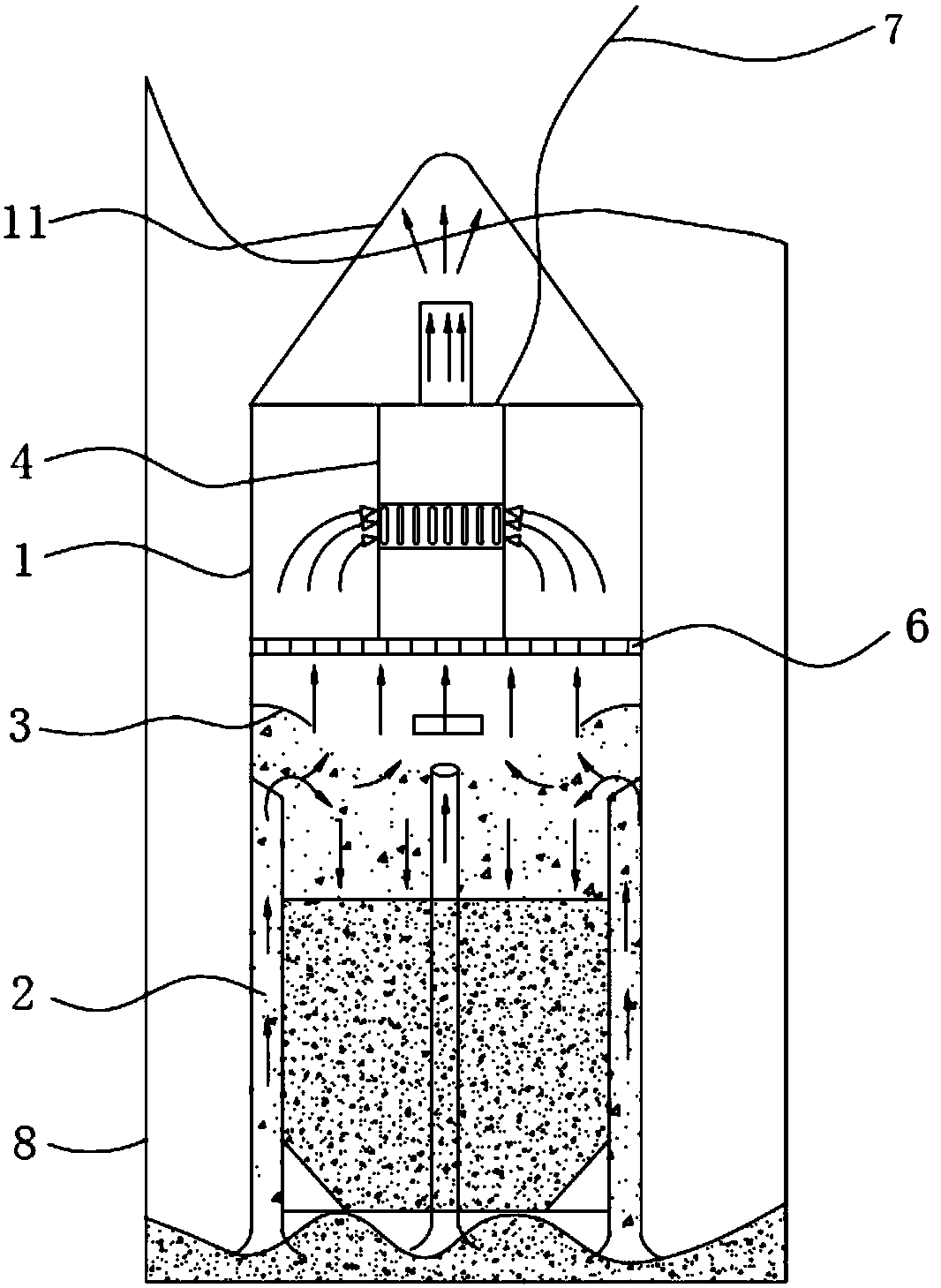

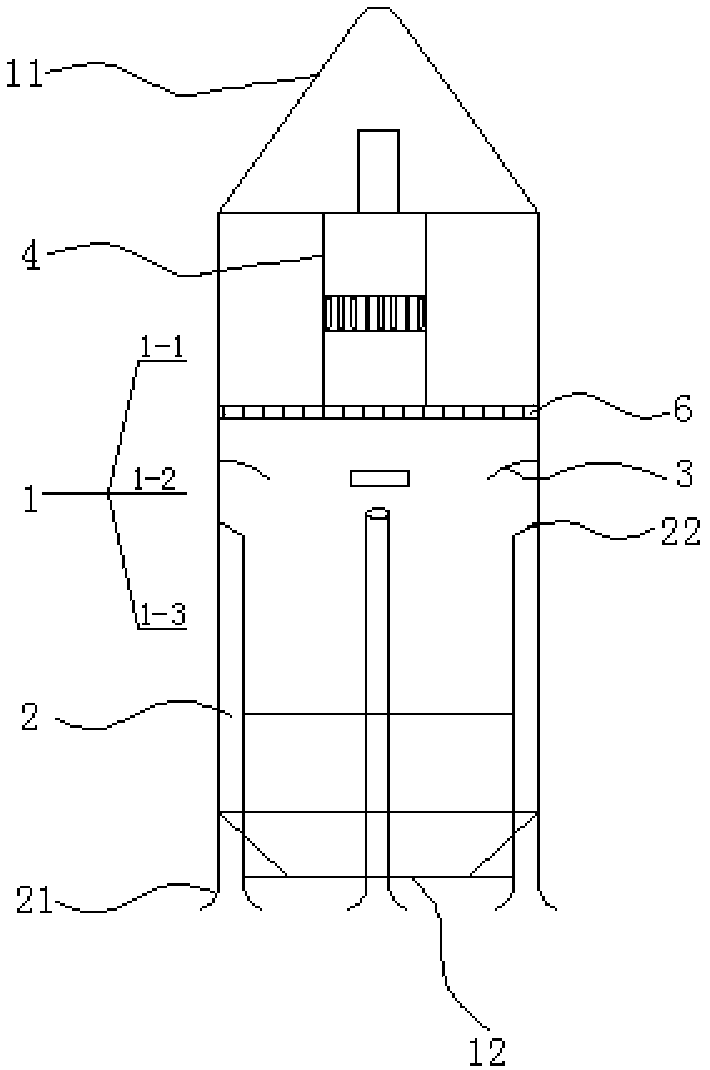

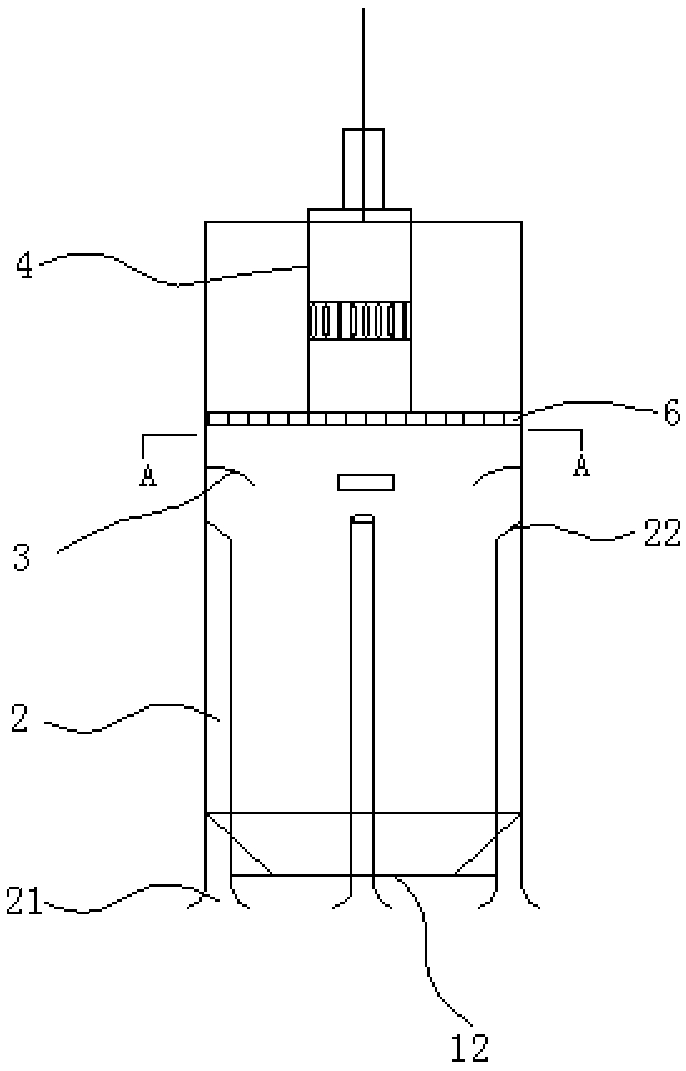

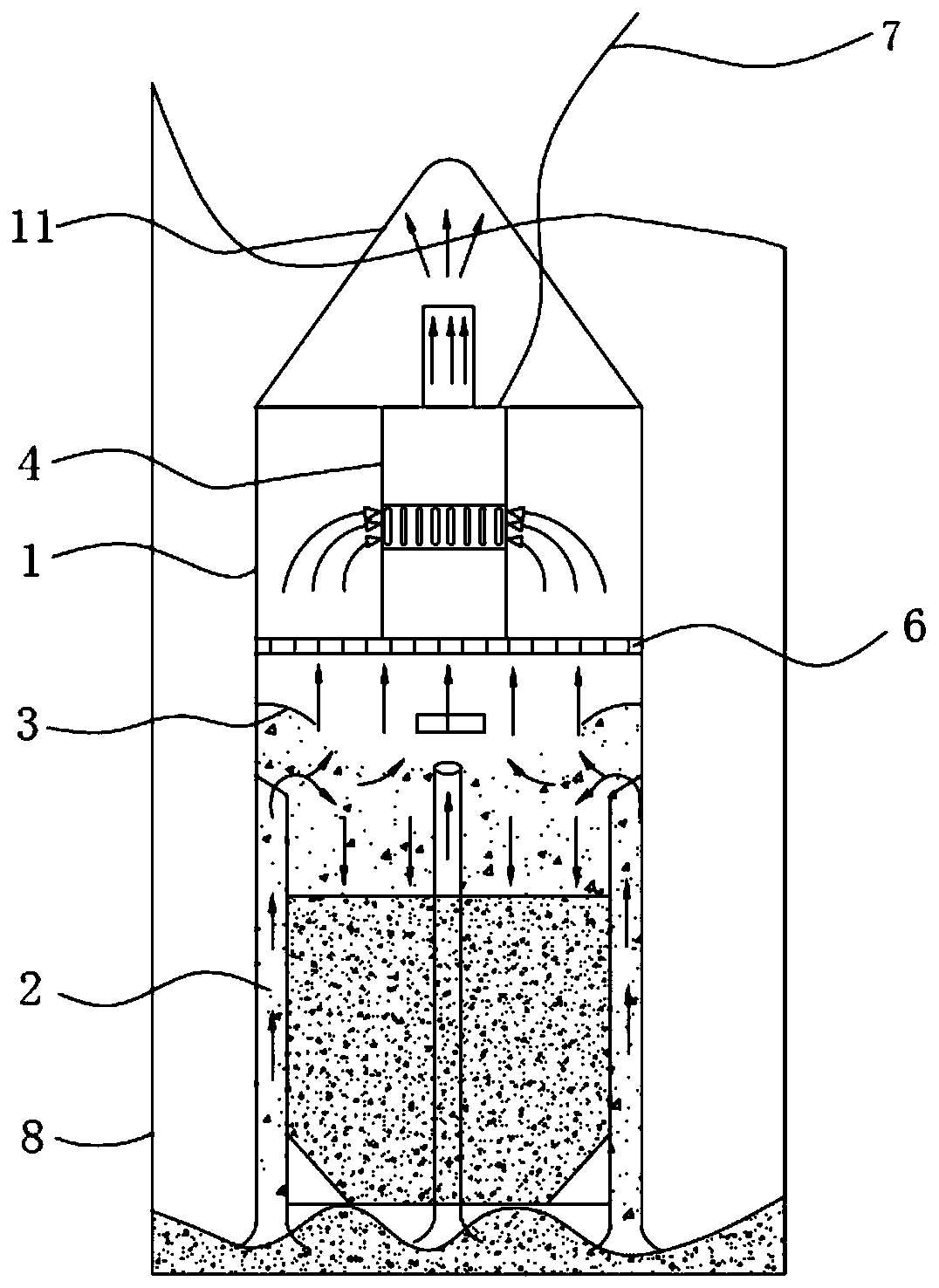

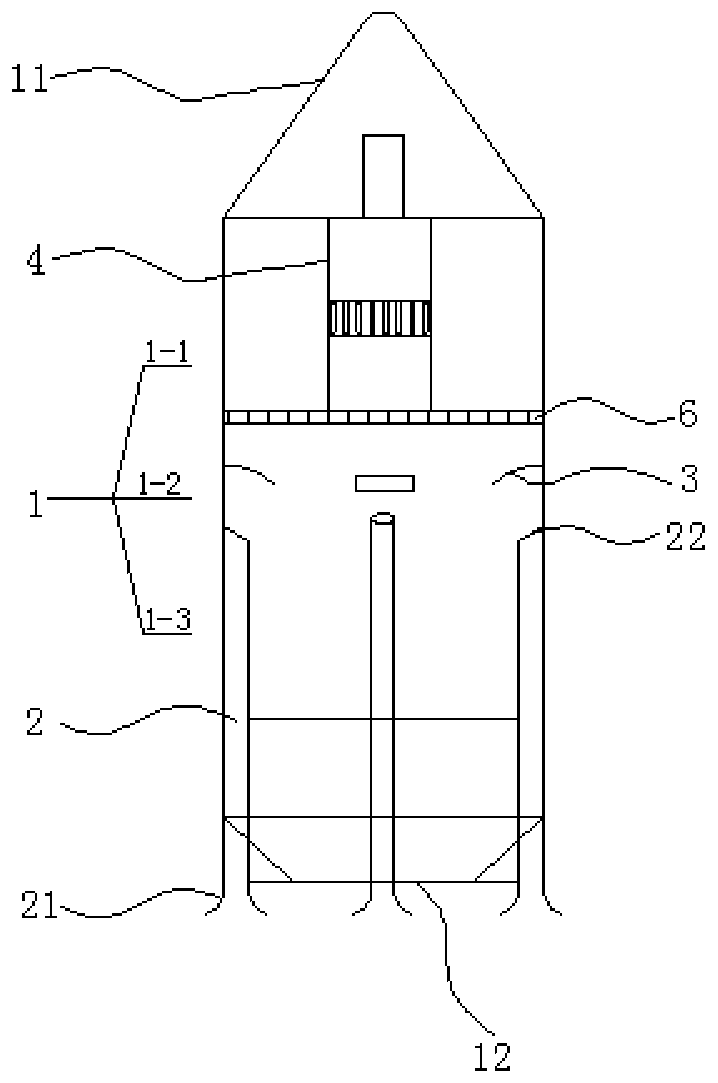

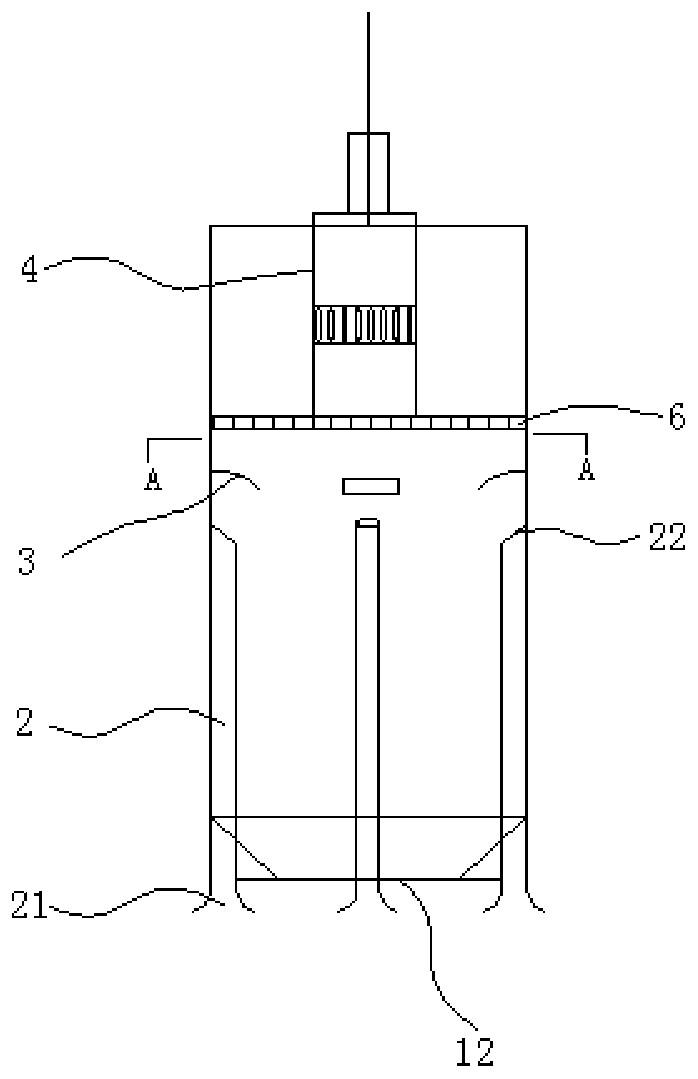

Sucking-in type slag removing machine

The invention provides a sucking-in type slag removing machine. The sucking-in type slag removing machine comprises a closed barrel body, at least one slag sucking pipe and a slag sucking device; a hoisting arm is installed on the top of the barrel body; the bottom segment of the barrel body is provided with a sealed slag outlet; the slag sucking pipe is installed in the barrel body in the axial direction of the barrel body; the inlet end of the slag sucking pipe stretches out of the bottom of the barrel body, and the outlet end of the slag sucking pipe is arranged in the barrel body; the slagsucking device is installed above the side portion of the outlet end of the slag sucking pipe, and is used for generating negative pressure sucking force in the barrel body and sucking and discharging slurry after a sediment-slurry mixture is separated; the sediment-slurry mixture in a drill hole / well enters the barrel body to be dispersed under the effects of the sucking force of the slag sucking device; sediment falls into the bottom segment of the barrel body, and the slurry is discharged outwards by the slag sucking device to be circulated. The sucking-in type slag removing machine belongs to an active slag removing manner, the slag removing machine can be used for removing large-particle-diameter stone slag and can also be used for removing slag in slurry holes and clean water holes,slag removing can be performed even though mud making and slag mixing are not needed, and the sucking-in type slag removing machine is high in slag removing effect and wide in using range.

Owner:任国勇

Ladle furnace refining agent and preparation thereof

InactiveCN101343679AFast slag removalImproved metallurgical propertiesProcess efficiency improvementWater vaporSlag

The invention relates to a ladle furnace molten steel refining agent and a preparation method thereof, belonging to the technical filed of the molten steel refining agent. The main components of the steel ladle furnace molten steel refining agent are 50 weight percent to 90 weight percent of ladle furnace refining waste slag, 4 weight percent to 20 weight percent of CaO, 6 weight percent to 30 weight percent of Al2O3 mixture and an adhesive solution with the weight concentration accounting for 0.3 weight percent to 3 weight percent. The preparation method adopts the steps: ladle furnace refining waste slag is positioned into a heating furnace to be heated for 0.5 hour to 1.5 hours through water vapor at a temperature of 800 DEG C to 1000 DEG C, the ladle furnace refining waste slag is evenly mixed with the adhesive solution with the weight percentage accounting for 5 percent to 15 percent of the Al2O3 mixture and with the weight percentage concentration accounting for 0.3 percent to 3 percent to manufacture particles after being taken out of the furnace and naturally cooled down and then dried for 1 to 3 hours at a temperature of 100 DEG C to 200 DEG C. Magnesium chloride is replaced by the adhesive solution, under the conditions that the caking capacity is guaranteed, both the use amount and the manufacture cost are reduced, the affect on the refining agent performance is reduced due to the existence of the excessive halogen family elements, the common heating replaced by the water vapor heating is adopted, the advantage of easy acquisition of the water vapor of the metallurgy enterprises can be displayed, and the ladle furnace molten steel refining agent and the preparation method are favorable for energy consumption reduction.

Owner:武汉钢铁有限公司 +1

Metal core welding wire for submerged arc welding of A304 and A304L austenitic stainess steel

InactiveCN1887503ASuitable for high-speed automatic weldingImprove melting efficiencyArc welding apparatusWelding/cutting media/materialsSlagManganese

The metal core welding wire for submerged arc welding of A304 and A304L austenitic stainless steel belongs to the field of welding material widely used in petroleum, chemical, ship-building and other fields. The present invention features that the metal core welding wire is formed through adding metal mixture powder in 40-58 wt% into low carbon steel belt material or super low carbon steel belt material, and the metal mixture powder consists of Cr 37-57 wt%, Ni 17-28 wt%, Mn 3-9 wt%, reduced Fe 7.5-30 wt%, Bi2O3 0.5-1.5 wt%, and Al-Mg alloy 2-10 wt%. The corresponding welding specification includes welding current of 380-600 A, welding voltage of 30-40 V and welding speed of 450-800 mm / min. The metal core welding wire has simple production process and excellent post-welding slag removing performance, and is especially suitable for high speed automatic welding.

Owner:CHINA PETROLEUM & CHEM CORP +1

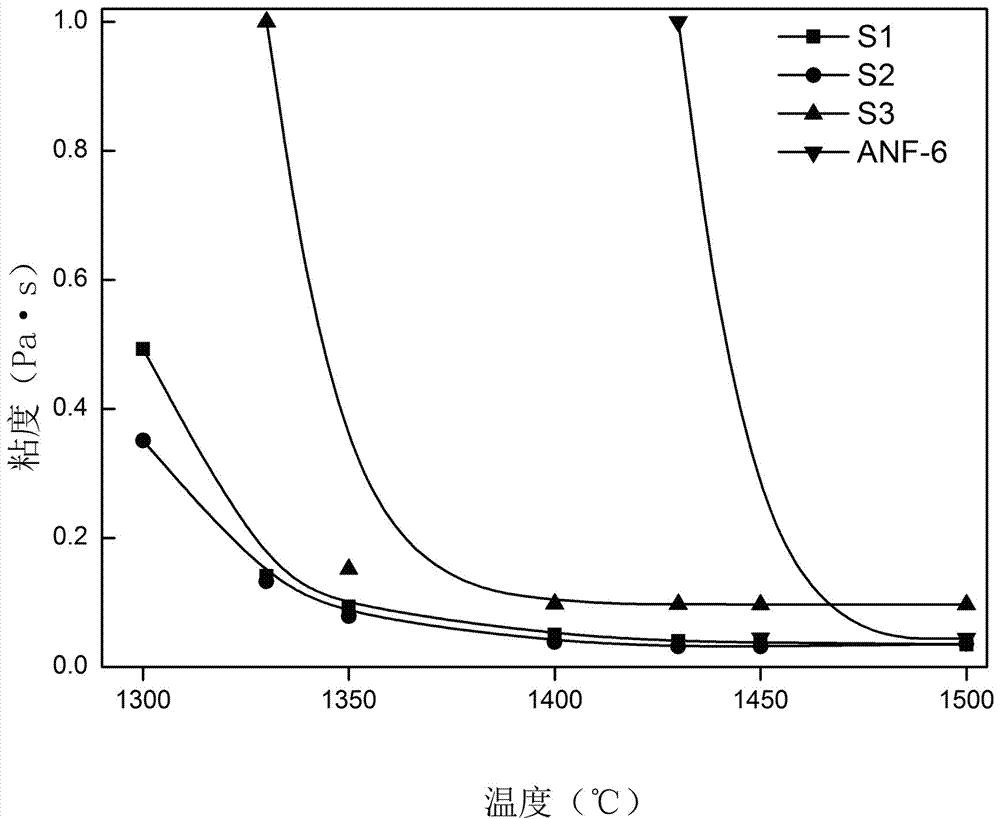

Special slag system for producing 17-4PH steel ingots and preparation and application method thereof

The invention relates to a special slag system for producing 17-4PH steel ingots. The special slag system is prepared from the following components in percentages by weight: 26-28% of Al2O3, 25-27% of CaO, 4-5% of SiO2, 5-6% of MgO and the balance of CaF2. The binary basicity CaO / SiO2 of the system is 5-6.75. The melting hemispherical temperature of the special slag system is 1220-1250 DEG C; 0.402-0.434 ohm / cm. The viscosity at 1500 DEG C is 0.0352-0.0359 Pa / s. The slag system provided by the invention is relatively low in melting point, relatively high in resistivity, relatively small in viscosity changing with temperature, relatively good in high-temperature plasticity, relatively high in basicity, low in content of fluorides and high in slugging speed, can meet the demand on production of 17-4PH steel ingots by means of an ingot pulling electroslag remelting process, can guarantee the internal quality and surface quality of the 17-4PH steel ingots, and has the advantages of being energy-saving and environment-friendly.

Owner:UNIV OF SCI & TECH LIAONING

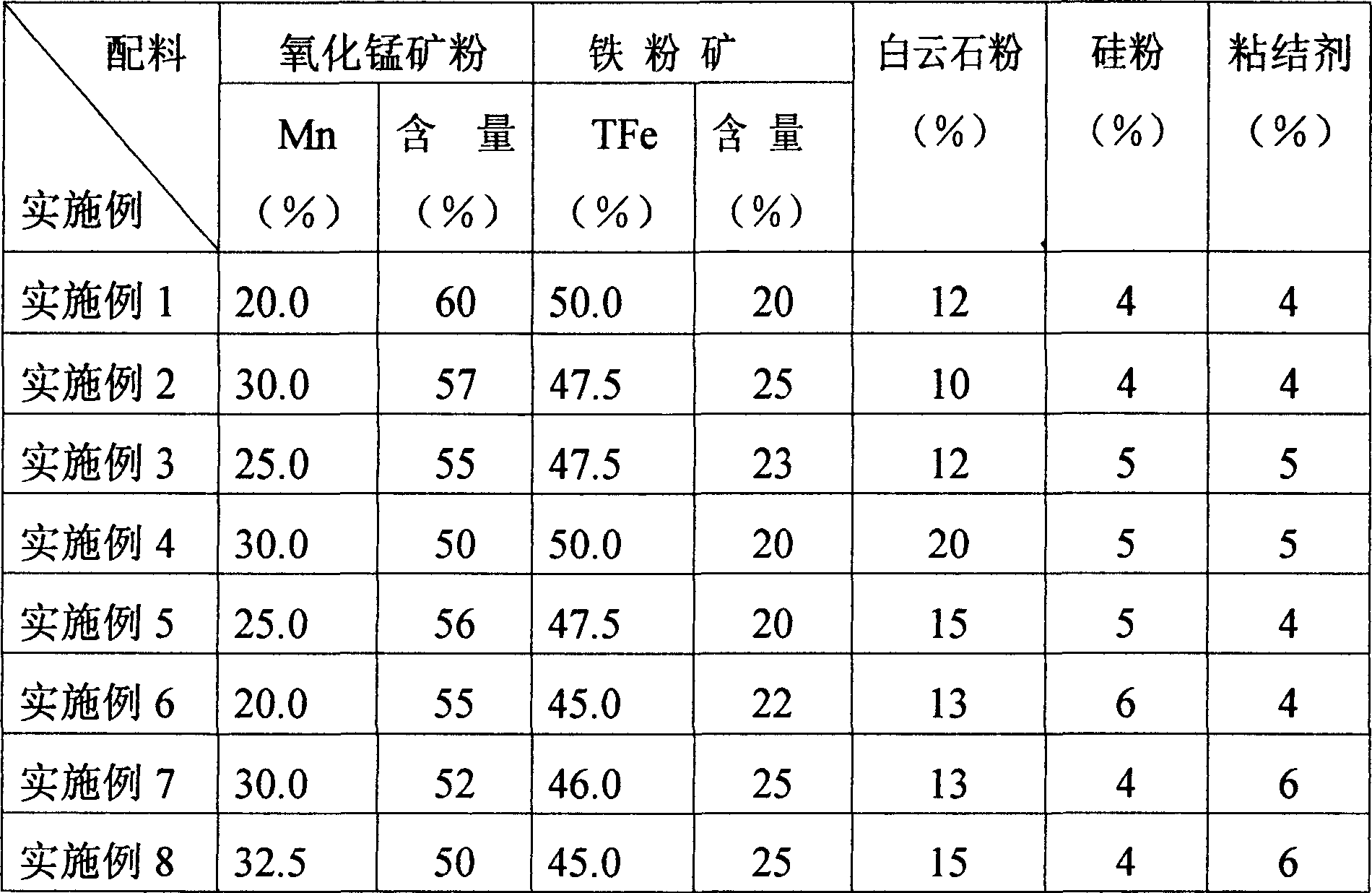

Composite ferromanganese mineral ball for steelmaking

A ferromanganese mineral ball compound for steel-making which consists of 50úÑ-60úÑof manganese oxide oreú¼20úÑ-25úÑof iron powder oreú¼10úÑ-20úÑof dolomite powder ú¼4úÑ-6úÑof silicon powder and 4úÑ-6úÑ of agglomerant by weight percentage. All of these components are mixed and press forming. Advantages of this compound are lower production costú¼higher product capability and higher slag-melting efficiency so as to increase manganses content by the end-point of steel-making and to reduce smelting cost. It also simplifies charging technique and makes deprivation of (P)íó(S)íó(Si)from steel easier. This environmental protective compound can be widely used as refrigerant and slag-melting agent in slagging process in electric steelmaking and pneumatic steelmaking and can be used to improve manganese use ratio.

Owner:ZHONGYE STEEL METALLURGIC SCI & TECH IND DEV MAANSHAN

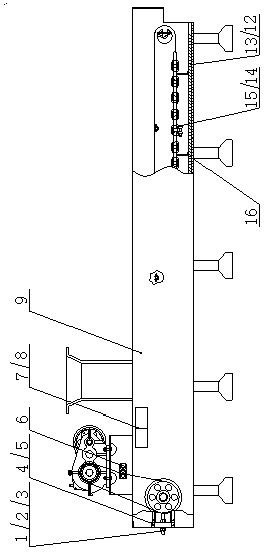

Novel horizontal chain-type slag remover

InactiveCN102815503AImprove corrosion resistanceExtended service lifeConveyorsLighting and heating apparatusSlagReduction drive

The invention belongs to the technical field of furnace slag transportation equipment, and aims to provide a novel horizontal chain-type slag remover consisting of a power device, a shell (9) and a transmission device, wherein a chain wheel group assembly (34) is arranged at the head of the shell (9) through a small chain wheel disk (35) and a small chain wheel shaft sleeve (36); a motor (28) is connected with a speed reducer (37) arranged on one side; a material inlet is formed above the shell (9) on one side of the motor (28); a plurality of upper and lower layer supporting rollers (21) which are arranged at certain intervals are sequentially arranged in the shell (9) on one side of the chain wheel group assembly (34); a concave guide wheel (17) is also arranged at the tails of the last group of supporting rollers (21); an L-shaped scraper blade (16) is arranged on a chain at a certain interval; and a material outlet is formed below the tail of the shell (9). The novel horizontal chain-type slag remover is high in slag removal speed, high in efficiency, wide in applicability range and long in service, and the shell is high in corrosion resistance.

Owner:张志军

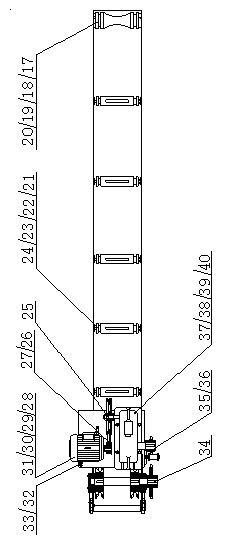

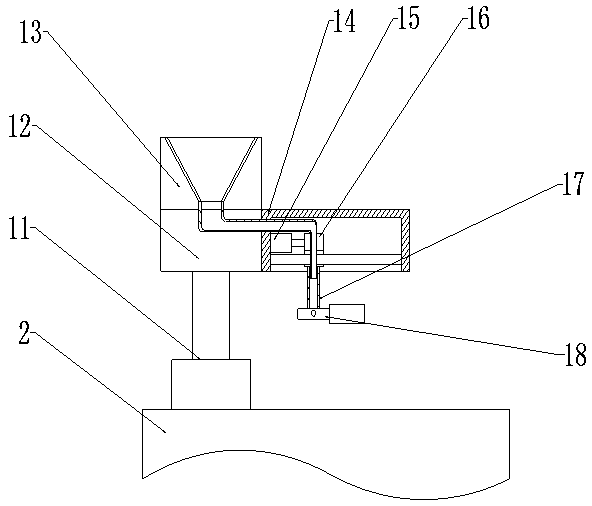

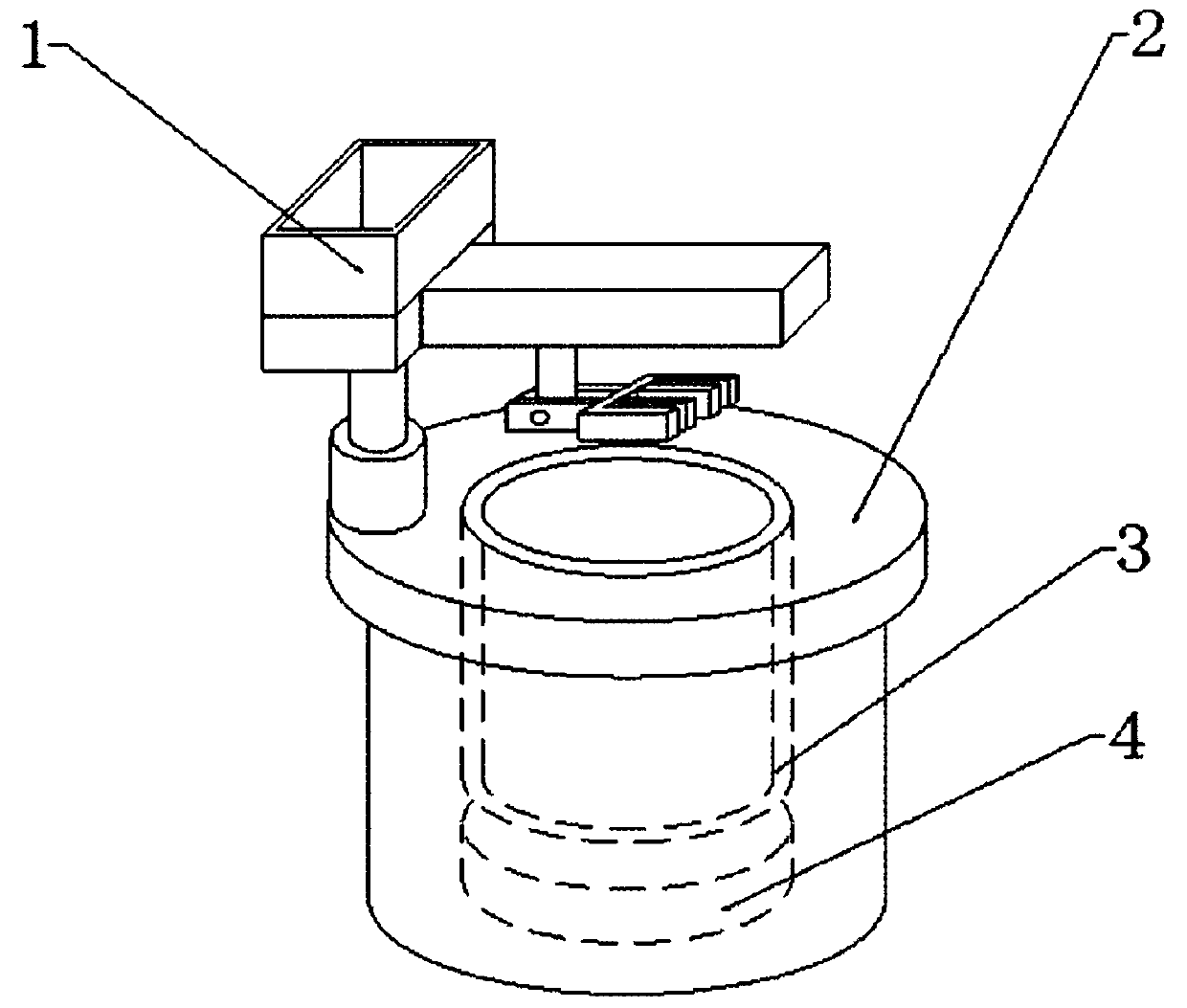

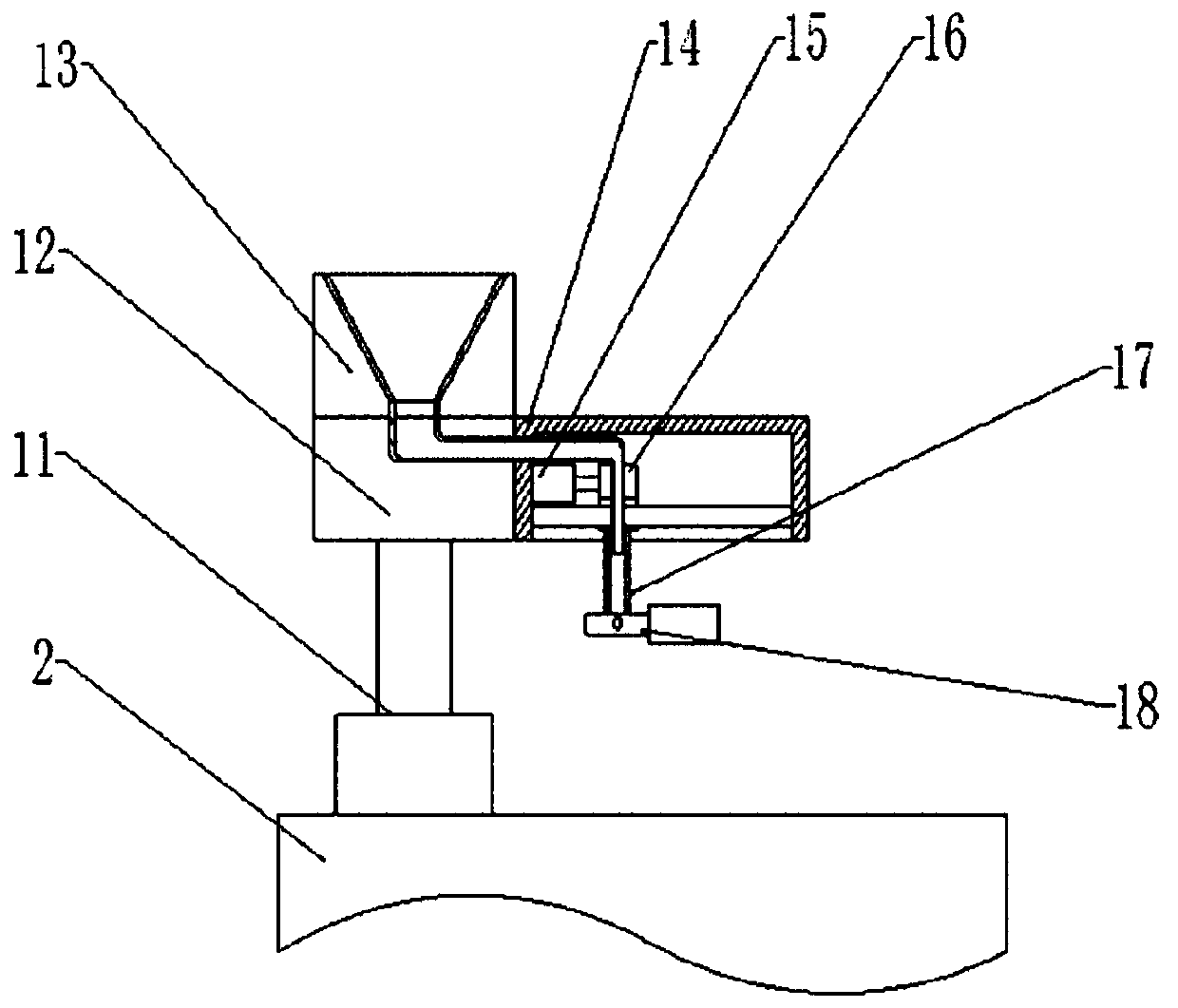

Smelting furnace slagging-off device

The invention provides a smelting furnace slagging-off device. The smelting furnace slagging-off device comprises a smelting furnace main body, a furnace hearth, a heating mechanism, an electric cylinder I, a fixed block, a feeding box, a connection frame, an electric cylinder II, an movable block, a hollow cylinder and a slagging-off plate, wherein the furnace hearth is arranged in the smelting furnace main body; the heating mechanism is mounted at the lower end of the furnace hearth; the electric cylinder I is mounted at the upper end of the smelting furnace main body; the fixed block is arranged at the upper end of the electric cylinder I; the feeding box is mounted at the upper end of the fixed block; the connection frame is fixed at the right end of the fixed block; the electric cylinder II is mounted on the inner left end surface of the connection frame; the movable block is arranged on the right end surface of the electric cylinder II; the hollow cylinder is fixed at the lower end of the movable block; the slagging-off plate is mounted on the hollow cylinder. Through the design, the function of applying a slag conglomeration agent is achieved, and the slagging-off speed is rapid; the smelting furnace slagging-off device is convenient to use and convenient to operate, can achieve the function of applying the slag conglomeration agent, and is rapid in slagging-off speed and high in reliability.

Owner:内蒙古金域凤形矿业耐磨材料有限公司

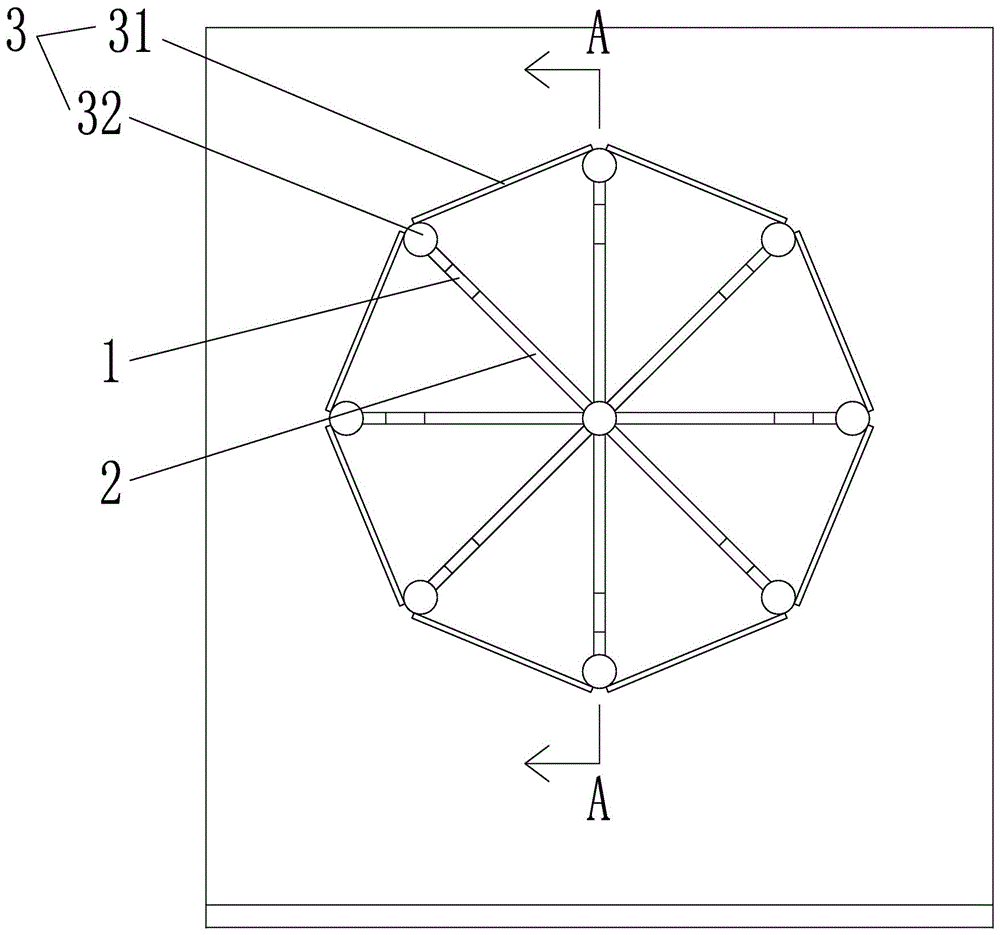

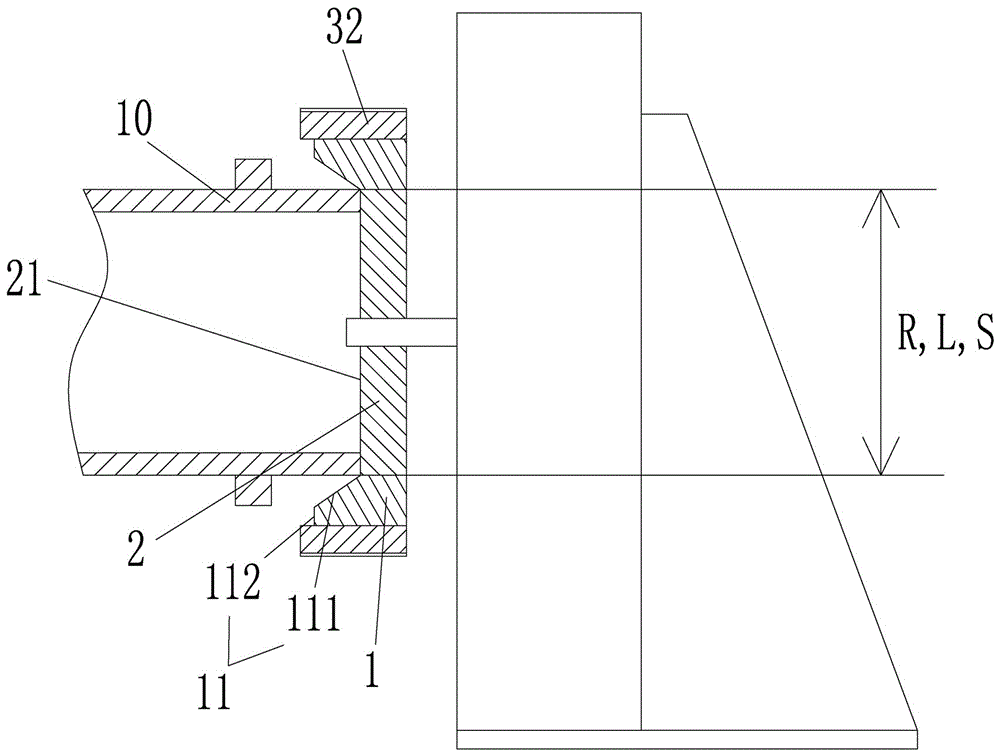

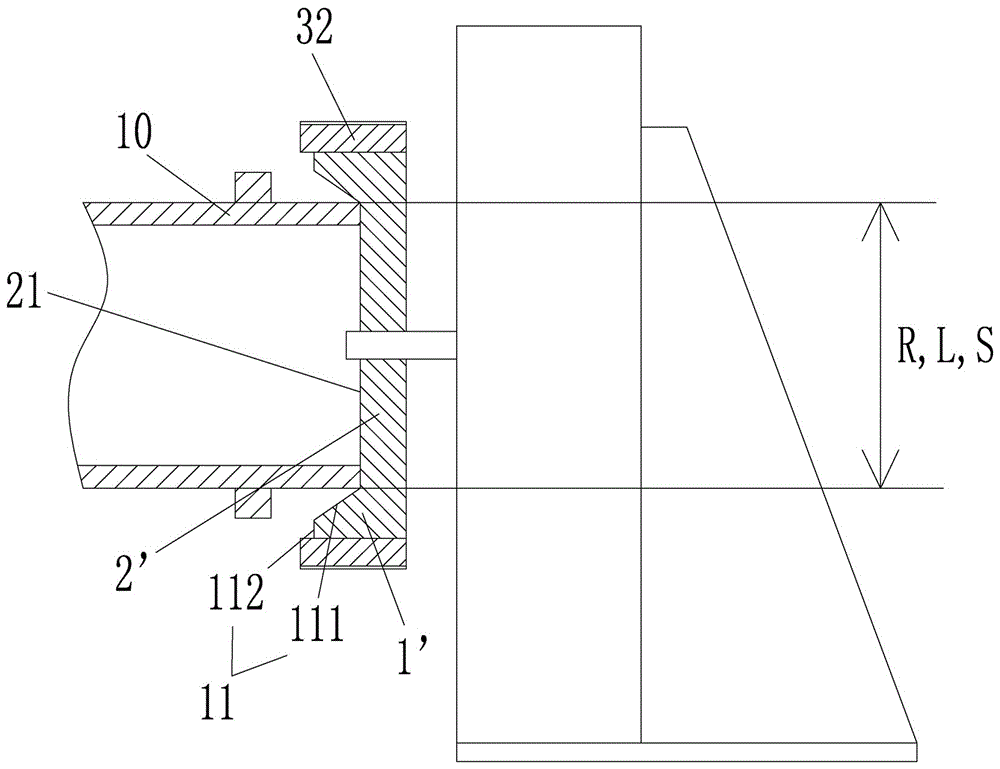

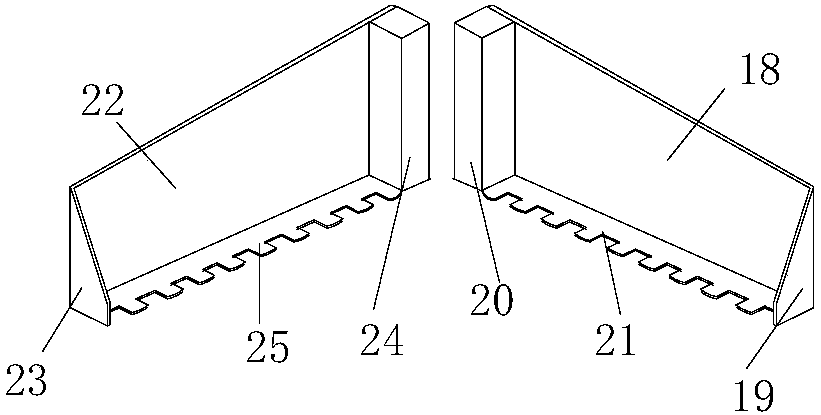

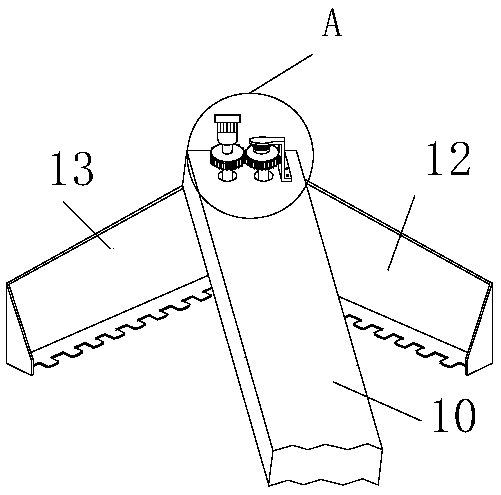

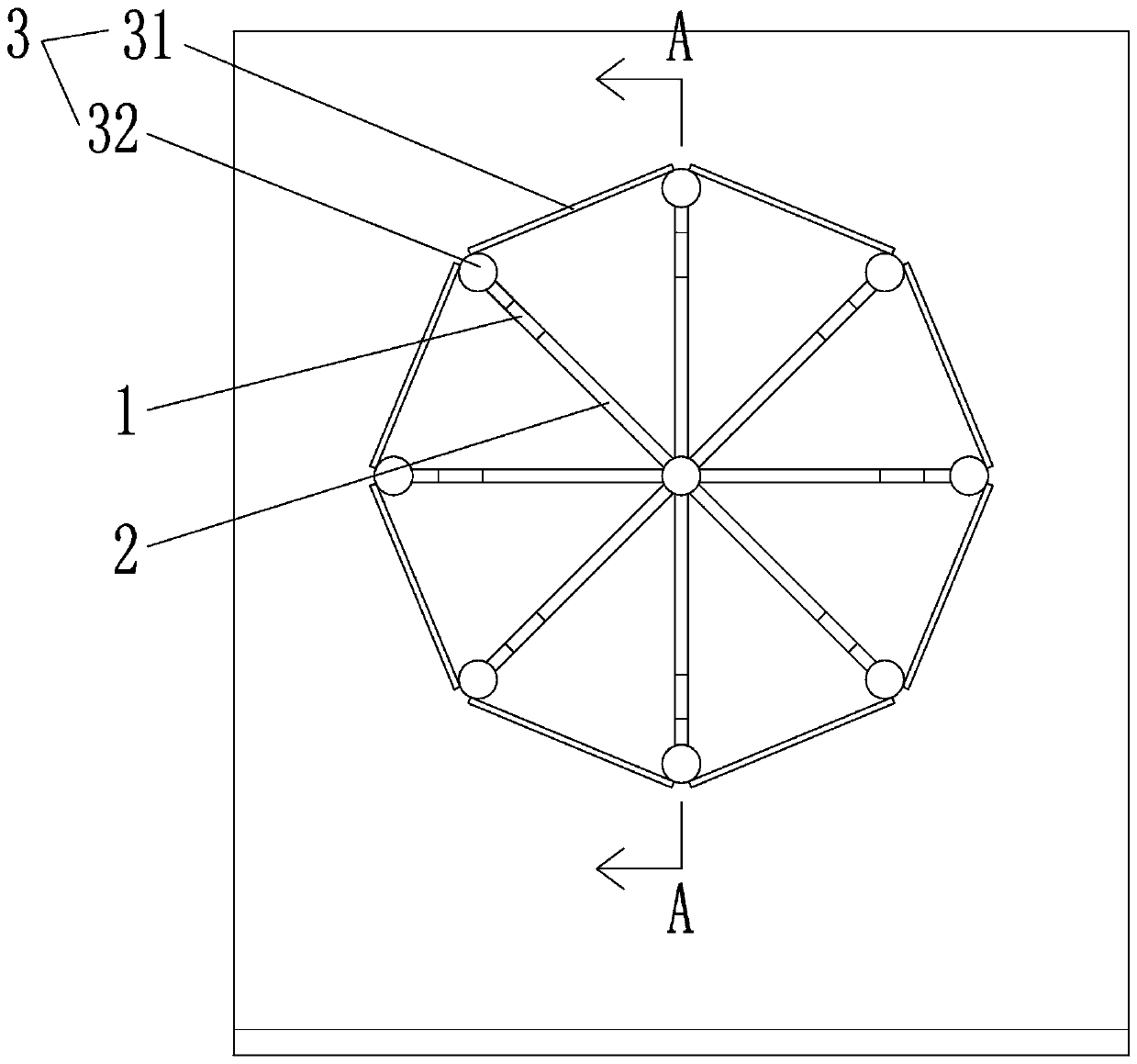

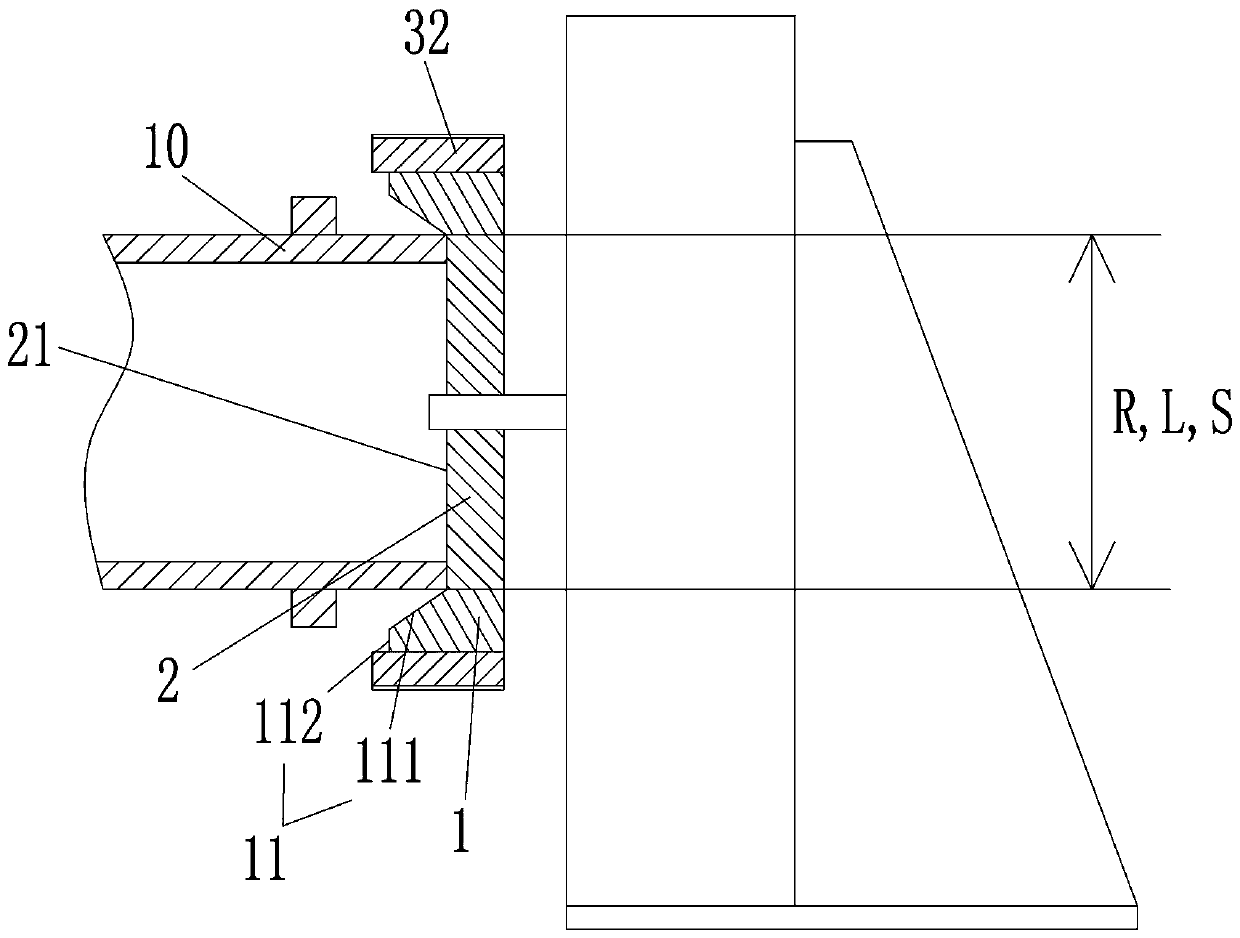

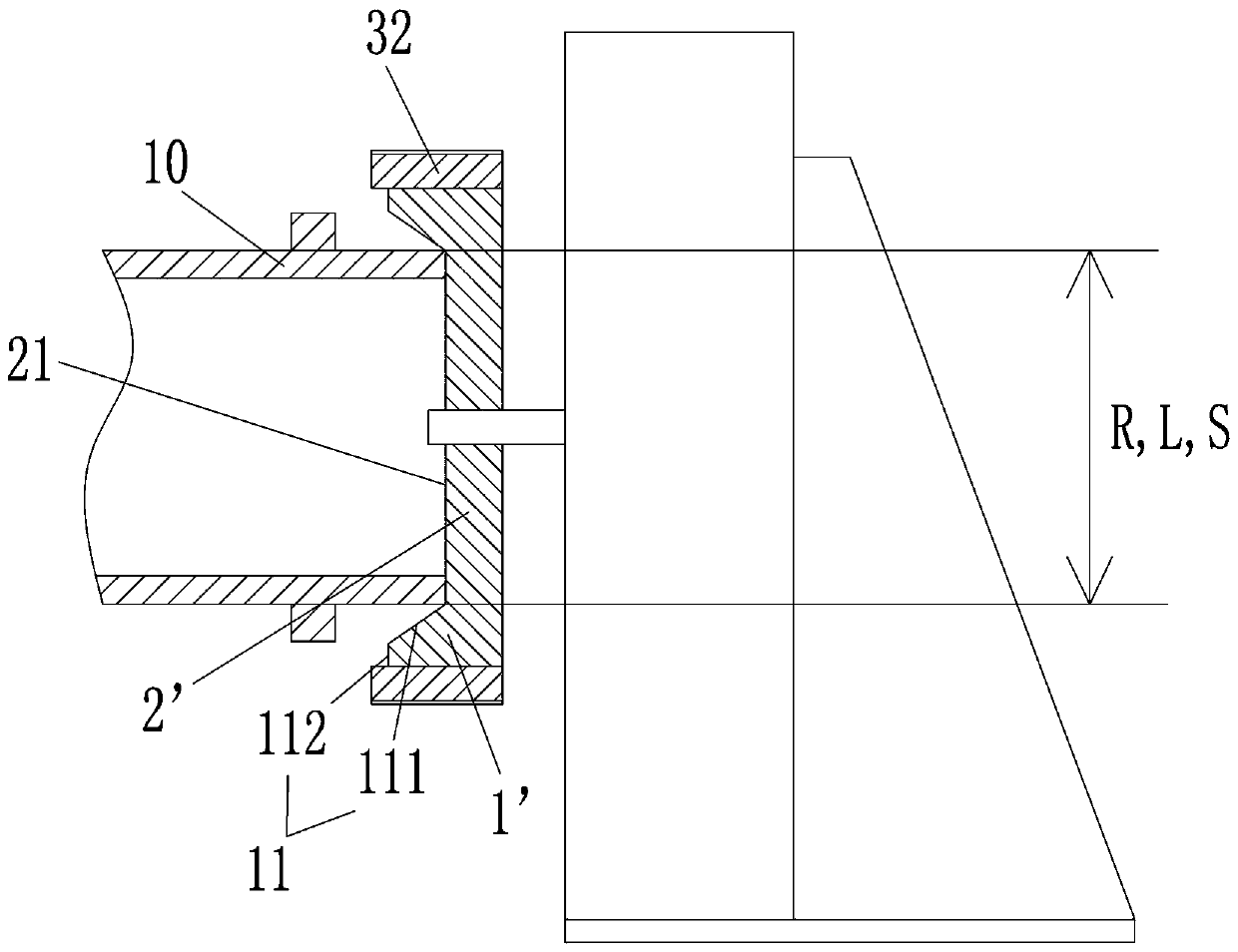

Slag scraper for steel ladle opening

The invention provides a slag scraper for a steel ladle opening. The slag scraper comprises a plurality of scraping knives. The scraping knives comprise the fixed ladle opening outer wall scraping knives and the ladle opening edge scraping knives. The multiple fixed ladle opening outer wall scraping knives and the multiple ladle opening edge scraping knives are concentrically distributed in a spoke shape in a scattering manner, and the multiple ladle opening outer wall scraping knives are distributed outside a spoke-shaped outer circumference face formed by the multiple ladle opening edge scraping knives. During work, the steel ladle opening is located in a spoke-shaped ring formed by the multiple ladle opening outer wall scraping knives. The inner diameter of the spoke-shaped ring formed by the multiple ladle opening outer wall scraping knives, the outer diameter of the spoke-shaped outer circumference face formed by the multiple ladle opening edge scraping knives and the outer diameter of the steel ladle opening are consistent. The slag scraper for the steel ladle opening is large in single-time slag removal quantity, a steel ladle operates safely, and the slag scraper is not prone to being damaged; and the slag scraper carries out slag removal treatment on the edge and the outer wall of the steel ladle opening with severe slag accumulation at the same time, the slag removal speed is high, and the efficiency is high.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

A method for removing slag from molten steel

InactiveCN102296144AIncrease in sizeIncrease alkalinityProcess efficiency improvementMolten saltMolten steel

The invention relates to a method for removing slag from molten steel, which controls the upper clearance of the molten steel tank to be greater than 300 mm when tapping the converter. When the molten steel tank is tilted to the angle of slag removal, first remove the solidified slag shell; then add lime particles into the molten steel tank according to the ratio of lime and slag of 1:3 to 6 and spread evenly; after the lime and steel slag fully react , Scrape out the residual steel slag in the molten steel tank. Due to the chemical reaction between the lime and the high-temperature molten steel, the steel slag is foamed and the volume of the steel slag is increased, and the steel slag can be discharged from the molten steel tank when it is overturned. And in the process of lime melting and reaction, the temperature of the surface layer of steel slag will decrease, which will increase the viscosity of steel slag and make the steel slag easy to remove, thereby reducing the pollution of molten steel by strong oxidizing steel slag on the surface of molten steel, improving the purity of molten steel, and reducing the amount of deoxidizer. consumption and cost expenditure, reduce the workload of deoxidation treatment, increase the speed of slag removal, and reduce labor intensity.

Owner:ANGANG STEEL CO LTD

A special slag system for producing 17-4ph steel ingot and its preparation and use method

A special slag system for producing 17-4PH steel ingot, the special slag system is composed of the following components by weight percentage: Al2O3: 26~28%, CaO: 25~27%, SiO2: 4~5%, MgO: 5% ~6%, the balance is CaF2; its binary basicity CaO / SiO2 is 5~6.75; the melting hemisphere temperature of this special slag system is 1220~1250℃; 0.402~0.434Ω·cm. The viscosity at 1500°C is 0.0352~0.0359 Pa•s. The slag system of the present invention has low melting point, high resistivity, small change in viscosity with temperature, good high-temperature plasticity, high alkalinity, low fluoride content, fast slag melting speed, and can satisfy ingot-pulling electroslag remelting The requirements for the production of 17-4PH steel ingots by law can guarantee the internal quality and surface quality of 17-4PH steel ingots, and have the advantages of energy saving and environmental protection.

Owner:UNIV OF SCI & TECH LIAONING

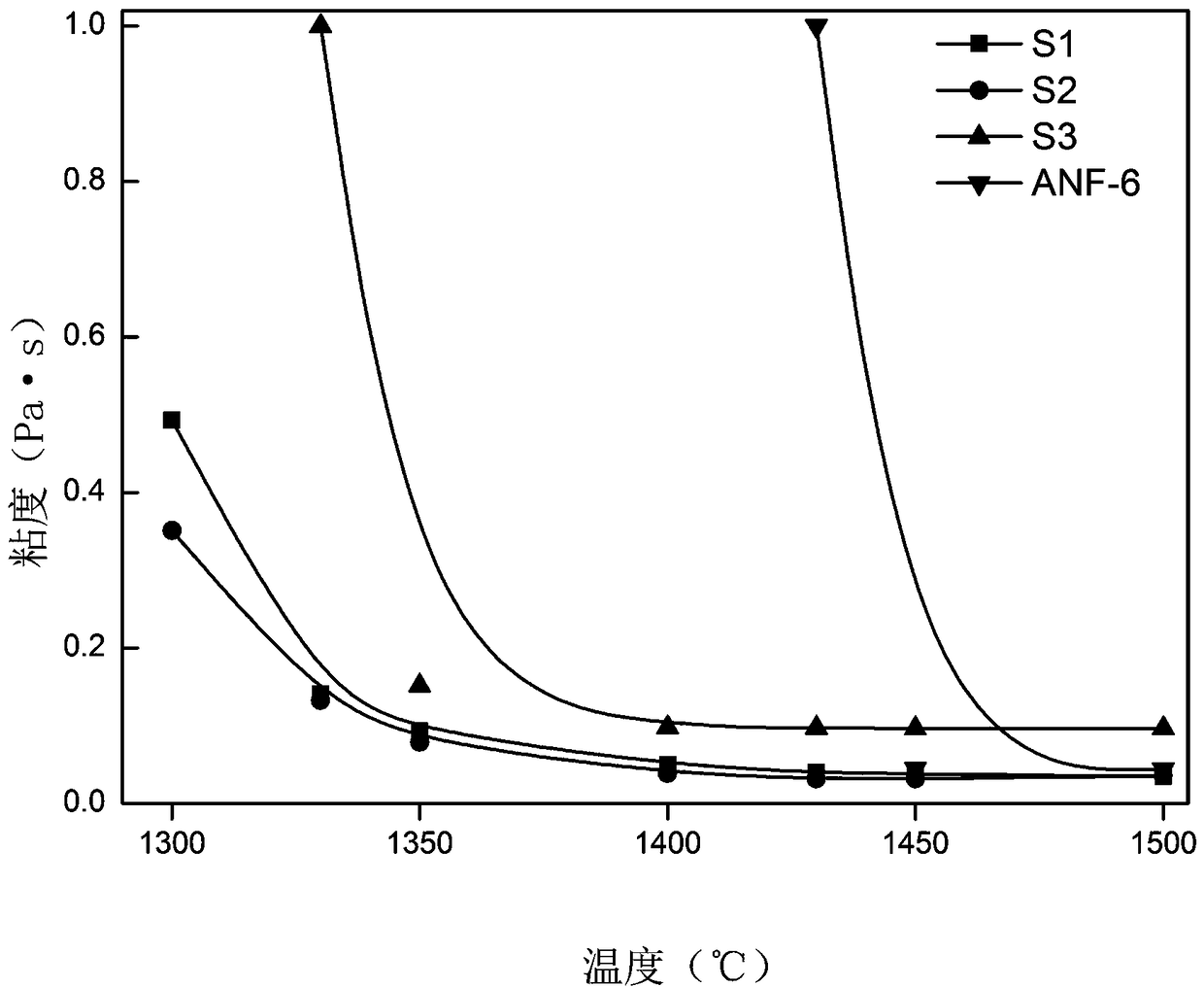

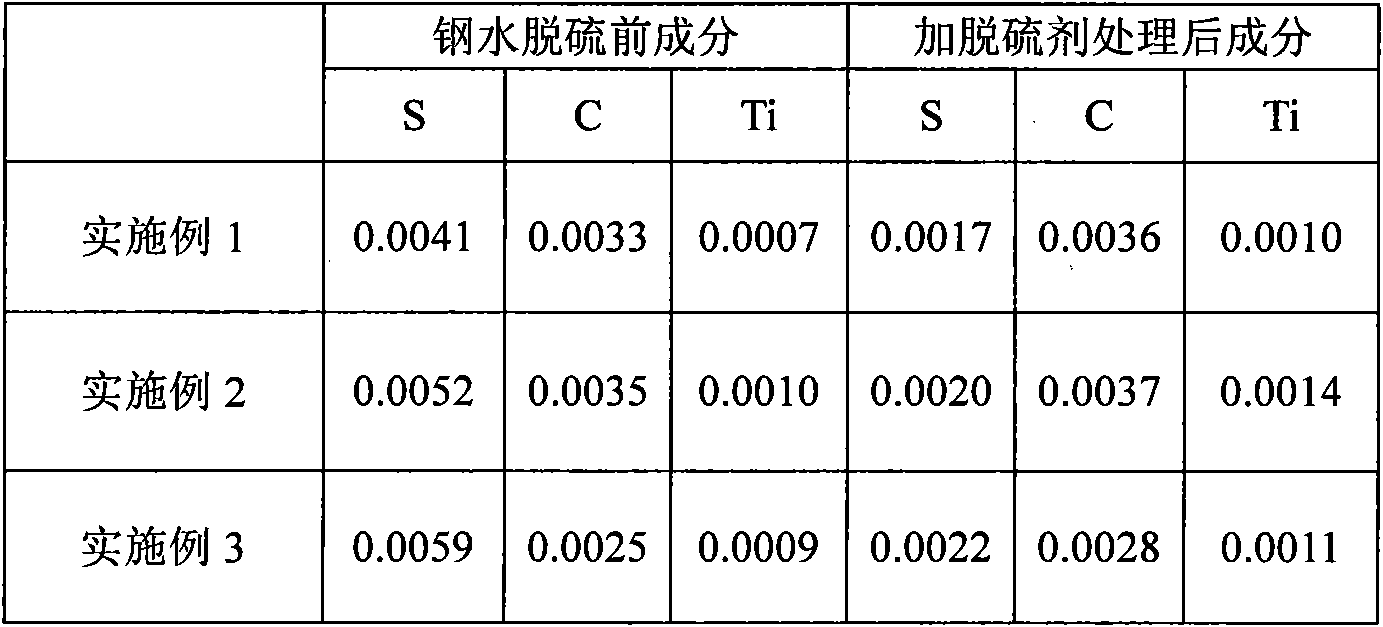

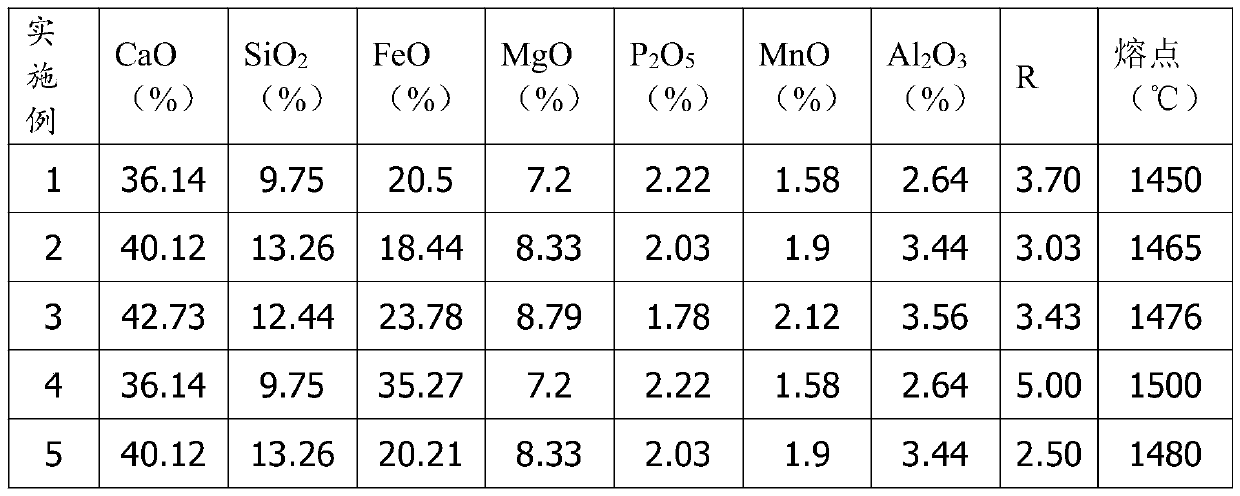

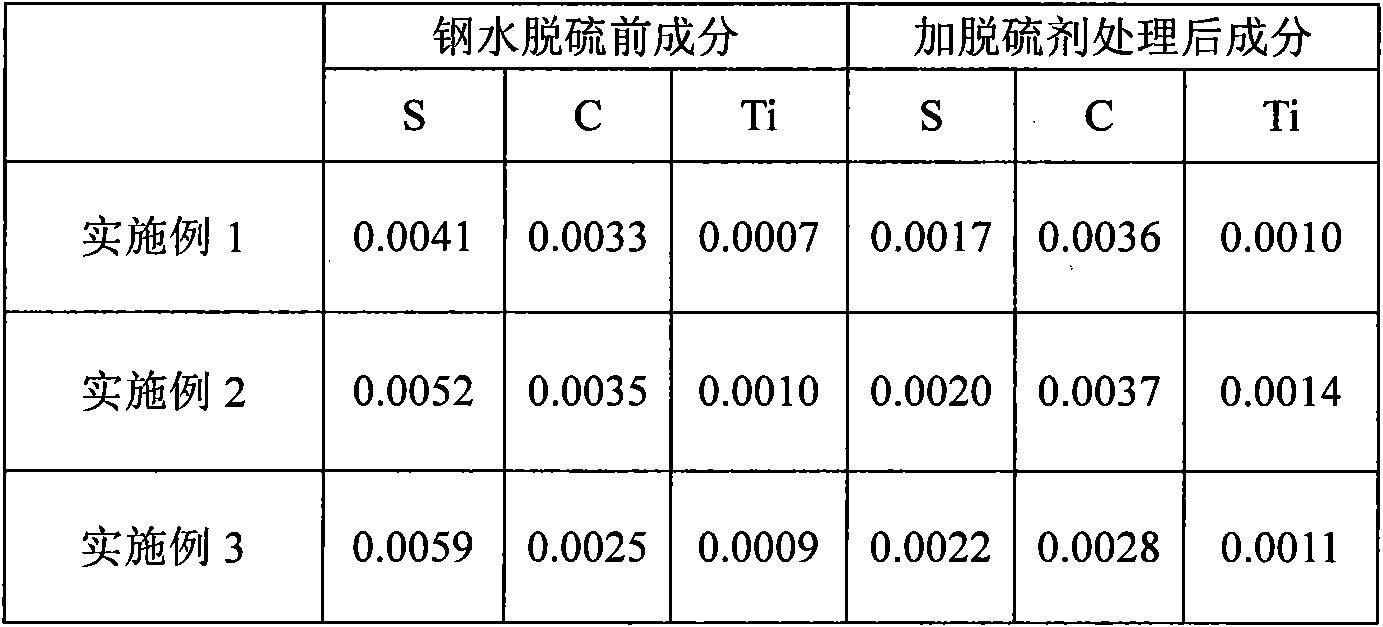

Calcium aluminate for desulfurization of ultralow titanium and carbon steel and preparation method thereof

The invention relates to calcium aluminate for desulfurization of ultralow titanium and carbon steel and a preparation method thereof. The calcium aluminate comprises more than or equal to 94% of Ca12Al14O33, less than or equal to 2% of Ca3Al2O6, less than or equal to 2% of Ca2SiO4, less than or equal to 1.5% of MgO, less than or equal to 0.01% of pure Ti and less than or equal to 0.02% of pure carbon. The preparation method comprises the following steps of: (1) preparing materials according to the following proportions: 60-65% of CaO and 35-40% of Al; (2) mixing the proportioned raw material particles in a material mixer; (3) adding the mixed materials into a smelting furnace, and blowing fuel to heat the furnace to make furnace temperature achieve 950-1050 DEG C; (4) blowing oxygen into the furnace, heating the furnace body to 1450-1500 DEG C; and (5) cooling and crushing premelted slag into 5-30 mm blocks. The desulfurizing agent provided by the invention has the advantages of low production cost, easy for storage, low melting point, high slag melting speed, high desulfurization effect and small corrosion to refractory materials, and the carbon increase amount and the titanium increase amount of liquid steel can be effectively controlled.

Owner:ANGANG STEEL CO LTD

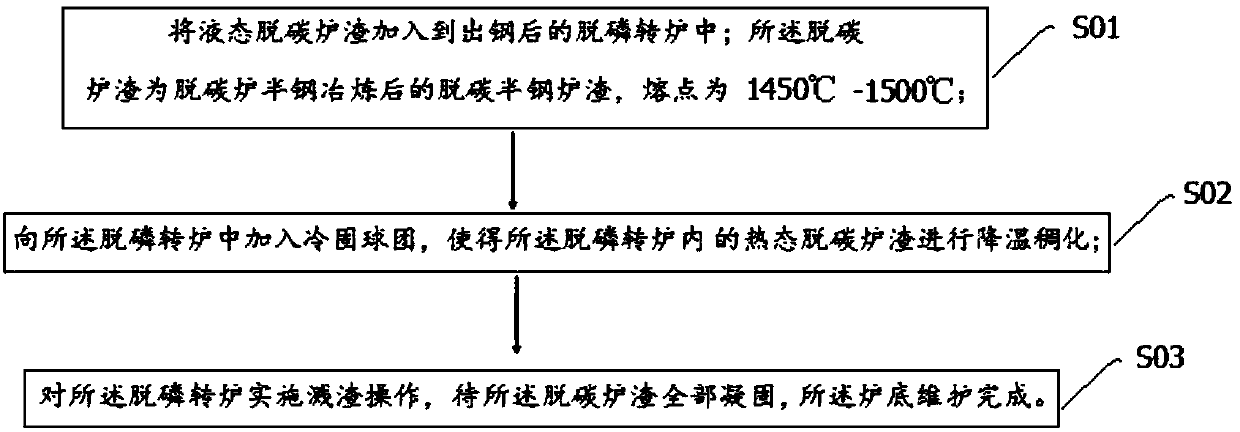

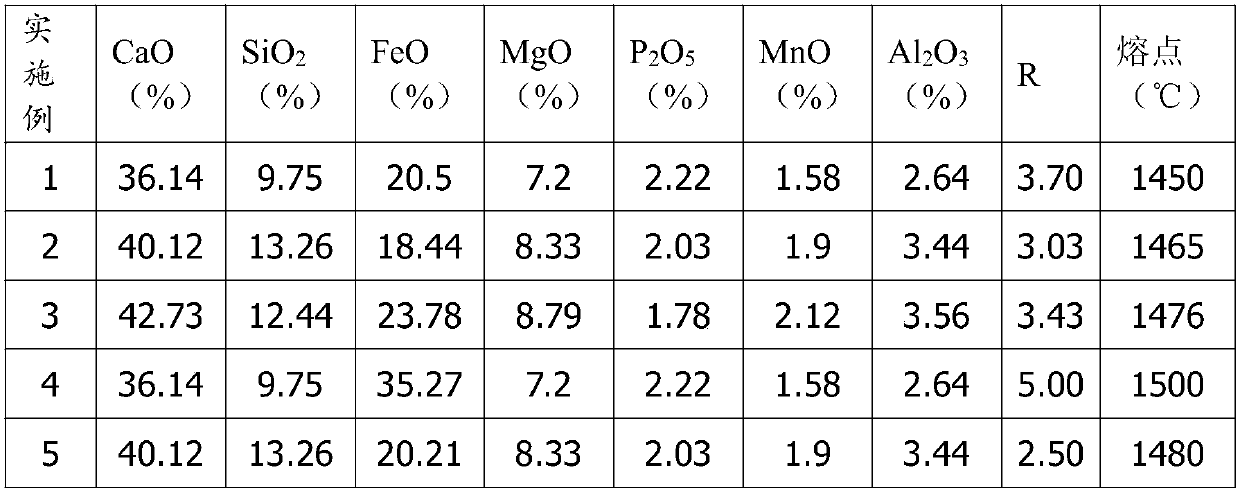

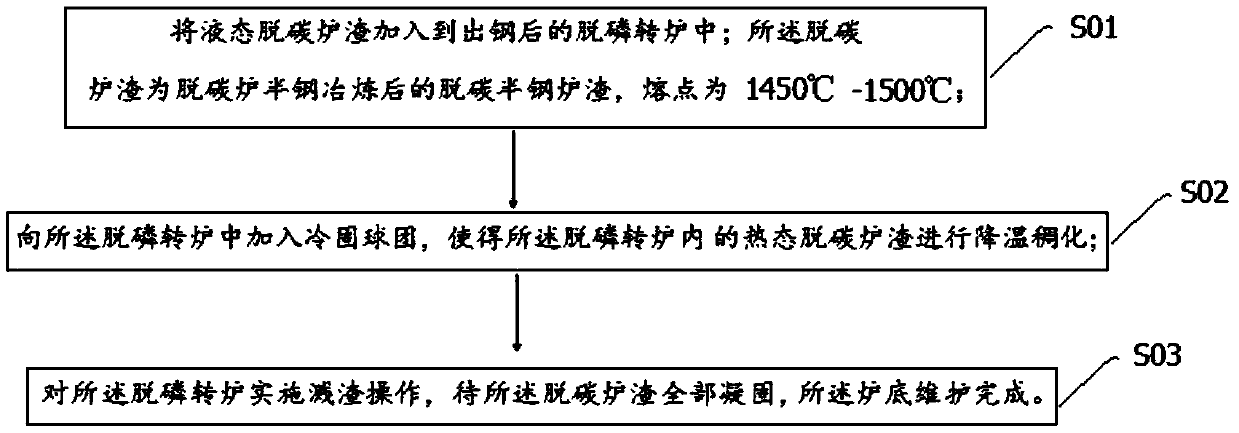

Dephosphorization converter bottom maintaining method

ActiveCN107557518AReduce consumptionGood adhesion to the furnace wallManufacturing convertersAlkalinitySlag

The invention discloses a dephosphorization converter bottom maintaining method. The dephosphorization converter bottom maintaining method comprises the steps that liquid decarbonized slag is added into a dephosphorization converter subjected to steel tapping, wherein the decarbonized slag is decarbonized semisteel slag obtained after semisteel is smelted in a decarbonization furnace, and the melting point of the decarbonized slag is 1450-1500 DEG C; cooled agglomerated pellets are added into the dephosphorization converter, so that the liquid decarbonized slag in the dephosphorization converter is cooled and densified; and the dephosphorization converter is subjected to slag splashing operation, and after the decarbonized slag is completely solidified, converter bottom maintaining is finished. The decarbonized slag is high in melting point, can be quickly solidified after slag splashing and achieves an effect of protecting a lining and the bottom of the converter; meanwhile, the decarbonized slag has the characteristics of being high in alkalinity and ferric oxide content and capable of reducing the consumption amount of lime of the dephosphorization converter and providing the initial high-ferric-oxide condition for the dephosphorization converter, so that the slagging speed in the initial stage of smelting is increased, and the purpose of smelting ultralow-phosphorus steel with the low cost is achieved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Smelting furnace slagging-off device

ActiveCN110940198ARealize the function of castingFast slag removalIncrustation removal devicesSlagEngineering

The invention provides a smelting furnace slagging-off device, which comprises a smelting furnace main body, a hearth, a heating mechanism, an electric cylinder I, a fixed block, a feeding box, a connecting frame, an electric cylinder II, a movable block, a hollow cylinder and a slagging-off plate, wherein the hearth is arranged in the smelting furnace main body; the heating mechanism is mounted at the lower end of the hearth; the electric cylinder I is mounted at the upper end of the smelting furnace main body; the fixed block is arranged at the upper end of the electric cylinder I; the feeding box is mounted at the upper end of the fixed block; the connecting frame is fixed at the right end of the fixed block; the electric cylinder II is mounted on the left end surface in the connectingframe; the movable block is arranged on the right end surface of the electric cylinder II; the hollow cylinder is fixed at the lower end of the movable block; and the slagging-off plate is mounted onthe hollow cylinder. According to the design, the function of applying a slag conglomeration agent is achieved, and the slagging-off speed is high. The smelting furnace slagging-off device is convenient to use and convenient to operate, can achieve the function of applying the slag conglomeration agent, and is high in slagging-off speed and high in reliability.

Owner:扬州市硕成伟业电热设备有限公司

High-finish-degree antibacterial stainless steel pump valve casting and manufacturing method thereof

The invention discloses a high-finish-degree antibacterial stainless steel pump valve casting. According to the stainless steel pump valve casting, the use amount of elements such as Cu, Zr and Ag is properly increased on the basis that low-carbon steel has good toughness and plasticity, good casting mold forming performance is given to a stainless steel casting material, the hardness and toughness are achieved, corrosion resistance is extremely excellent, the certain antibacterial property is achieved, the situation that the surface of the material breeds bacteria and consequently use is affected can be prevented, crystal nucleuses can be refined effectively through the added rare earth element, the surface quality of the casting is improved, shrinkage cavities are reduced, and a high-finish-degree material is obtained; and the deoxygenation and impurity removal effects are achieved through a composite refining agent of nanometer Ca-RE intermediate phase alloy powder loaded by honeycomb ceramic powder and graphene, the slagging speed is high, efficiency is high, the degree of purity of molten steel can be increased effectively, the performance of stainless steel heat-treated multiple times is stable, and the energy-saving and efficient production effects of products are achieved.

Owner:TONGLING JINGWEI FLUID SCI & TECH

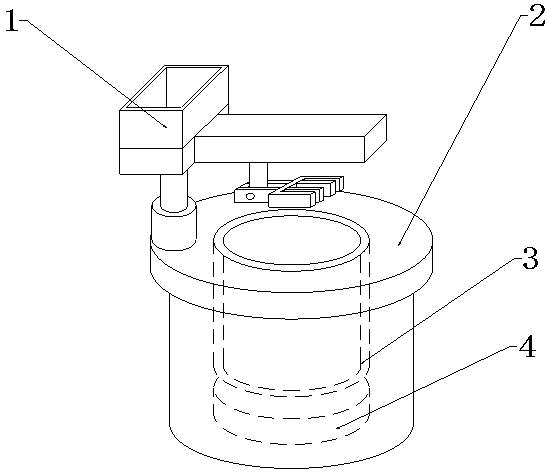

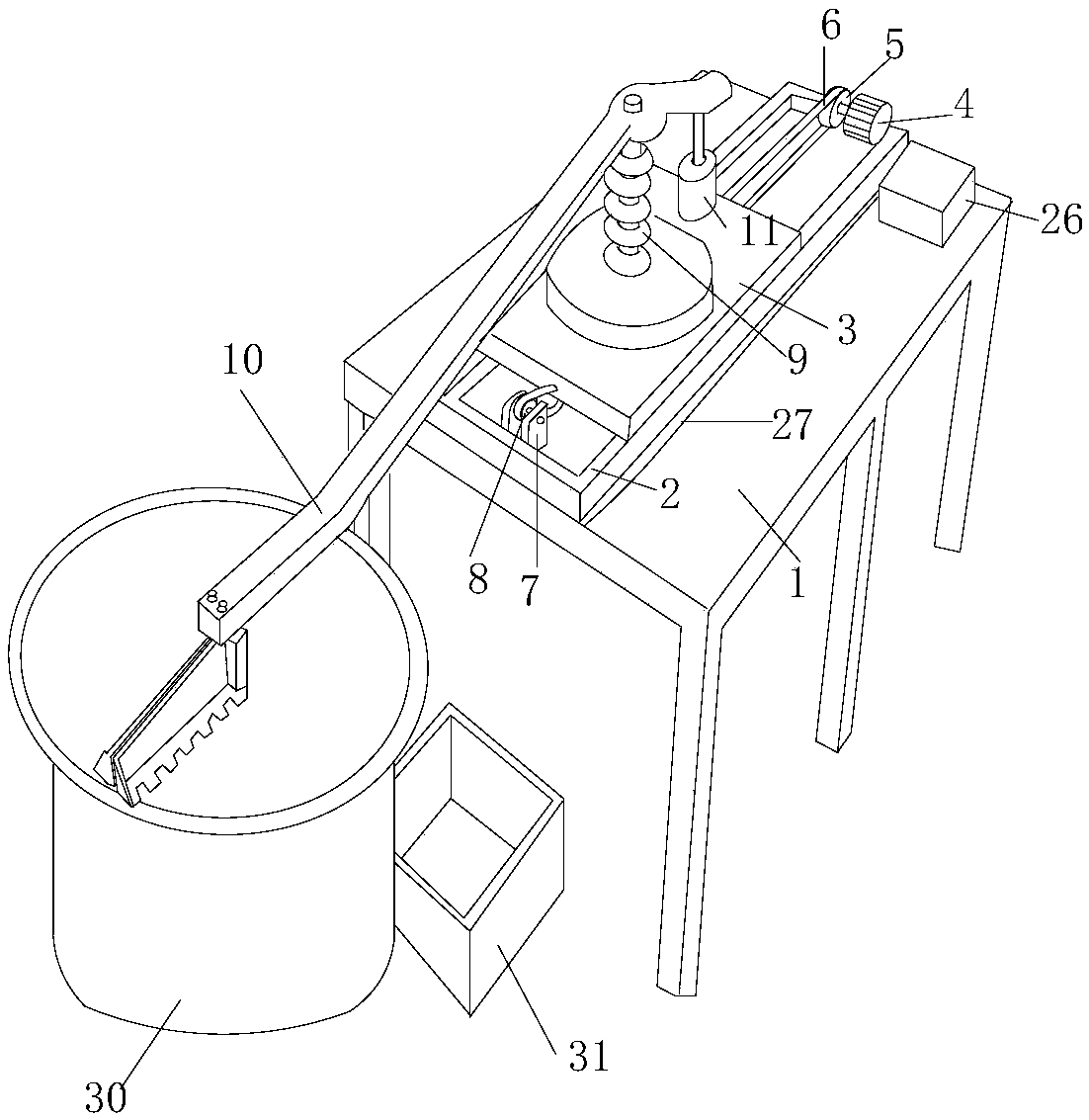

Molten aluminum slag fetching machine

InactiveCN107900321ASimple structureEasy to install and maintainCasting cleaning apparatusSlagMaterials science

The invention belongs to the technical field of metal smelting equipment and discloses a molten aluminum slag fetching machine. The molten aluminum slag fetching machine comprises a worktable. The worktable is provided with a moving track. A servo motor is arranged at one end of the moving track. A wheel is arranged on an output shaft of the servo motor. A belt used for pulling a base is arrangedbelow the base. A support is arranged at the other end of the moving track. A belt wheel capable of rotating is arranged on the support. One end of a belt is connected with the wheel in a sliding manner and is then fixedly installed at one end of the base, the other end of the belt is connected with the belt wheel in a sliding manner and is then fixedly installed at the other end of the base, andthe wheel and the belt wheel can tension the belt. A spring vertical beam perpendicular to the base is installed on the base, and a slag fetching arm is movably installed on the spring vertical beam.The base is further provided with a hydraulic rod. The hydraulic rod comprises a cylinder body and a piston rod stretching out from the front end of the cylinder body. The cylinder body is installed on the base. The piston rod is fixedly connected with the tail end of the slag fetching arm. A slag fetching claw is arranged at the front end of the slag fetching arm. The molten aluminum slag fetching machine is simple in structure and capable of effectively improving the slag fetching efficiency.

Owner:柳州市金升汽车配件有限公司

A slag scraper for ladle mouth

Owner:BAOSTEEL DESHENG STAINLESS STEEL

A suction type slag cleaner

The invention provides a sucking-in type slag removing machine. The sucking-in type slag removing machine comprises a closed barrel body, at least one slag sucking pipe and a slag sucking device; a hoisting arm is installed on the top of the barrel body; the bottom segment of the barrel body is provided with a sealed slag outlet; the slag sucking pipe is installed in the barrel body in the axial direction of the barrel body; the inlet end of the slag sucking pipe stretches out of the bottom of the barrel body, and the outlet end of the slag sucking pipe is arranged in the barrel body; the slagsucking device is installed above the side portion of the outlet end of the slag sucking pipe, and is used for generating negative pressure sucking force in the barrel body and sucking and discharging slurry after a sediment-slurry mixture is separated; the sediment-slurry mixture in a drill hole / well enters the barrel body to be dispersed under the effects of the sucking force of the slag sucking device; sediment falls into the bottom segment of the barrel body, and the slurry is discharged outwards by the slag sucking device to be circulated. The sucking-in type slag removing machine belongs to an active slag removing manner, the slag removing machine can be used for removing large-particle-diameter stone slag and can also be used for removing slag in slurry holes and clean water holes,slag removing can be performed even though mud making and slag mixing are not needed, and the sucking-in type slag removing machine is high in slag removing effect and wide in using range.

Owner:任国勇

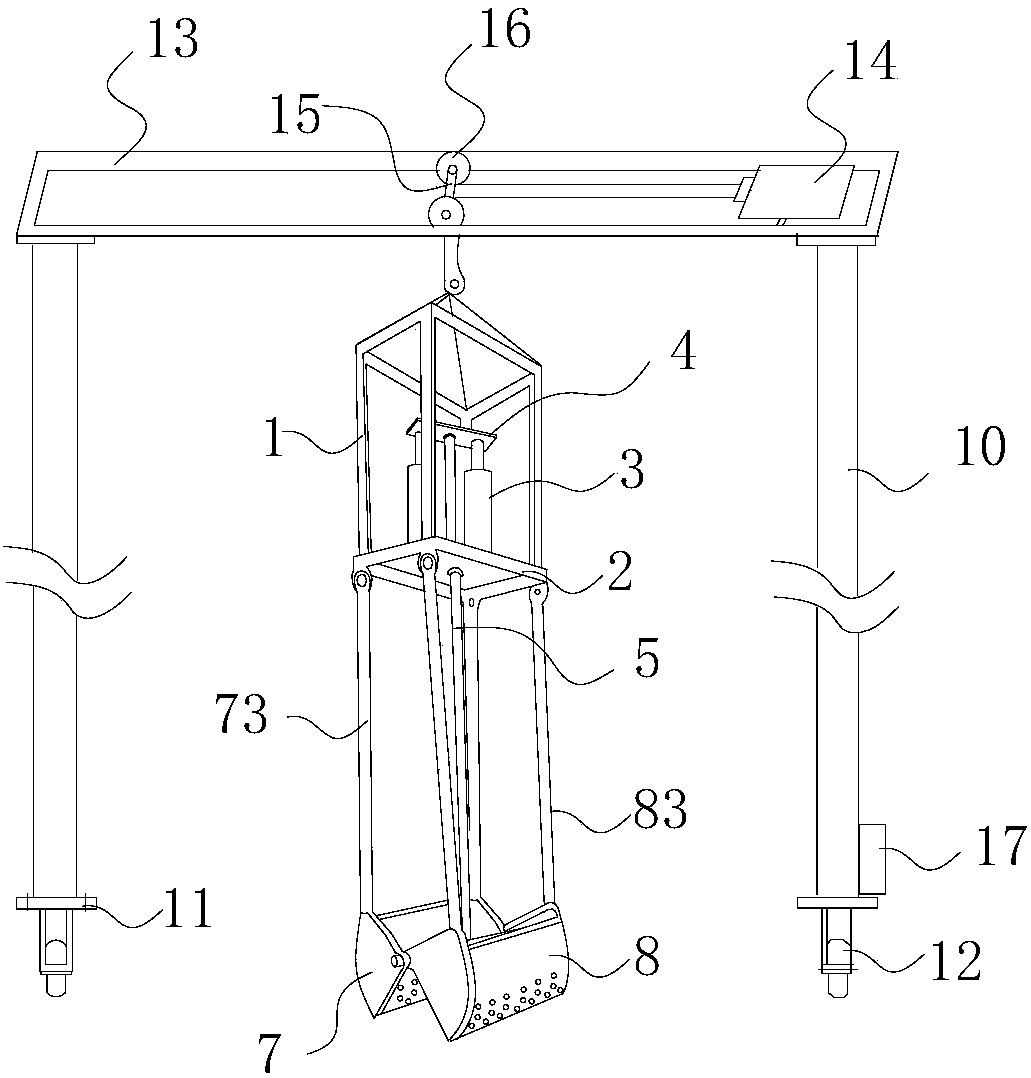

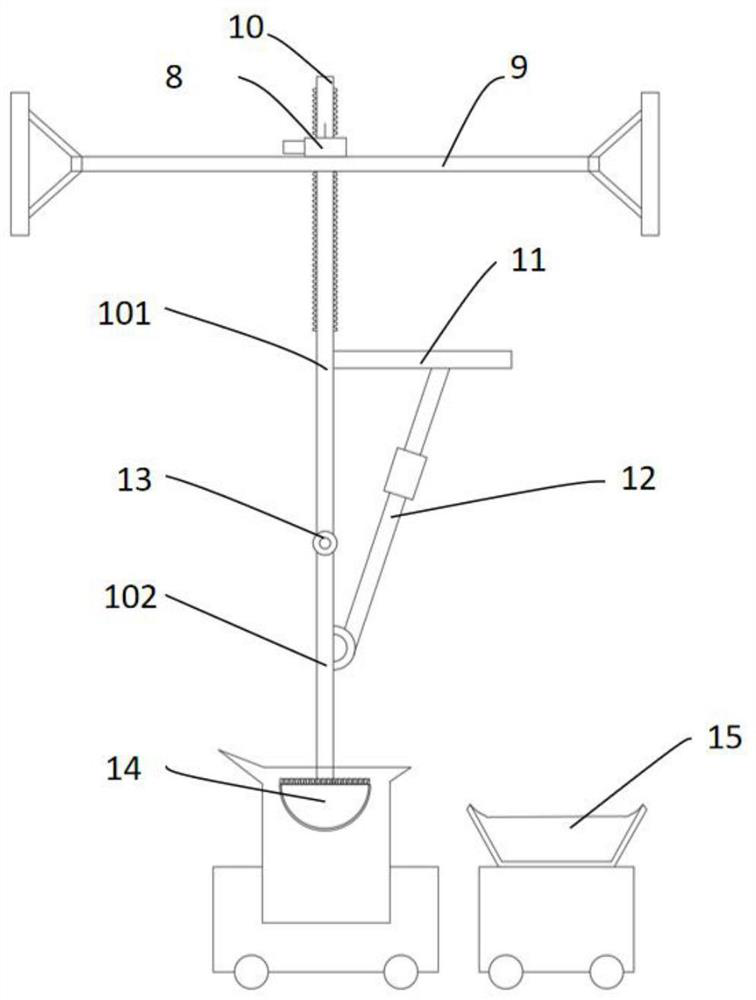

Novel slag collection device

InactiveCN108085456AFast slag removalHigh slag removal efficiencyCasting cleaning apparatusProcess efficiency improvementSlagPortal frame

The invention belongs to the technical field of ferrous metallurgy. A novel slag collection device comprises a portal frame and a slag collection mechanism arranged on the portal frame. The slag collection mechanism comprises a hanging bracket. A slag claw is connected with a lower portion of the hanging bracket, a hydraulic drive device driving the slag claw is arranged on the hanging bracket. The novel slag collection device is used for working on slag collection of ladles, and a structure of the novel slag collection device is simple. The slag can be quickly taken out and the efficiency ofthe slag collection is effectively improved.

Owner:柳州市金升汽车配件有限公司

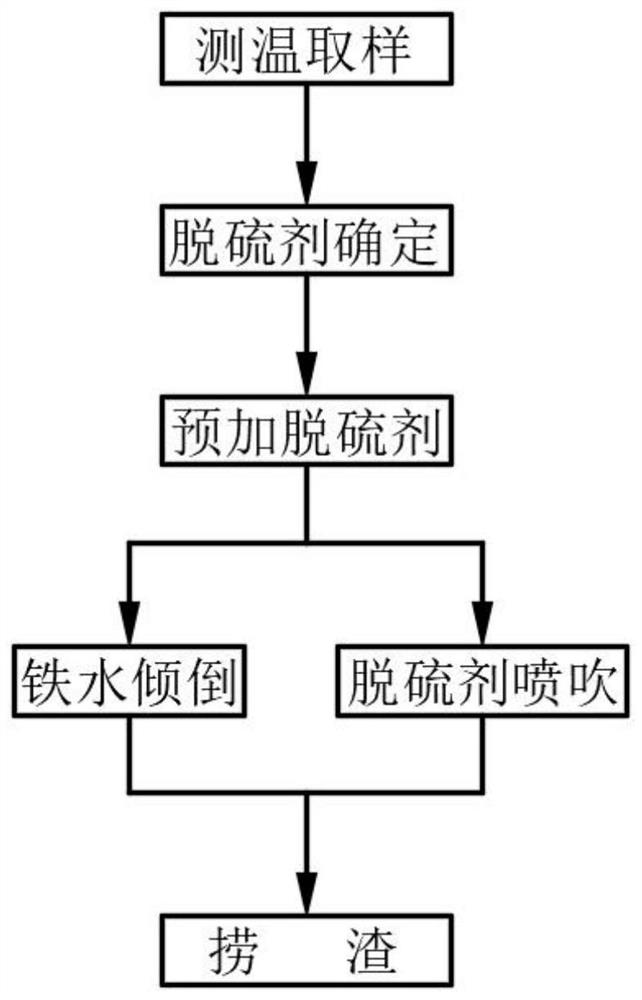

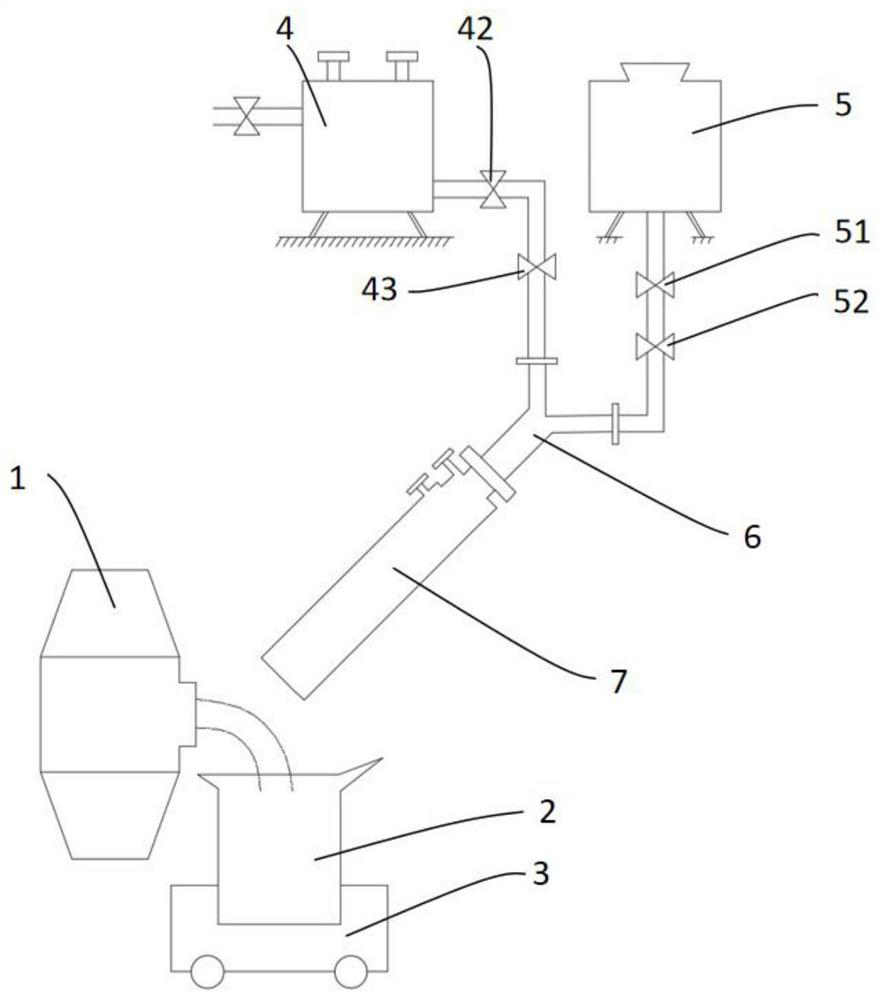

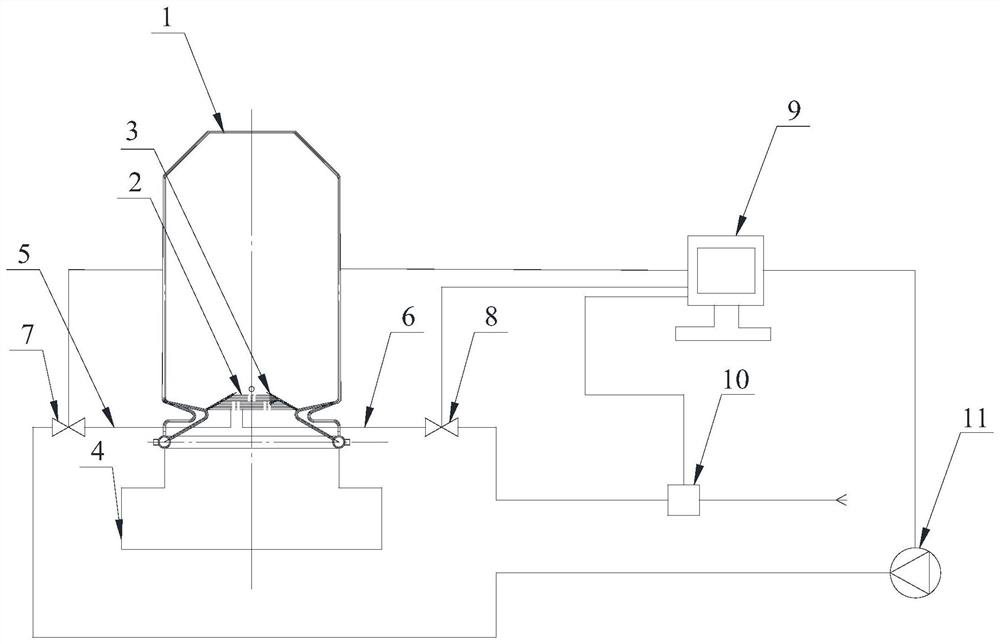

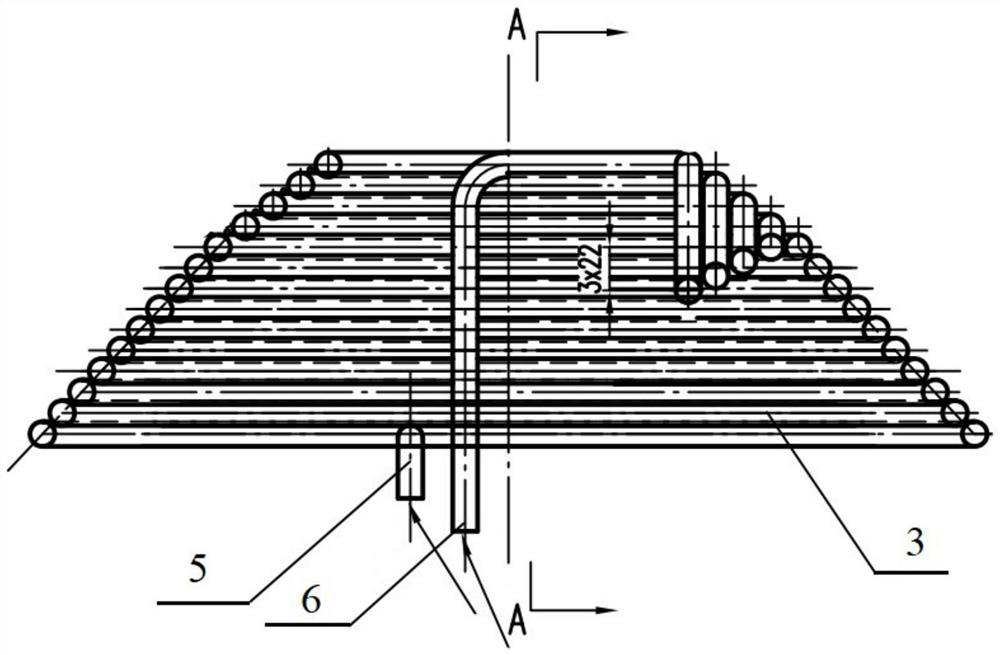

Molten iron desulfurization pretreatment process and method

The invention relates to a molten iron desulphurization pretreatment process and method, belongs to the technical field of molten iron desulphurization processes, and solves the problems of poor desulphurization effect, large slag salvaging iron loss and the like of a molten iron desulphurization process. The method comprises the following steps: S1, temperature measurement and sampling are conducted, specifically, temperature measurement and sampling are conducted on molten iron; S2, the injection amount is determined, and the total demand quantity of a desulfurizing agent is determined according to the content of initial sulfur and the type requirement of the steel type; S3, the desulfurizing agent is pre-added, specifically, the desulfurizing agent with the basic demand quantity is pre-added to the bottom of a molten iron ladle; S4, molten iron pouring and desulfurizing agent injection are conducted, specifically, the molten iron in a torpedo ladle is poured into the molten iron ladle, and meanwhile a spraying gun is used for being aligned with falling molten iron flow to spray out the desulfurizing agent; and S5, slag salvaging is conducted, specifically, desulfurization slag floating on the surface of the molten iron is salvaged away from the molten iron ladle through a special slag salvaging machine. According to the method, the desulfurizing agent is released in two directions to react with the molten iron, desulfurization is carried out in a mode of pouring the molten iron while injecting, desulfurization is carried out in cooperation with existing equipment, special slag salvaging equipment is manufactured for salvaging slag, and therefore the purposes of efficient and rapid desulfurization and slag salvaging are achieved.

Owner:吕梁建龙实业有限公司

A method for maintaining the bottom of a dephosphorization converter

ActiveCN107557518BReduce consumptionGood adhesion to the furnace wallManufacturing convertersSlagFerric

The invention discloses a dephosphorization converter bottom maintaining method. The dephosphorization converter bottom maintaining method comprises the steps that liquid decarbonized slag is added into a dephosphorization converter subjected to steel tapping, wherein the decarbonized slag is decarbonized semisteel slag obtained after semisteel is smelted in a decarbonization furnace, and the melting point of the decarbonized slag is 1450-1500 DEG C; cooled agglomerated pellets are added into the dephosphorization converter, so that the liquid decarbonized slag in the dephosphorization converter is cooled and densified; and the dephosphorization converter is subjected to slag splashing operation, and after the decarbonized slag is completely solidified, converter bottom maintaining is finished. The decarbonized slag is high in melting point, can be quickly solidified after slag splashing and achieves an effect of protecting a lining and the bottom of the converter; meanwhile, the decarbonized slag has the characteristics of being high in alkalinity and ferric oxide content and capable of reducing the consumption amount of lime of the dephosphorization converter and providing the initial high-ferric-oxide condition for the dephosphorization converter, so that the slagging speed in the initial stage of smelting is increased, and the purpose of smelting ultralow-phosphorus steel with the low cost is achieved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Calcium aluminate for desulfurization of ultralow titanium and carbon steel and preparation method thereof

The invention relates to calcium aluminate for desulfurization of ultralow titanium and carbon steel and a preparation method thereof. The calcium aluminate comprises more than or equal to 94% of Ca12Al14O33, less than or equal to 2% of Ca3Al2O6, less than or equal to 2% of Ca2SiO4, less than or equal to 1.5% of MgO, less than or equal to 0.01% of pure Ti and less than or equal to 0.02% of pure carbon. The preparation method comprises the following steps of: (1) preparing materials according to the following proportions: 60-65% of CaO and 35-40% of Al; (2) mixing the proportioned raw material particles in a material mixer; (3) adding the mixed materials into a smelting furnace, and blowing fuel to heat the furnace to make furnace temperature achieve 950-1050 DEG C; (4) blowing oxygen into the furnace, heating the furnace body to 1450-1500 DEG C; and (5) cooling and crushing premelted slag into 5-30 mm blocks. The desulfurizing agent provided by the invention has the advantages of low production cost, easy for storage, low melting point, high slag melting speed, high desulfurization effect and small corrosion to refractory materials, and the carbon increase amount and the titanium increase amount of liquid steel can be effectively controlled.

Owner:ANGANG STEEL CO LTD

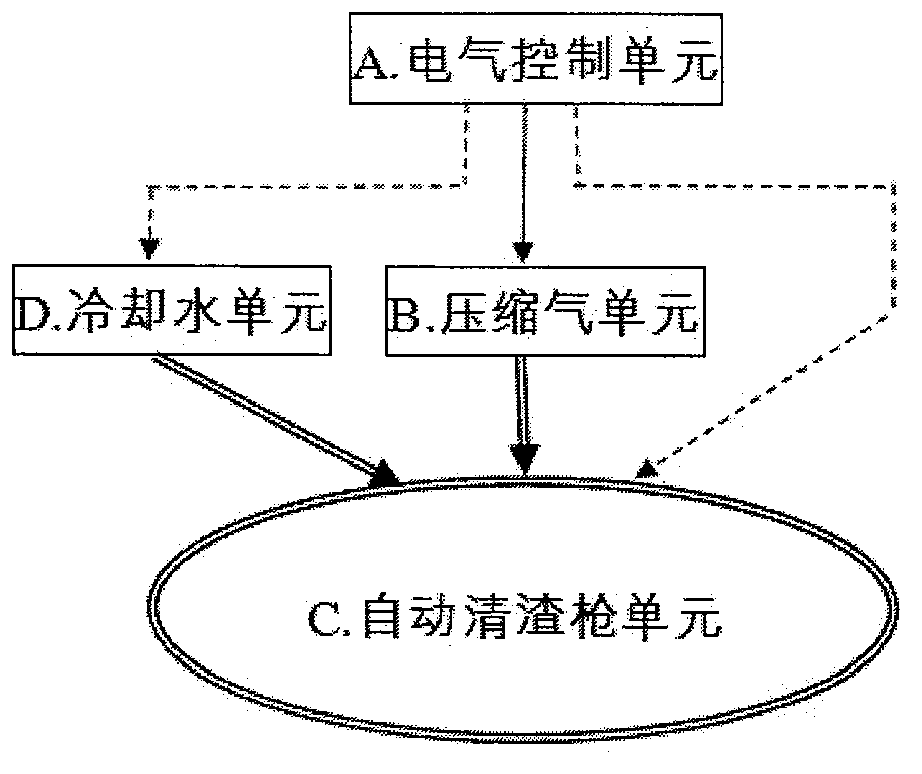

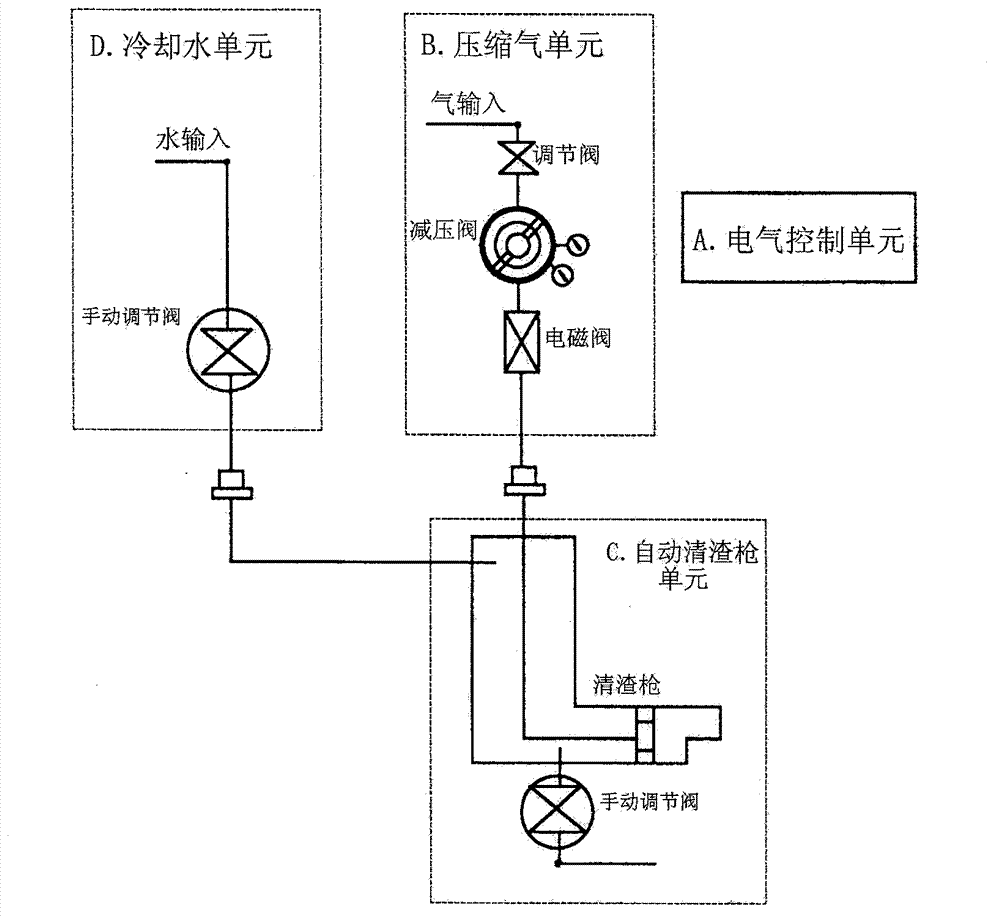

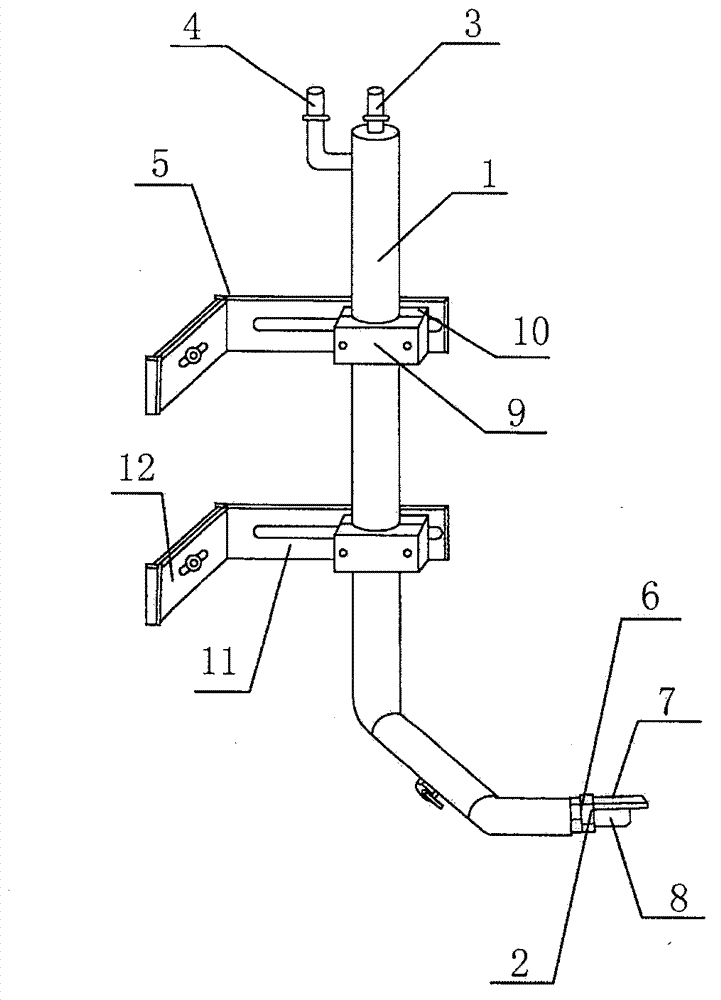

Automatic scarfing device for flame cutting of continuous casting

ActiveCN102151939BImprove cleanlinessSolve persistent problemsGas flame welding apparatusMetallic materialsEngineering

The invention discloses an automatic scarfing device for flame cutting of a continuous casting. The automatic scarfing device consists of four parts, namely an electric control unit A, a compressed air unit B, an automatic scarfing gun unit C and a cooling water unit D. The automatic scarfing device and a matched flame cutting device are ideal equipment for fixed size cutting of steel wires or steel blasts rolled by a continuous casting machine in a steel factory; and the technical performance exceeds the national standard, the industrial standard and the process rule requirement of users. The finished product ratio of the steel blast made by fixed size cutting is over 99 percent; oxygen, fuel gas and compressed air for cutting are all saved by over 85 percent; a cutting gap is reduced from the conventional 8 millimeters to about 2 millimeters; the residues can be cleared away, so the problem that the residues may be suspended during flame cutting of the continuous casting can be solved; and the automatic scarfing device has a very good popularization value, is applicable to industries of metallurgy, shipbuilding, petroleum, chemical engineering, metal structures and the like, and particularly used for quickly and continuously cutting and scarfing a metal material with the temperature less than or equal to 950 DEG C.

Owner:温州上冶机械设备有限公司

Molten steel refining agent and preparation method

InactiveCN100467621CSolve pollutionSolve resource problemsProcess efficiency improvementSlagHeating furnace

This invention discloses molten steel refining agent contains mainly of: 60-90 wt% lable furnace refinery slag, 4-15 wt% of CaO, 6-25wt% of Al2O3 mixture and saturated magnesium chloride solution with concentration of 5wt% at the percentage of 15-25 wt% of said mixture. The method for preparing this inventive agent is: mixing above-mentioned components and then making pellets, then heating them at 600-900 deg.C for 1.3-3 Hrs, and natural cooling after taking them out of the oven. This invented product has advantages of: quick melting of slag and excellent metallurgic effect, better desulphuration of 60-70% with adding 3-6 kg of the agent per ton of steel.

Owner:武汉钢铁有限公司 +1

Anti-slag-blocking slag discharging opening structure for entrained-flow bed gasification furnace and arrangement method thereof

ActiveCN113862040ASolve the phenomenon of cloggingHigh starting positionGranular/pulverulent flues gasificationProduction lineThermodynamics

The invention relates to an anti-slag-blocking slag discharging opening structure for an entrained-flow bed gasification furnace and an arrangement method thereof, belongs to the field of slag discharge of gasification furnaces, and aims to solve the problems that the slag discharging opening in the existing entrained-flow bed gasification furnace is often blocked in the slag discharge process, and once the slag is blocked, the slag can only be removed by blowing out the gasification furnace, thus the whole production line is completely stopped, and huge economic loss is caused to the enterprise. According to the anti-slag-blocking slag discharging opening structure for the entrained-flow bed gasification furnace and the arrangement method thereof, the slag discharging opening structure adopts a structural form of 'narrow inlet and wide outlet', and the position of the inlet end of the slag discharging opening is higher than the position of the inlet of a traditional slag discharging opening, the temperature of the liquid slag entering the slag discharging opening is higher, and is 80-100 DEG C higher than the temperature of the slag discharging opening in the initial slag falling position in the traditional form. Ash slag can be discharged in a liquid state through the high slag melting temperature, solid slag cannot be formed, and slag blockage of the slag discharging opening can be prevented.

Owner:HARBIN INST OF TECH

Method for removing ladle dross

ActiveCN100340363CFast slag removalEfficient slag removalCasting cleaning apparatusLiquid slagMolten steel

The invention provides the method of removing liquid steel scum, comprising the following steps: dragging the scum from liquid steel liquid level with harrow rotary dragging method, at the same time, adding the anti-oxidization agent on the clean liquid steel surface. Because of adopting the harrow rotary dragging method, the invention solves the problems of big loss of scarfing cinder, hard operation and heavy labor strength. Adding the anti-oxidization agent avoids the secondary oxidization of liquid steel. The method uses the freezing slag agent to solidify the liquid slag. It strengthens the effect of removing slag.

Owner:YANTAI SHENGLIDA ENG TECH

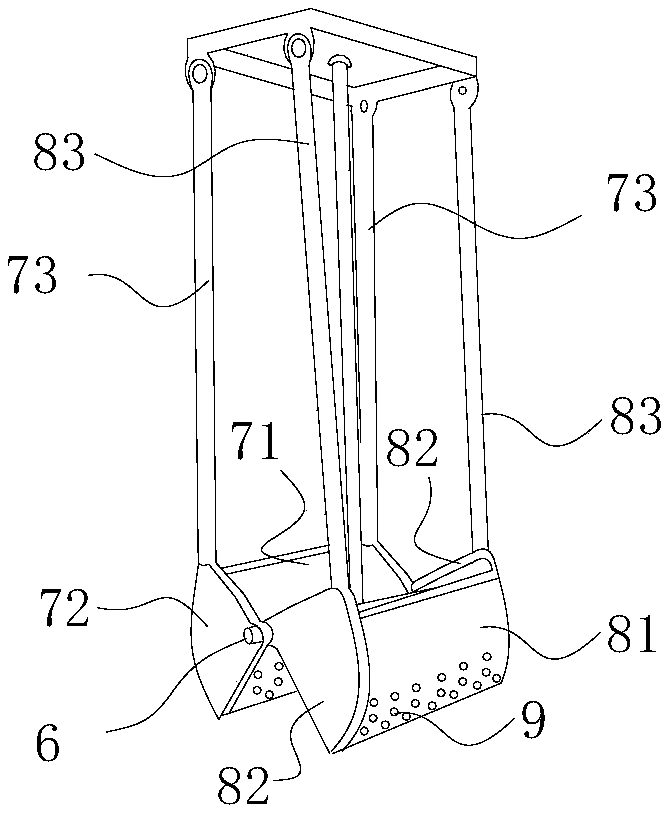

Slag removing device and method used for molten steel vacuum treatment insert tube

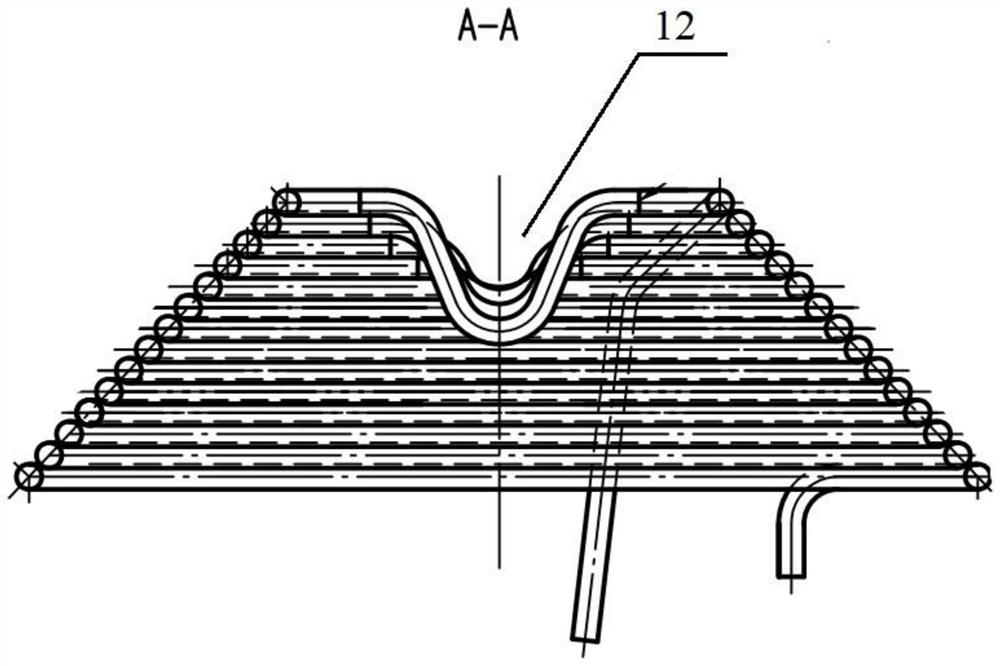

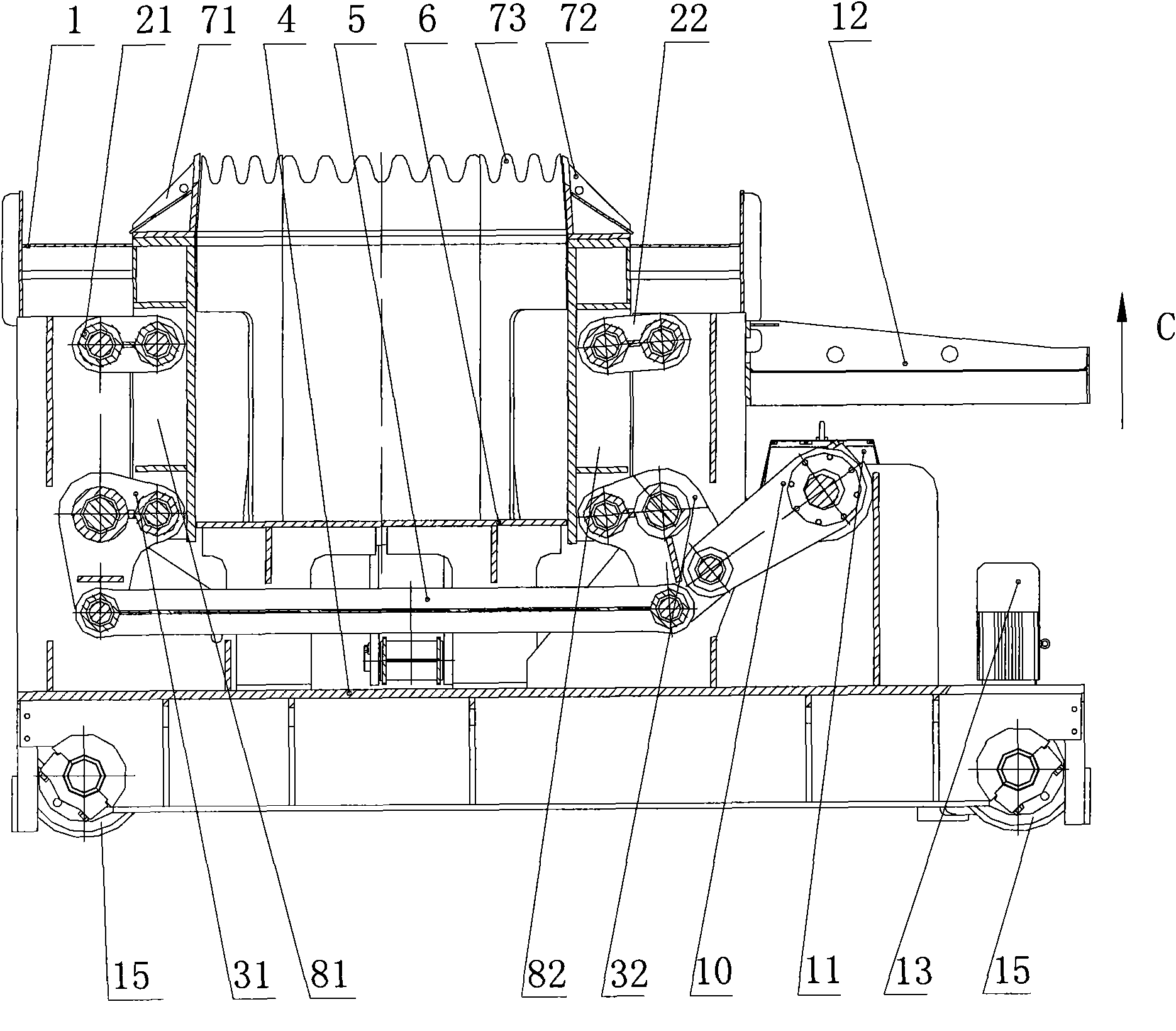

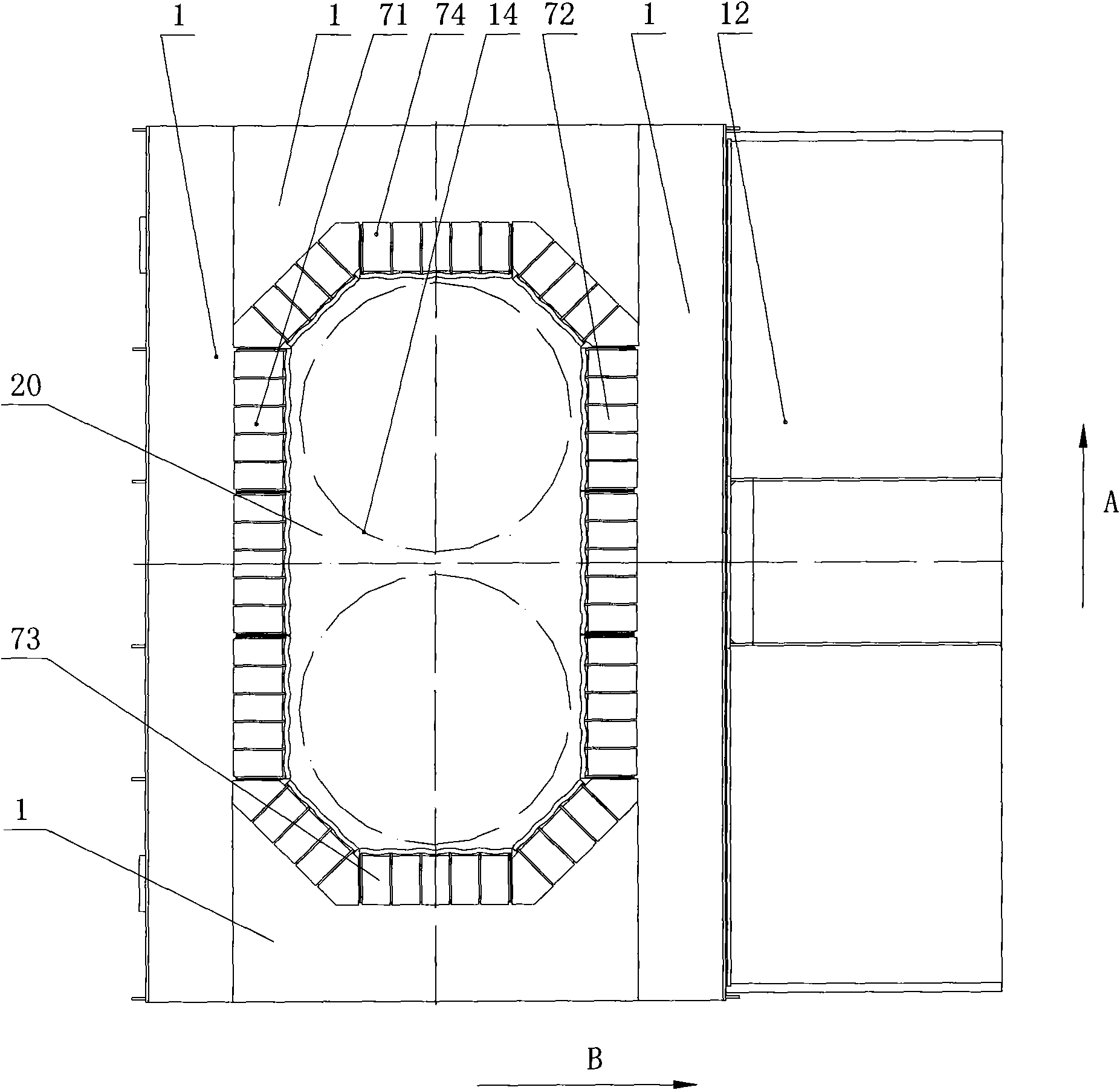

The invention provides a slag removing device used for a molten steel vacuum treatment insert tube (14), wherein the slag removing device comprises a car body (4), two pairs of shovel blades (71,72,73, and 74) and a drive device. A pair of shovel blades (71 and 72) is oppositely arranged along the lateral direction (A) of the car body, and the other pair of shovel blades (73 and74) is oppositely arranged along the longitudinal direction (B) of the car body, so that the two pairs of shovel blades can form a slag removing space (20) suitable for the molten steel vacuum treatment insert tube to insert; the driving device drives the shovel blades to vibrate up and down along the height direction (C) of the car body. The invention also provides a method for removing slags by the slag removing device. Even the steel slags with high cohesional strength can be easily removed by using the slag removing device and method; moreover, since the slag removing speed is high, the working efficiency ofa vacuum treatment device can be increased; in addition, as the motion path of the shovel blades of the slag removing device is relatively stable, the vacuum treatment insert tube can not be damaged.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Process for high pressure compaction of fluorite ball with sodium silicate as binder

The invention discloses a process for high pressure compaction of a fluorite ball with sodium silicate as a binder. The process comprises the following steps: uniformly mixing fluorite flotation powder, fluorite ore powder and a sodium silicate solution in a mixer; placing an obtained mixed material in a high pressure ball press machine for extrusion so as to obtain a ball; and roasting and cooling the ball. The fluorite ball obtained through high pressure compaction with sodium silicate as the binder has a high grade, a wide and high range (with the content of CaF2 in a range of 75 to 95 wt% and normally no less than 85 wt%), a reasonable reaction specific surface area and performances and mechanical strength satisfying requirements for a flux used in metal smelting. The fluorite ball provided by the invention can be extensively used in metal smelting in a blast furnace and for special steel, stainless steel (all the varieties), nonferrous metals and the like and enables a slugging speed to be accelerated and smelting time to be shortened; compared with a fluorite block, application amount of the fluorite ball is greatly reduced, and production cost and the quantity of discharged slag are reduced.

Owner:郴州德宇高新材料有限公司

Submerged-arc welding metal core weldingwire for austenite stainless steel

InactiveCN100382924CNo redness issuesHigh welding currentArc welding apparatusWelding/cutting media/materialsManganeseAlloy

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com