Novel horizontal chain-type slag remover

A slag remover, a horizontal technology, applied in conveyors, conveyor objects, lighting and heating equipment, etc., can solve the problems that slag removal equipment affects the normal operation of the boiler, affects the stability of combustion in the furnace, and increases the power consumption of fans. Achieve the effect of low noise, high power and fast slag removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

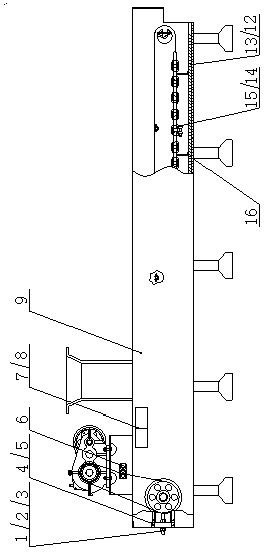

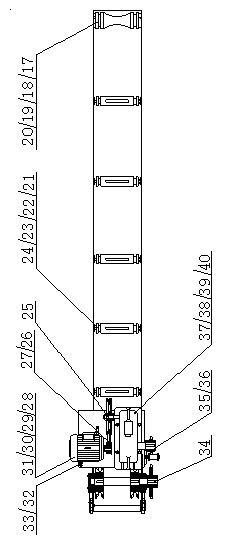

[0021] The present invention will be further described below in conjunction with the drawings:

[0022] A new type of horizontal chain type slag remover, composed of power unit, housing 9, transmission device; as attached figure 1 , 2 As shown, the head of the housing 9 is provided with a sprocket assembly 34 through a small sprocket plate 35 and a small sprocket bushing 36. On the side of the sprocket assembly 34, an electric motor 28 is arranged above the housing 9, and the electric motor 28 and The reducer 37 provided on one side is connected together, and an inlet is provided above the housing 9 on the side of the motor 28; inside the housing 9 on the side of the sprocket assembly 34, there are two layers of upper and lower layers in turn. The supporting rollers 21 are spaced apart. Bearings are provided on the shafts at both ends of the supporting rollers 21, which are mounted on the housing 9 for sliding fit. The rear part of the last group of supporting rollers 21 is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com