Molten iron desulfurization pretreatment process and method

A desulfurization pretreatment and molten iron desulfurization technology, applied in the field of molten iron desulfurization process, can solve the problems of large equipment area, poor desulfurization effect, large iron loss, etc., to increase desulfurization efficiency, increase contact reaction, and quickly remove slag Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

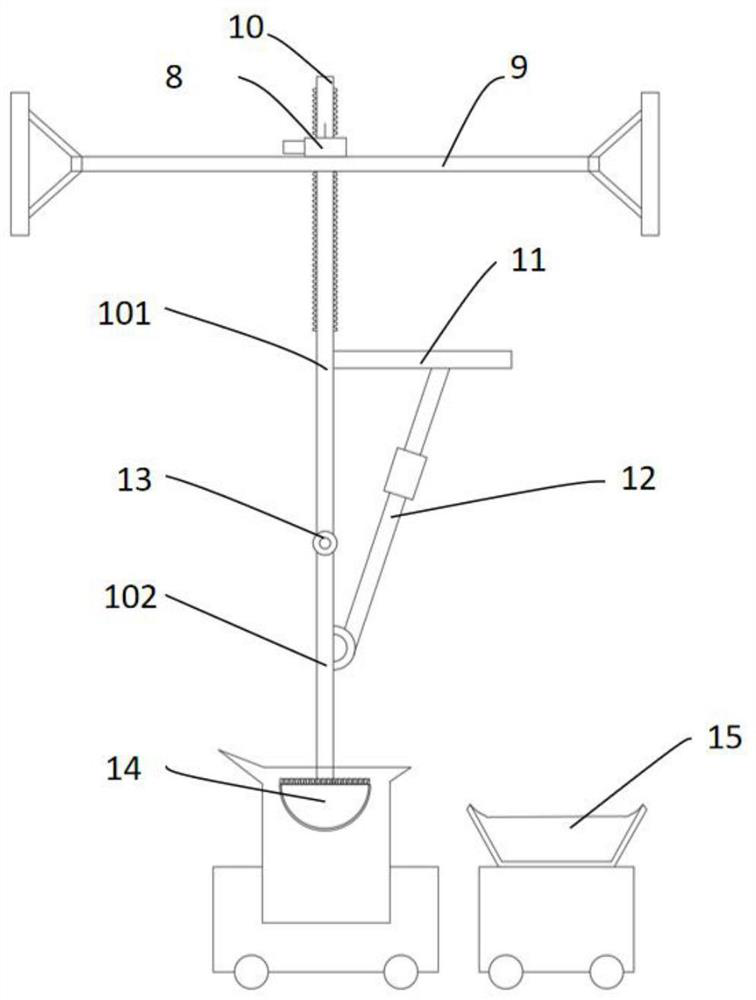

[0033] In order to make the purpose, technical solution and beneficial effect of the patent of the present invention clearer, the technical solution of the patent of the present invention will be described in detail below in conjunction with the accompanying drawings.

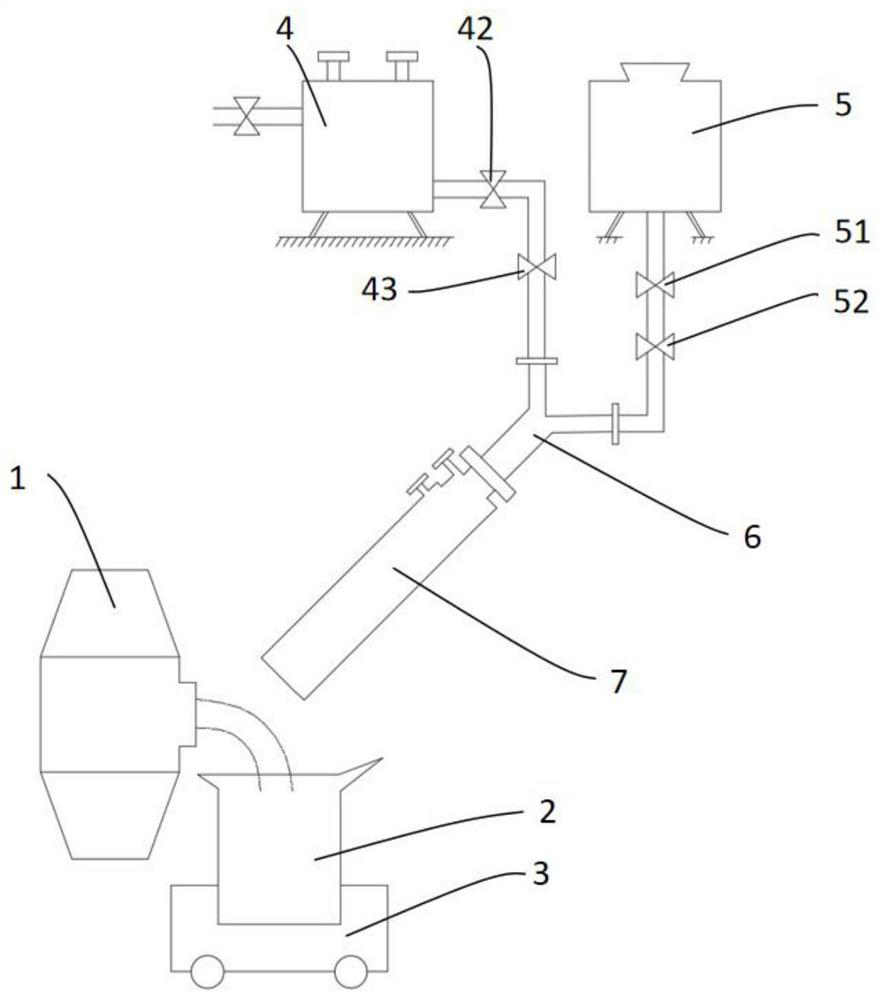

[0034] A desulfurization pretreatment process and method for molten iron. The desulfurization pretreatment process releases a desulfurizer in the top and bottom directions of the ladle to fully contact and react with the molten iron for desulfurization. The desulfurization at the top of the ladle uses pouring of molten iron and blowing desulfurization The method of simultaneous administration of agents.

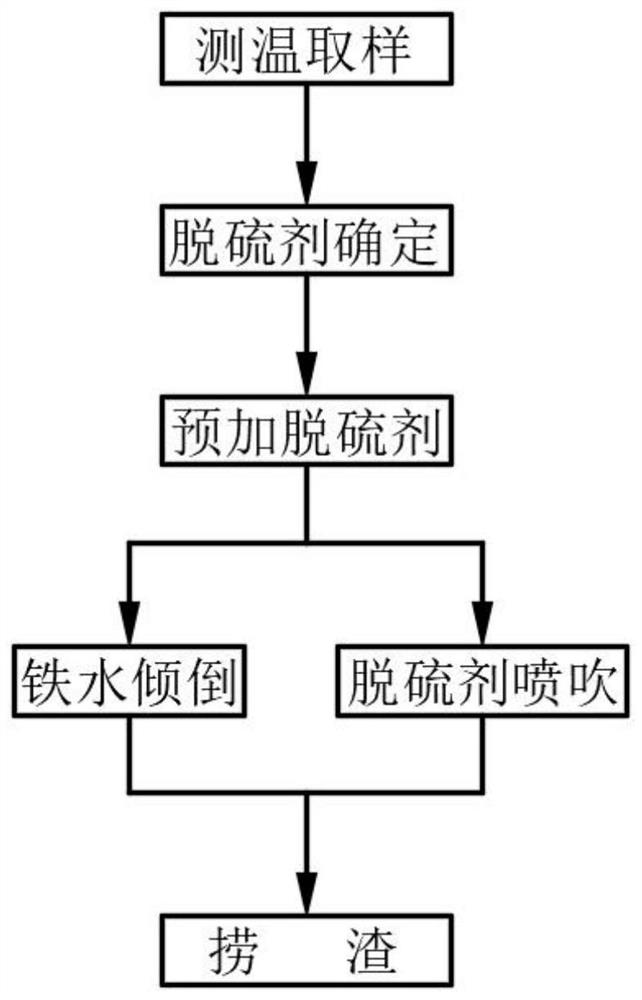

[0035] Such as figure 1 , the detailed desulfurization process includes the following steps:

[0036] S1, temperature measurement and sampling, move the torpedo tanker with molten iron to the overturned place, place the molten iron ladle under the side of the overturned place, measure the temperature and samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com