Method for preparing chemicals by double-tube parallel multi-zone catalytic conversion of crude oil

A technology for catalytic conversion and chemicals, applied in chemical instruments and methods, catalytic cracking, production of bulk chemicals, etc., can solve the problems of low content of gasoline aromatics, low yield of low-carbon olefins, and low content of aromatics in gasoline, etc. The effect of reducing coke yield, increasing aromatics content, and high aromatics content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

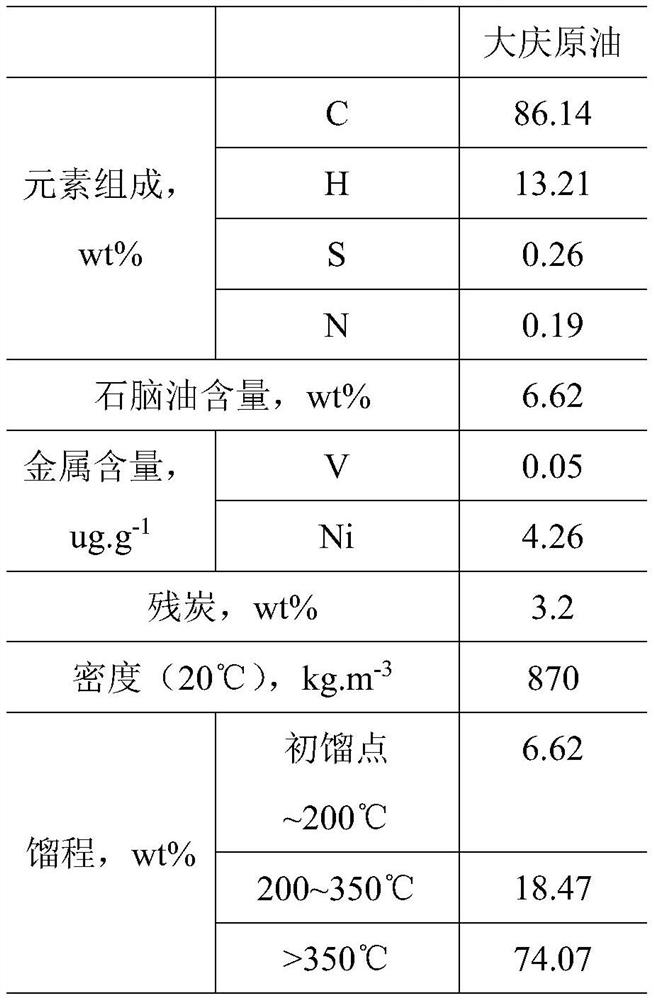

[0040] This example takes an upward reaction tube with a swirl structure as an example. After desalination and dehydration, the crude oil is divided into light components and heavy components according to the boiling point after desalination and dehydration, and fractions below 200°C are classified into light components. , The distillate above 200°C is a heavy component.

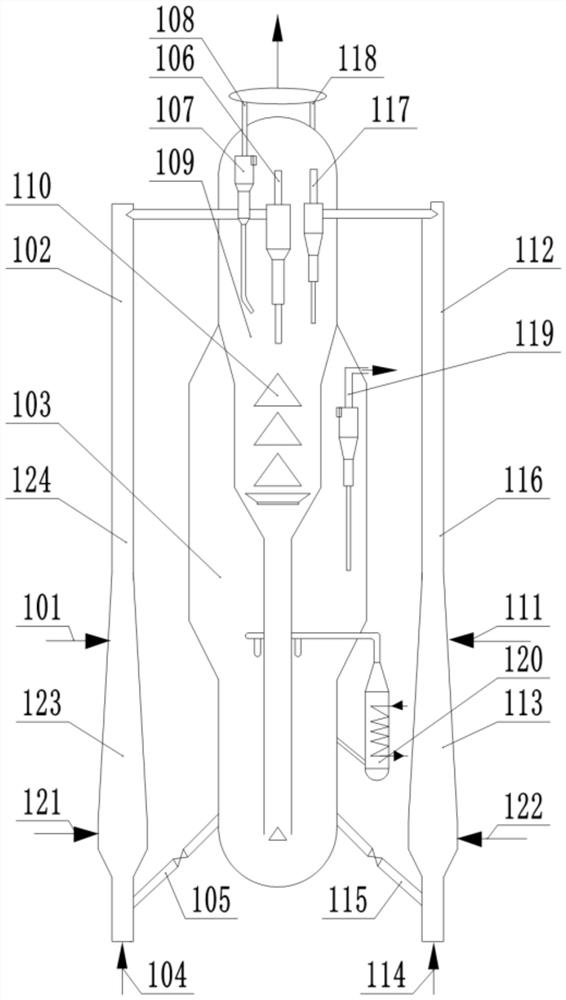

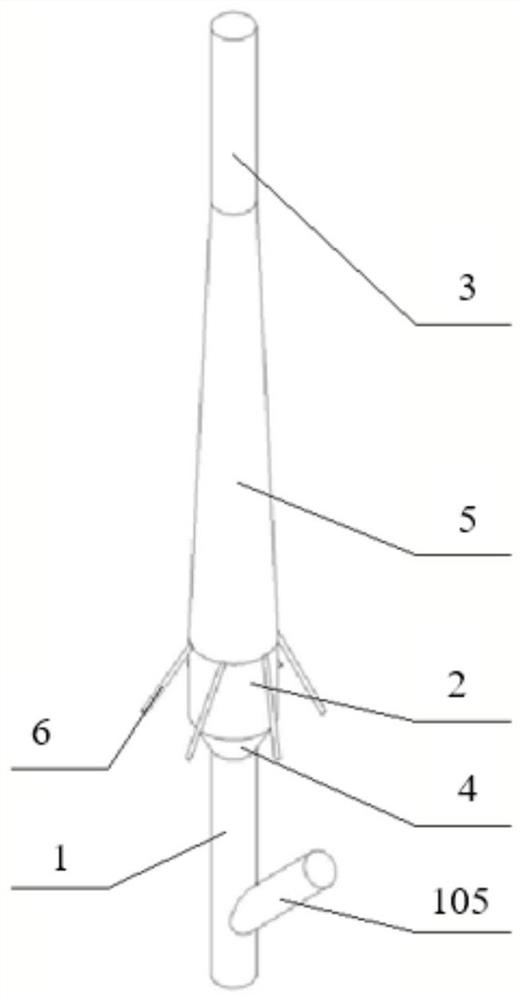

[0041] see figure 1 As shown in the process flow and schematic diagram of the device, the low-carbon alkanes 121 are injected from the lower part of the first riser reactor 102, and the high-temperature regeneration from the regenerator 103 is transported by the regeneration inclined pipe 105, and the pre-lifting steam or the lifting dry gas 104 is lifted up. Catalyst undergoes contact reaction, reacts for 0.1-5.0s at 600-800°C, agent-oil ratio 5-30, and pressure 0.1-0.4MPa, then leaves the light alkane reaction zone 123 and enters the first heavy oil reaction zone 124. The bottom of the reaction zone is mi...

Embodiment 2

[0043] The upward reaction tube with swirl feed structure is adopted, and the crude oil is directly fed.

[0044] see figure 1 As shown in the process flow and schematic diagram of the device, the low-carbon alkanes 121 are injected from the lower part of the first riser reactor 102, and the high-temperature regeneration from the regenerator 103 is transported by the regeneration inclined pipe 105, and the pre-lifting steam or the lifting dry gas 104 is lifted up. Catalyst undergoes contact reaction, reacts for 0.1-5.0s at 600-800°C, agent-oil ratio 5-30, and pressure 0.1-0.4MPa, then leaves the light alkane reaction zone 123 and enters the first heavy oil reaction zone 124. The bottom of the reaction zone is mixed with crude oil 101 preheated to 150-250°C, reacted for 0.1-5.0s at 500-700°C, agent-oil ratio 5-30, and pressure 0.1-0.4MPa, then enters the gas-solid separator 106 and The top spin 107 of the settler separates the oil agent, and the main reaction oil gas 108 enter...

Embodiment 3

[0046] A descending reaction tube with a swirling feed structure is used. After desalination and dehydration, the crude oil is first desalted and dehydrated, and then flashed or distilled. According to the boiling point, it is divided into light components and heavy components. °C fractions are heavy components. For the specific process, refer to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com