A slag scraper for ladle mouth

A slag scraper and bag mouth technology, which is used in mechanical cleaning, manufacturing tools, metal processing equipment, etc., can solve the problems of slag removal on the outer wall of difficult bag mouths, low work efficiency, and limited slag cleaning range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

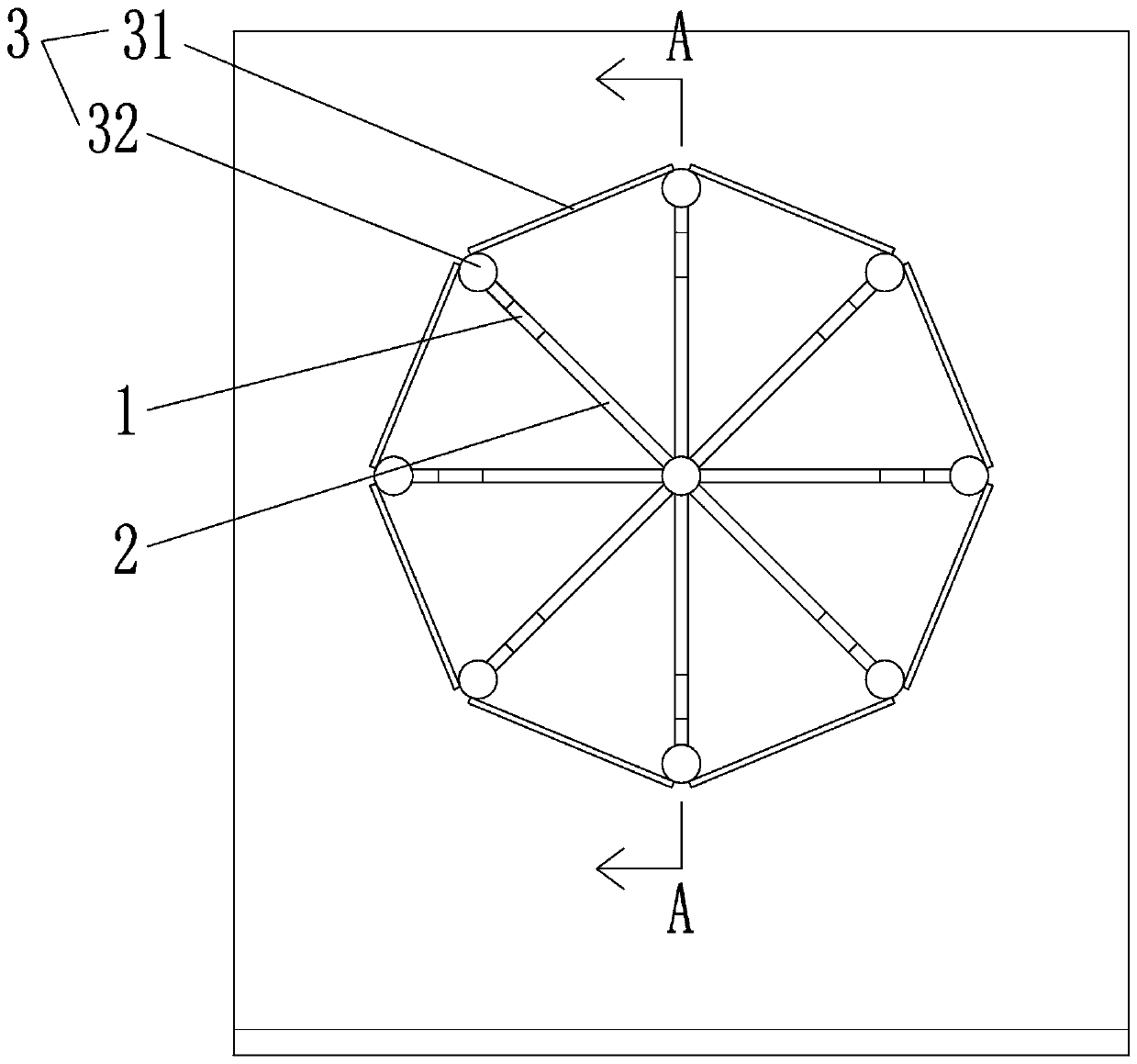

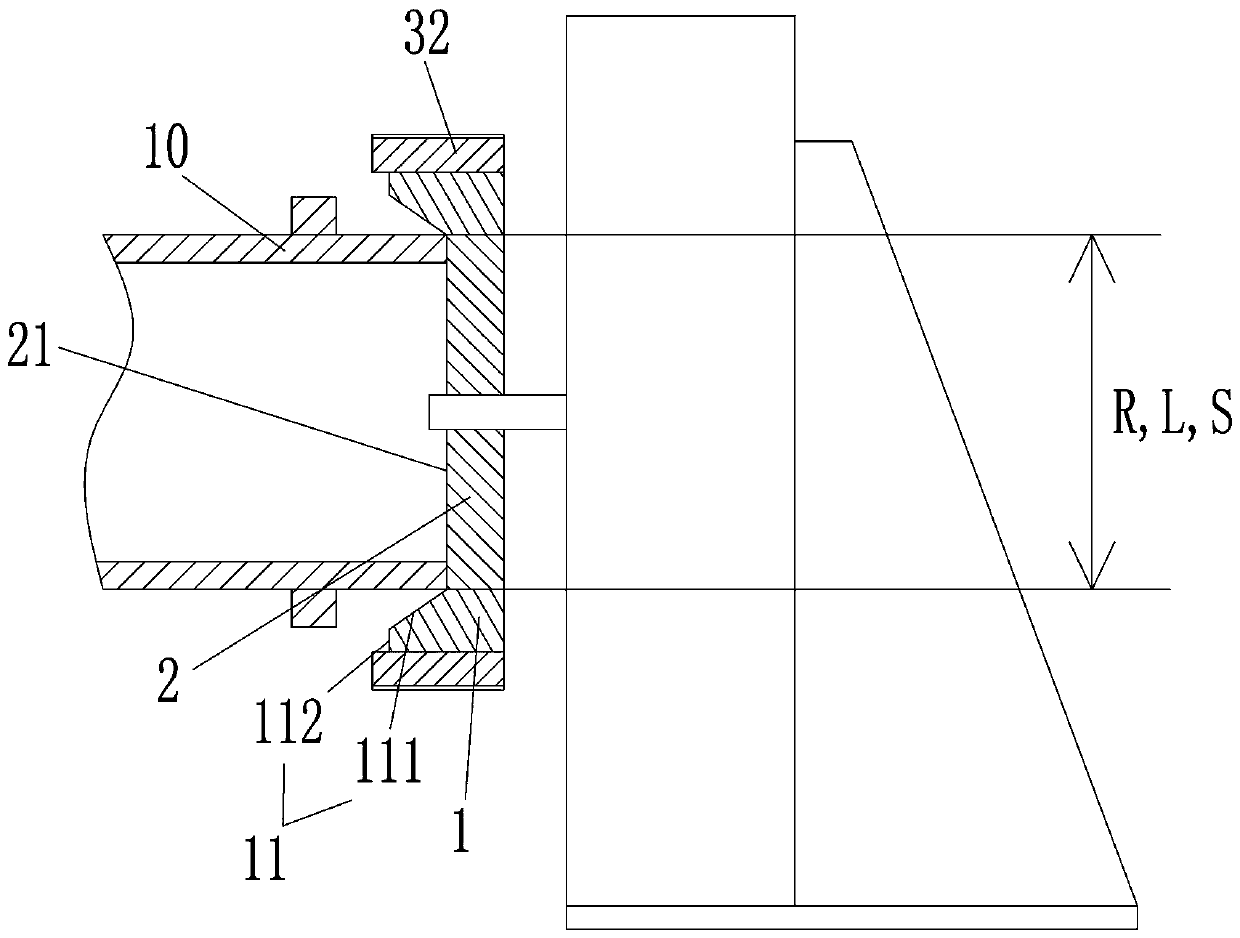

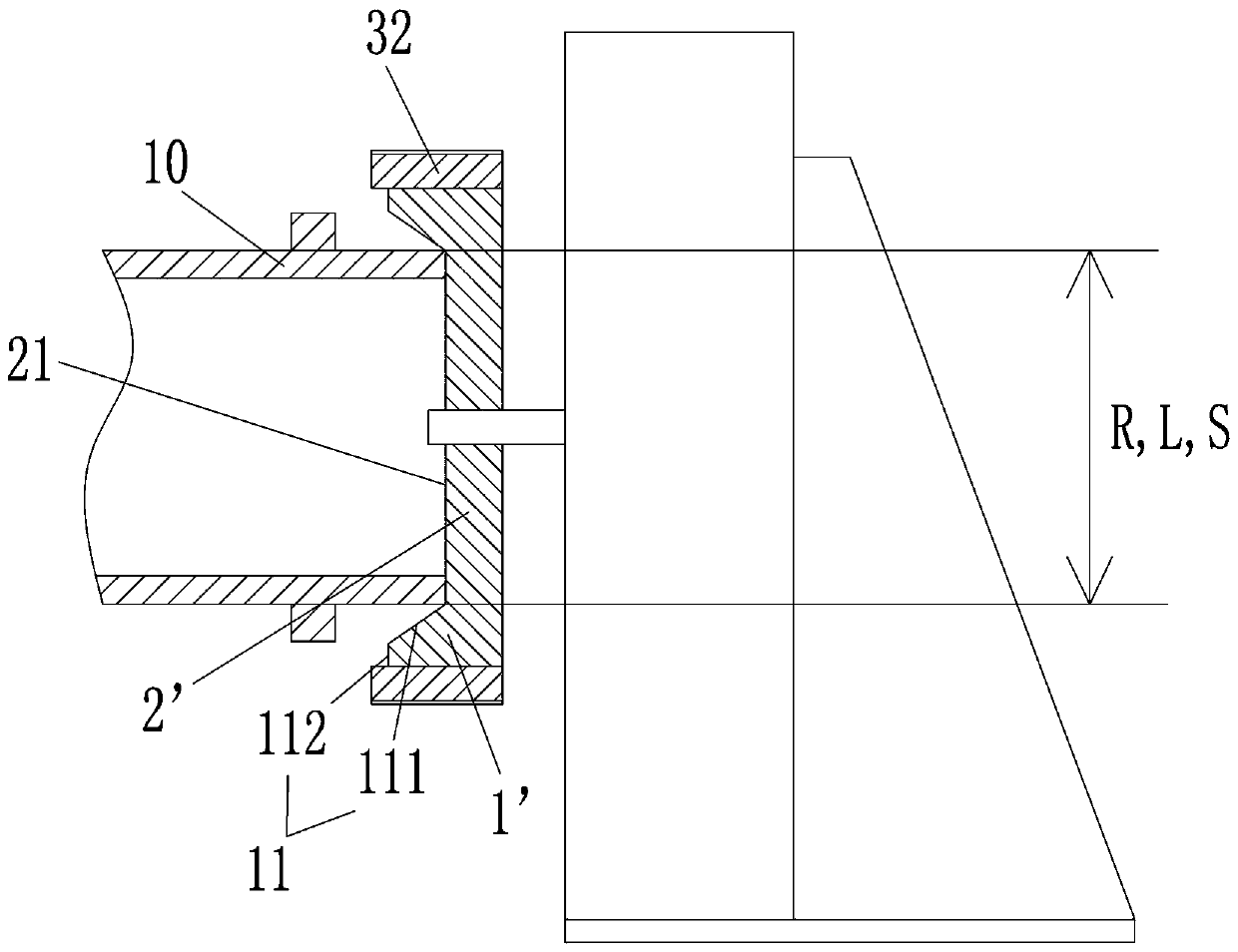

[0016] figure 1 and figure 2 The first embodiment of the slag scraper for ladle ladle according to the present invention is shown. Such as figure 1 and figure 2 As shown, a slag scraper for ladle ladle includes several scrapers, the scrapers include fixed ladle outer wall scraper 1 and ladle edge scraper 2, several fixed ladle outer wall scrapers 1 and several ladle edge The scraper 2 is distributed in a concentric spoke shape, and several scrapers 1 on the outer wall of the mouth are distributed outside the spoke-shaped outer circumferential surface formed by the scraper 2 along the mouth of the spoke-shaped mouth. In the spoke-shaped ring formed by 1; the part of the ladle outer wall scraper 1 extending from the ladle mouth to the ladle body, the side edge non-parallel to the ladle axis is the outer wall scraper blade 11, the outer wall scraper blade 11 It includes an inner edge 111 that is inclined toward the direction of the ladle body and a side edge 112 that is adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com