A suction type slag cleaner

A kind of slag cleaning machine and suction technology, applied in construction, infrastructure engineering, sheet pile walls, etc., can solve problems such as inaccessible, difficult to clean holes thoroughly, complicated installation and disassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

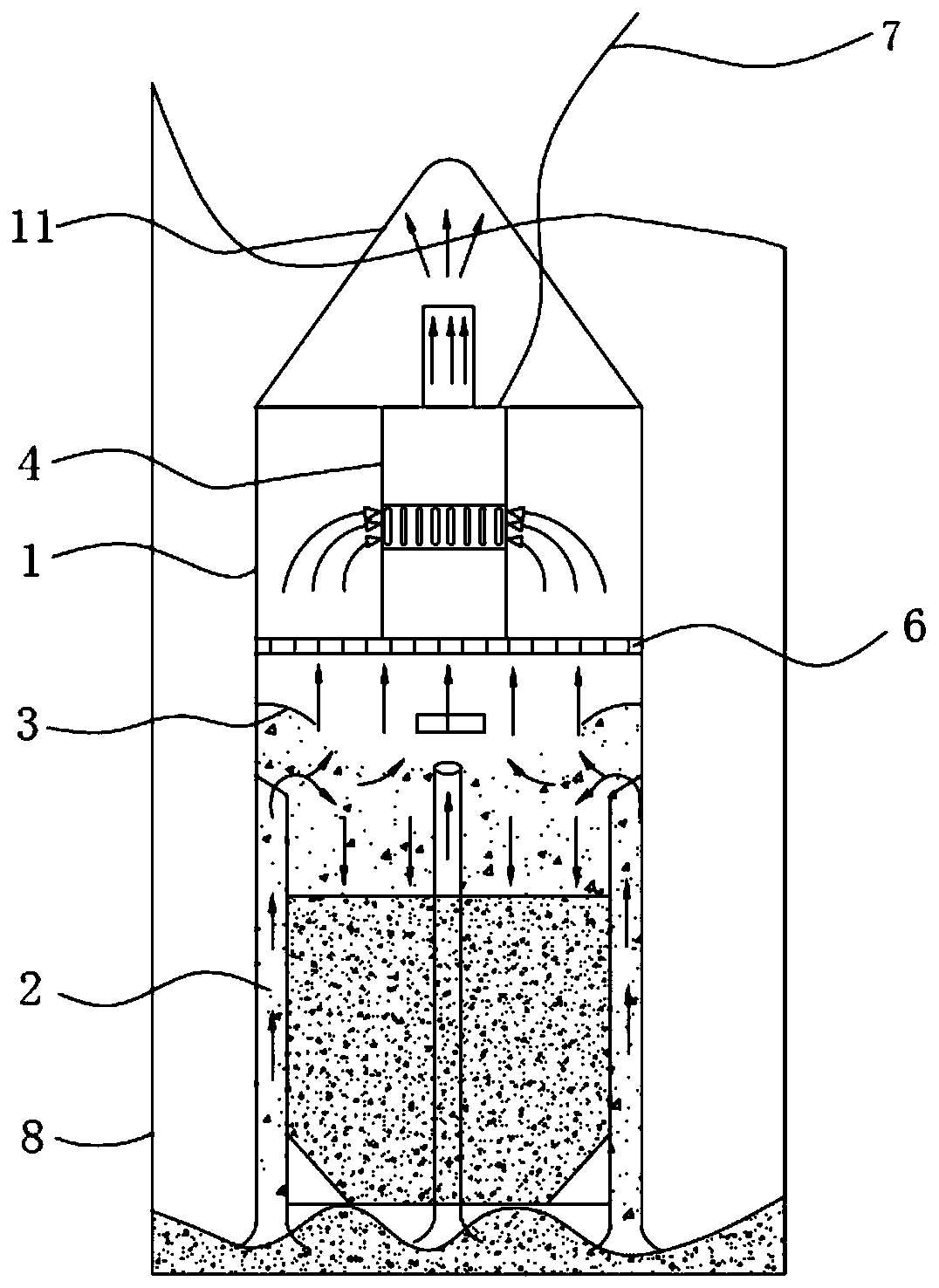

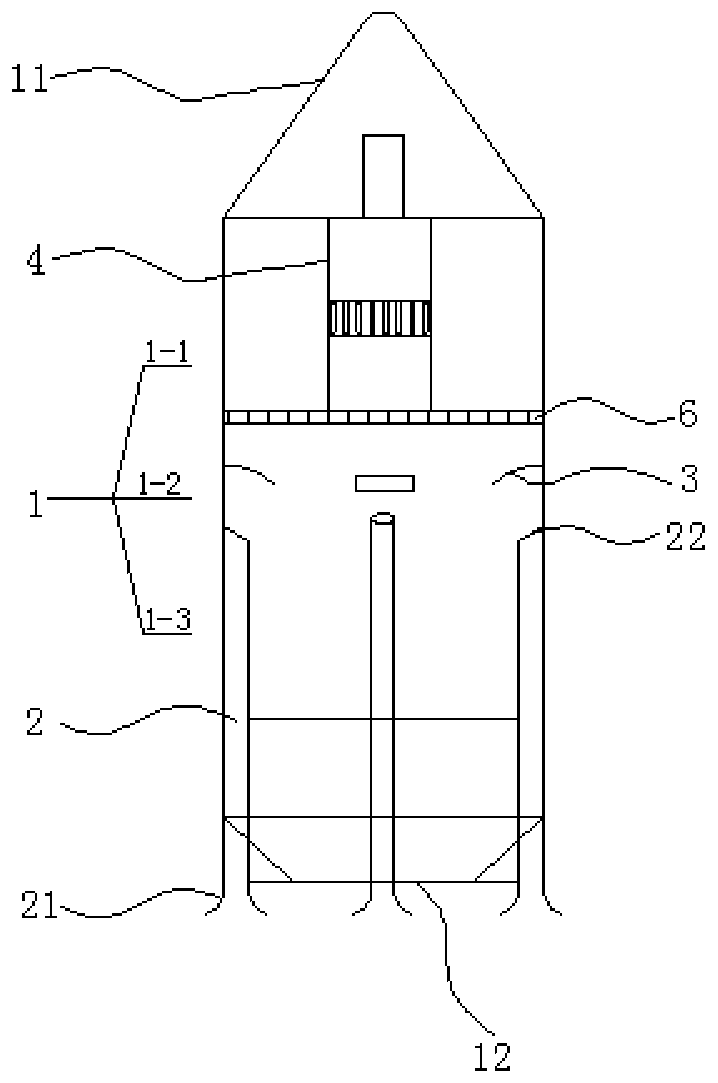

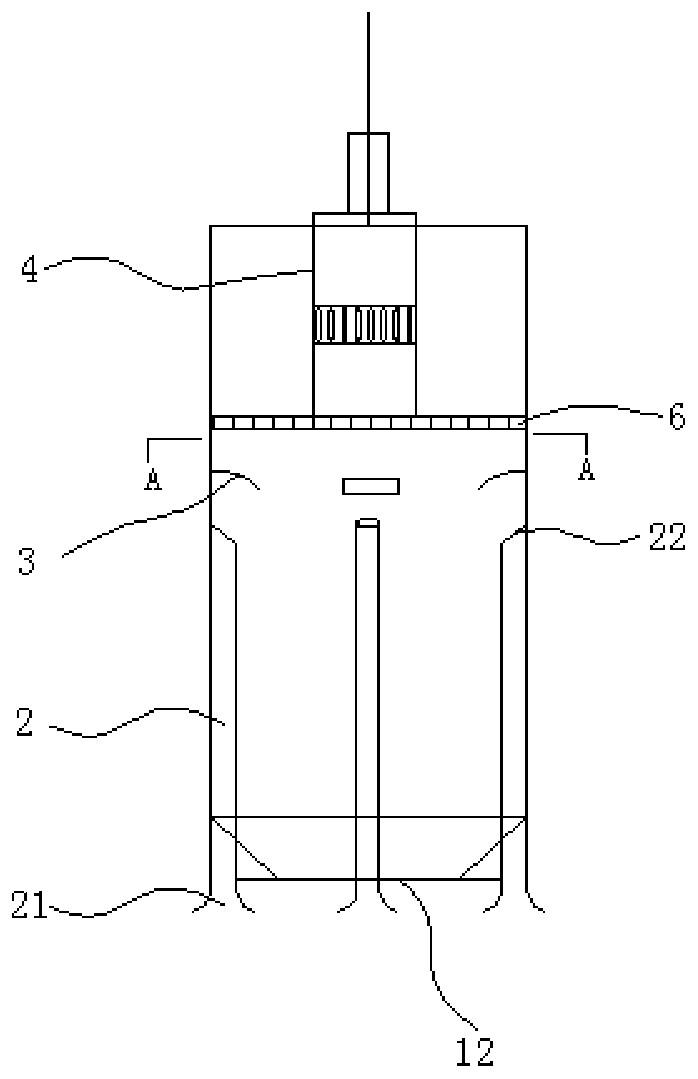

[0038] Embodiment 1: refer to Figure 1 to Figure 4 shown;

[0039] A suction type slag cleaner, comprising: a closed cylinder 1, a slag suction device 4 and at least one slag suction pipe 2.

[0040] Specifically, a boom 11 is fixedly installed on the top of the cylinder 1 for lifting and lowering the cylinder 1, and a sealed slag outlet 12 is provided at the bottom of the cylinder 1; It is installed in the cylinder body 1 in the direction, the inlet end protrudes from the bottom of the cylinder body 1, and the outlet end is arranged in the cylinder body 1; the slag suction device 4 is installed on the side above the outlet end of the slag suction pipe 2 for producing cylinder The negative pressure suction in the body 1 and the slurry after the separation of the sludge-serum mixture is sucked and discharged; the sediment-slurry mixture in the borehole / well 8 is diffused into the cylinder through the slag suction pipe 2 under the suction of the slag suction device 4, The sed...

Embodiment 2

[0052] The structure of embodiment 2 is similar to embodiment 1, with reference to Figure 5 , the difference is that:

[0053] The cylinder body 1 is equipped with at least one slurry discharge pipe 5 axially, the top of the slurry discharge pipe 5 communicates with the outlet end of the slag suction device 4, and the bottom end of the slurry discharge pipe 5 protrudes from the cylinder body 1. Preferably, A slurry discharge pipe 5 is installed on the central axis of the cylinder body 1 .

[0054] The slurry discharged from the discharge port of the slag suction device 4 is discharged to the center of the borehole / well 8 through the slurry discharge pipe 42, which can fully mix the sludge and the slurry, thereby increasing the cleaning speed of the sludge.

Embodiment 3

[0056] The structure of embodiment 3 is similar to that of embodiment 1, the difference is that the slag suction device 4 is driven by a built-in battery.

[0057] In this way, it is convenient to use in the field and in areas where power supply is inconvenient, so that the use of the suction slag cleaner is more convenient, safer and more extensive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com