Automatic scarfing device for flame cutting of continuous casting

A flame cutting and automatic cleaning technology, which is applied to gas flame welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of slag hanging at the flame cutting edge of continuous casting slabs, and achieve the effect of good promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention are specifically described below in conjunction with the accompanying drawings:

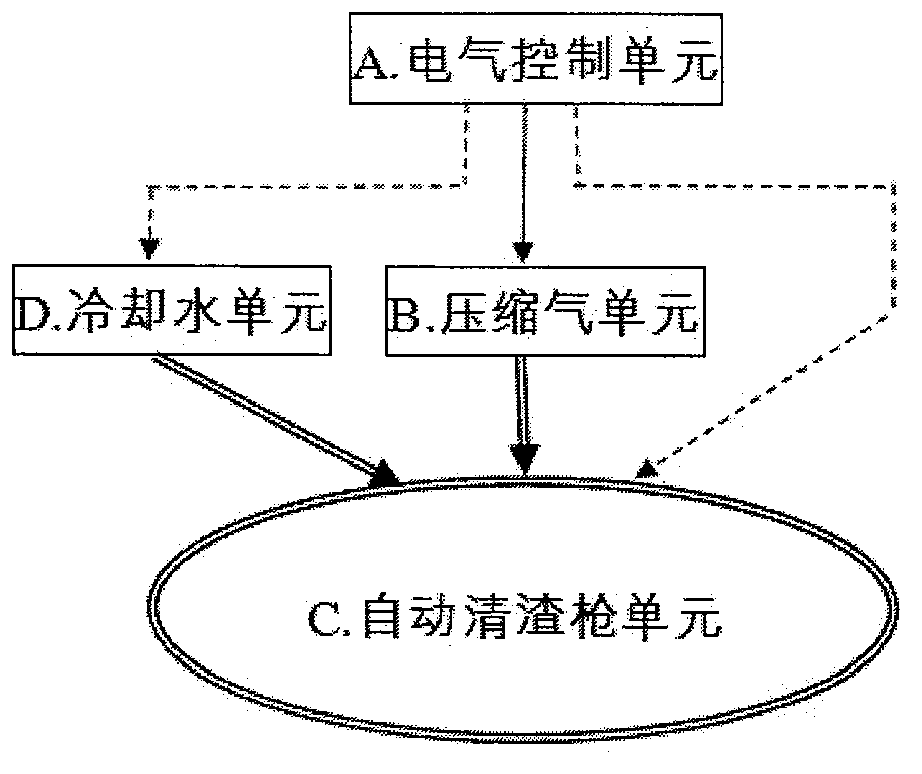

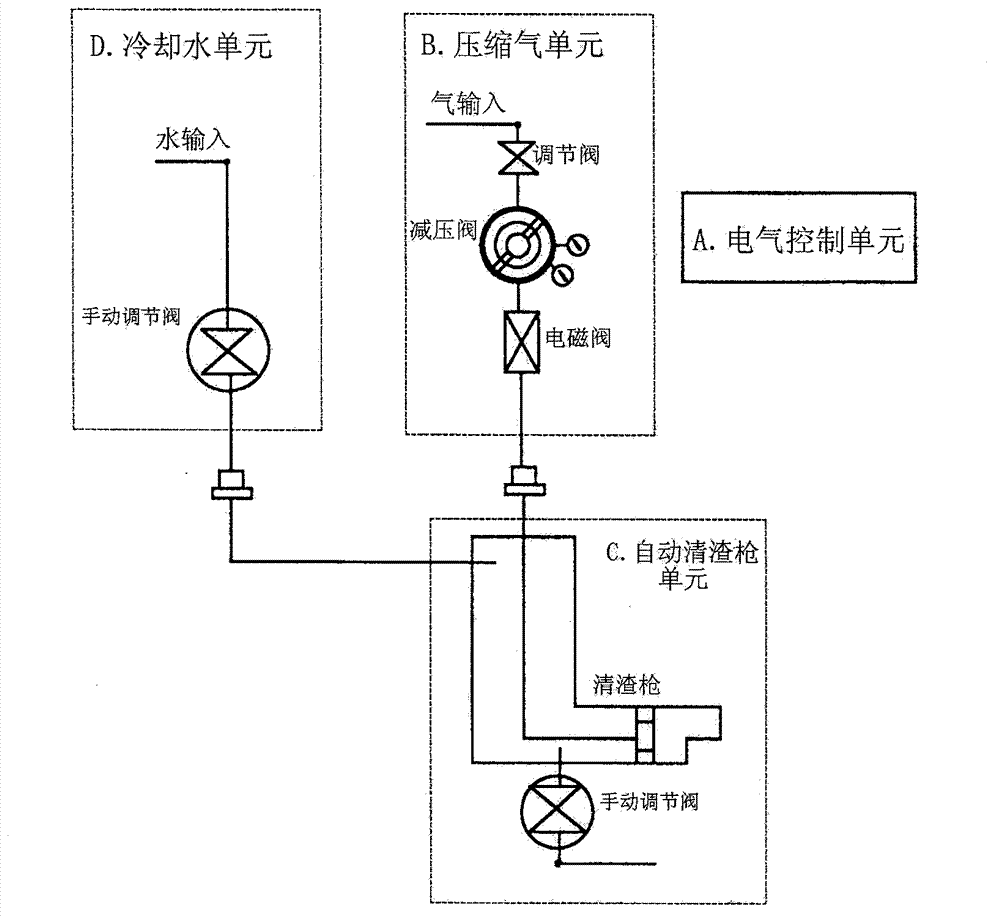

[0017] Reference attached figure 1 , 2 , The embodiment of the present invention is composed of an electrical control unit A, a compressed air unit B, an automatic slag cleaning gun unit C, and a cooling water unit D. The electrical control unit A is electrically connected to the solenoid valve in the compressed air unit B, the air outlet pipe in the compressed air unit B is connected to the corresponding inlet pipe in the automatic slag cleaning gun unit C, and the water outlet pipe in the cooling water unit D is connected to the automatic cleaning gun unit C. The corresponding water inlet pipe in the slag gun unit C is connected, and the automatic slag cleaning gun unit C is arranged on the positioning clamp of the continuous casting slab flame cutting device.

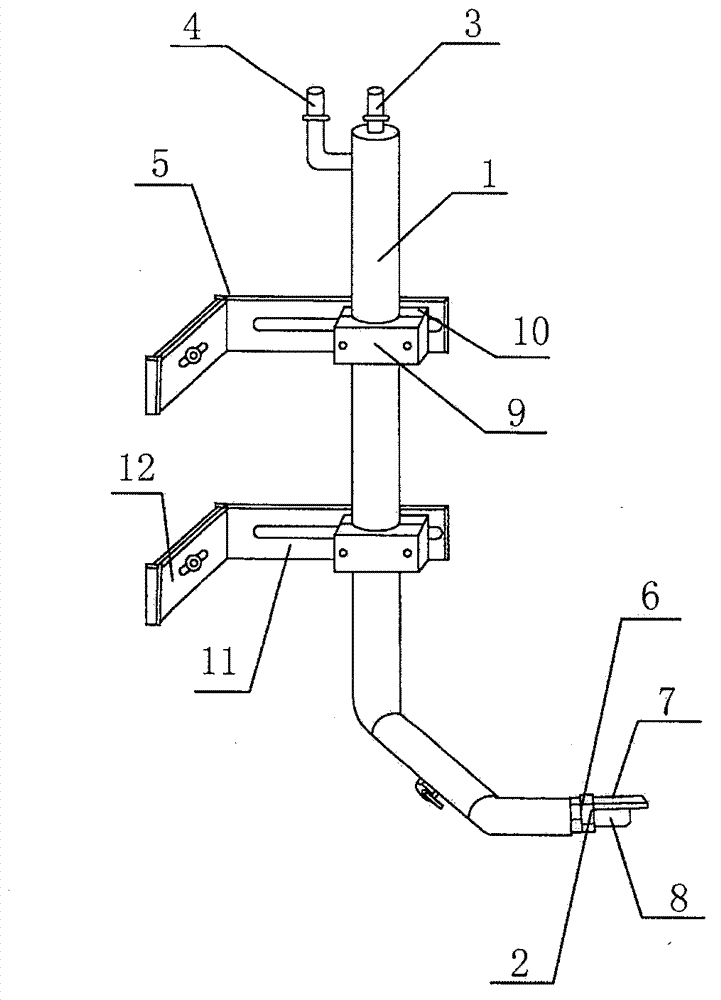

[0018] Reference attached image 3 , 4 , The automatic slag cleaning gun unit C of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com