Slag removing device and method used for molten steel vacuum treatment insert tube

A vacuum treatment device and vacuum treatment technology, which are applied in the direction of improving process efficiency, can solve the problems of destroying the vacuum treatment insertion tube, difficult to remove steel slag with high bonding strength, and slow slag cleaning speed, so as to improve the operation rate, the movement The effect of stable path and fast cleaning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

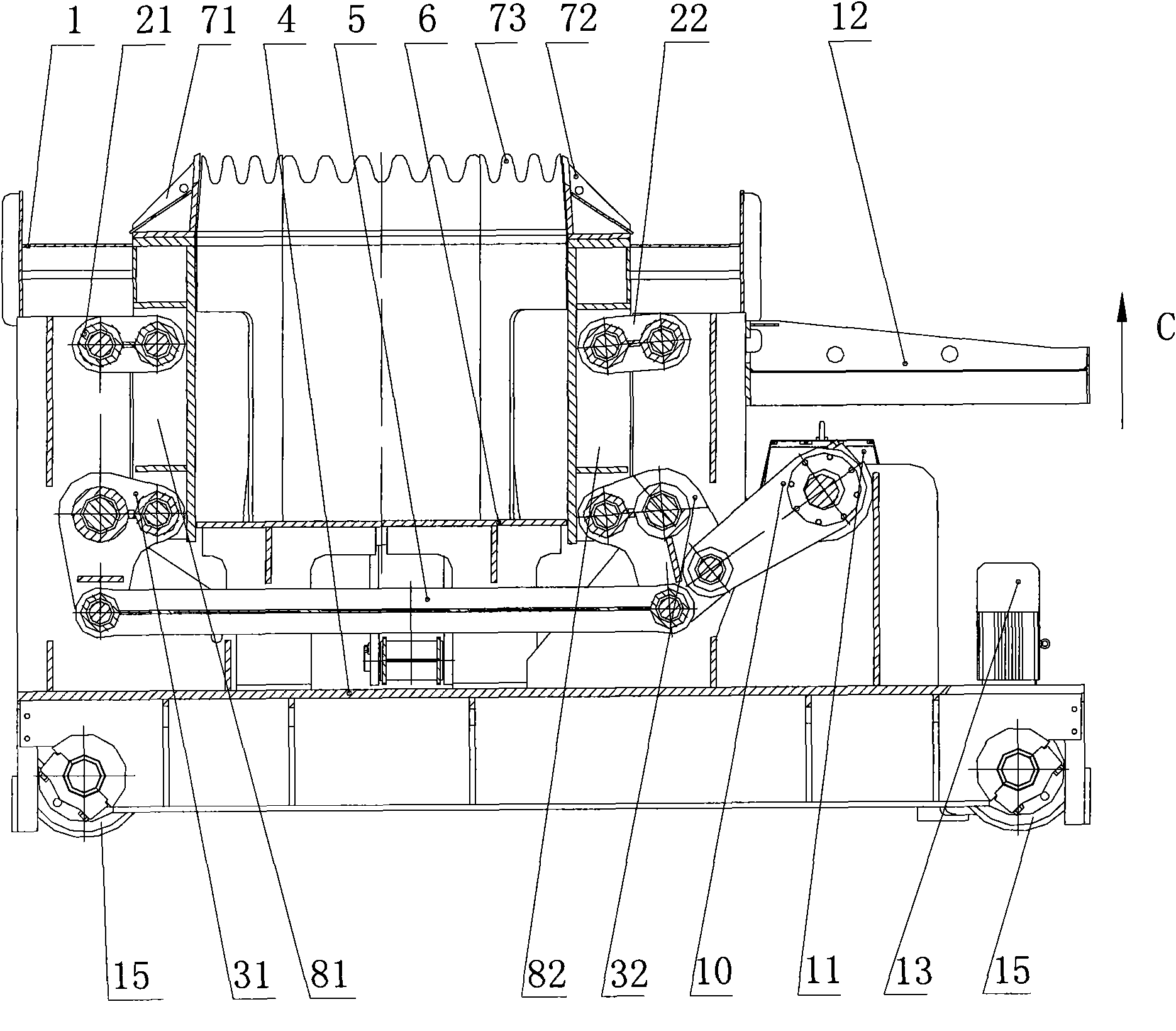

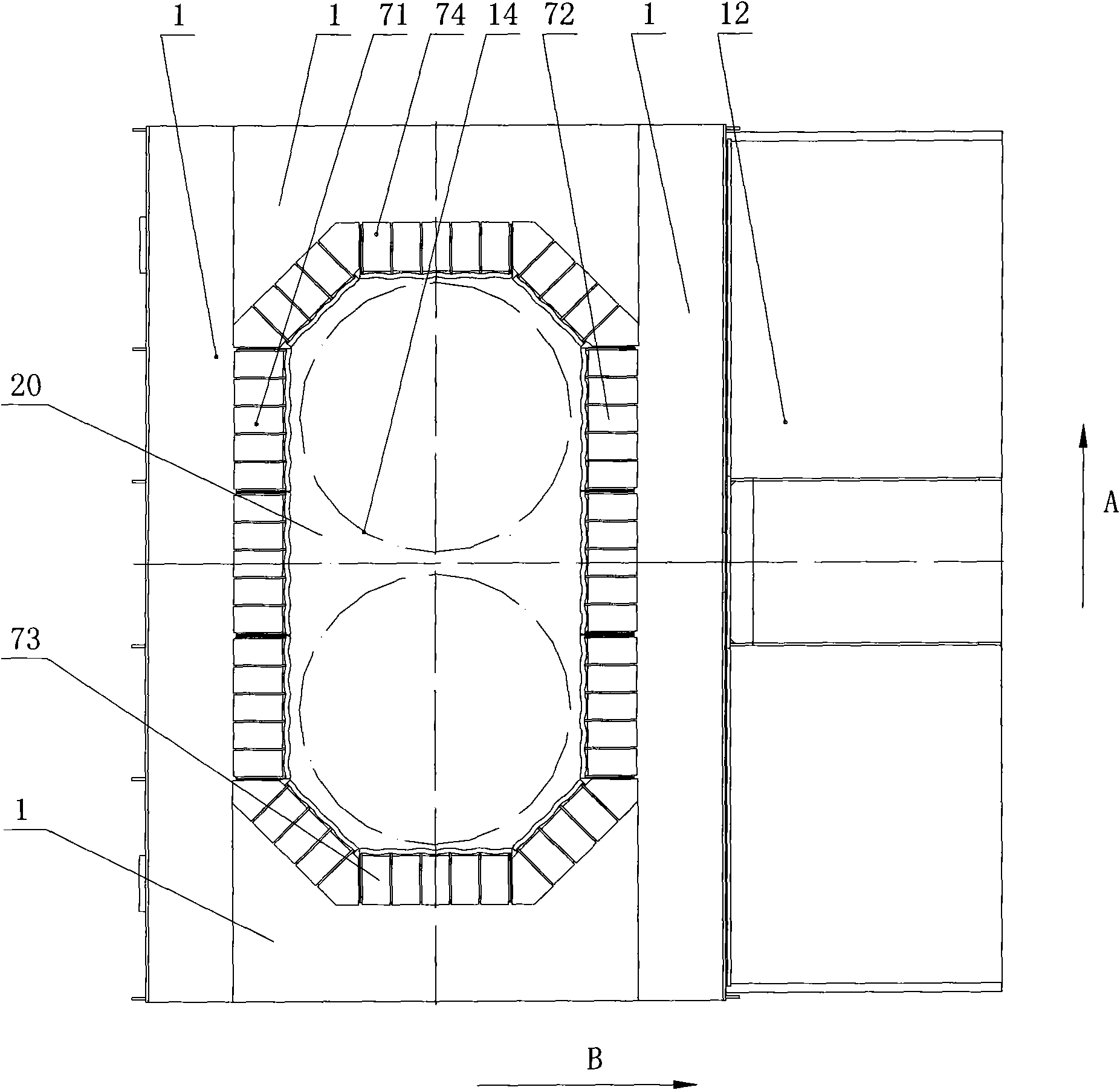

[0022] Preferably, as figure 1 As shown, the slag cleaning device further includes a walking device arranged on the body 4 to facilitate the movement of the slag cleaning device during the working process, for example, to move to a working position to perform slag cleaning operations, or to complete slag cleaning Leave the work position after the job. The walking device may be various walking devices known in the art, such as a sliding walking device, a rolling walking device, etc. As a specific implementation, the walking device includes wheels 15 driven by a motor 13.

[0023] The above-mentioned motors 11 and 13 can be various motors known in the art, such as variable speed motors. A protective cover 12 may be provided above the motors 11 and 13 to prevent the thermal radiation of the molten steel vacuum treatment insertion tube 14 and the scattered steel slag from damaging the motors 11 and 13.

[0024] The present invention also provides a slag removal method for the vacuum t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com