Submerged-arc welding metal core weldingwire for austenite stainless steel

An austenitic stainless steel, submerged arc welding technology, applied in arc welding equipment, metal processing equipment, welding medium and other directions, can solve the problems of complex production process, reduced production efficiency, complex manufacturing process, etc., and achieves simple and convenient production process. The effect of improving production efficiency and stable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

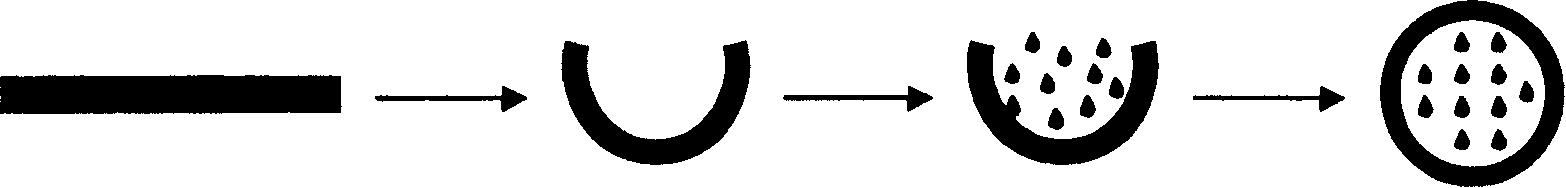

Method used

Image

Examples

specific Embodiment approach

[0026] Several examples of metal-cored wires for submerged arc welding in the present invention are selected to compare the welding effect with the solid wire H00Cr19Ni12Mo2 for submerged arc welding commonly used in production. The base material is A316L, and its chemical composition is shown in Table 1. The submerged arc flux is HJ260, dried at 400°C before welding, and kept warm for 2 hours. Welding grooves and weld samples are selected in accordance with GB / T17854-199 and GB4334.5-90. The specific implementation is as follows:

[0027] 1. Select 14×0.5 (width 14mm, thickness 0.5mm) low-carbon steel strip with a filling rate of 40%, and obtain a welding wire with a diameter of 4mm after drawing and diameter reduction. The mass percentage of each alloy element in the metal core is: 55% Cr, 31% Ni, 3% Mn, 4% Fe, 4% Mo, 1% Bi 2 o 3 . , 2% Al-Mg.

[0028] 2. Select 14×0.5 (14mm in width and 0.5mm in thickness) low-carbon steel strip with a filling rate of 44%. After drawi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com