Hollow tungsten electrode TOPTIG welding method

A tungsten electrode and hollow technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of small welding current and limited welding range, so as to increase the area, increase the welding wire deposition rate, and increase the welding capacity. The effect of the current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

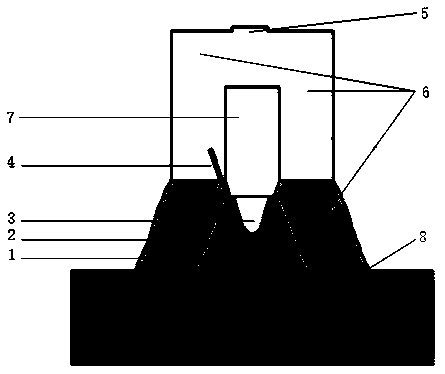

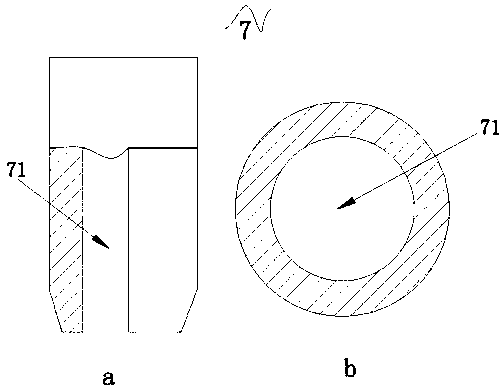

[0019] combine figure 1 and figure 2 , in an embodiment of the present invention, a hollow tungsten electrode TOPTIG welding method is provided, the method is realized by a TOPTIG welding torch, the tungsten electrode in the TOPTIG welding torch is set as a hollow tungsten electrode 7, and the hollow tungsten electrode 7 is used to generate a welding arc 2; and the top position of the hollow tungsten pole 7 is provided with a gas inlet 5, the hollow tungsten pole 7 is provided with an inner hole 71, and the two sides of the lower end of the hollow tungsten pole 7 are set at 20° to the vertical direction, and in A gas outlet 3 is provided at the center position of the lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com