Dephosphorization converter bottom maintaining method

A dephosphorization converter and furnace bottom technology, which is applied in the direction of manufacturing converters, etc., can solve the problems of poor adhesion of dephosphorization furnace slag, inability to adhere to the furnace wall, and failure to protect the furnace lining, so as to ensure the bottom blowing effect and protect the furnace. Furnace lining and bottom, the effect of reducing the consumption of lime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

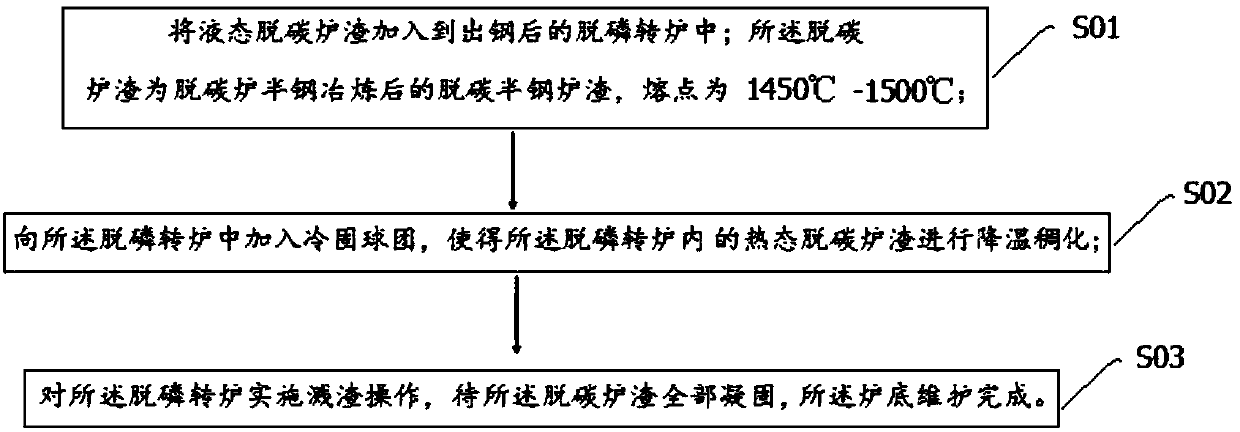

[0028] The method for maintaining the bottom of the dephosphorization converter according to the embodiment of the present invention, the method includes:

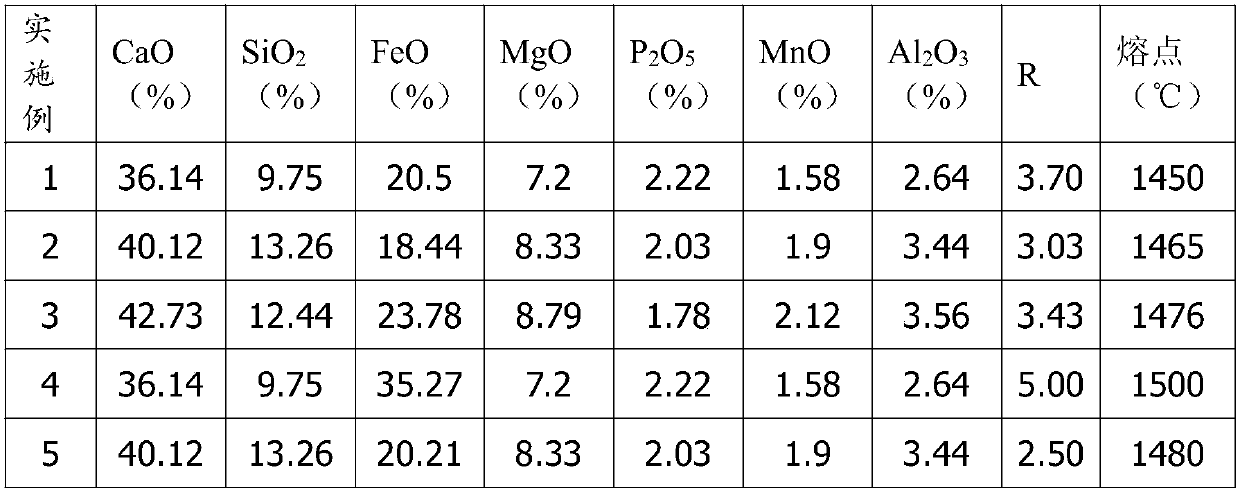

[0029] S101: Pour the liquid decarburized slag after smelting semi-steel in the decarburization furnace into the feeding device; the decarburized slag is decarburized semi-steel slag with a melting point of 1450°C; the composition of the decarburized slag is shown in Table 1 ; The basicity R of the decarburized slag is 3.7;

[0030] Pour the decarburized slag into the dephosphorized converter after tapping through a feeding device; the feeding device is a slag tank; the capacity of the dephosphorized converter is 300t, and the amount of added decarburized slag is 10t;

[0031] S102: Add cold solidified pellets to the dephosphorization converter, so that the hot decarburization slag in the dephosphorization converter is cooled and thickened; the amount of cold solidified pellets is based on the next batch of molten iron ent...

Embodiment 2

[0035] The method for maintaining the bottom of the dephosphorization converter according to the embodiment of the present invention, the method includes:

[0036] S201: Pour the liquid decarburized slag after smelting semi-steel in the decarburization furnace into the feeding device; the decarburized slag is decarburized semi-steel slag with a melting point of 1465°C; the composition of the decarburized slag is shown in Table 1 ; The basicity R of the decarburized slag is 3.03;

[0037] The decarburization slag is poured into the dephosphorization converter after tapping through the feeding device; the feeding device is a slag tank, and the slag irrigation is provided with a diversion nozzle to prevent the process of mixing slag from spreading; the capacity of the dephosphorization converter is 300t, the addition of described decarburization slag is 10t;

[0038] S202: Add cold-fixed pellets to the dephosphorization converter, so that the hot decarburization slag in the deph...

Embodiment 3

[0042] The method for maintaining the bottom of the dephosphorization converter according to the embodiment of the present invention, the method includes:

[0043] S301: Pour the liquid decarburized slag after smelting semi-steel in the decarburization furnace into the feeding device; the decarburized slag is decarburized semi-steel slag with a melting point of 1476°C; the composition of the decarburized slag is shown in Table 1 ; The basicity R of the decarburized slag is 3.43;

[0044] Pour the decarburized slag into the dephosphorized converter after tapping through a feeding device; the feeding device is a slag tank; the capacity of the dephosphorized converter is 300t, and the amount of added decarburized slag is 20t;

[0045]S302: Add cold-fixed pellets to the dephosphorization converter, so that the hot decarburization slag in the dephosphorization converter is cooled and thickened; the amount of cold-fixed pellets is based on the temperature of molten iron, the amount ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com