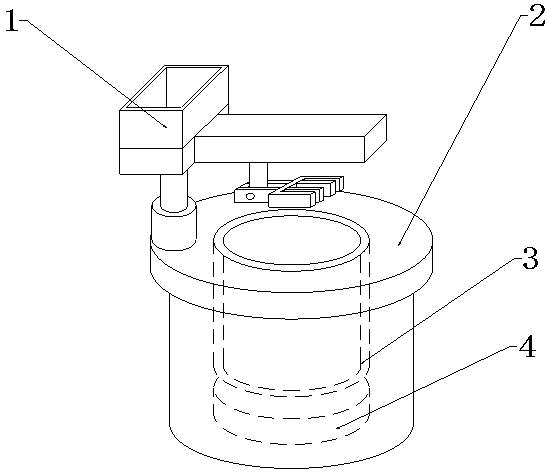

Smelting furnace slagging-off device

A smelting furnace and slag removal technology, which is applied in the direction of descaling devices, furnaces, furnace components, etc., can solve the problems of low specific gravity, increased labor workload of staff, and no slag accumulating agent storage mechanism, etc., achieving fast slag removal speed, The effect of increasing labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

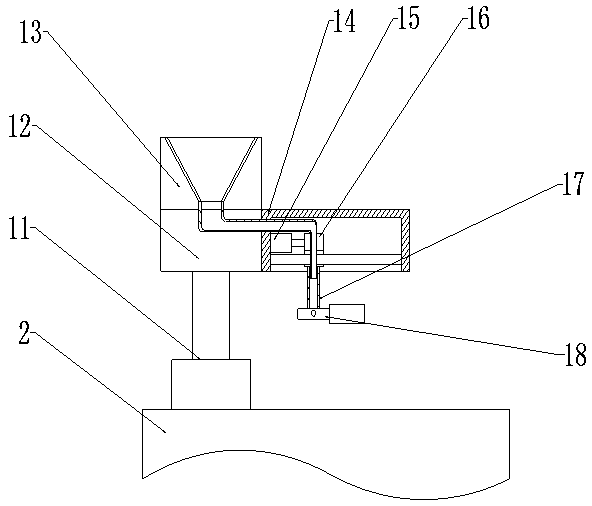

[0019] Specific implementation method: when in use, the user first opens and puts the metal to be processed into the hearth 3, then the user opens the heating mechanism 4, the heating mechanism 4 works to melt the metal to be processed, and then the user opens the electric cylinder 11, The electric cylinder one 11 works to make the fixed block 12 move down, the fixed block 12 moves down to drive the connecting frame 14 to move down, the connecting frame 14 moves down to drive the moving block 16 to move down, and the moving block 16 moves down to drive the hollow cylinder 17 moves downward, and the hollow cylinder 17 moves downward to make the telescopic tube elongate. When the hollow cylinder 17 moves downward to a certain position, the electric cylinder one 11 is closed, and then the user pours the slag-accumulating agent into the feed box 13 , and then the slagging agent enters into the furnace hearth 3 through the telescopic tube under the action of gravity, and then the us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com