Composite ferromanganese mineral ball for steelmaking

A technology of iron ore balls and manganese oxide ore, which is applied in the field of slag-making balls for steelmaking, and can solve the problems of difficult control of the addition amount, inconspicuous effect of slagging, and splashing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] For further describing the present invention, below in conjunction with embodiment and comparative example the present invention is described in more detail, but the present invention is not limited to these examples, as the manganese grade of manganese oxide ore powder, the iron grade of iron powder ore can be lower or higher than embodiment .

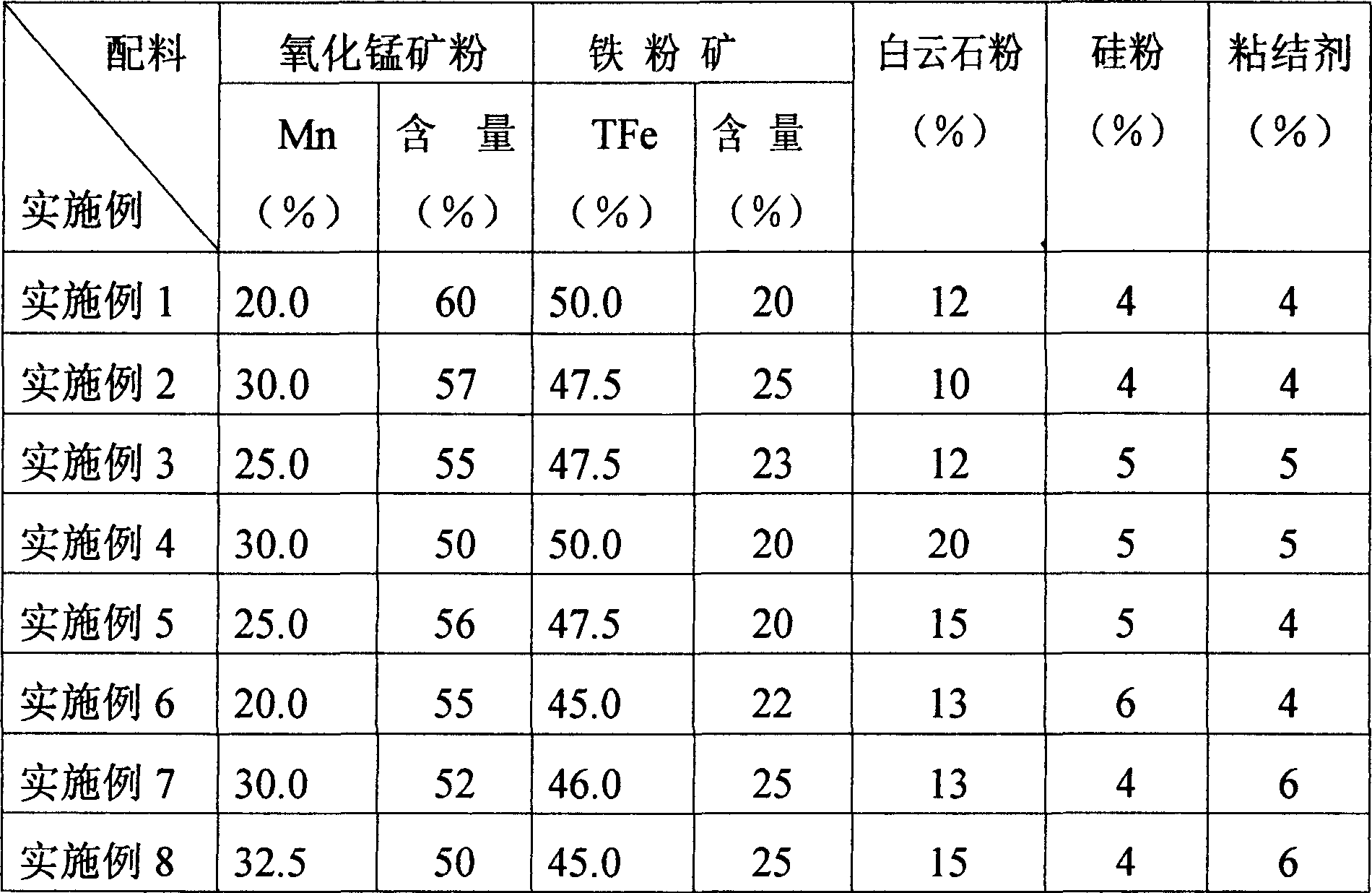

[0022] Mn20%-30% manganese oxide ore powder with a particle size of 0-2mm, iron powder ore with a particle size of 0-3mm TFe45%-50%, dolomite powder with a particle size of 0-2mm, and a particle size of 0-3mm The silicon powder of 2mm, bonding agent prepare steelmaking composite manganese iron ore ball of the present invention according to grade (Mn%, TFe%) shown in table 1, each component content (weight %):

[0023] Table 1

[0024]

[0025] After mixing the components of the composite manganese iron ore ball for steelmaking in the present invention according to the general method, add an appropriate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com