Method for increasing residual manganese content in molten steel at end point of converter

A converter end point and content technology, which is applied in the field of steelmaking technology, can solve the problems that the tapping temperature cannot meet the requirements of tapping, the unfavorable cleanliness of molten steel, and the reduction of molten steel in the furnace, etc., so as to prevent rephosphorization and tapping Effects of lowering slag, reducing converter blowing loss, and reducing steelmaking cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

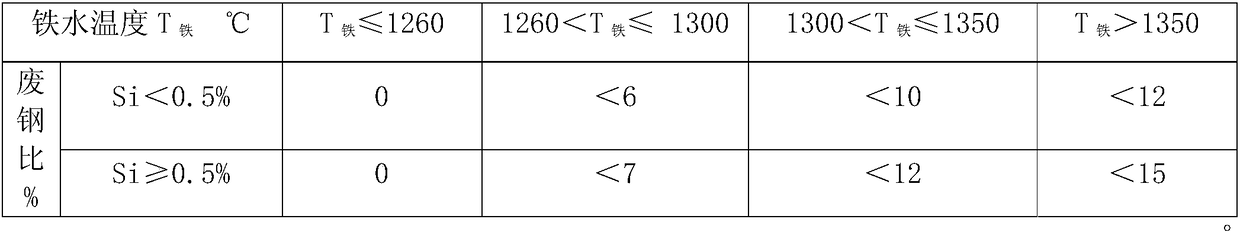

[0043] Table 1 shows the conditions of molten iron and steel scrap mixed into the converter for blowing low-carbon steel with a steel carbon requirement of 0.05-0.10%.

[0044] Table 1 The situation of molten iron and steel scrap blended into the converter

[0045] C%

Si%

Mn%

P%

S%

T 铁 ℃

Amount of molten iron t

Amount of scrap steel t

4.02

0.46

0.12

0.075

0.005

1290

101

6

[0046] The total amount of lime added is converted according to the effective CaO content of 80%, the adjustment coefficient λ value of 1.1, and the final slag basicity of 3.0. The amount of added iron per ton is:

[0047] Then, the total amount of lime that needs to be added is: 40.59×101=4099.59kg≈4.1t.

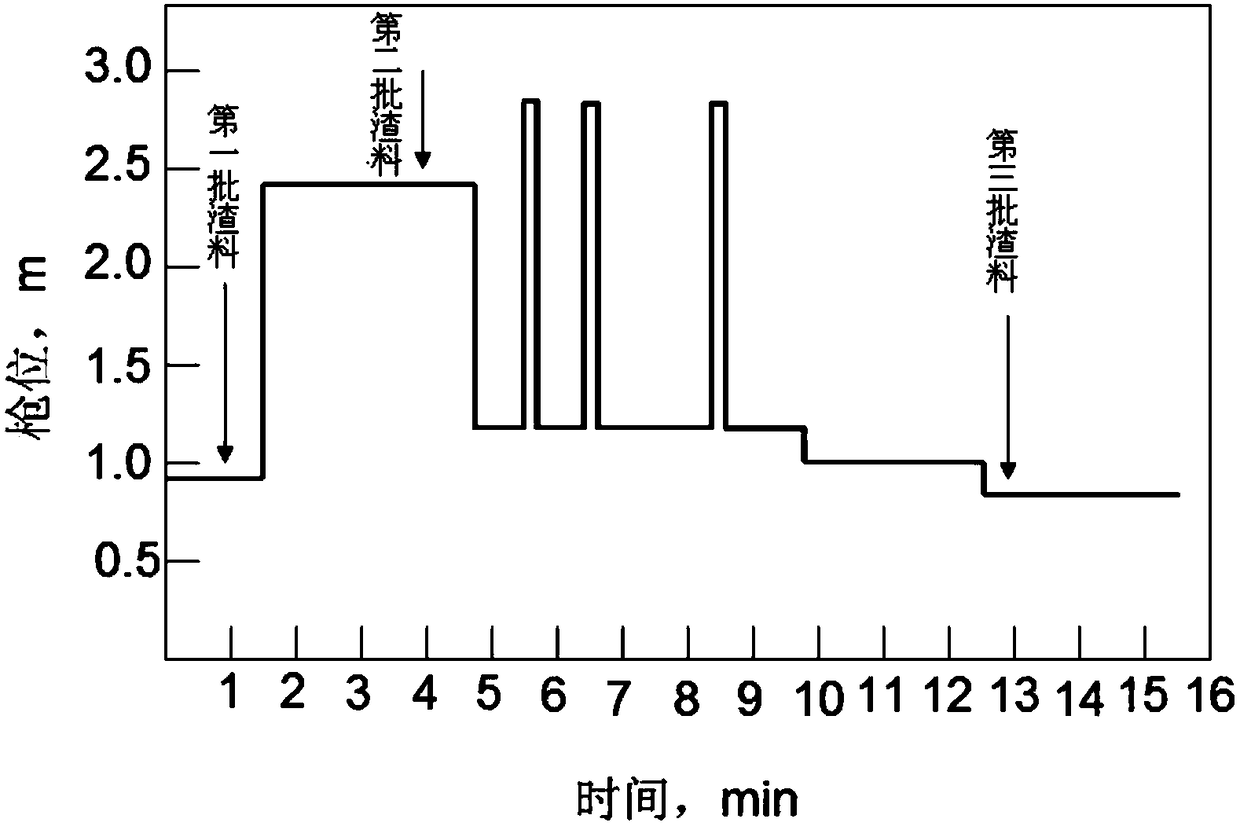

[0048] When blowing oxygen in the lowering lance, first add 2.5t of lime and 0.5t of iron carbon balls to the first batch of slag, add the second batch of lime slag after blowing for 4.5min, the addition amount is 0.48t, and 3min befor...

Embodiment 2

[0058] Table 3 shows the conditions of molten iron and steel scrap that are blended into the converter for blowing high-carbon steel with a steel carbon requirement of 0.35-0.60%.

[0059] Table 3 The situation of molten iron and steel scrap blended into the converter

[0060] C%

Si%

Mn%

P%

S%

T 铁 ℃

Amount of molten iron t

Amount of scrap steel t

4.14

0.52

0.13

0.070

0.005

1330

102

5

[0061] The total amount of lime added is converted according to the effective CaO content of 80%, the adjustment coefficient λ value of 1.0, and the final slag basicity of 3.0.

[0062] It can be seen that the amount of iron added per ton is:

[0063] Then, the total amount of lime that needs to be added is: 45.9×102=4681.8kg≈4.7t.

[0064] When blowing oxygen in the lowering lance, first add 2.8t of lime to the first batch of slag, and add 0.6t of iron carbon balls. After blowing for 5 minutes, add the second batch of lime a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com