Pyrolusite blocks and production thereof

A technology for pyrolusite and manganese ore, which is applied in the field of pyrolusite-bonded agglomeration and its preparation, can solve the problems of limited resources of pyrolusite, cannot be used directly, and is easily blown away by hot air, and can reduce splashing and processing costs in converters. Low, strong bond effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

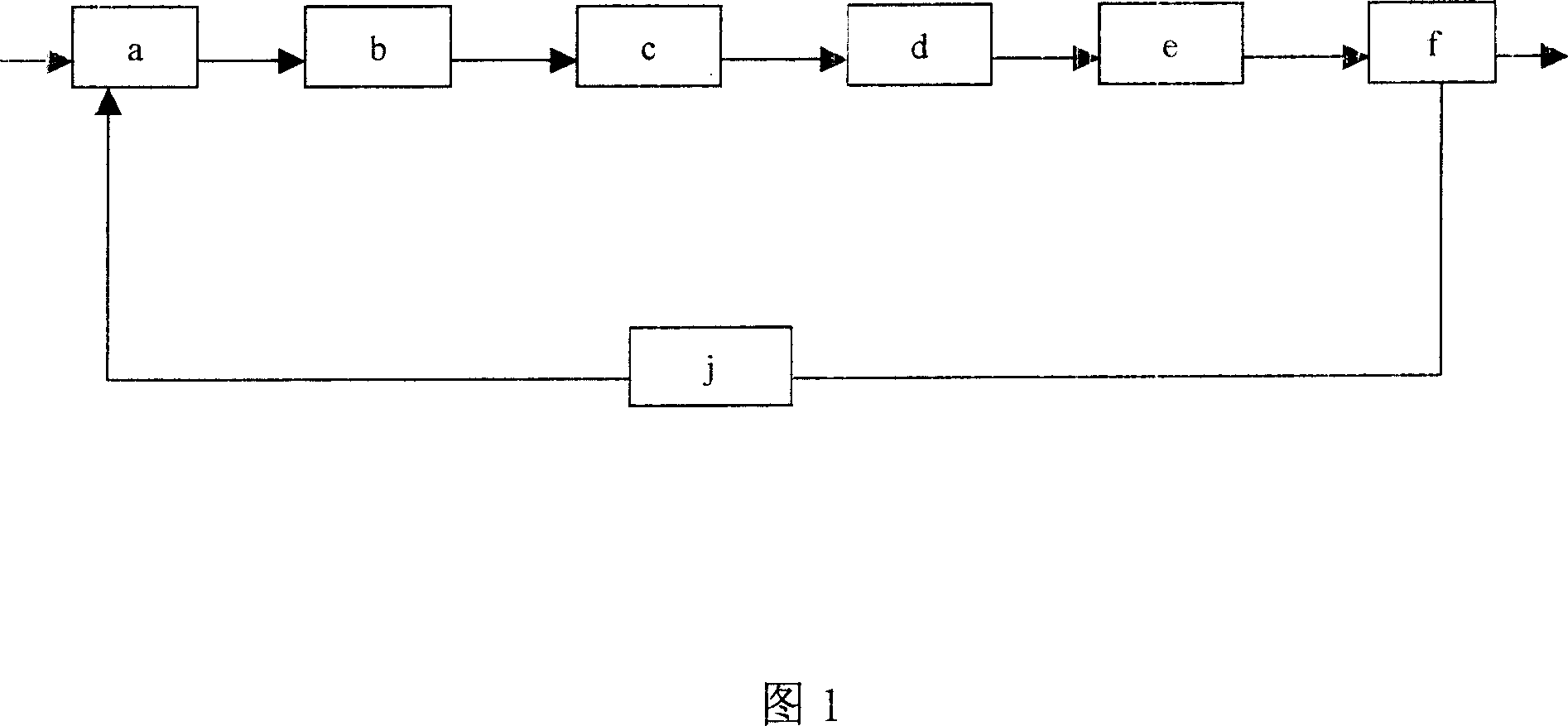

Method used

Image

Examples

Embodiment 1

[0023] Under normal temperature and pressure, mix 3% of sodium pyrolusite, 3% of dextrin, 2% of gypsum powder, 2% of Si-containing or non-Si-containing cement, and 1% of urea into 80% of pyrolusite powder according to Table 1. , add 2% water and stir in a blender, fully mix; after aging, the wet material is pressed into a block in a ball press; naturally dried in the air, then sieved, weighed, and bagged. The Si-containing cement block was used as the blast furnace washing material, and the Si-free cement block was used as the slagging agent, coolant, and alloy element addition material for steelmaking. The test results are listed in Table 1.

Embodiment 2

[0025] Repeat the method of Example 1 by the specified component content in Table 1, and the test results are listed in Table 1.

Embodiment 3

[0027] Repeat the method of Example 1 by the specified component content in Table 1, and the test results are listed in Table 1.

[0028] The content of each component (weight

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com