A method for improving the service life of the converter lining in the production of low-carbon and low-phosphorus steel

A technology for carbon and low-phosphorus steel and converter lining, which is applied in the field of improving the service life of converter lining in the production of low-carbon and low-phosphorus steel. Residual manganese content, improving the service life of the furnace lining, and the effect of lining maintenance guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

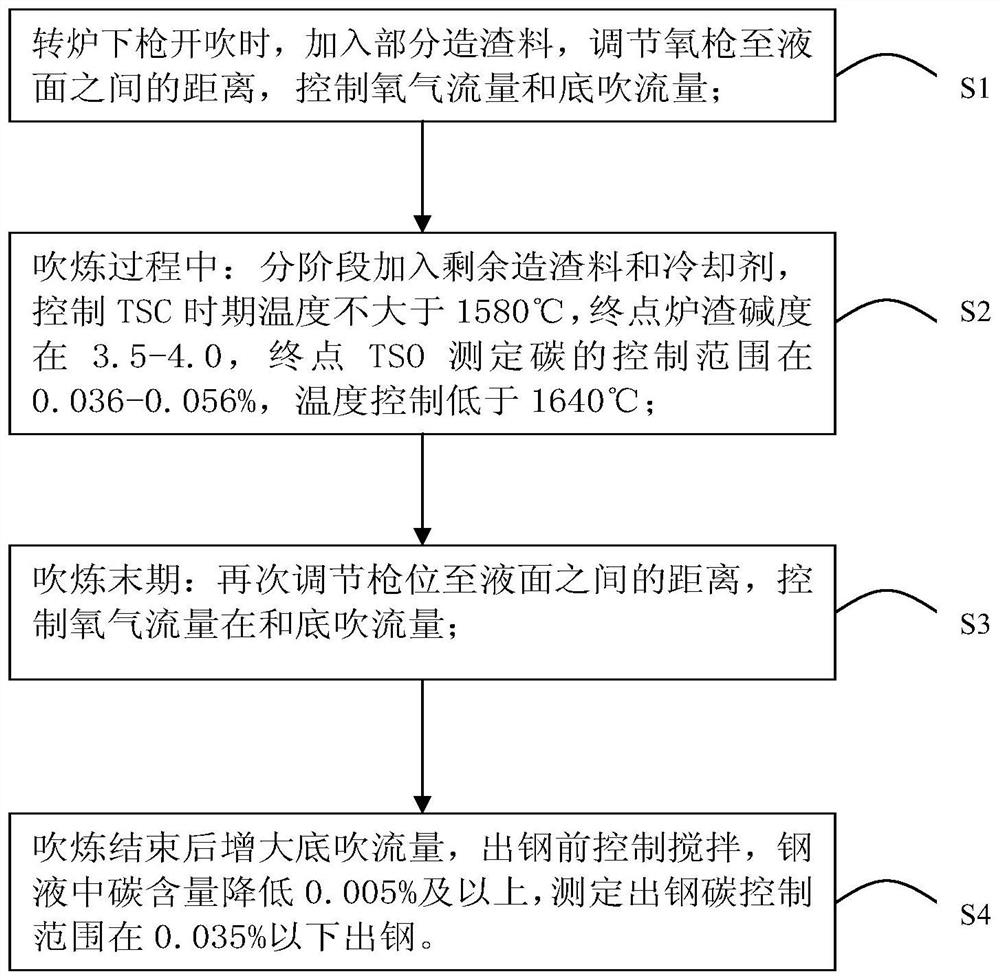

Method used

Image

Examples

Embodiment 1

[0038] S1) When the lower gun of the converter is turned on, all the lime in the slagging material is added at 36.8kg / t, the light burnt magnesium ball is added at 9.3kg / t, the limestone is added at 10kg / t for 60% of the total amount, and the dolomite is added at 16.5 Add 60% of the total amount in kg / t, adjust the distance between the oxygen lance and the liquid surface to 1.5m, and control the oxygen flow rate to 31500m 3 / h and bottom blowing flow rate is 300m 3 / h;

[0039] S2) During the blowing process: add the remaining slagging material and coolant in stages, control the temperature in the TSC period to 1575°C, the slag basicity at the end point is 3.5-4.0, the carbon measured by TSO at the end point is controlled at 0.041%, and the temperature is controlled at 1632°C;

[0040] The addition amount of the coolant is 10-20kg / t, and the addition method is: add in batches: add 30% in the middle period before blowing, add 50% in the middle period of blowing, and add 20% in...

Embodiment 2

[0046] S1) When the lower lance of the converter is turned on, all the lime in the slagging material is added at 35.76kg / t; Add 60% of the total amount at 18kg / t, adjust the distance between the oxygen lance and the liquid surface to 1.4m, and control the oxygen flow rate to 31000m 3 / h and bottom blowing flow rate is 280m 3 / h;

[0047] S2) During the blowing process: add the remaining slagging material and coolant in stages, control the temperature in the TSC period to 1564°C, the slag basicity at the end point is 3.5-4.0, the carbon at the end point TSO is controlled at 0.039%, and the temperature is controlled below 1639°C ;

[0048] The addition amount of the coolant is 10-20kg / t, and the addition method is: add in batches: add 30% in the middle period before blowing, add 50% in the middle period of blowing, and add 20% in the middle and late period of blowing; the coolant includes ore, sinter and return;

[0049] In the remaining slagging material, limestone is added...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com