A special slag system for producing 17-4ph steel ingot and its preparation and use method

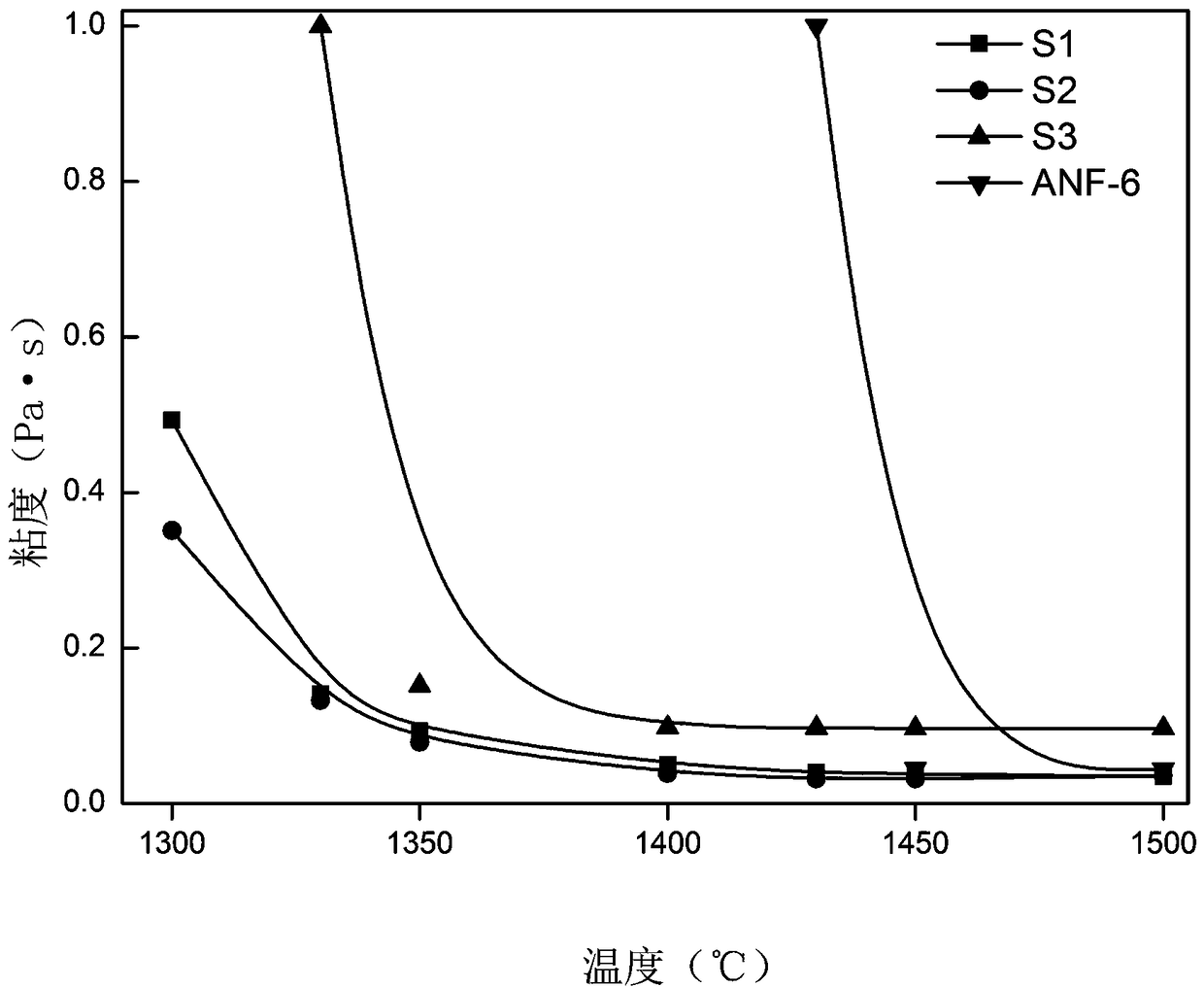

A technology of slag system and steel ingot, which is applied in the field of special slag system for energy saving and environmental protection. It can solve the problems of sudden change in viscosity, heavy skin surface quality, and low resistivity, so as to reduce fluoride volatilization, reduce environmental hazards, and improve high temperature. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] High-purity fluorite block, lime, industrial alumina powder, fused magnesia and silica are used as raw materials. After mixing the prepared raw materials, electroslag furnace graphite electrode is used to slag. After all the materials are melted, the refining is continued for 40 minutes; then casting into a cast iron plate with a bottom thickness of 60mm, cooled and solidified to room temperature, crushed by a crusher, and screened out the part with a particle size of 5-10mm to obtain precipitation-hardening martensitic powder for the production of precipitation-hardening martensitic powder by the ingot-type electroslag remelting method. The pre-melted slag of the stainless steel 17-4PH steel ingot is packaged into a 10kg bag for use in the ingot pumping electroslag furnace.

[0033] The above special slag is composed of the following components by weight percentage: Al 2 o 3 : 26.2%, CaO: 25.7%, SiO 2 : 4.89%, MgO: 5.2%, the balance is CaF 2 ; Binary alkalinity of s...

Embodiment 2

[0049] The pre-melted slag electroslag remelted 0Cr17Ni4Cu4Nb steel (namely 17-4PH) smelted in the above example 1 was used for production in a 1.5-ton electroslag furnace of an enterprise in Jiangsu.

[0050] During the electroslag remelting this time, the pre-melted slag was directly placed in the crystallizer of the electroslag furnace, and the solid slag starting process was adopted. The amount of slag used this time was 30kg, and the slag melting time was 30min. During smelting, the voltage is 57V-58V, the current is 6800A-7500A, the crystallizer specification is Ф330mm, and the electrode rod is a 205mm square rod forged by intermediate frequency furnace + refining furnace process. The actual remelting melts a 700kg steel ingot, and the melting time is 3 hours.

[0051] The surface quality of the finished electroslag ingot is good, without obvious defects such as slag grooves and nodules, and the content of S and P is low. Compared with the electrode material, the content...

Embodiment 3

[0053] Mix fluorite, quicklime, alumina, fused magnesia, and silica in proportion, melt and stir evenly, and melt at 1500~1560°C for 43 minutes; then pour it into a water-cooled slag pan made of steel plate, and cool to At room temperature, crush it to a particle size of 5-10mm to make a special slag system for the production of 17-4PH steel ingots with the above-mentioned composition content. Obtain low-pollution and energy-saving pre-melted slag for producing hollow ingots by ingot-pulling electroslag remelting, pack it into a 20kg bag, and use it in an electric slag furnace.

[0054] The above special slag is composed of the following components by weight percentage: Al 2 o 3 : 27.8%, CaO: 26.9%, SiO 2 : 4.1%, MgO: 5.9% configuration, the balance is CaF 2 ; Binary alkalinity of slag CaO / SiO 2 is 6.5.

[0055] The above pre-melted slag was used to produce electroslag remelting 17-4PH in an enterprise in Anhui. The slag melting process was started with liquid slag, that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com