Rectangular impact drill bit for declined rock groove segment during diaphragm wall construction and construction method

A technology of percussion drilling and trough section, which is applied in the direction of drill bit, sheet pile wall, drilling equipment, etc. It can solve the problems of unguaranteed, extended construction period, time-consuming and labor-intensive groove quality, etc., to overcome high cost and long construction period, and improve slag cleaning efficiency , The effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following non-limiting examples serve to illustrate the invention.

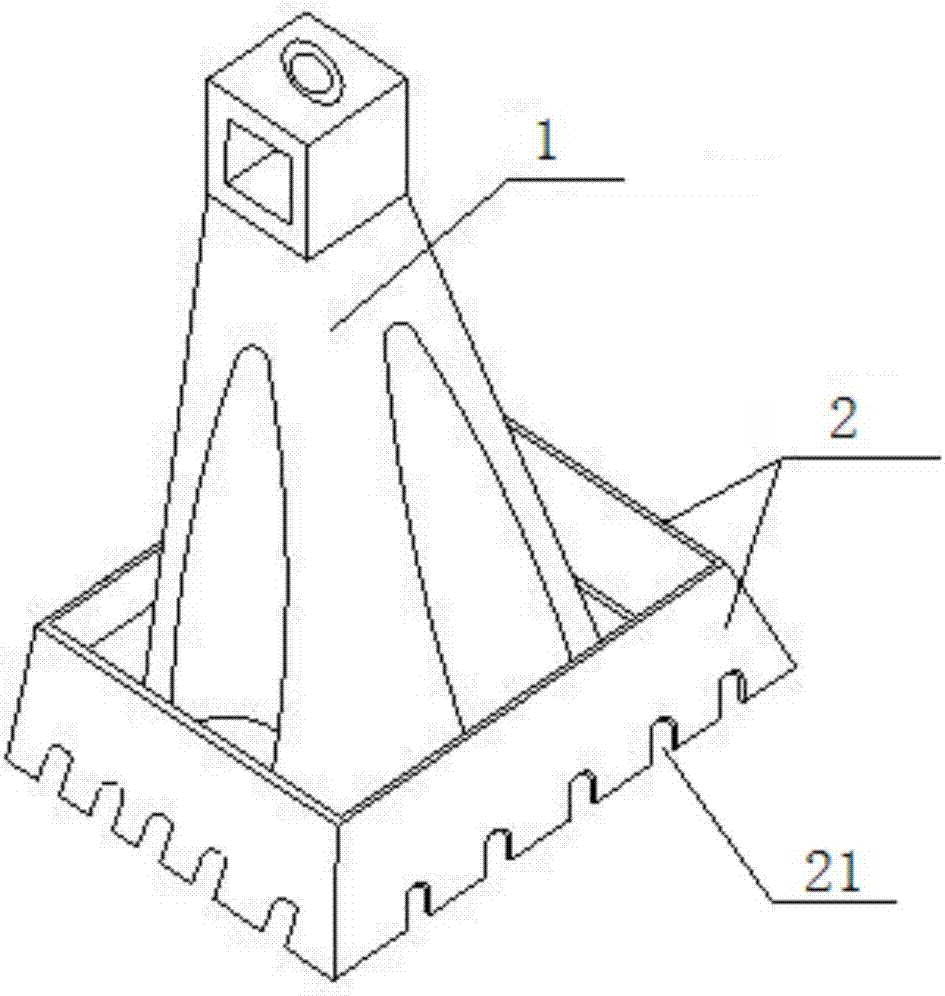

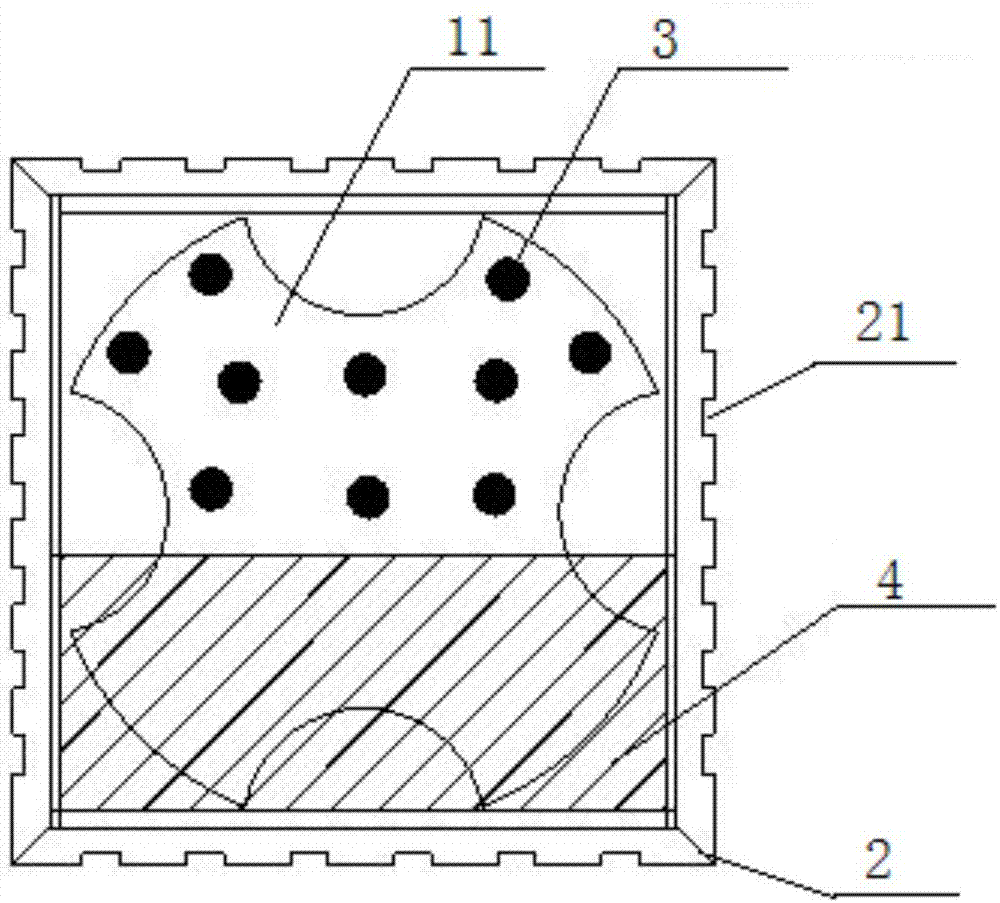

[0028] reference figure 1 , 2 As shown, a rectangular percussion drill bit for the inclined rock trough section of ground connecting wall construction includes a plum blossom percussion drill 1, and also includes a side plate 2, a cone hammer 3, a hammer plate 4, a side plate 2, a cone hammer 3 The hammer plate 4 is preferably made of metal materials, such as steel. The side plate 2 is a flat plate with a serrated edge 21 on one side. The four side plates 2 surround the side of the hammer impact surface 11 of the plum blossom impact drill 1 to form a rectangle. The bottom side of each side plate 2 is a serrated edge 21, and The plane formed by each bottom edge 2 is flush with the hammer impact surface 11 of the quincunx hammer drill 1. The hammer impact surface 11 of the quincunx hammer drill 1 is divided by a line parallel to a certain side plate 2. The impact surface is divided into two halves, one...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com