Carbon crucible outer wall slag remover

A technology of slag cleaning machine and crucible, which is applied to descaling devices, furnaces, lighting and heating equipment, etc. It can solve the problems of laborious manual cleaning and low efficiency of slag cleaning, so as to improve safety, improve work efficiency and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

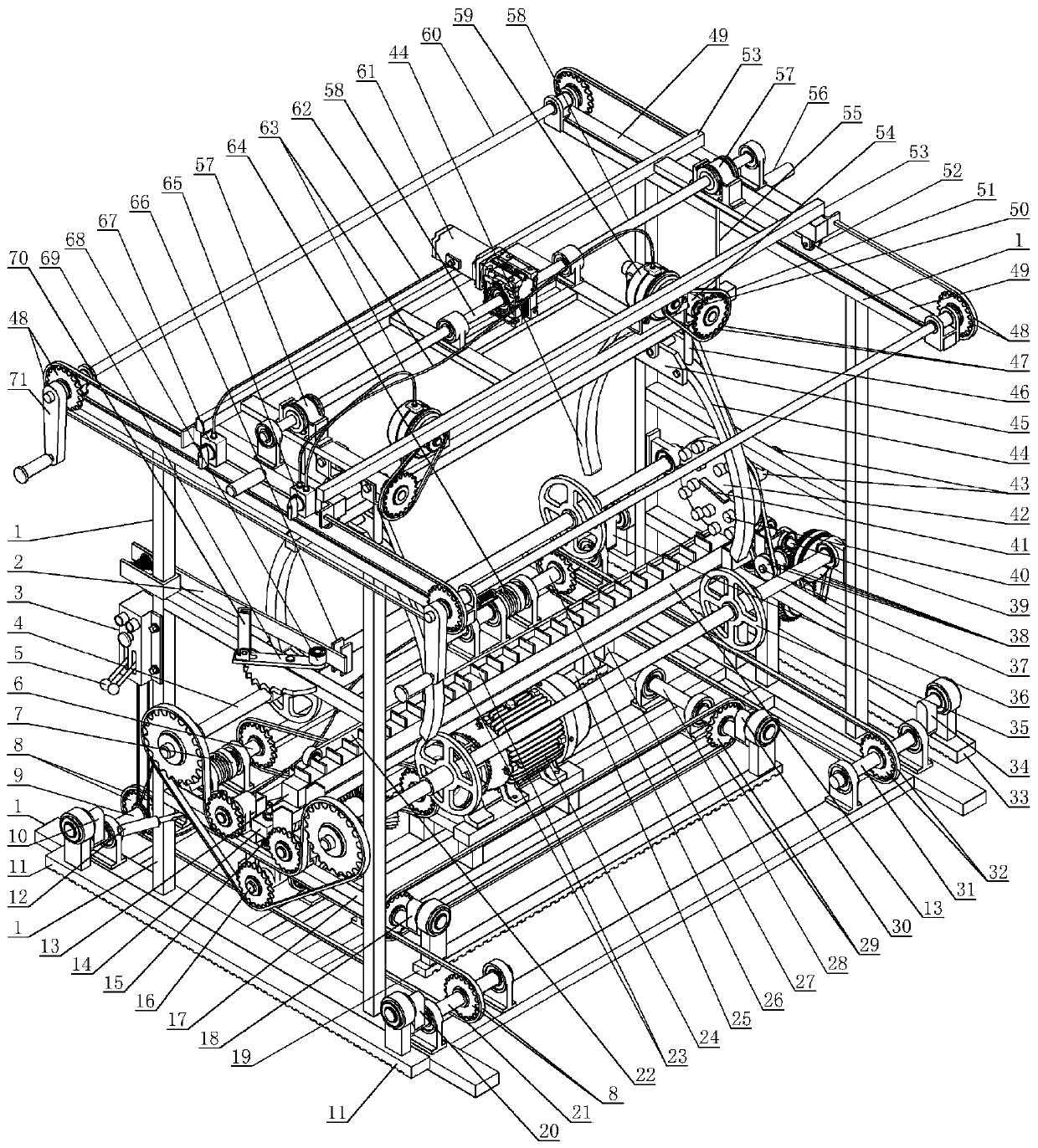

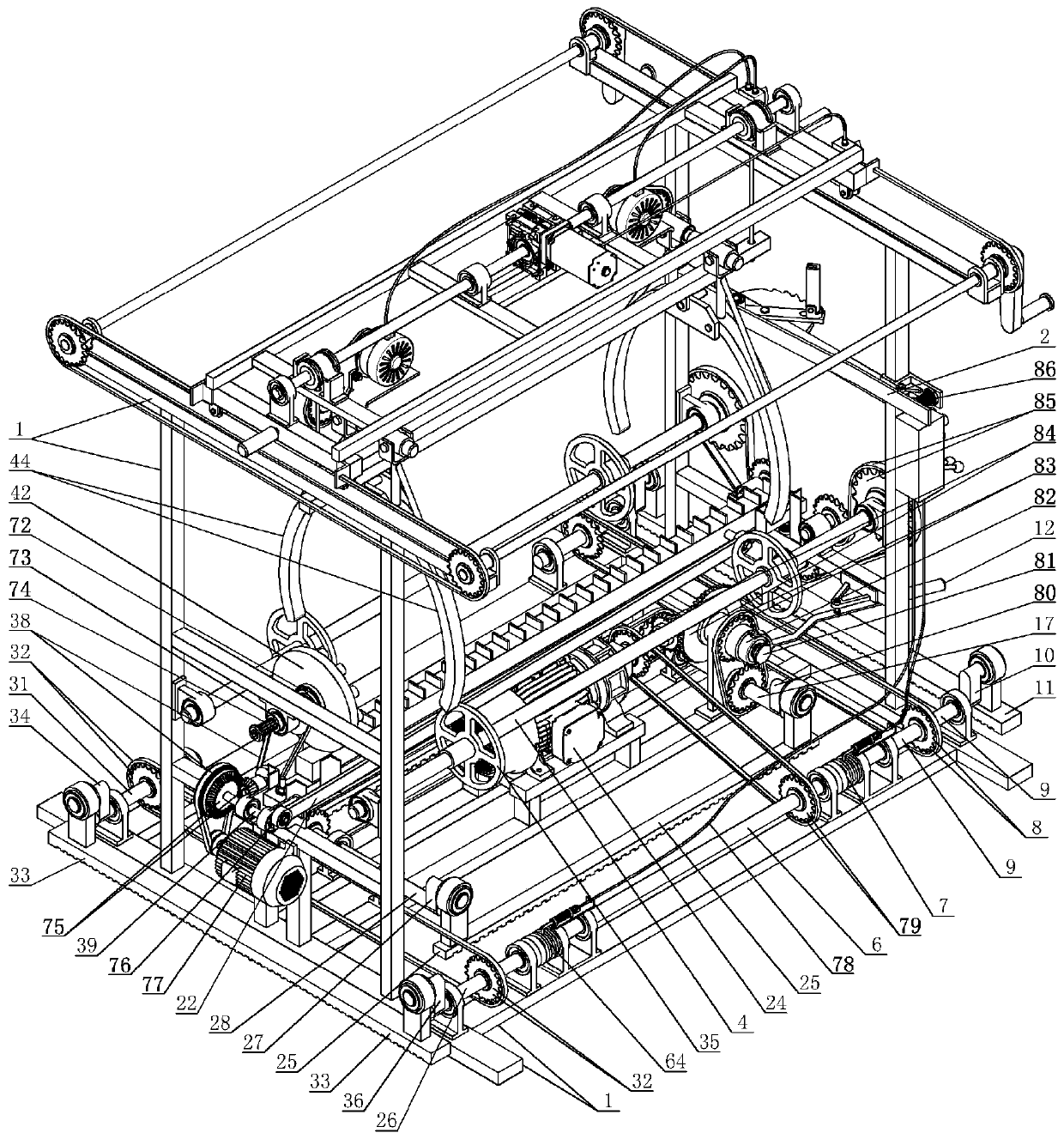

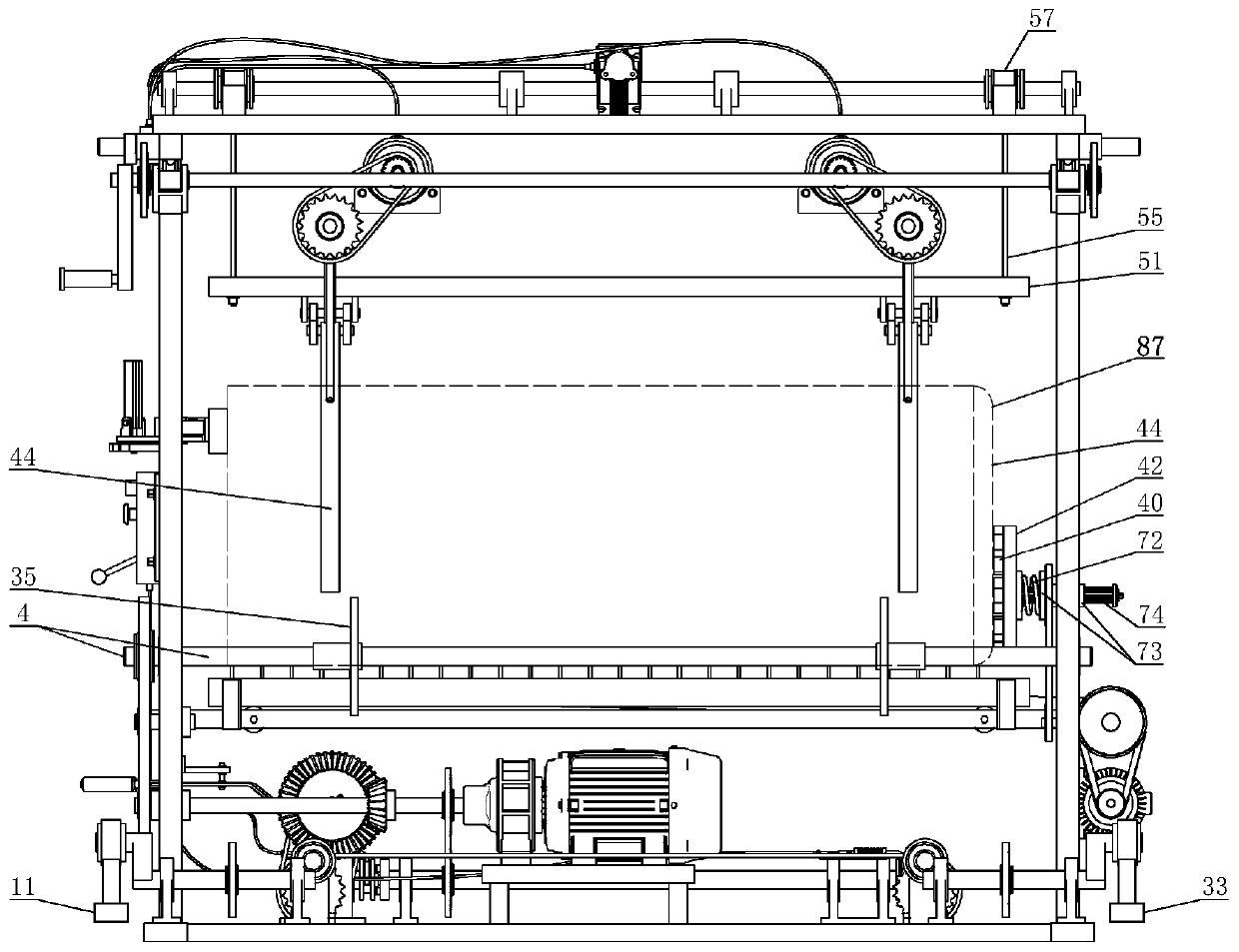

[0036] Carbon crucible outer wall slag cleaning machine, such as Figure 1 to Figure 6 As shown, it has a frame 1, and two supporting rollers 4 for supporting the carbon crucible are mounted on the frame, and at least one of the supporting rollers in the two supporting rollers is the power for rotating the carbon crucible Roller, two supporting rollers are arranged parallel to each other, and a tool holder 13 is arranged in the gap between the two supporting rollers. The tool holder is supported by the frame and is reciprocally slidingly connected with the frame along the axial direction of the supporting roller, and the top surface of the tool holder is fixed. There are a plurality of outer wall scrapers 23, and each outer wall scraper is arranged at intervals along the axial direction of the supporting roller, and a knife holder driving device is installed on the described knife rest or the frame.

[0037] The top surface of each outer wall scraper is flush, and the top surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com