A device and method for removing sediment at the bottom of hole-forming cast-in-place piles

A cast-in-place pile and sediment technology, which is applied in earthwork drilling, drilling equipment, wellbore/well parts, etc., can solve the problems of high energy consumption and low removal efficiency, and achieve the effects of improving work efficiency, convenient operation and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

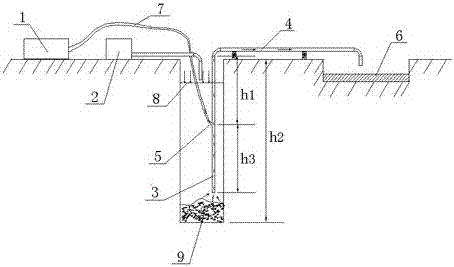

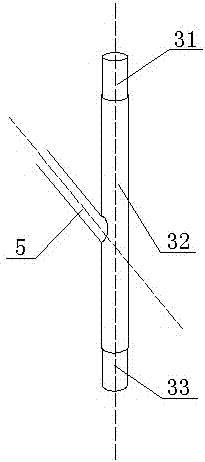

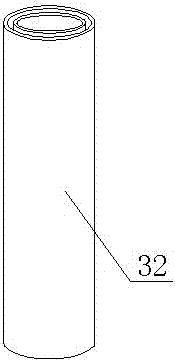

[0039] Such as figure 1As shown, a device for removing sediment at the bottom of a hole-forming cast-in-place pile described in this embodiment includes an air supply mechanism 1, a liquid delivery mechanism 2, a hose 7, and a slag discharge pipe, and the slag discharge pipe includes a slag discharge pipe The vertical part 3 and the horizontal part 4 of the slag discharge pipe, the vertical part 3 of the slag discharge pipe communicates with the air supply mechanism 1 through the hose 7, and the vertical part 3 of the slag discharge pipe includes an upper pipe 31, a middle pipe 32 and a lower pipe 33. The middle pipe 32 includes an outer pipe 321 and an inner pipe 322 whose central axes coincide. The upper pipe 31 is threaded with the outer pipe 321 or the inner pipe 322. The lower pipe 33 is also threaded with the outer pipe 321 or the inner pipe 322.

[0040] This embodiment also includes an inclined pipe 5 , which runs obliquely downward through the inner pipe and the outer...

Embodiment 2

[0050] Such as figure 2 As shown, on the basis of Embodiment 1, this embodiment has also made the following limitations: the included angle between the central axis of the inclined tube 5 and the central axis of the inner tube 322 in this embodiment is 15 to 20 degrees, and the inner tube 322 The ratio of the diameter to the diameter of the hose 7 is 3-5. After adopting such a design in this embodiment, the slurry-gas mixture is better produced under the same energy consumption, and it has a stronger power to bring the sediment out of the bottom of the hole, which improves the efficiency of slag removal and avoids Unnecessary energy consumption is produced.

Embodiment 3

[0052] Such as Figure 3~8 As shown, the present embodiment has been further designed on the basis of embodiment 1 or embodiment 2, specifically as follows:

[0053] The upper tube 31 itself is provided with a first external thread 34, the upper inner wall of the outer tube 321 is provided with an upper internal thread 36 that matches the first external thread 34, and the lower tube 33 is provided with a second external thread 35. The lower part of the inner wall of the pipe is provided with a lower internal thread 37 matched with the second external thread 35 . Through this design, the sediment enters the inner pipe from the lower pipe, and then enters the upper pipe until it is discharged from the slag discharge pipe. In this process, the sediment will not contact with each thread at all, thus ensuring that the thread is not affected by the sediment and can Maintaining a normal state for a long time facilitates the normal and rapid adjustment of the length of the slag disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com