Pipeline flash butt welding rotation mechanical internal slag removing system

A technology of flash butt welding and rotating machinery, which is applied in the direction of metal processing machinery parts, welding equipment, resistance welding equipment, etc., and can solve problems such as difficulty in ensuring weld quality, increase in weld defect rate, and poor weld surface quality. Achieve the effect of good weld surface quality, low manufacturing cost and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

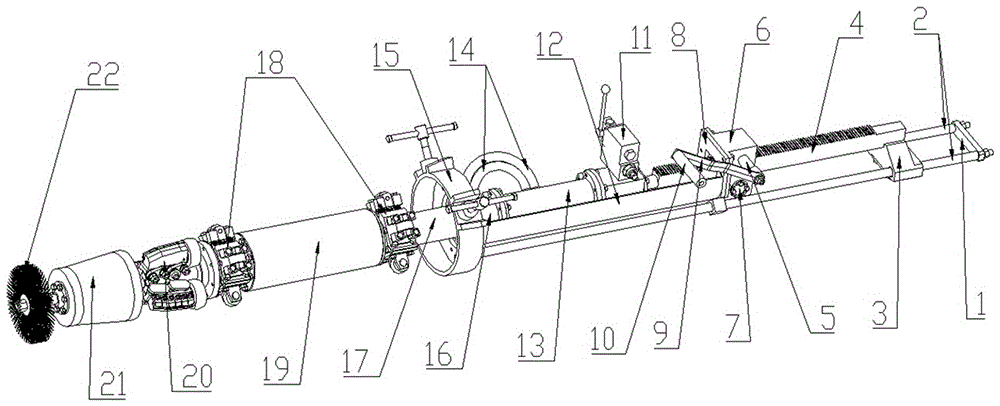

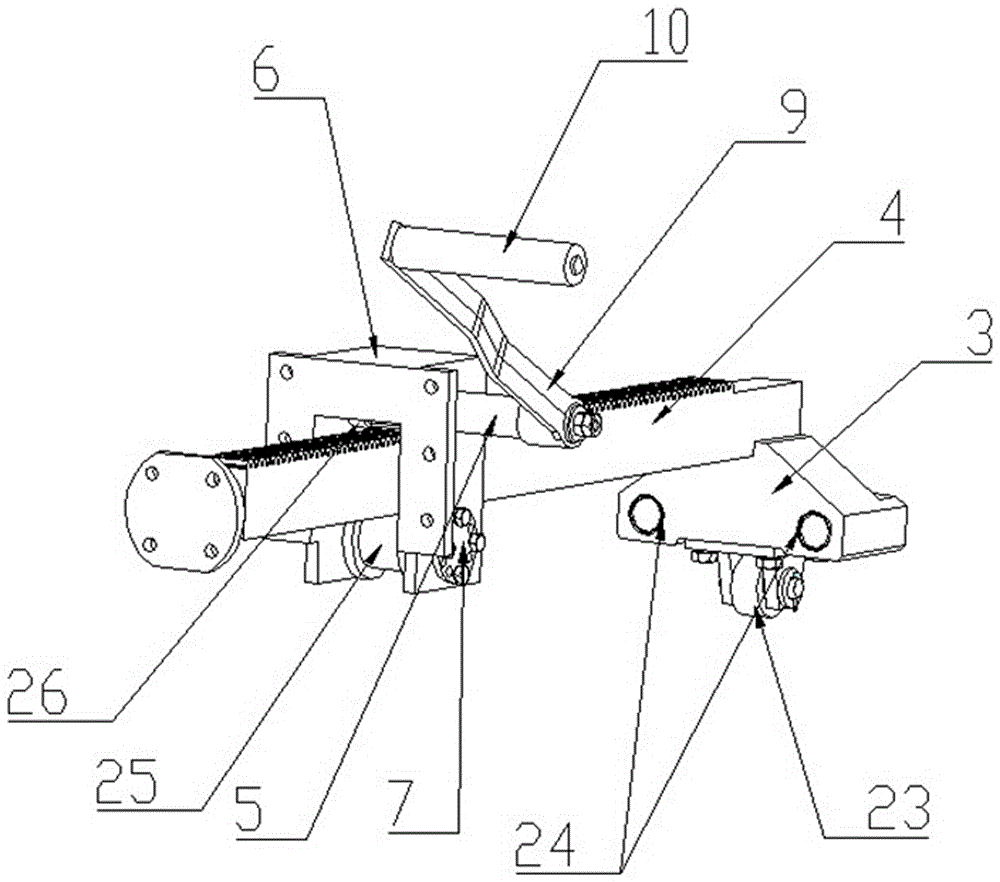

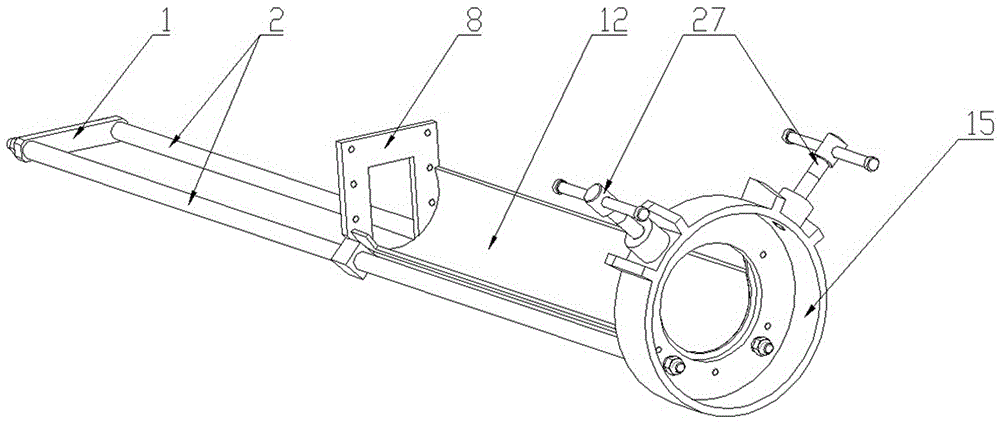

[0024] like Figure 1-Figure 7As shown, the pipe flash butt welding rotary mechanical internal slag removal system according to the present invention mainly includes a propulsion mechanism, a hydraulic power system and a slag removal knife group, and the slag removal knife group rotates under the drive of the hydraulic power system and Driven by the propulsion mechanism, it moves inside the pipeline to clean up the weld residue on the inner wall of the pipeline. Wherein, the propulsion mechanism includes a gear box 6 fixedly connected to a positioning bracket, a gear 26 rotatably connected in the gear box 6 through the gear shaft 5, and a gear 26 rotatably connected in the gear box 6 through the rack supporting wheel shaft 7. The rack pulley 25 at the bottom, the rack 4 that is placed on the rack pulley 25 and passes through the gear box 6 to mesh with the gear 26, the rack bracket 3 that is arranged at the bottom of the rear end of the rack 4, can rotate through the pin The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com