Construction waste slag removing system and method for open type heading machine

An open roadheader and roadheader technology, which is applied in earth drilling, mining equipment, underground transportation, etc., can solve the problems that concrete and other materials cannot be transported in time, the normal tunneling of TBM is affected, and other vehicles cannot pass through. Improve the construction environment, shorten the construction period, and ensure the effect of operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

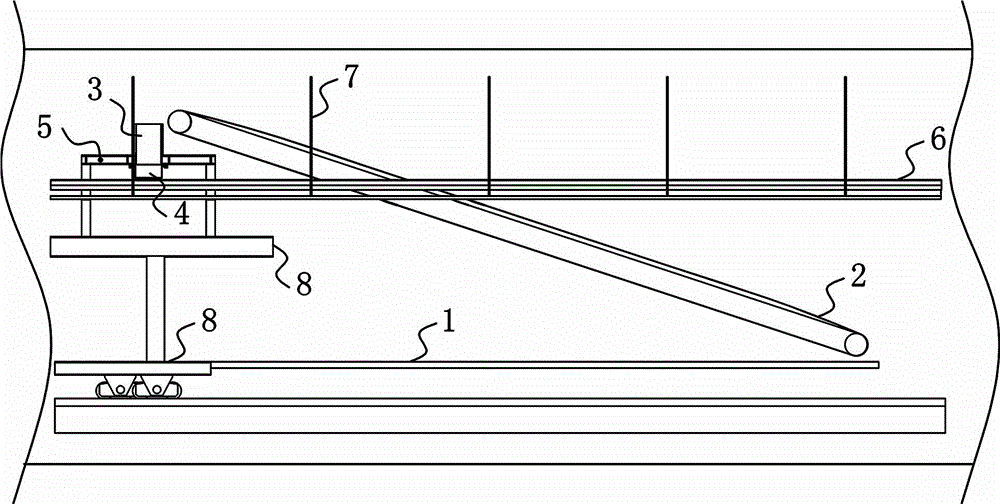

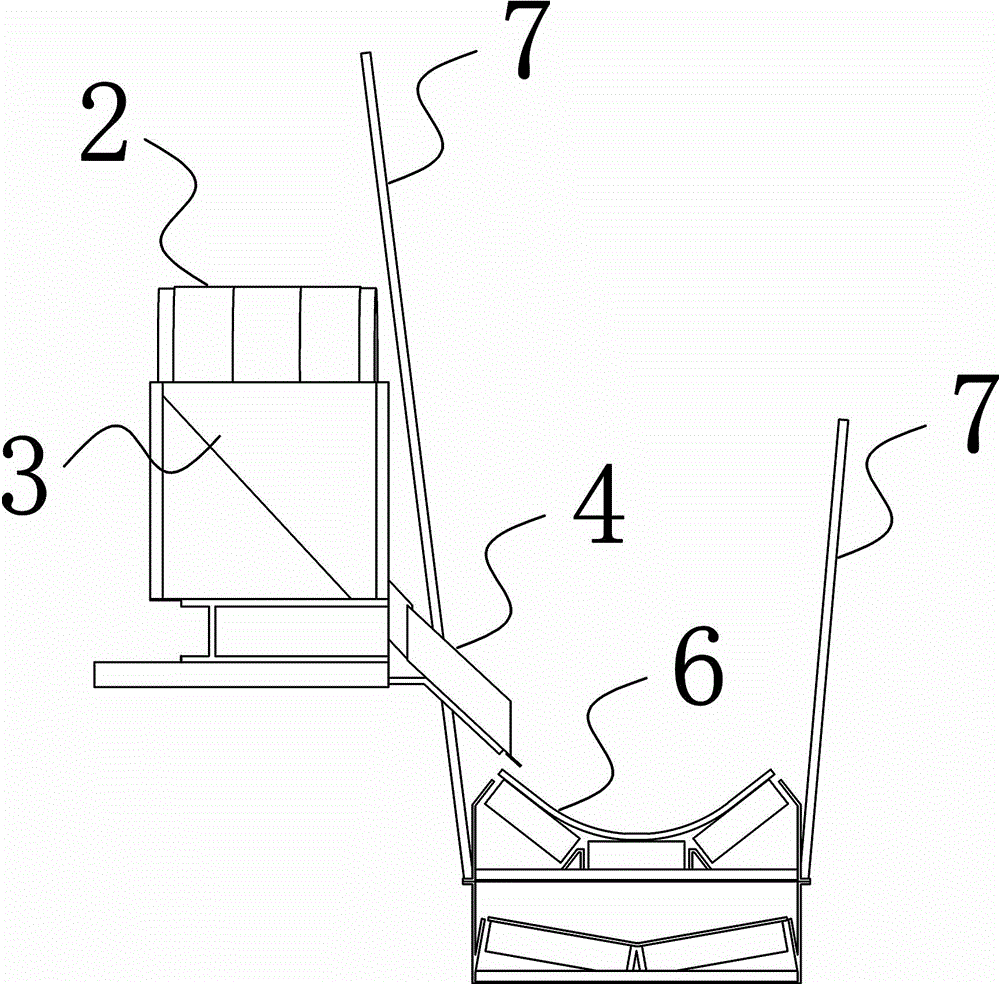

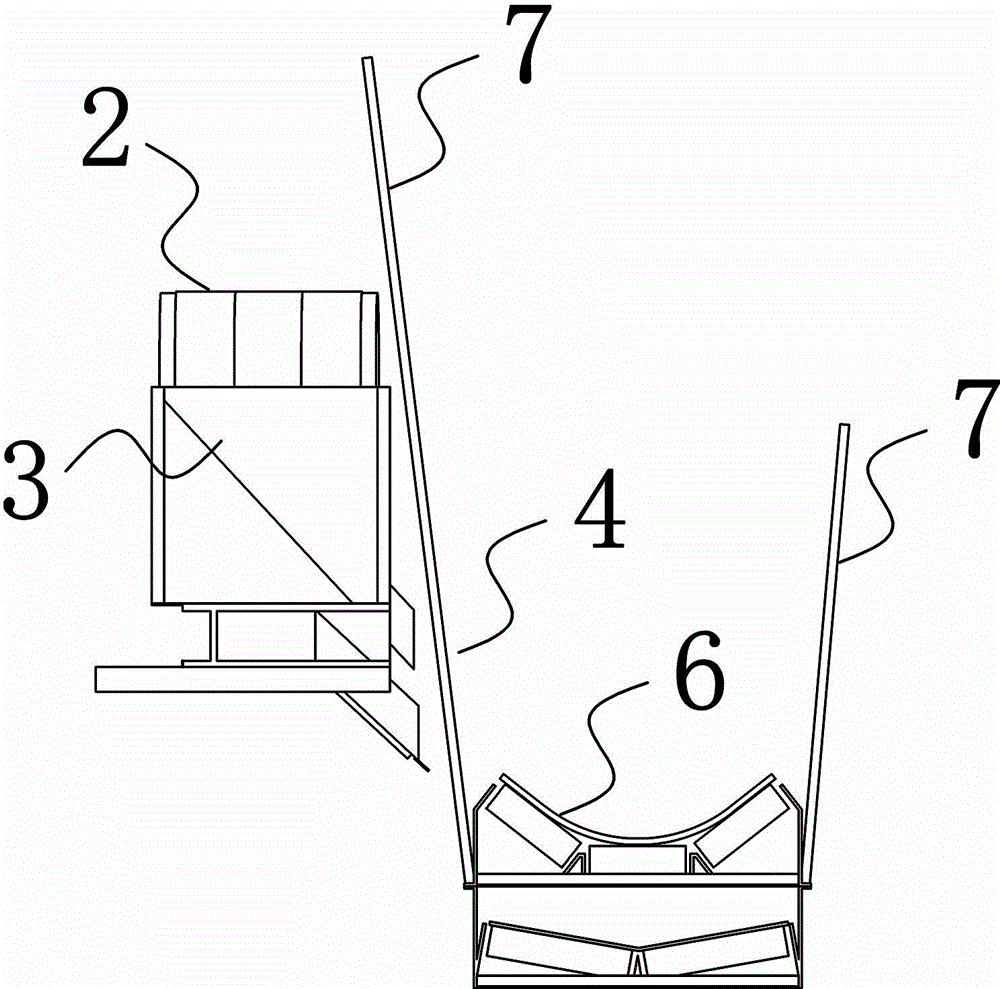

[0034] Such as Figure 1~4 In, 9, a construction waste slag cleaning system of an open roadheader, a slag removal belt 2 is installed obliquely at the tail area 12 of the roadheader, the head end of the slag removal belt 2 is located below, and the head end is fixedly installed on the bracket 1 On the top, the support 1 is connected with the roadheader trailer 8, the tail end of the slag removal belt 2 is fixedly installed on the top of the roadheader trailer 8, and the tail end of the slag removal belt 2 is provided with a slag discharge bucket 3, and the slag discharge bucket 3 is connected to the movable chute 4 Then, the movable chute 4 is overlapped with the continuous belt 6 of the tunnel.

[0035] The average daily slag removal volume of the roadheader is about 40 cubic meters, and the transportation load of the slag removal belt is relatively small. Therefore, the principle of selection of the slag removal belt 2 is to be as narrow as possible. When arranging the slag...

Embodiment 2

[0044] Such as Figure 1~4, 9, a method for cleaning up waste slag using the construction waste slag cleaning system of the open type roadheader described in embodiment 1, comprising the following steps:

[0045] 1. Manually excavate the construction waste slag from under the track and pile it near the head end of the slag removal belt 2;

[0046] 2. When the roadheader starts to excavate, after the tunnel continuous belt 6 is started, start the slag removal belt 2;

[0047] 3. Manually shovel the waste slag onto the slag removal belt 2. The waste slag moves up with the slag removal belt 2, and is transported by the slag removal belt 2 to the tunnel continuous belt 6 through the slag discharge hopper 3 and the movable chute 4, and then the tunnel continuous belt 6 Transport the spoil to the outside of the cave;

[0048] Through the above steps, the construction waste slag cleaning can be realized.

[0049] Preferably, the movable chute 4 has two working states: a slagging s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com