Steel ladle slag clearing device and steel ladle slag clearing method

A ladle and slag cleaning technology, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of time-consuming, labor-intensive, dangerous environment, and ejection everywhere.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

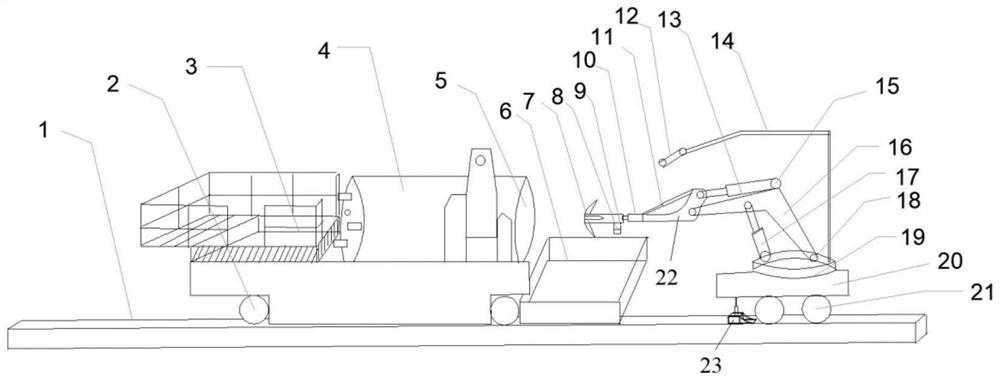

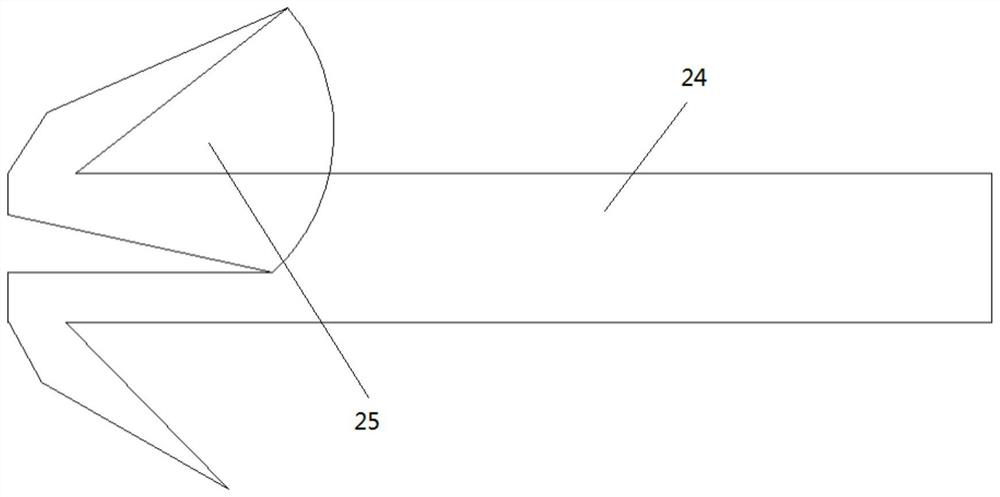

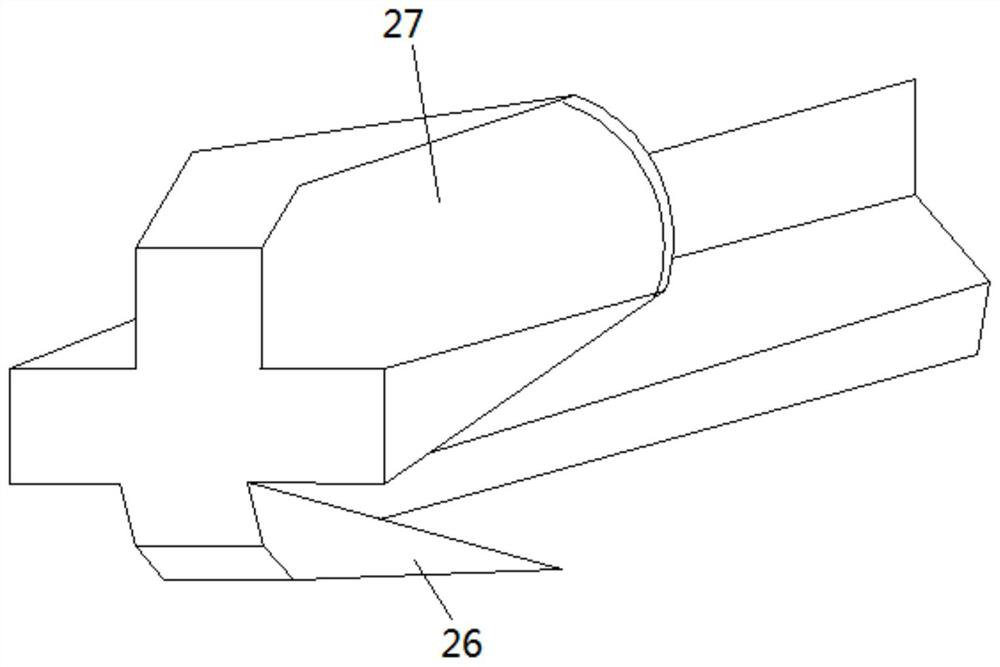

[0057] see Figure 1-3 , the present embodiment provides a ladle cleaning equipment, including a ladle device, a slag cleaning device and a control system; the ladle device includes a ladle car 3 and a ladle 4, and the ladle car 3 is used to support the ladle 4; The slag device includes a slag remover 20, a slag remover 7 and a driving device, and the slag remover 7 is movably connected with the drive device; the slag remover 7 includes a slag removal rod 24 and a slag removal head 25; it is characterized in that , the control system controls the driving device, the slag cleaner 7 can reach any position of the ladle 5 of the ladle 4 driven by the driving device, and the slag cleaner 7 can be in the Driven by the driving device, it rotates around the slag removal rod 24.

[0058] The drive device includes a hydraulic cylinder drive module and a motor drive module; the slag cleaner 7 can reach any position of the bag mouth 5 of the ladle 4 driven by the hydraulic cylinder drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com