Molten iron pretreatment adhering type slag removing technology and device

A technology of molten iron pretreatment and slag dipping, which is applied in the direction of improving process efficiency, mechanical cleaning, and manufacturing tools, etc., can solve the problems of cooling and crusting, low slag removal rate by gas slag, and achieves fast cooling speed and covers an area of Small, small iron loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

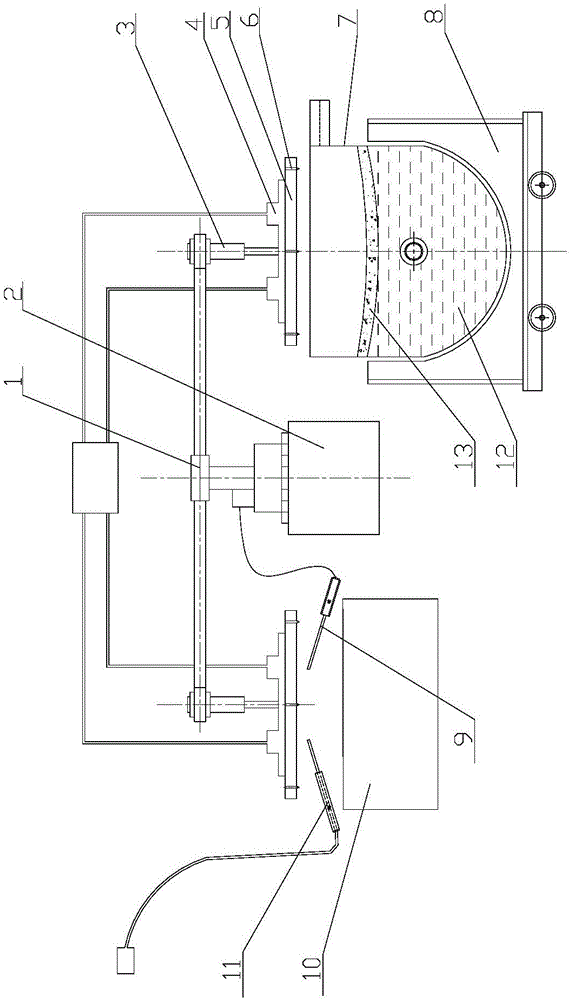

[0047] In the smelting laboratory, a "500kg multifunctional experimental furnace" was used to simulate the molten iron tank 7, and the adhesion type slag removal device of the present invention was used to perform a slag removal experiment on the molten iron tank 7 with a capacity of 400 kg. The diameter of the slag pan 5 that is used is 80% of the diameter of the mouth of the molten iron tank 7, the cooling water pressure of the water cooling system 4 is 0.5MPa, and the temperature measurement system 6 is 4 thermocouples installed on the slag pan 5. 4 high-pressure water guns 11 and 4 mechanical wind shovels 9 are installed above the 10; adopt once to dip slag during the slag removal operation, and the slag-stick pan 5 stays in the slag layer 13 for 60 seconds, and the high-pressure water gun 11 spray processing time is In 30 seconds, the residue can be cleaned up without the need for a mechanical wind shovel 9 to remove the residue.

Embodiment 2

[0049] In the smelting laboratory, a "500kg multifunctional experimental furnace" was used to simulate the molten iron tank 7, and the adhesion type slag removal device of the present invention was used to perform a slag removal experiment on the molten iron tank 7 with a capacity of 400 kg. The diameter of the slag pan 5 that is used is 85% of the diameter of the 7 tank mouths of the molten iron tank, the cooling water pressure of the water cooling system 4 is 0.8MPa, and the temperature measurement system 6 is 6 thermocouples installed on the slag pan 5. 5 high-pressure water guns 11 and 3 mechanical air shovels 9 are installed above the 10; the slag removal operation adopts secondary slag dipping, and the slag-sticking tray 5 stays in the slag layer 13 for 90 seconds each time the slag is stained; 11 The spray treatment time is 45 seconds, and the remaining small amount of residue is cleaned by mechanical air shovel 9.

Embodiment 3

[0051] In the smelting laboratory, a "500kg multifunctional experimental furnace" was used to simulate the molten iron tank 7, and the adhesion type slag removal device of the present invention was used to perform a slag removal experiment on the molten iron tank 7 with a capacity of 400 kg. The diameter of the slag pan 5 that is used is 90% of the diameter of the mouth of the molten iron tank 7, the cooling water pressure of the water cooling system 4 is 1.0MPa, and the temperature measurement system 6 is 8 thermocouples installed on the slag pan 5, and the slag pan is installed on the slag pan. 6 high-pressure water guns 11 and 2 mechanical wind shovels 9 are installed above the 10; adopt once to dip slag during the slag removal operation, and the slag-stick pan 5 stays in the slag layer 13 for 120 seconds, and the high-pressure water gun 11 spraying treatment time is For 60 seconds, the remaining small amount of residue is cleaned by mechanical wind shovel 9.

[0052] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com