Vacuum die casting stopping device and control method thereof

A cut-off device and vacuum die-casting technology, which is applied in the field of die-casting mold accessories, can solve problems such as easy blockage of air passages, difficult removal of oil mixed with waste residue, and influence on the reliability of the air extraction device, so as to ensure product quality and complete residue removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

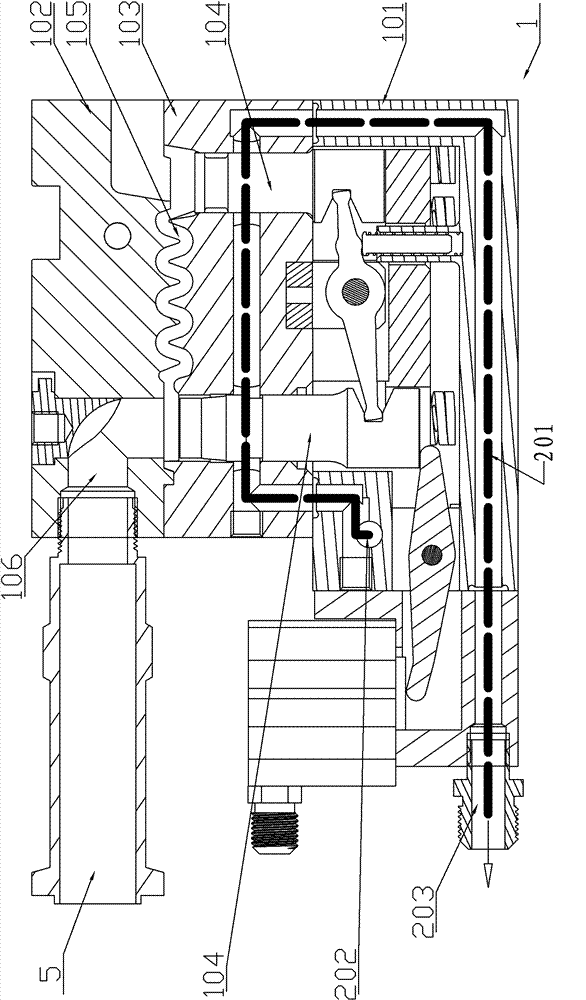

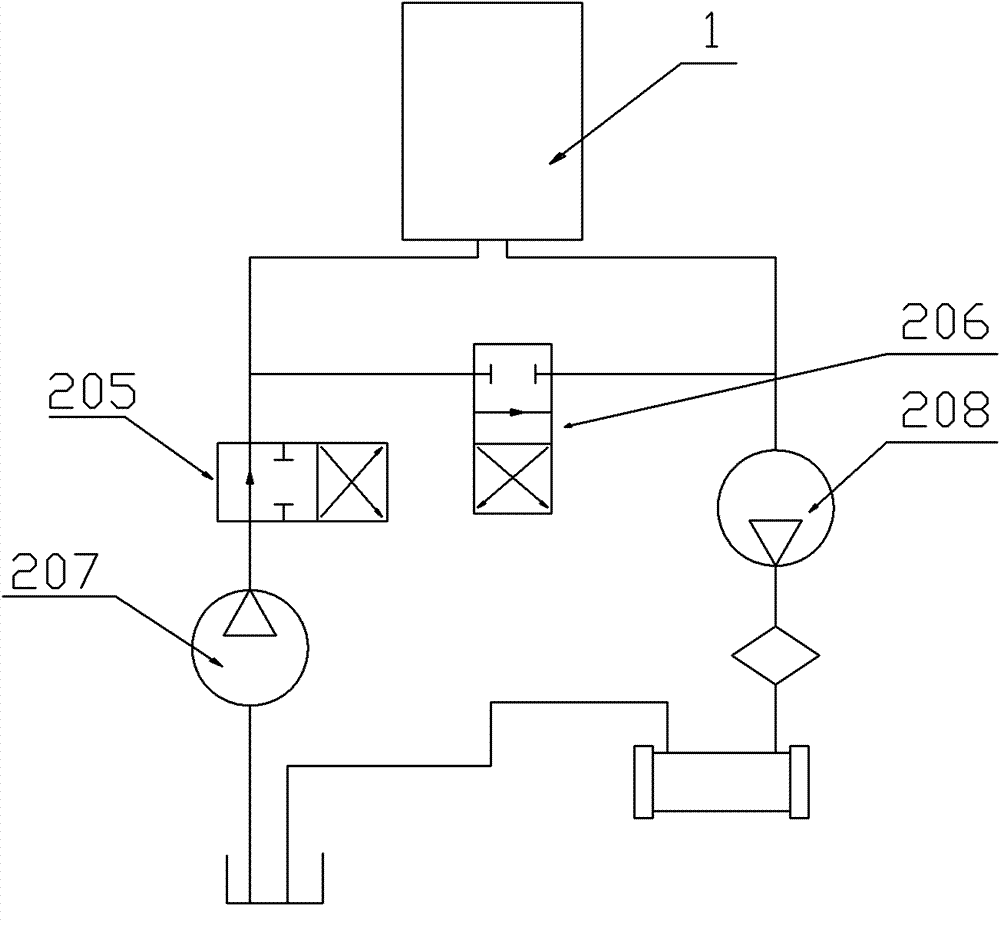

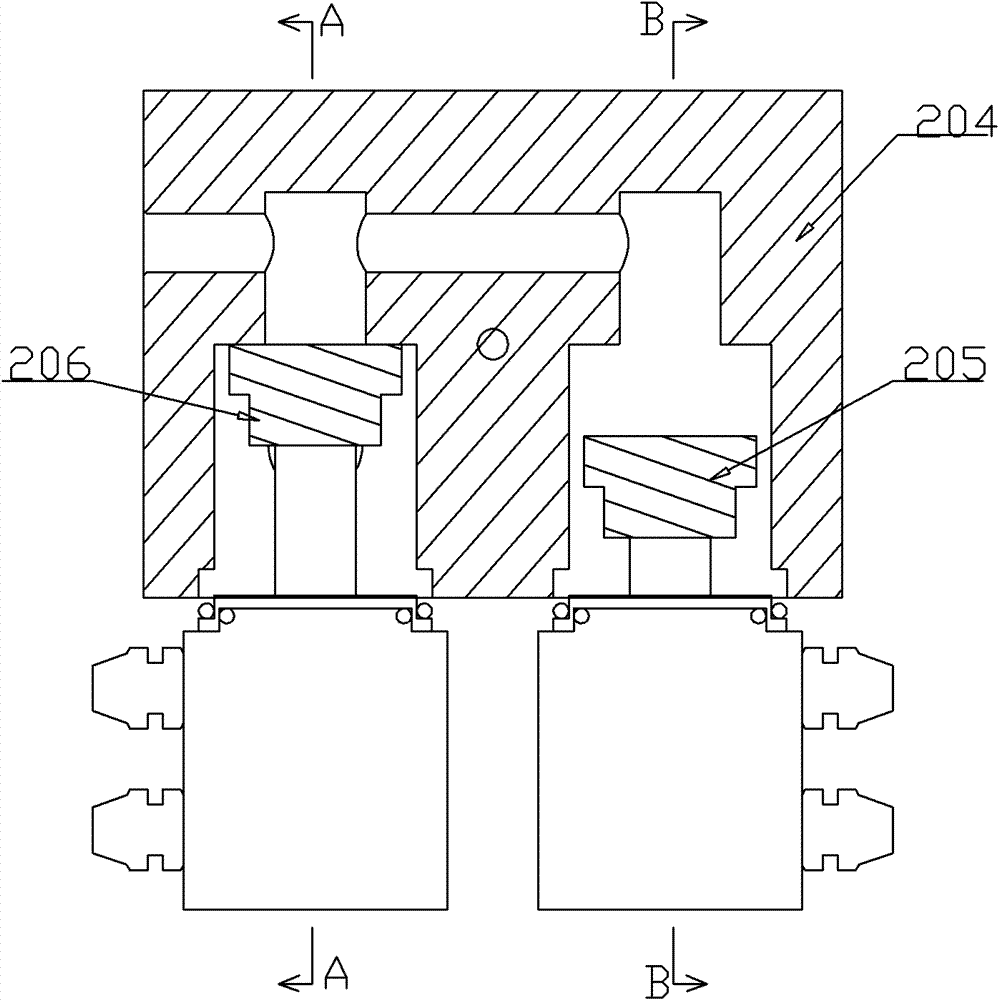

[0035] Such as figure 1 As shown, the vacuum stop valve 1 includes a stop valve seat 101, an upper valve body 102, a lower valve body 3 and a valve core 104. The upper end of the valve core 104 passes through the lower valve body 103 and can move therein; the lower valve body 103 is provided with Through the cut-off valve oil passage 201 of the valve core 104 , both ends of the cut-off valve oil passage 201 extend in the valve seat wall and form an oil inlet 202 and an oil outlet 203 on the valve seat. The oil inlet 202 of the shut-off valve oil passage is connected with the oil outlet pump 207, and its oil outlet 203 is connected with the oil well pump 208; 102 , the exhaust passage 105 at the junction of the lower valve body 103 is connected, the end of the shut-off valve air passage 106 is connected with the head end of the air pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com