Anti-deformation supporting structure of foundation pit and construction method thereof

A foundation pit support and anti-deformation technology, applied in foundation structure engineering, excavation, sheet pile wall, etc., to achieve the effect of improving stress state, high bearing capacity of single pile, and controlling the deformation of foundation pit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

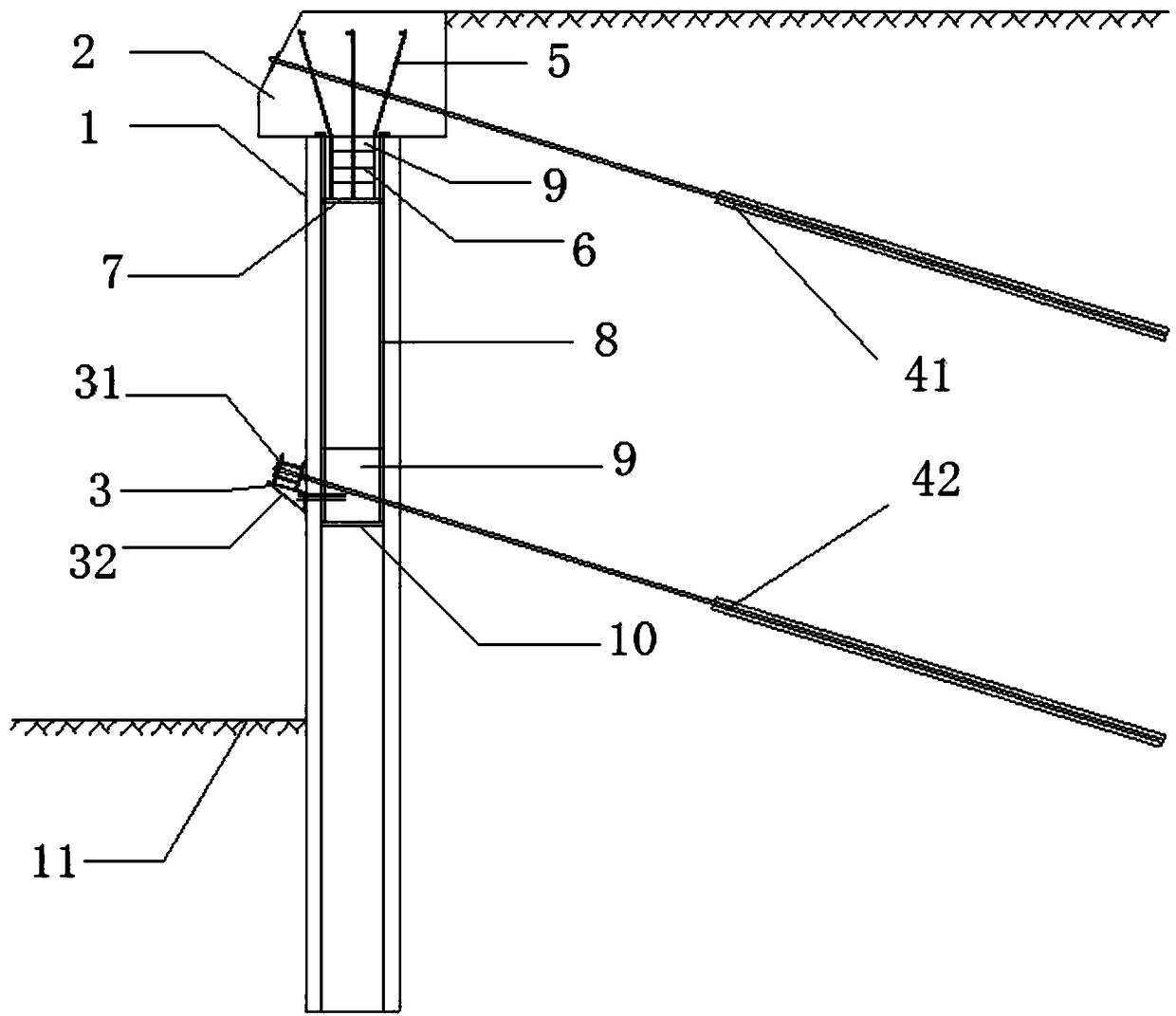

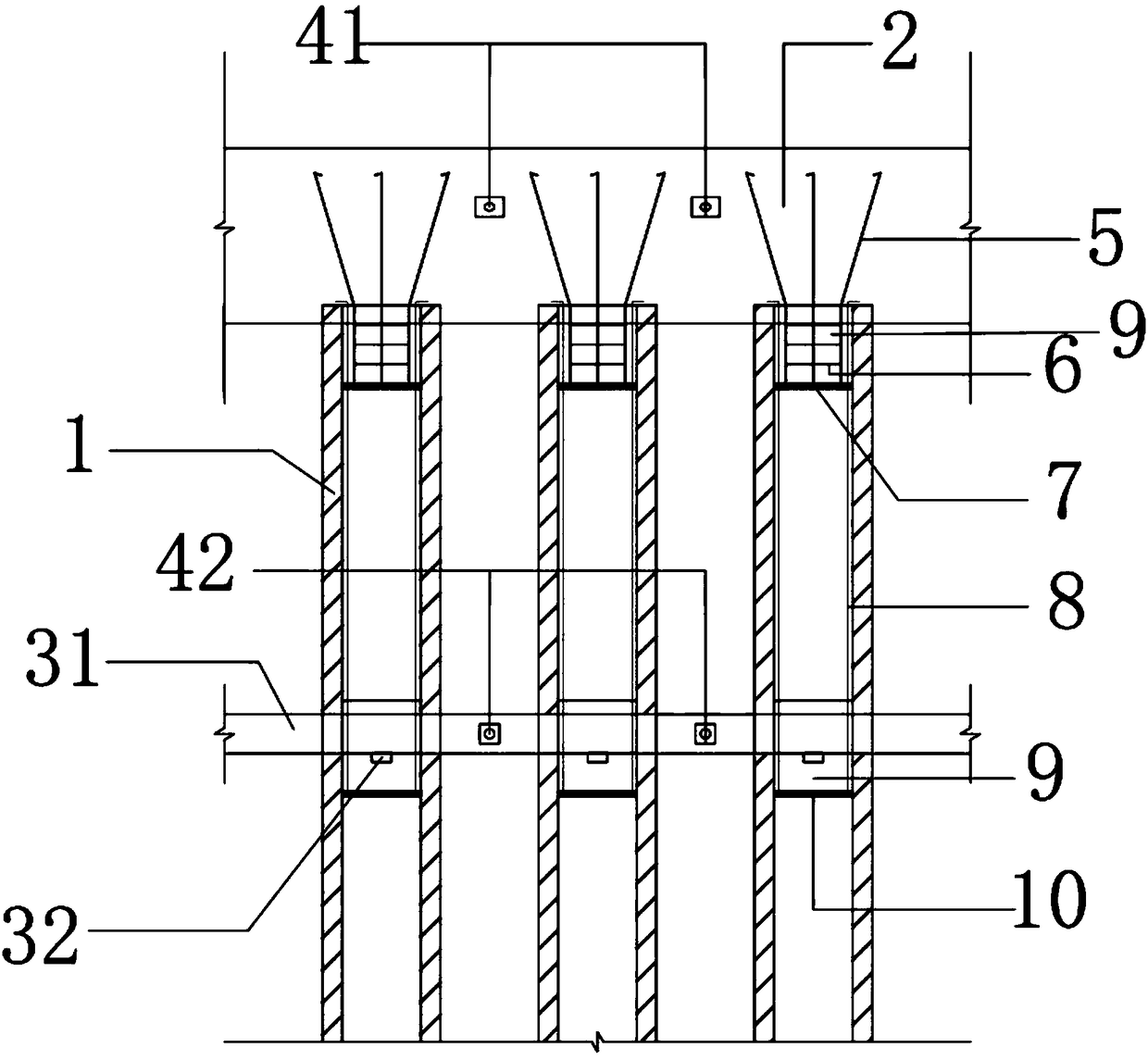

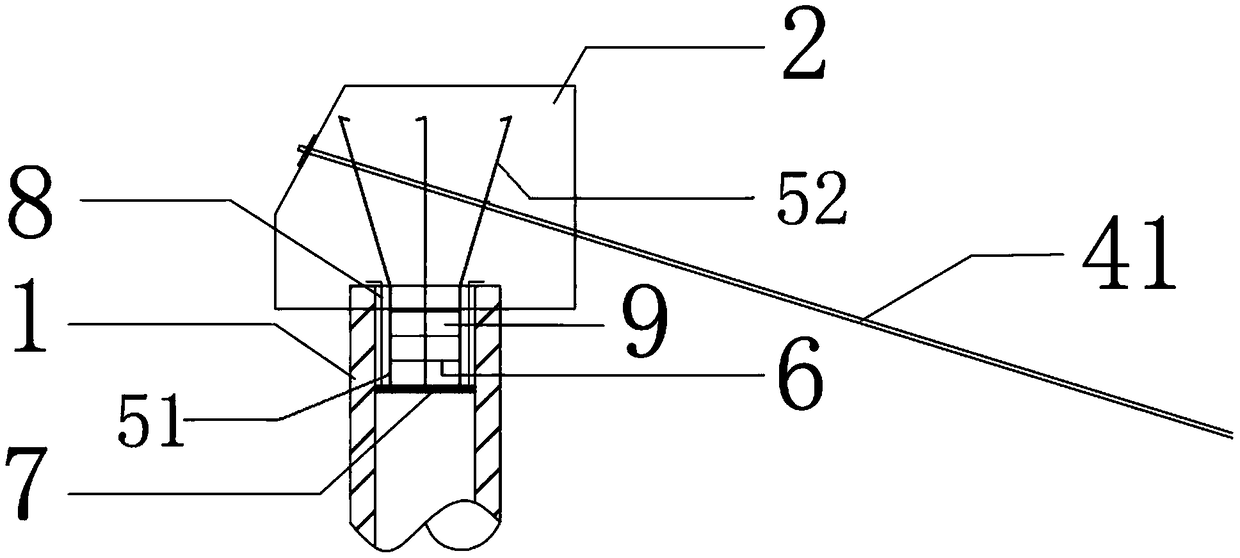

[0042] like Figures 1 to 6As shown, a deformation-resistant foundation pit support structure includes a plurality of prestressed concrete pipe piles 1 vertically arranged in parallel around the foundation pit, and the pile tops of two adjacent prestressed concrete pipe piles 1 pass through crowns. The beams 2 are connected, and the pile bodies are connected through the waist beam 3; the top of the prestressed concrete pipe pile 1 is radially fixed with a first supporting plate 7, and above the first supporting plate 7, several main reinforcements are fixed through the core-filled concrete 9; All the main bars 5 are evenly arranged in a circle around the inner wall of the prestressed concrete pipe pile 1, and are welded together by the stirrups 6; each main bar 5 is formed by connecting a vertical section 51 and an inclined section 52, and the vertical section 51 is fixed Inside the prestressed concrete pipe pile 1, the inclined section 52 is fixed inside the crown beam 2; the...

Embodiment 2

[0059] like image 3 , 4 , 7 to 10, a deformation-resistant foundation pit support structure, including a plurality of prestressed concrete pipe piles 1 vertically arranged in parallel around the foundation pit, and the pile tops of two adjacent prestressed concrete pipe piles 1 The crown beams 2 are connected between them, and the pile bodies are connected by a waist beam 3; the top of the prestressed concrete pipe pile 1 is radially fixed with a first supporting plate 7, and the top of the first supporting plate 7 is fixed with a core-filled concrete 9 Several main reinforcements; all the main reinforcements 5 are evenly arranged in a circle around the inner wall of the prestressed concrete pipe pile 1, and are connected into one body through the stirrups 6; each main reinforcement 5 is formed by connecting a vertical section 51 and an inclined section 52, and the vertical The straight section 51 is fixed inside the prestressed concrete pipe pile 1, and the inclined section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com