Pile forming operation method for protection barrel type cement soil mixing pile

A cement-soil mixing pile and cement-soil technology, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve problems such as the flow of cement slurry, waste of cement materials, and difficulty in uniform mixing of cement slurry and undisturbed soil, so as to reduce water content rate, increase the amount of curing agent, and improve the effect of uneven pile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the accompanying drawings and examples of implementation.

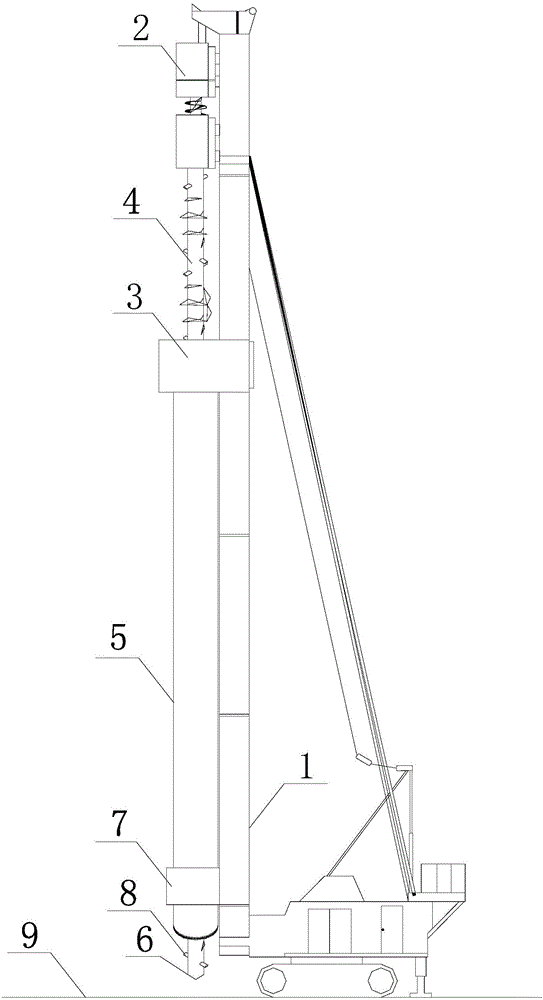

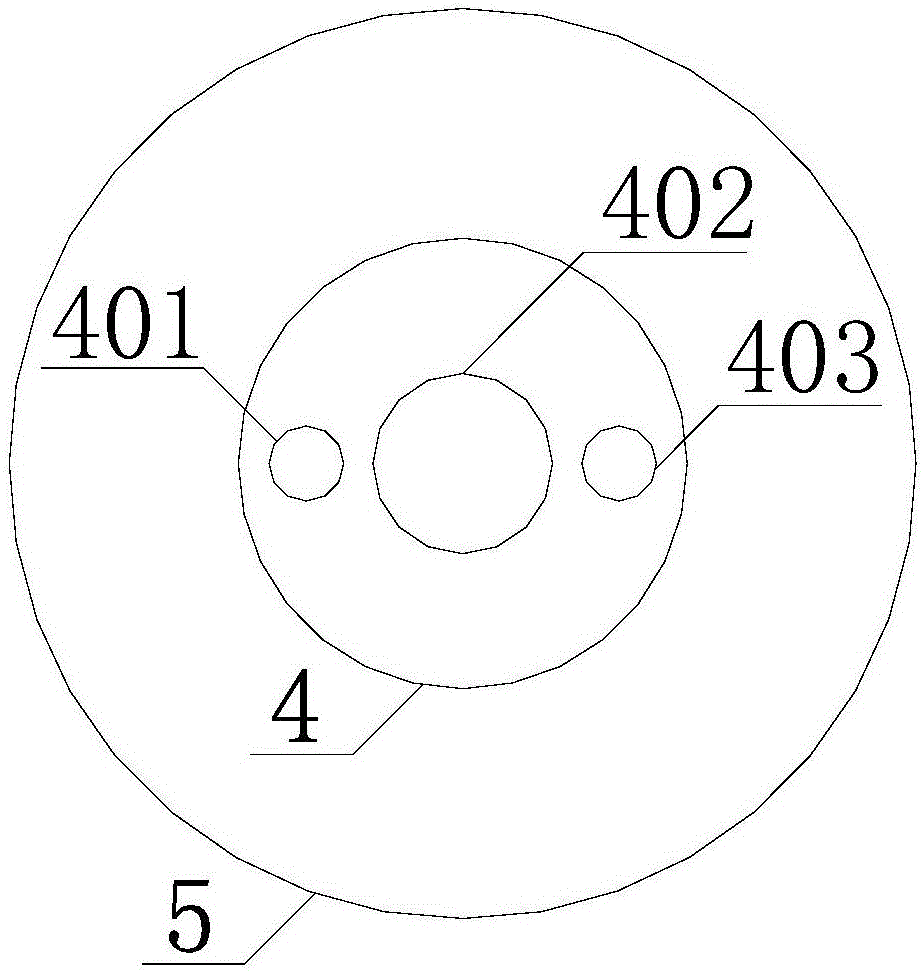

[0020] like figure 1 As shown, the casing-type cement-soil mixer is mainly composed of a crawler mixer pile frame 1, a mixer power head 2, a casing power head 3, a stirring shaft 4, a casing 5, a drill bit 6, a support frame 7, and a mixing blade 8. It is characterized in that the casing and the drill pipe are hollow steel pipes, and inside the casing there are spray pipes 401, material spray pipes 402 and water spray pipes 403 arranged in parallel, wherein the spray pipe 402 is located in the center of the drill pipe and has a large diameter. The slurry pipe 401 and the water spray pipe 403 are distributed on both sides of the material spray pipe; the water spray pipe 403 sprays water or sprays slurry depending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com