Construction method of ultrahigh bearing capacity stiff composite pile

A construction method and bearing capacity technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of high pressure, less curing agent injection, low work efficiency, etc., and achieve high pile strength, high construction efficiency, The effect of large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

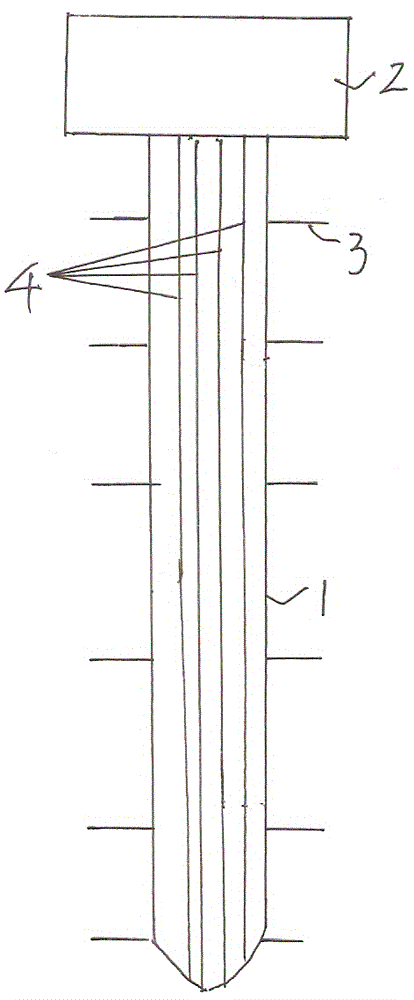

[0012] A construction method for ultra-high bearing capacity rigid composite piles, first constructing cement-soil peripheral piles, and then constructing inner core piles in the peripheral piles; when constructing peripheral piles, cement-soil mixing adopts cement-soil mixing with blades arranged on all axes The device is used for simultaneous stirring within the entire pile length; the cement-soil mixing device with blades arranged on the whole shaft includes a stirring shaft 1, which is connected to a power head 2, and the part below the power head of the stirring shaft is arranged at intervals of 20-50 cm A layer of stirring blades 3; multiple nozzles are arranged in the inner cavity of the stirring shaft for spraying water, dry powder, sand or curing agent, and the nozzles of the multiple nozzles 4 are located at the bottom of the stirring shaft; The material can be stirred into a pile at one time; when the pile end or a certain part of the pile body requires high cement-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com