Construction method of drilling follow casting pile used for building or bridge foundation

A technology of bridge foundation and pipe-while-drilling, applied in infrastructure engineering, construction, sheet pile walls, etc., can solve the problems of low pile bearing capacity, broken piles and necking, construction mud polluting the environment cost, etc. The effect of high body strength and improved construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

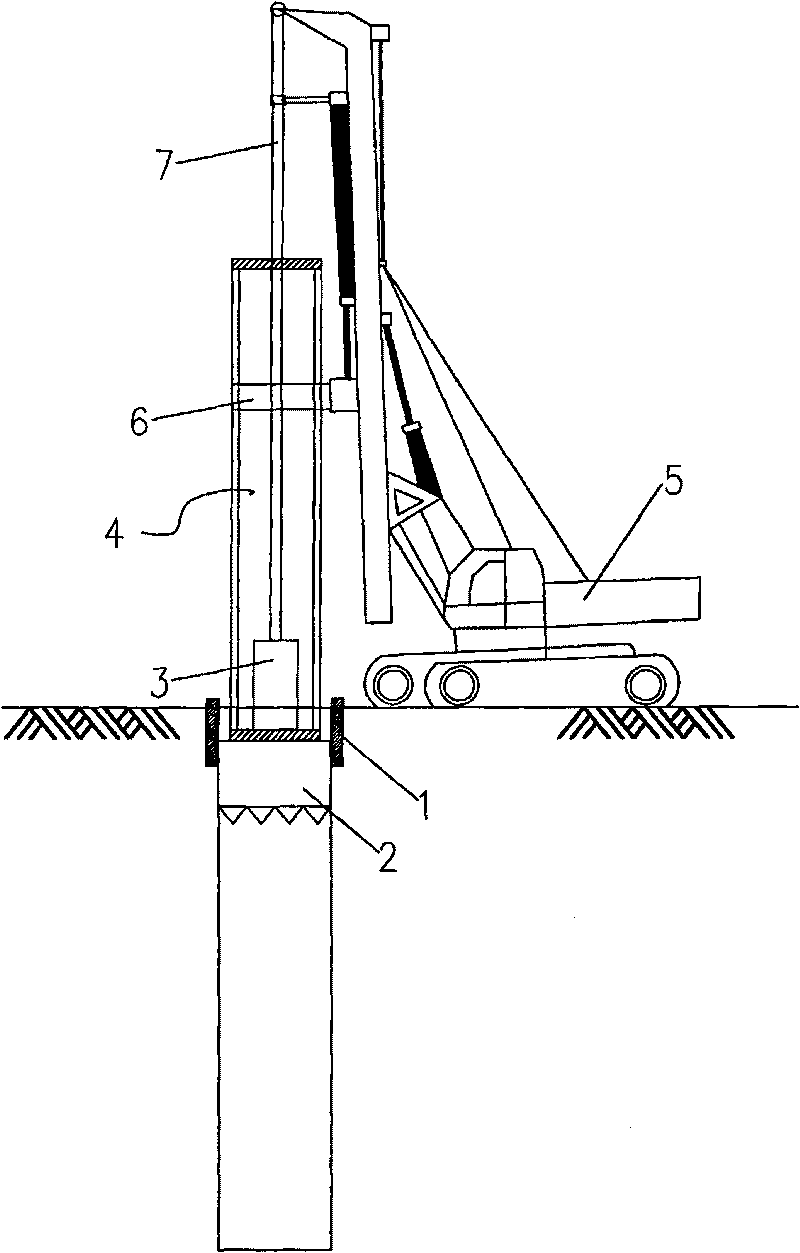

[0031] like figure 1 Shown: the drilling is positioned, the drilling rig is in place, the pipe body 4 of the first section is put on the drill pipe 7, and the pipe body is a high-strength prestressed concrete pipe or steel pipe, and then the pipe body 4 is clamped with the clamp 6 on the drilling rig 5 The front end of the drill pipe 7 is equipped with a down-the-hole hammer impactor 3 and a reaming retractable drill bit 2. After adjusting the position and the verticality of the drill pipe 7, the drill is started; in order to protect the ground hole from collapsing when drilling, a 1.0m Casing 1 of ~1.5m.

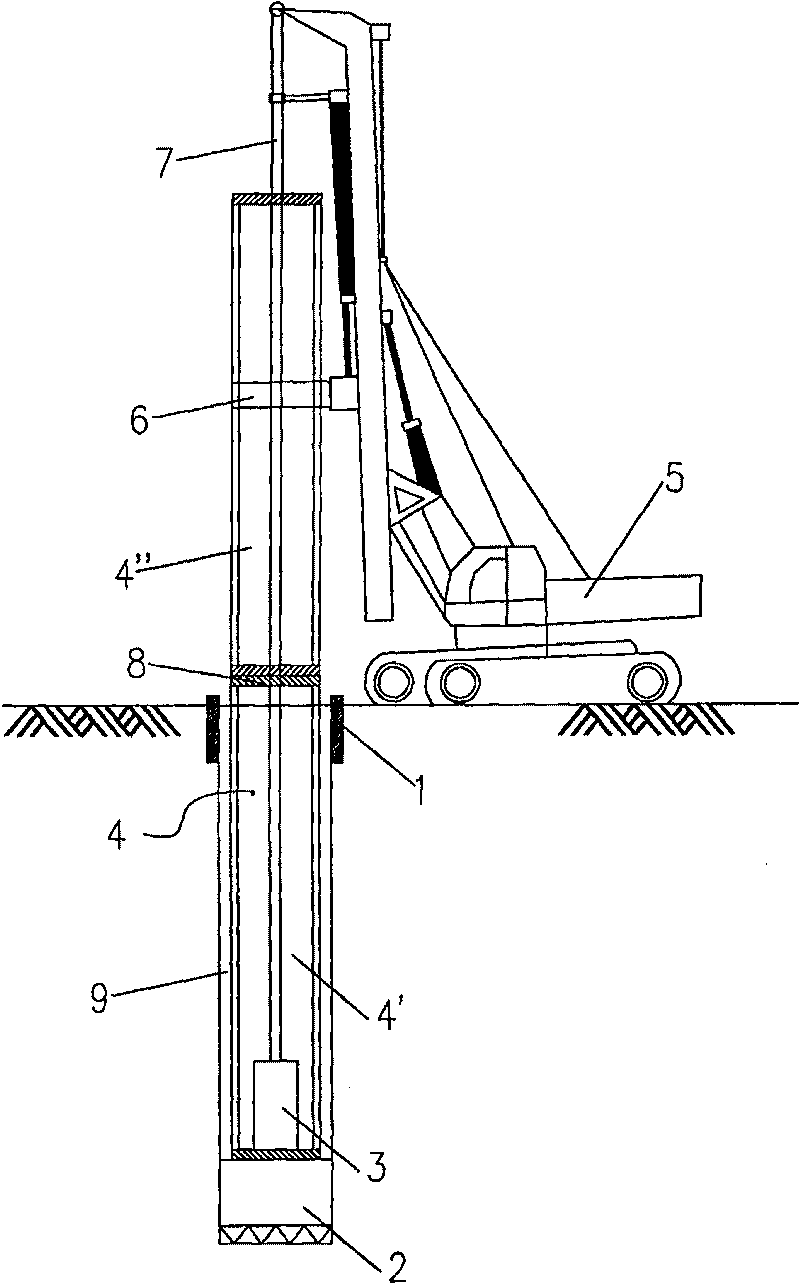

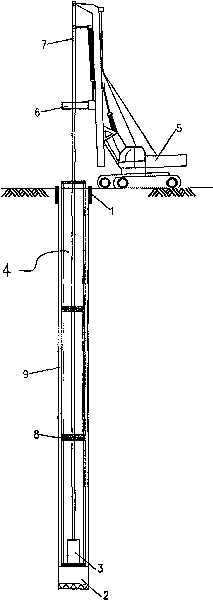

[0032] like figure 2 As shown: under the action of the down-the-hole hammer impactor 3, the reaming retractable drill bit 2 drills downward, and the drill rod 7 drives the pipe body 4 to sink. When the first section of pipe body 4' sinks to 20-50cm from the ground, stop drilling and install the second section of pipe body 4". Barge the multi-section pipe body 4 to the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com