Construction method of water-stop curtain for deep foundation pit by using high-pressure rotary grouting pile machine

A technology of high-pressure rotary jetting pile machine and water-stop curtain, which is applied in basic structure engineering, sheet pile wall, construction, etc., can solve the problem of increasing the income of construction site personnel, materials, machinery and materials, and increasing the construction period of deep foundation pit water-stop curtain , the increase of construction costs and other problems, to achieve the effect of optimizing construction technical parameters, shortening construction period and improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Use the following methods to construct the water-stop curtain for the above-mentioned deep foundation pit:

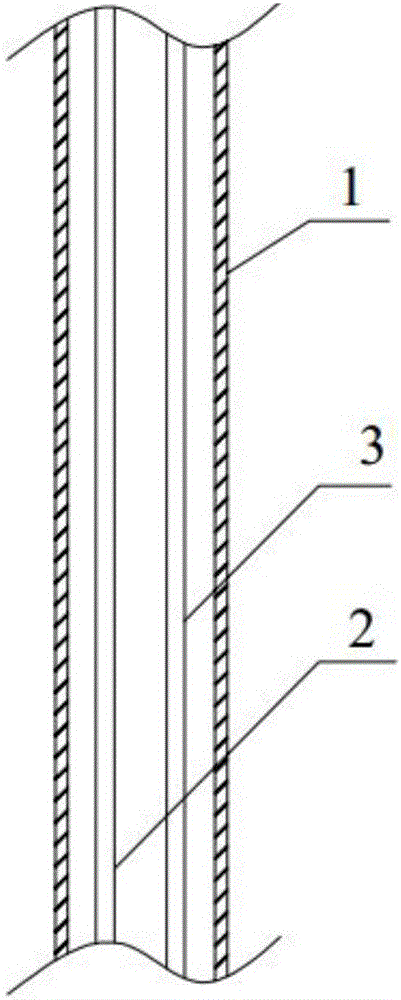

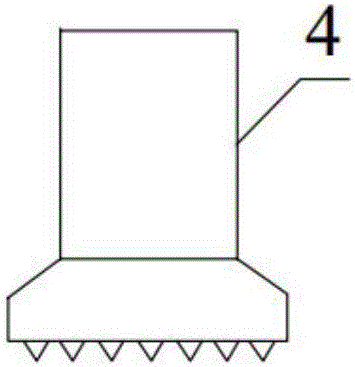

[0038] (1) Modification of high-pressure rotary grouting pile machine

[0039] The CFG pile driver is refitted into a high-pressure rotary grouting pile driver. The modification method is to install the grouting pipe and the gas injection pipe inside the drill pipe of the CFG pile driver. The specific installation method is to remove the drill pipe of the CFG pile driver in sections; The tops of the grouting pipe and the air injection pipe are respectively connected with the high-pressure mud pump and the air compressor, and then the grouting pipe and the air injection pipe are passed through each section of the drill pipe in turn, and the grouting pipe and the air injection pipe are passed through each section of the drill pipe at the same time. The gas injection pipe is fixed and welded at the end of each section of drill pipe with steel hoops. Using the above...

Embodiment 2

[0053] Use the following methods to construct the water-stop curtain for the above-mentioned deep foundation pit:

[0054] (1) Modification of high-pressure rotary grouting pile machine

[0055] The CFG pile driver is refitted into a high-pressure rotary grouting pile driver. The modification method is to install the grouting pipe and the gas injection pipe inside the drill pipe of the CFG pile driver. The specific installation method is to remove the drill pipe of the CFG pile driver in sections; The tops of the grouting pipe and the air injection pipe are respectively connected with the high-pressure mud pump and the air compressor, and then the grouting pipe and the air injection pipe are passed through each section of the drill pipe in turn, and the grouting pipe and the air injection pipe are passed through each section of the drill pipe at the same time. The gas injection pipe is fixed and welded at the end of each section of drill pipe with steel hoops. Using the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com