Super-large-diameter prestressed concrete tubular pile for offshore wind power and construction method thereof

An ultra-large-diameter, offshore wind power technology, applied in wind power generation, wind engine assembly, installation/supporting wind engine configuration, etc., can solve problems such as high cost, steel pipe piles are susceptible to erosion, corrosion weight, etc., to reduce settlement , Improve the stability and bending resistance of the pile body, and improve the bearing capacity of the pile foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

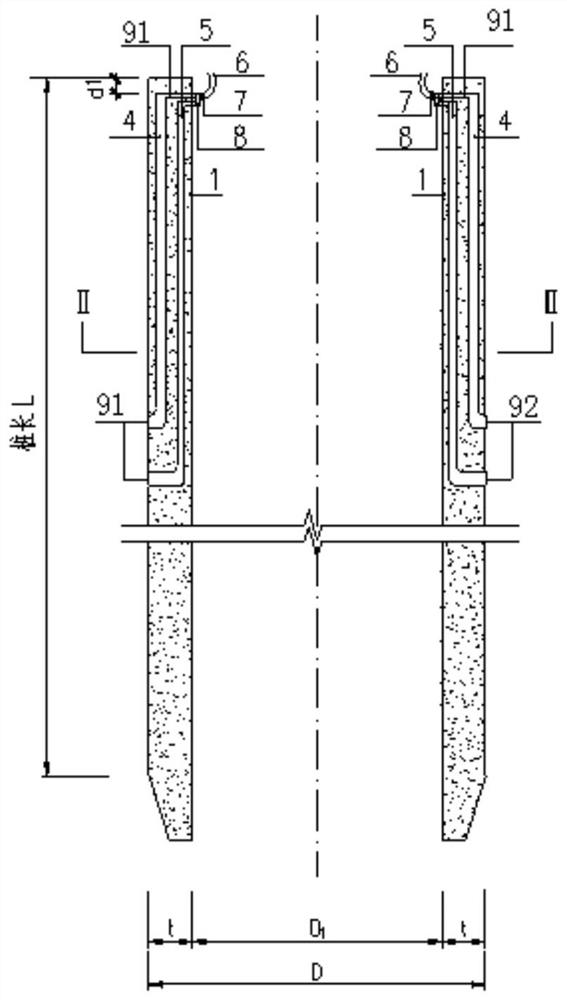

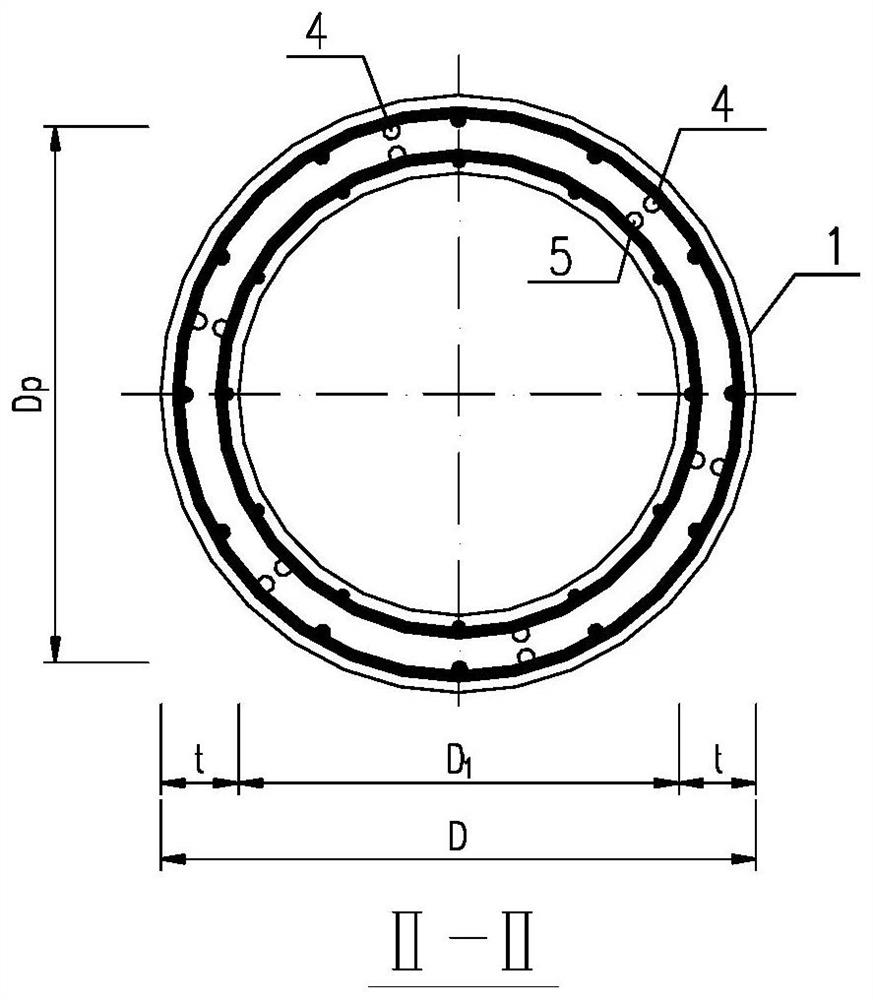

[0056] The present invention will be described in detail below in conjunction with embodiments and accompanying drawings.

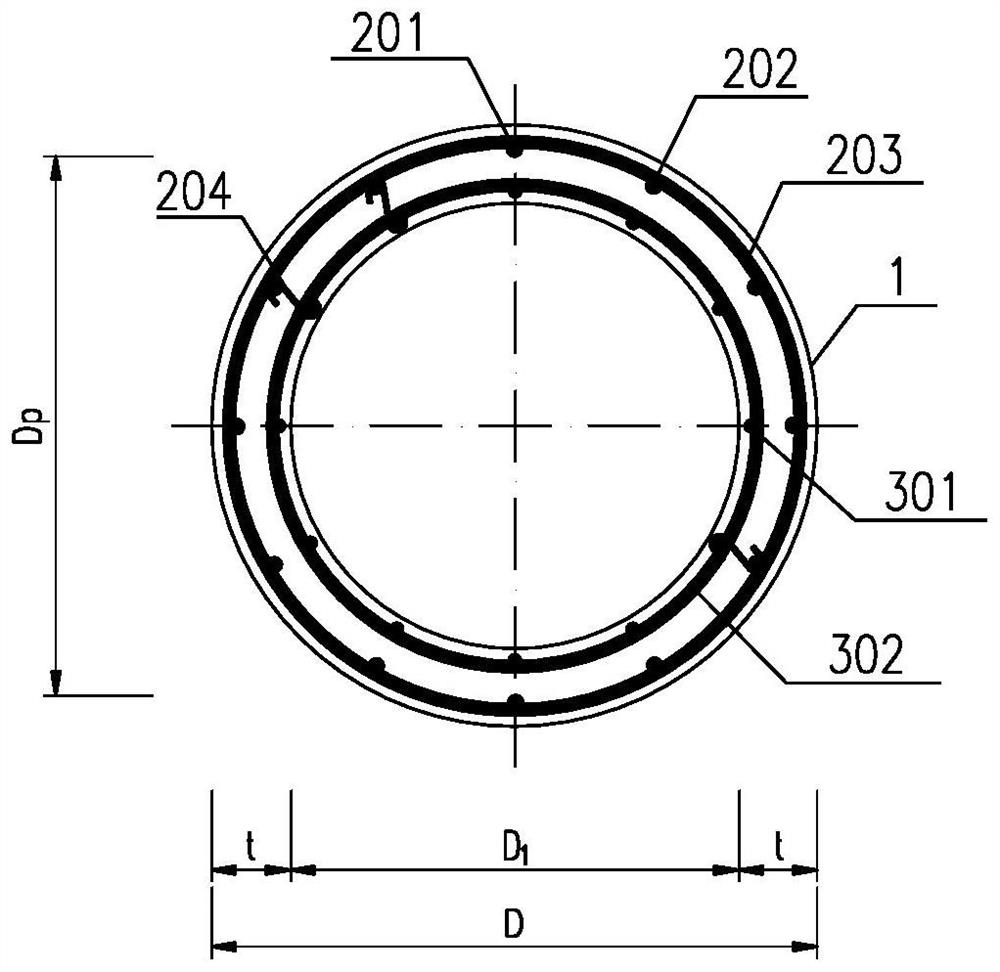

[0057] like Figure 1-3 As shown, the ultra-large diameter prestressed concrete tubular pile of the present invention includes the tubular pile body. During construction, it mainly includes the following steps: A, binding the steel cage skeleton 1; B, on the steel cage skeleton 1, The main components of the post-fixing grouting device-outer ring laminated grout pipe 4, inner ring laminated grout pipe 5; C, using post-tensioning construction technology to promote the formed concrete barrel pile to meet the preset prestress; D, with steps B. Based on the pre-embedded outer ring lamination grout pipe 4 and inner ring lamination grout pipe 5, other auxiliary components of the post grouting device are assembled on site, and the on-site construction of the concrete barrel pile is completed through the post grouting construction process.

[0058] The specific s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com