Reinforced CFG pile mixture suitable for soft soil area, CFG pile, composite foundation and construction method of composite foundation

A kind of mixed material and reinforced technology, which is applied in the direction of soil protection, foundation structure engineering, sheet pile wall, etc., can solve the problems such as the decline of pile body strength, achieve the effect of reducing cement consumption, good control effect, and improving pile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6 and comparative example 1~10

[0053] A CFG pile mixture is made of the following raw materials: cement, fly ash, fine aggregate, coarse aggregate, water, silicon powder, water glass, and polycarboxylate water reducer. Among them, the cement model is P.O 42.5 grade ordinary Portland cement; the fly ash grade is grade II; the fine aggregate is medium-coarse sand; the coarse aggregate is gravel with a particle size of 5-20 mm; ~200nm; the modulus of water glass is 2.9, and the concentration is 20 degrees Baume; the polycarboxylate superplasticizer is a polycarboxylate superplasticizer with methacrylic acid as the main chain, specifically Dingli brand CQJ-JSS002 polycarboxylate superplasticizer Aqua.

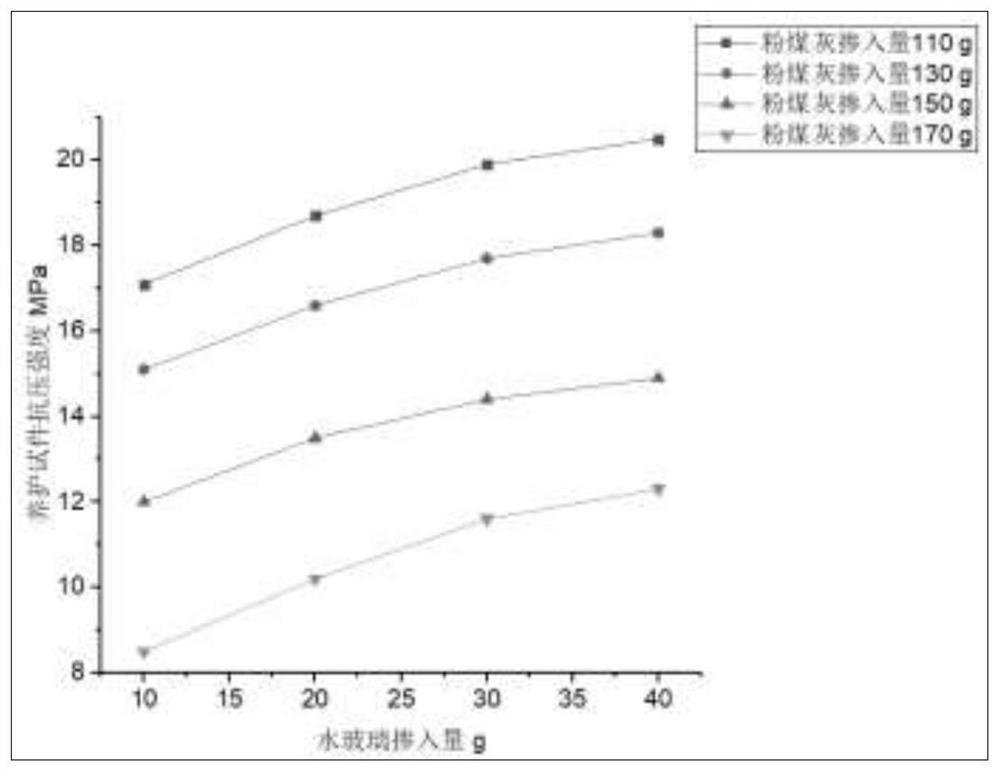

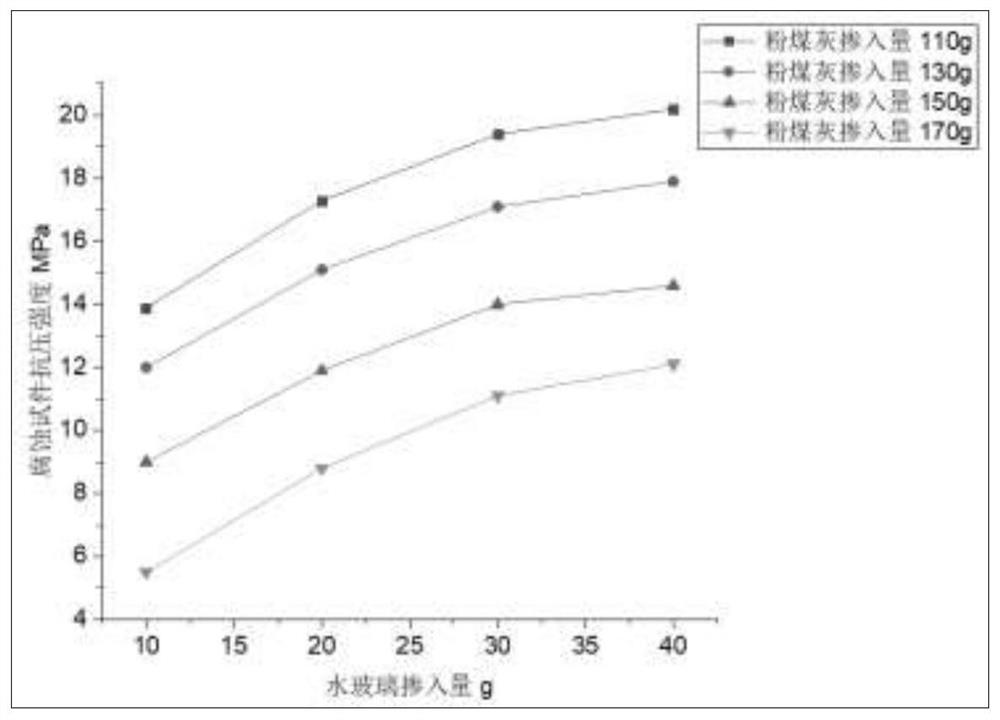

[0054] The above-mentioned CFG pile mixture was made into concrete specimens, and the mix proportions of the concrete specimens in Examples 1-6 and Comparative Examples 1-10 are shown in Table 1.

[0055] The preparation method of the concrete specimen is as follows: add water glass, silica fume, coarse aggrega...

Embodiment 7

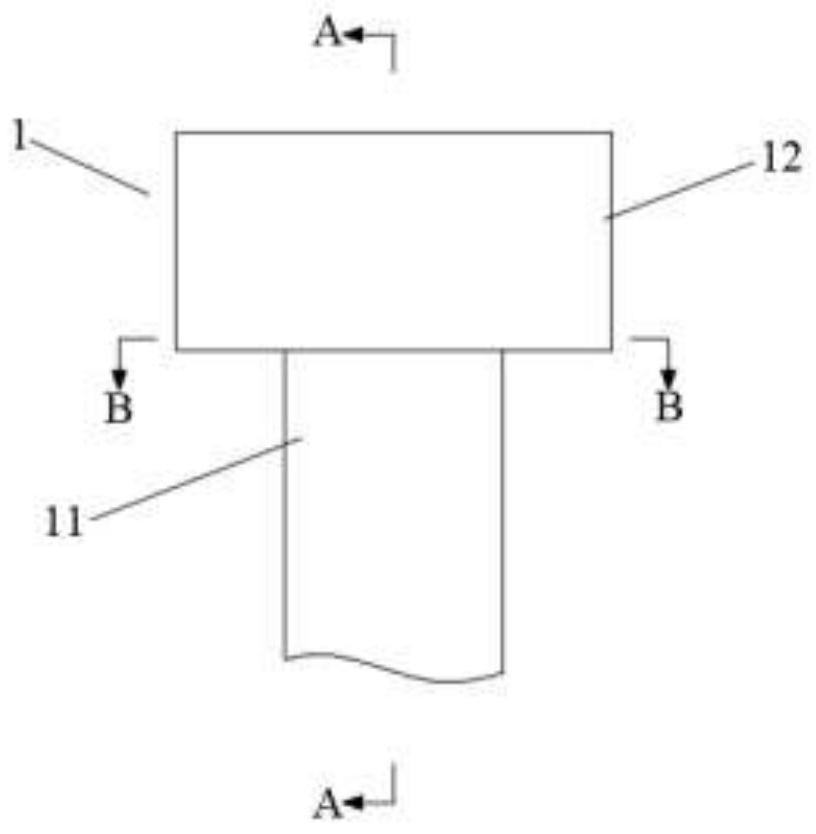

[0065] Such as Figure 3-5 As shown, the reinforced CFG pile suitable for soft soil areas in this embodiment, the CFG pile 1 includes a pile body 11, the pile body 11 is a cast-in-place pile body, and the pile body 11 is mixed with any CFG pile in Examples 1-6 The material is prepared.

[0066] In this embodiment, a pile cap 12 is fixed on the top of the pile body 11. The pile cap 12 is a prefabricated reinforced concrete pile cap. The pile cap 12 is a square structure. A cylindrical groove 121, the top of the pile body 11 is located in the cylindrical groove 121 and is fixedly connected with the top surface of the cylindrical groove 121 through the mortar layer 13.

[0067] In order to prevent the pile head from being damaged under pressure, a pile cap 12 is arranged at the pile head of the pile body 11 . The pile cap can expand the load-bearing area of the top of the CFG pile 1 to change the stress form of the pile top, and arranging a certain number of steel bars in the...

Embodiment 8

[0071] Such as Figure 6~7 As shown, the CFG pile composite foundation in this embodiment includes a foundation 2 and multiple rows of CFG piles 1 in Embodiment 7 distributed on the foundation 2 . In this embodiment, two adjacent rows of CFG piles 1 are arranged staggeredly, and the distance between any adjacent two pile bodies 11 on the foundation 2 is equal, that is, each CFG pile is adjacent to it in another row of CFG piles. The two closest CFG piles are distributed in an equilateral triangle. The distance between the axis lines of any two adjacent pile bodies 11 is 1.5-2.0m.

[0072] In this embodiment, the distance between piles is calculated based on numerical simulation, which involves engineering properties of soil, side friction of piles, and the like. Through numerical simulation, the pile body 11 can significantly improve the bearing capacity of the soil within a certain range, and the range is circular (such as Figure 8 shown in the shaded part). Pile body 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com