High-pressure jet grouting pile hole leading construction integrated device and construction method thereof

A technology of high-pressure rotary jetting pile and high-pressure jetting, which is applied to the driving device for drilling, excavation, sheet pile wall, etc. problems, to achieve the effect of rapid construction, good hole wall quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

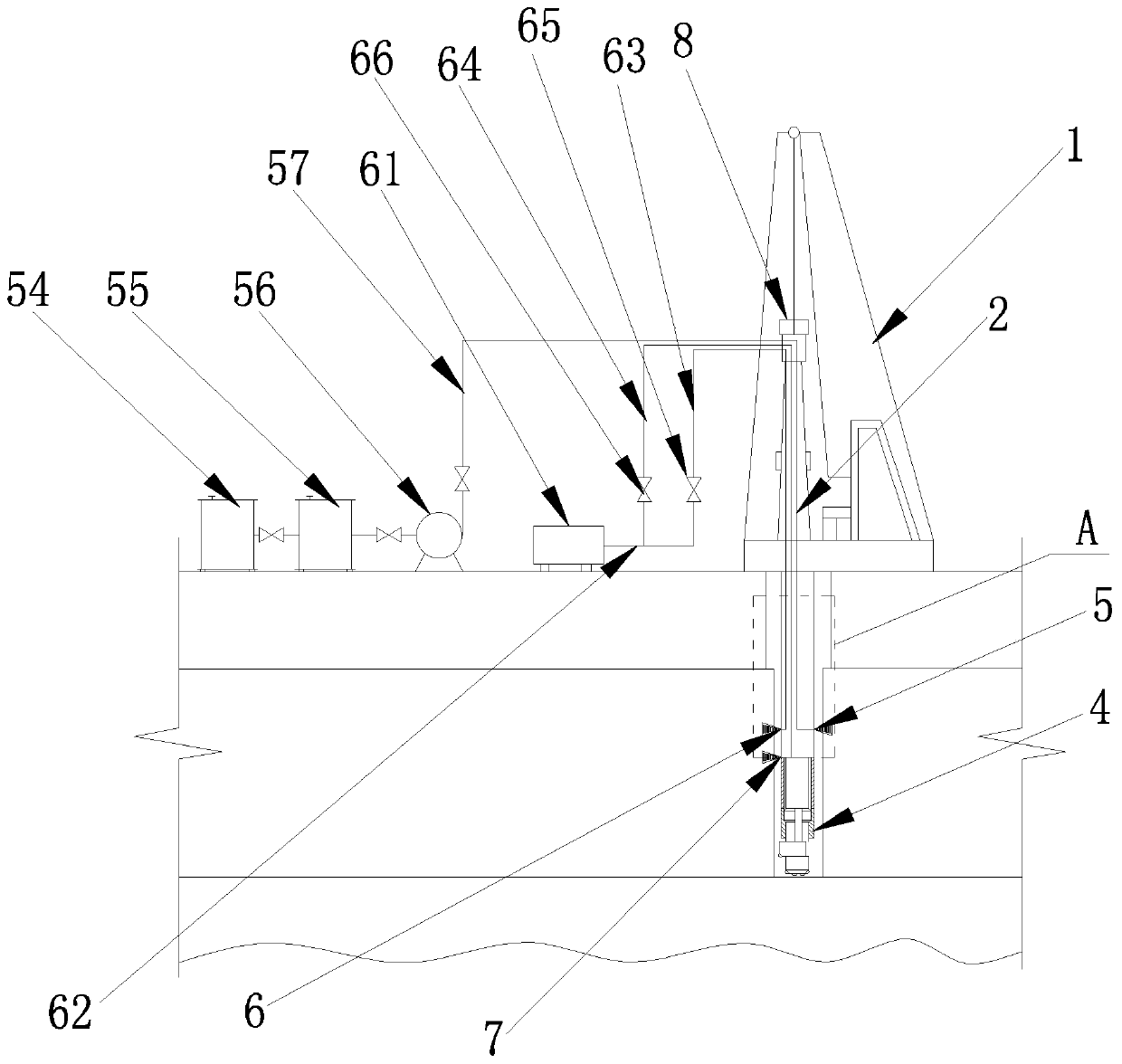

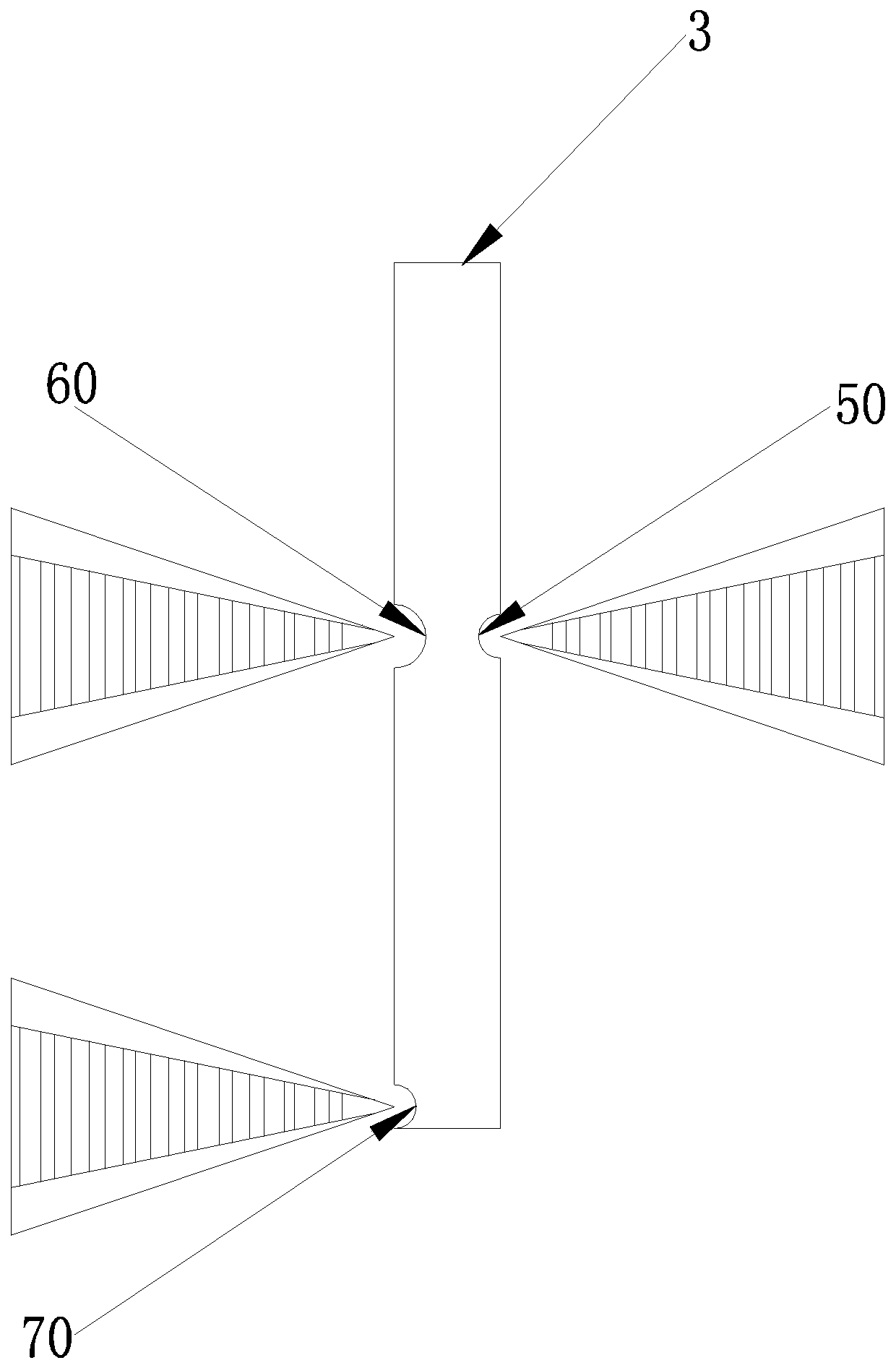

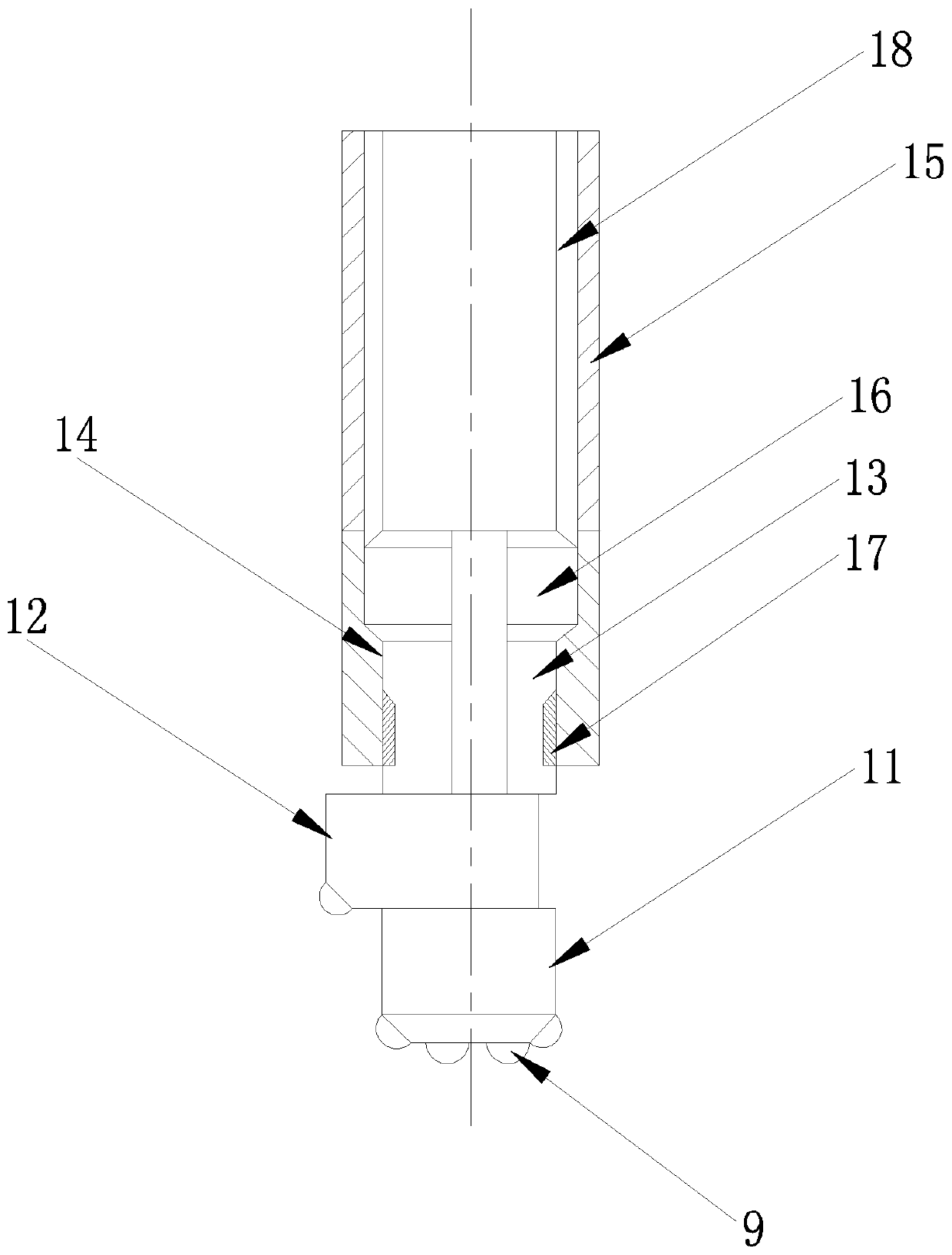

[0040] like Figure 1-3 As shown, a high-pressure rotary grouting pile introduction hole construction integrated device includes a rotary jet drilling machine 1, a high-pressure jet drill pipe 2 and a triple pipe 3; the triple pipe 3 is fixed at the bottom of the high-pressure jet drill pipe 2, and the bottom of the triple pipe 3 is fixed A down-the-hole hammer 4 is provided; the triple pipe 3 includes a slurry ejector 5, an inner air ejector 6, and an outer air ejector 7 arranged sequentially from the inside to the outside; the down-the-hole hammer with a casing drill provided by the present invention High-efficiency drilling and forming holes under various complex geological conditions such as soft and hard formations, gravel layers, pebble layers, and floating stone rock layers. At the same time, due to the rotation and follow-up of the casing drill, the hole diameter and hole wall quality are good. , high vertical precision and rapid construction; overcome the noise, vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com