Rock-socketed pipe pile foundation with pile core by concrete pouring and pile side by static pressure grouting and construction method for rock-socketed pipe pile foundation

A technology of pouring concrete and concrete pipe piles, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., to achieve the effects of improving bearing capacity, simple and reliable construction methods, and improving pile body strength and pile side frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

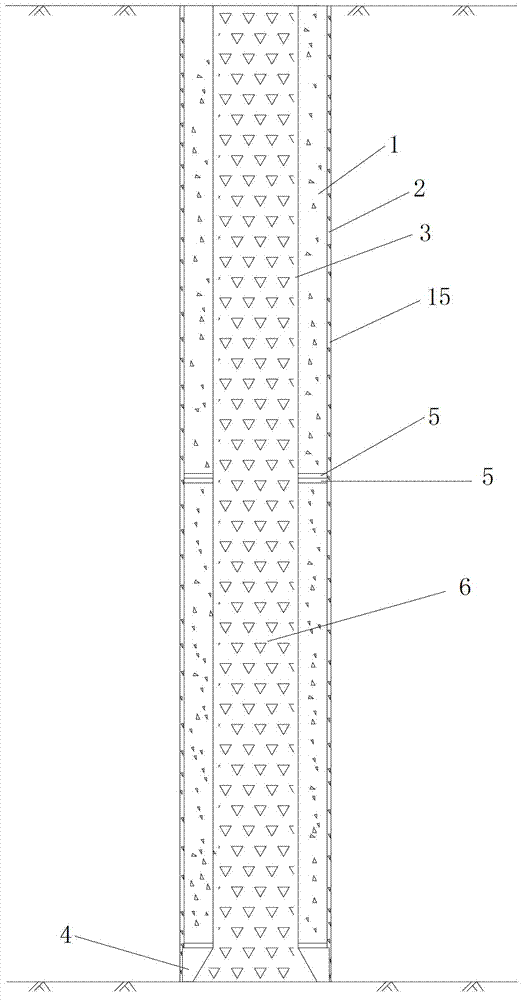

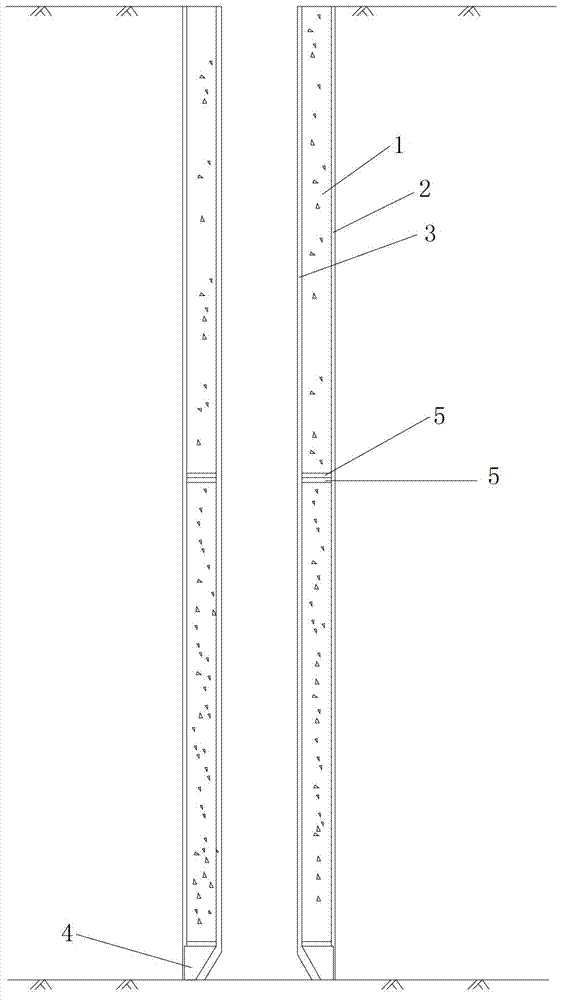

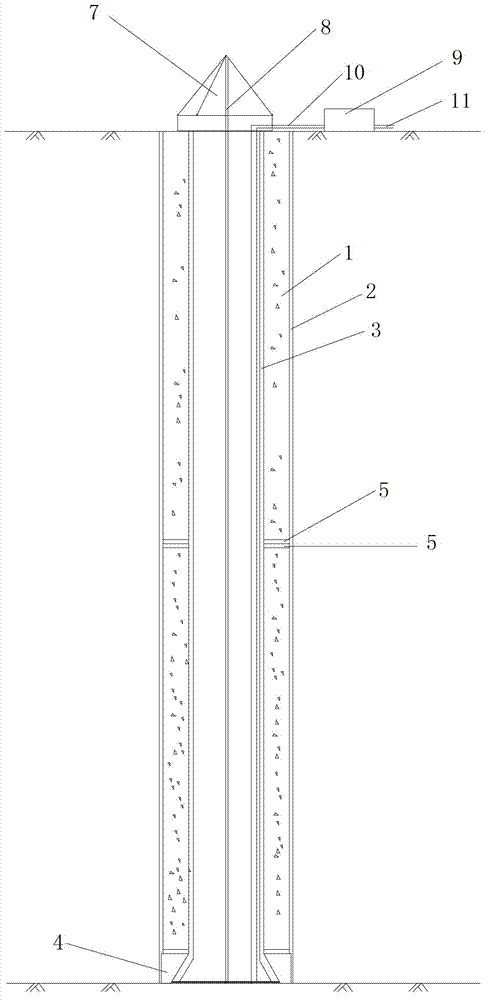

[0032] In order to make the present invention easier to understand, the features and effects of the present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the present invention is not limited to the following embodiments.

[0033] See Figure 1~5 As shown, the rock-socketed pipe pile foundation of the pile core pouring concrete pile side static pressure grouting includes: prestressed concrete pipe pile 1, pile shoe 4, pile core pouring concrete 6 and pile side static pressure grouting cement formed The slurry 11, the pile shoe 4 is connected with the lower end plate 5 of the prestressed concrete pipe pile 1 at the lowest section of the pipe pile foundation; the upper and lower sections of the prestressed concrete pipe pile 1 are welded by electric welding or mechanically connected, The pipe pile joints are sealed and connected with a water stop strip; the concrete 6 poured into the pile core is under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com