Small-diameter cast-in-place tube pile composite foundation treatment method for permafrost foundation of Qinghai-Tibet highway

A technology for permafrost foundation and composite foundation, which is applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problem that the thermal thawing subsidence of permafrost foundation is not well solved, and achieves easy quality control, simple construction technology, Actionable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

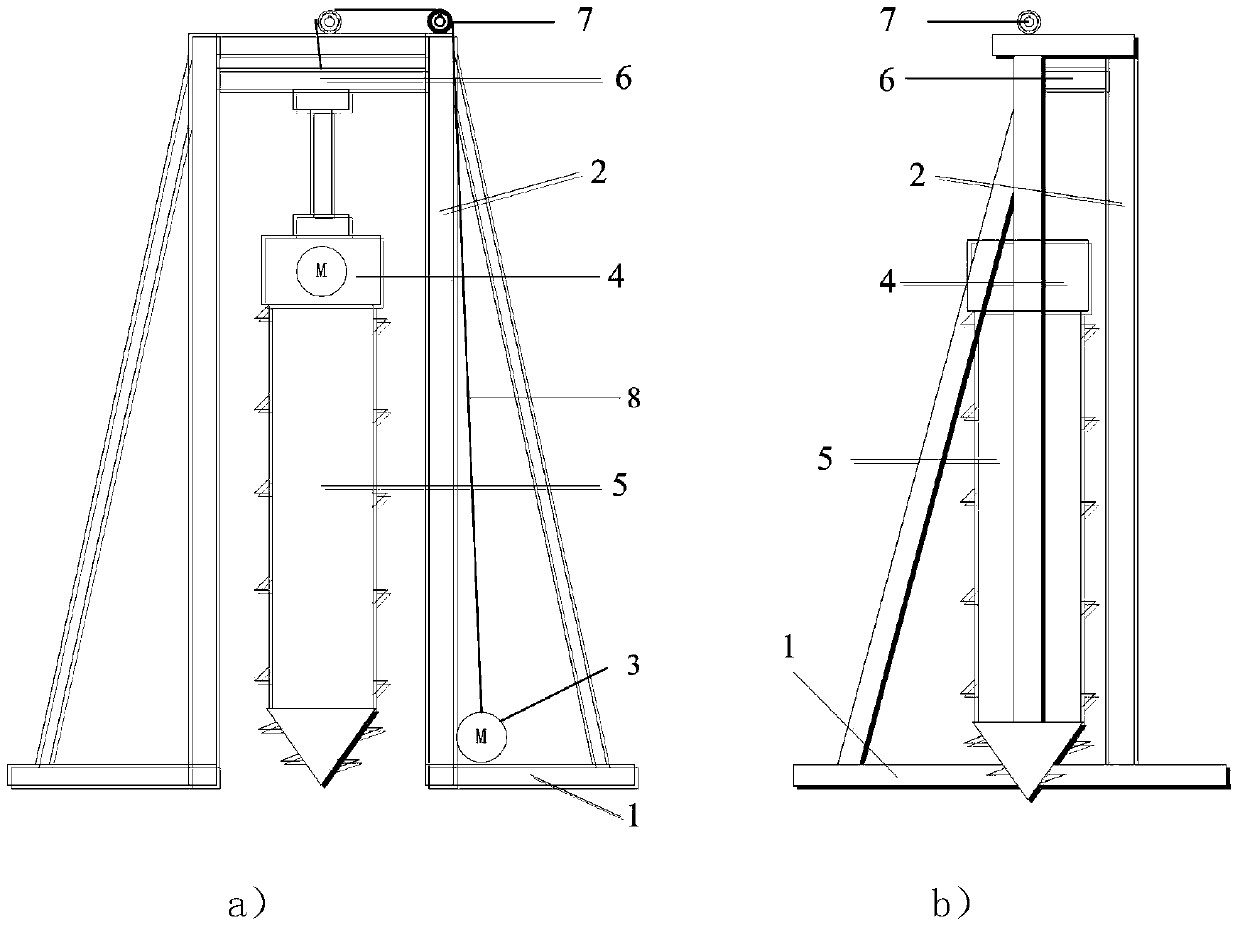

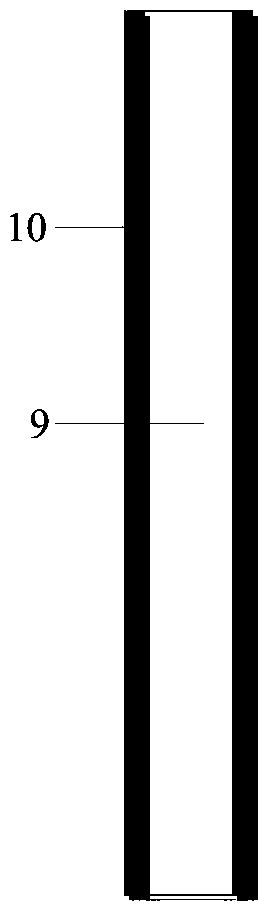

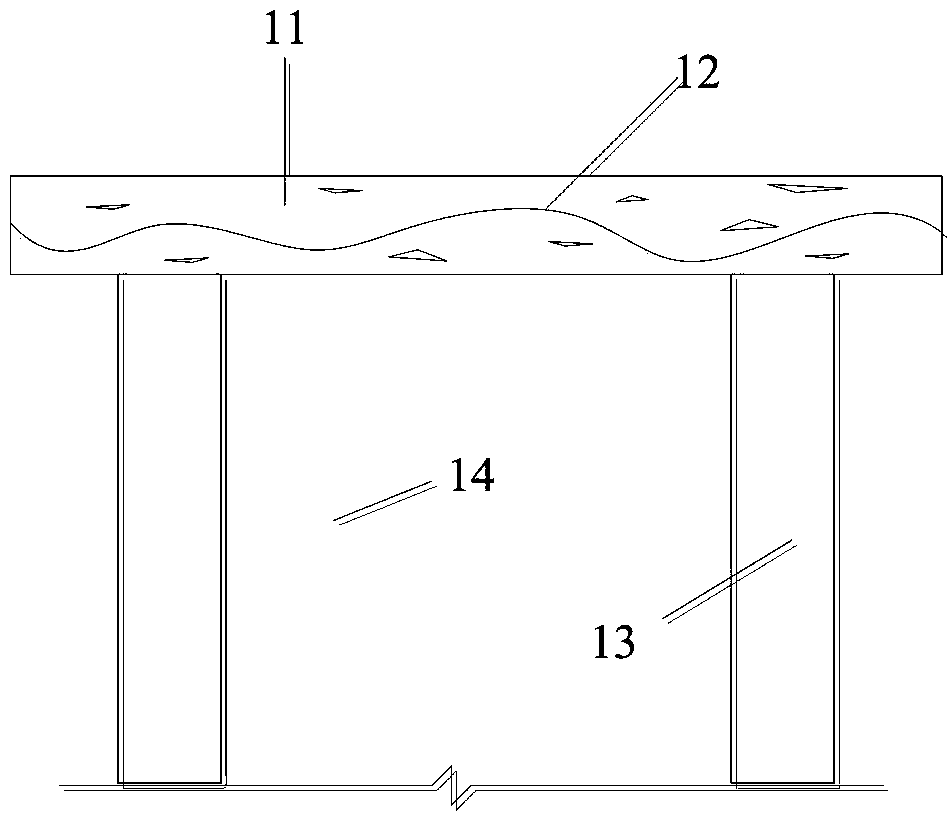

[0035] Such as figure 1 The small-diameter cast-in-place pipe pile machine shown in the steel pipe mold is positioned on the pre-treated permafrost foundation 14, the equipment foundation 1 is fixedly connected with the bottom of the gantry support 2, and the inner side of the gantry support 2 is provided with a chute , the sliding rod 6 is connected with the chute on the gantry bracket, the sliding rod 6 is connected with the rotary machine 4 (with a power source inside), and the lower part of the rotary machine 4 is connected to the steel pipe cavity structure 5 with a diameter of about 50-80 cm and a spiral outside. fixed. Fix the pulley power source 3 on the equipment foundation 1, fix the pulley 7 in the middle of the top of the gantry support 2 and the right end, and the steel wire rope 8 connects the slide bar 6 with the pulley power source 3 through the pulley 7 to realize the up and down movement of the slide bar 6.

[0036] Start the power source of the rotating mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com