Concrete for precasting magnesium oxide carbonized pile and application thereof

A technology of magnesium oxide carbonized piles and magnesium oxide, which is applied in the direction of sheet pile walls, manufacturing tools, ceramic molding machines, etc., can solve the problems of lack of experimental data, etc., and achieve the effects of good quality stability, good water retention, and sufficient bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

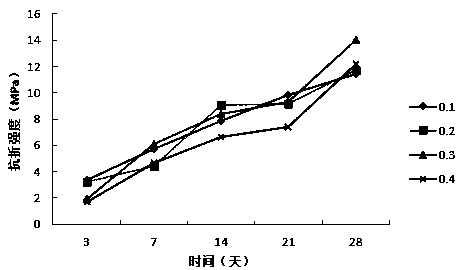

[0030] A concrete formula for prefabricated piles includes the following raw materials by weight: 337.5g of magnesium oxide, 337.5g of cement, 75g of fly ash, 750g of water, 5500g of sand, 8000g of gravel, and 40g of water reducing agent. Inject into a mold with a length of 400 mm, a width of 100 mm, and a height of 100 mm for vibration, and immediately put it into a carbonization box for carbonization curing. After 24 hours, it will be removed from the mold and continue to be cured. 2 The concentration is 20%. When the carbonization reaches 3 days, 7 days, 14 days and 28 days, the block is subjected to a flexural strength test, and the average value of the test strength is taken as the result.

Embodiment 2

[0032] A concrete formula for prefabricated piles includes the following raw materials: magnesia 300g, cement 300g, fly ash 150g, water 750g, sand 5500g, crushed stone 8000g, water reducer 40g, mix the mixture evenly and pour it into the specification Vibrate in a mold with a length of 400mm, a width of 100mm, and a height of 100mm, immediately put it into a carbonization box for carbonization curing, demould after 24 hours and continue curing. The parameters of the carbonization box are controlled at 20°C, 60% humidity, and 2 The concentration is 20%. When the carbonization reaches 3 days, 7 days, 14 days and 28 days, the block is subjected to a flexural strength test, and the average value of the test strength is taken as the result.

Embodiment 3

[0034] A concrete formula for prefabricated piles includes the following raw materials: 262.5g of magnesium oxide, 262.5g of cement, 225g of fly ash, 750g of water, 5500g of sand, 8000g of gravel, and 40g of water reducing agent. Inject into a mold with a length of 400 mm, a width of 100 mm, and a height of 100 mm for vibration, and immediately put it into a carbonization box for carbonization curing. After 24 hours, it will be removed from the mold and continue to be cured. 2 The concentration is 20%. When the carbonization reaches 3 days, 7 days, 14 days and 28 days, the block is subjected to a flexural strength test, and the average value of the test strength is taken as the result.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com