Quincunx cement soil mixing high-strength bearing pile and forming method

A cement-soil mixing pile and cement-soil mixing technology are applied in sheet pile wall, construction, infrastructure engineering and other directions, which can solve the problems of small pile foundation area, single-column cement-soil pile inclination and scrapping, etc., and achieve high strength of the pile body. , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

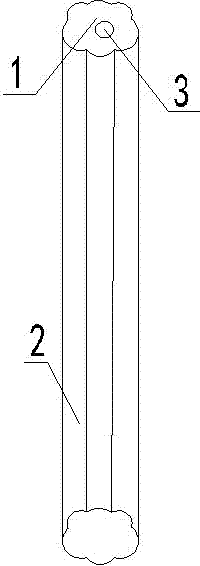

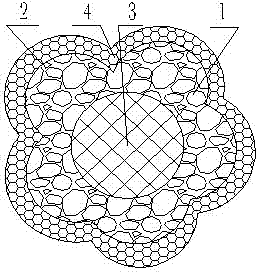

[0017] Embodiment 1: with reference to attached Figure 1-3 . A plum blossom-shaped cement-soil mixing high-strength load-bearing pile, including a cement-soil mixing pile 1, the two ends of the cement-soil mixing pile 1 and the pile body 2 are formed by connecting multiple plum blossom petals, and a concrete cement pile (solid core) 3 is located in the plum blossom-shaped cement-soil mixing high-strength bearing pile body. The concrete pipe pile 3 can be a prefabricated cement solid core pile or a prefabricated hollow cement pile, and can also be replaced by high-strength plastic columns, steel columns, steel pipes, profiles, etc. of various shapes. The included angles between the petals of multiple plum blossoms are equal or unequal.

Embodiment 2

[0018] Example 2: A plum blossom-shaped cement-soil mixing high-strength load-bearing pile, including a cement-soil mixing pile 1, the two ends of the cement-soil mixing pile 1 and the pile body 2 are formed by connecting multiple plum blossom petals, a concrete cement pile (Tube pile) 3 is located in the plum blossom-shaped cement-soil mixing high-strength load-bearing pile body. The concrete pipe pile 3 can be a prefabricated cement solid core pile or a prefabricated hollow cement pile, and can also be replaced by high-strength plastic columns, steel columns, steel pipes, profiles, etc. of various shapes. The included angles between the petals of multiple plum blossoms are equal or unequal.

Embodiment 3

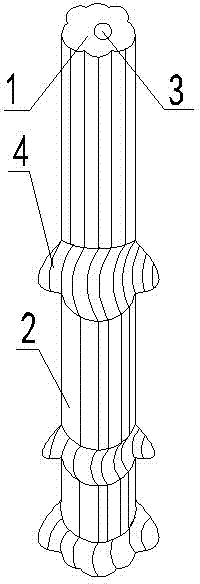

[0019] Embodiment 3: on the basis of above-mentioned embodiment 1 or 2, with reference to appended Figure 2-5 . The cement-soil mixing pile 1 with many plum blossoms has a pile body 2 with multiple rings of protrusions 4 . The multi-circle protrusions 4 on the pile body 2 of the multi-plum blossom cement-soil mixing pile 1 are distributed at intervals. A plurality of concrete cement piles (pipe piles) 3 are located in the plum blossom-shaped cement-soil mixing high-strength load-bearing pile body. The plurality of concrete pipe piles 3 can be prefabricated cement solid core piles or prefabricated hollow cement piles, and can also be replaced by high-strength plastic columns, steel columns, steel pipes, profiles, etc. of various shapes. The included angles between the petals of multiple plum blossoms are equal or unequal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com