Plum-blossom-shaped cement soil mixing pile and forming method thereof

A cement-soil mixing pile and plum blossom-shaped technology, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc., can solve the problem of small pile foundation area, single-column cement-soil pile inclination, single-column cement-soil pile body strength, etc. problems, to achieve the effect of good stability and high pile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

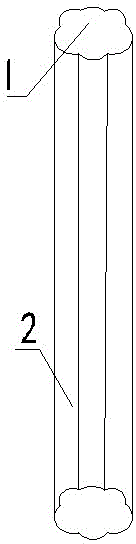

[0015] Embodiment 1: with reference to attached figure 1 . A plum blossom-shaped cement-soil mixing pile includes a cement-soil mixing pile 1, the two ends of the cement-soil mixing pile 1 and the pile body 2 are formed by connecting multiple plum blossom petals. The included angles between the petals of multiple plum blossoms are equal or unequal.

Embodiment 2

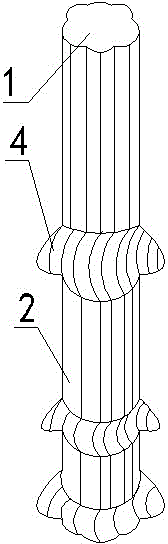

[0016] Embodiment 2: On the basis of above-mentioned embodiment 1, with reference to appended figure 2 and 3 . The cement-soil mixing pile 1 with many plum blossoms has a pile body 2 with multiple rings of protrusions 4 . The multi-circle protrusions 4 on the pile body 2 of the multi-plum blossom cement-soil mixing pile 1 are distributed at intervals.

Embodiment 3

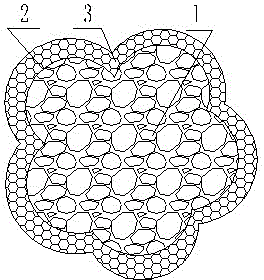

[0017] Embodiment 3: on the basis of above-mentioned embodiment 1 or 2, with reference to appended Figure 4 . Multiple plum blossom cement-soil mixing piles 1 are arranged side by side to form a double-row dislocation or multi-row dislocation cement-soil mixing pile structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com