Patents

Literature

32results about How to "Large pile diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

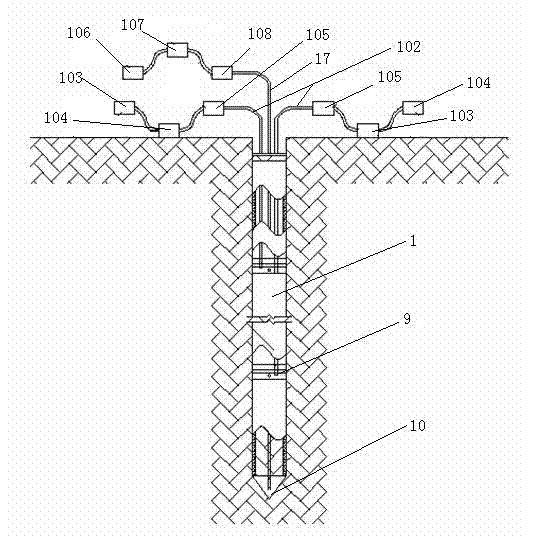

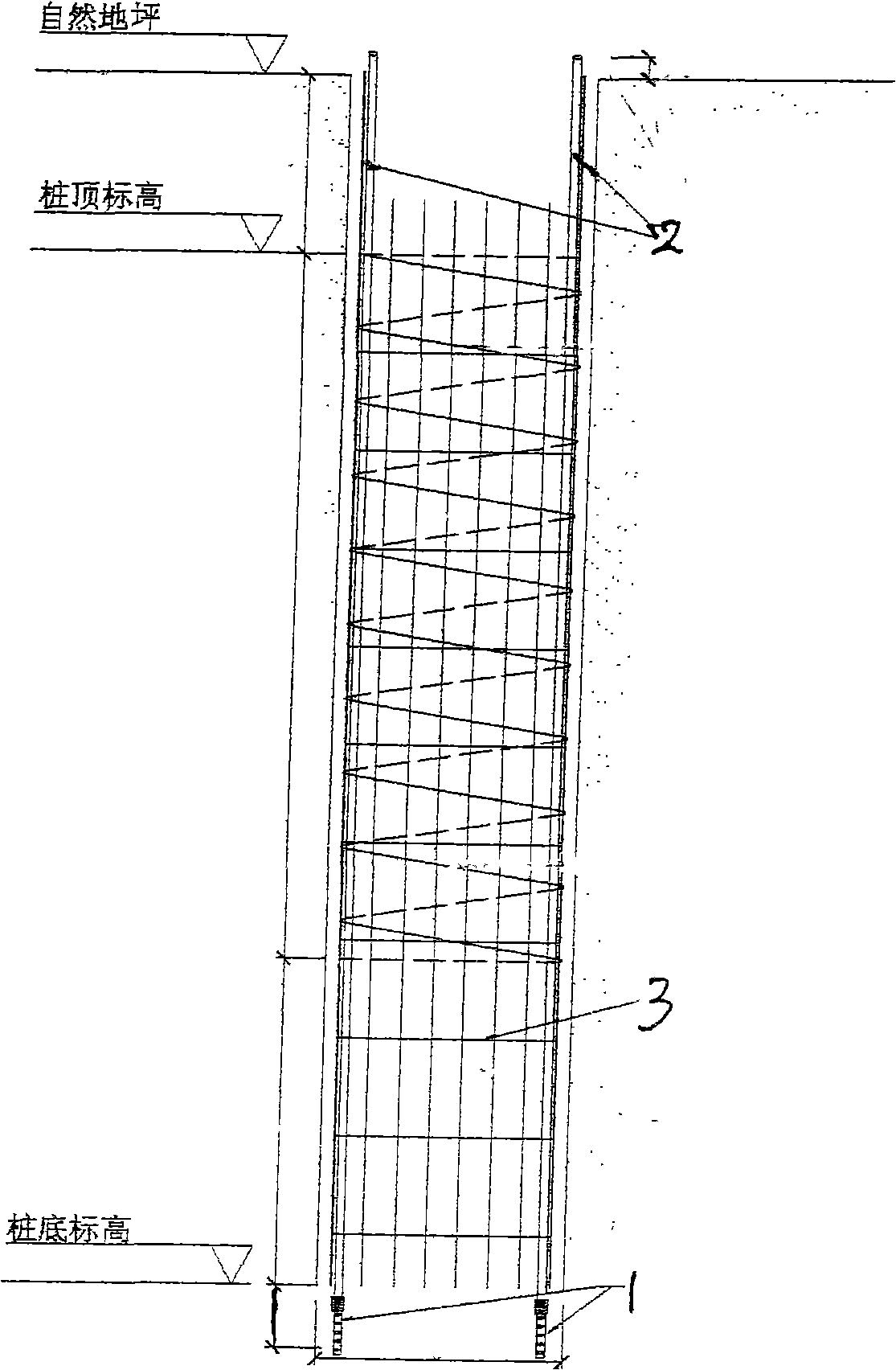

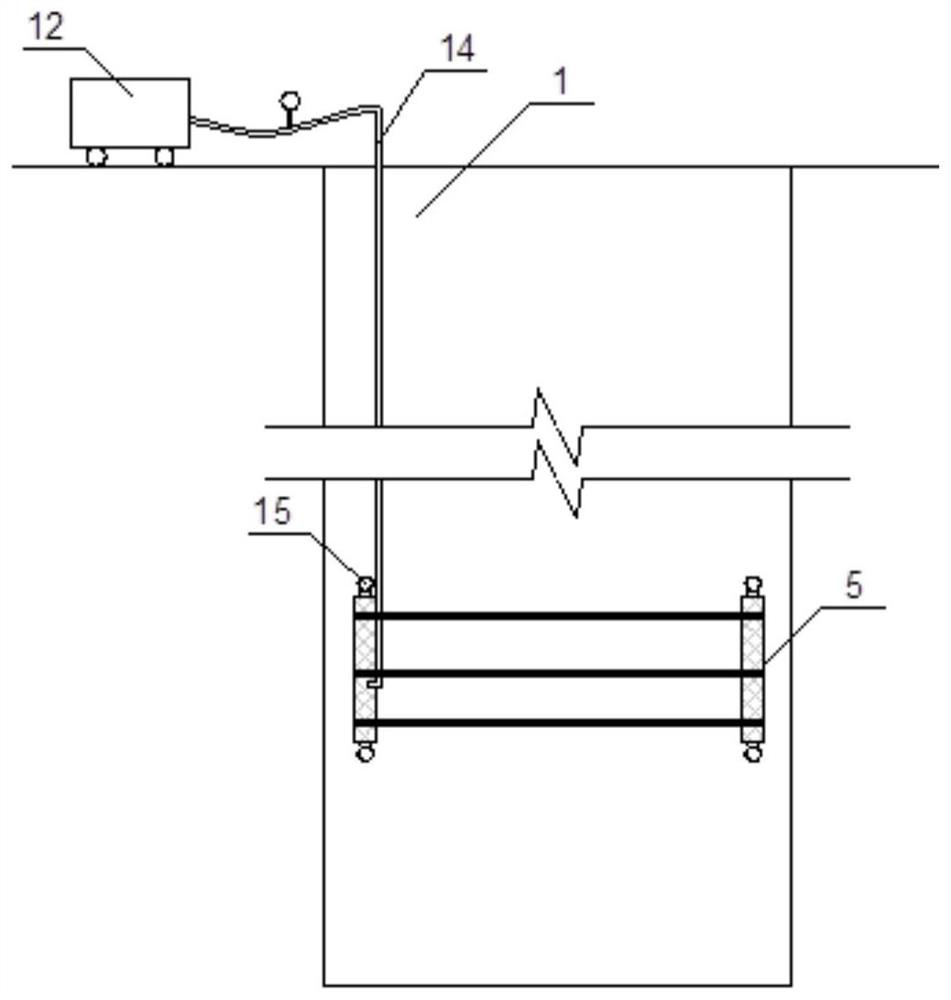

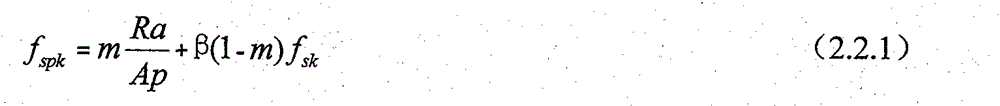

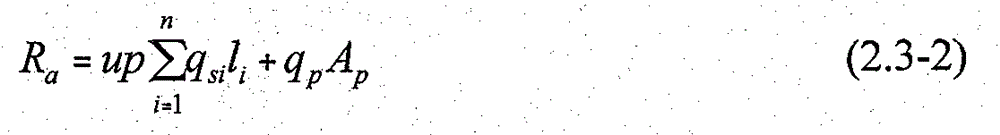

Joint grouting method from bottom and side of prestressed pipe pile

The invention relates to a joint grouting method from bottom and side of a prestressed pipe pile. The pipe pile in the soil is subjected to pressure joint grouting on the bottom and side (hole wall) of the pile through a ground grouting device by pre-burying pipelines at the bottom and side of the prestressed pipe pile. Post-grouting quality control adopts a dual-control method of grouting amount and grouting pressure; and cement injection quantity control is used as a primary part, and pumping end pressure is used as an auxiliary part. On one hand, a convex slurry pack stone body formed by grouting plays a protection role on a joint of the pipe pile and the use durability of the pipe pile is improved. In addition, the mechanical performance of a soil body and a boundary condition between the pile soils are changed by grouting, and the strength and the stability of rock-soil around the pile are further improved, so as to improve the bearing capacity of a pile foundation and reduce the settling volume. Therefore, the pile arrangement quantity and the size of a cushion cap can be reduced, the construction period can be shortened, and the construction costs can be reduced.

Owner:CHANGSHA UNIVERSITY

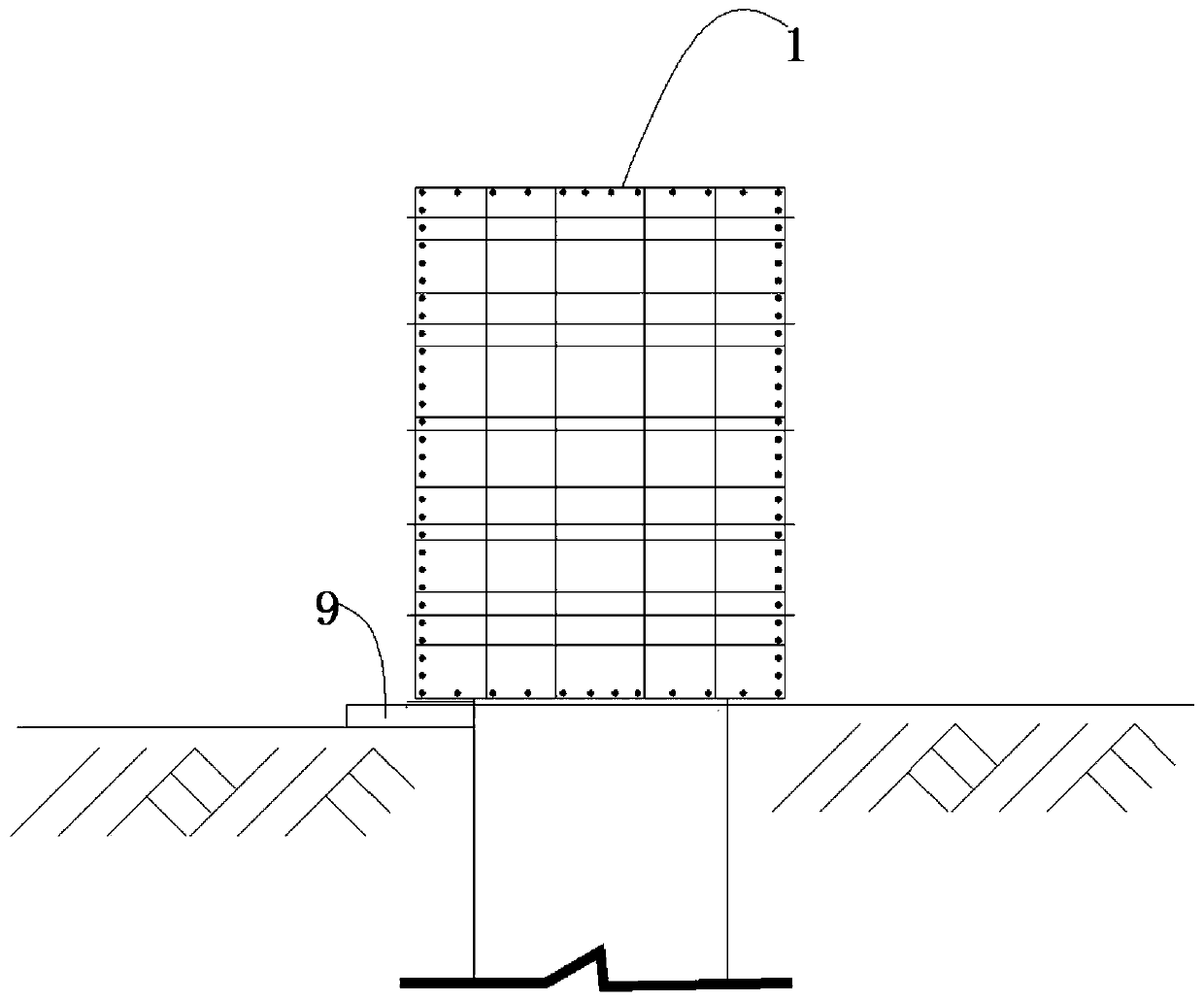

Pipe-jacking working well applicable to desert waterless sand area and construction method

PendingCN109797778AGood effectLarge pile diameterArtificial islandsShaft sinkingStructural engineeringEngineering

The invention provides a pipe-jacking working well applicable to desert waterless sand area and a construction method. The pipe-jacking working well is characterized in that a plurality of bore pilesare circumferentially uniformly arranged around the circle center the working well to form the main protecting and stress structure of the working well, a crown beam is arranged at the top of each bored pile, each circular crown beam and the working well are of a concentric circle structure, a liner is located on the inner side of each bored pile and vertically arranged along the depth direction of the working well, hidden beams are embedded into each liner and arranged at intervals along the length direction of the liner from top to bottom, a bottom plate is located at the bottom of the working well, a well bottom reinforcing jet grouting pile is arranged below the bottom plate, and hole reinforcing jet grouting piles located at positions where jacking pipe joints enter and exit holes arearranged on the outer sides of the bored piles. The pipe-jacking working well has the advantages that soil stability during excavation can be guaranteed by the bored piles, and the bored piles can bear large counter force needed by pipe-jacking construction; the liners can increase sand stability among the piles and evenly transmits horizontal load to the bored piles.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

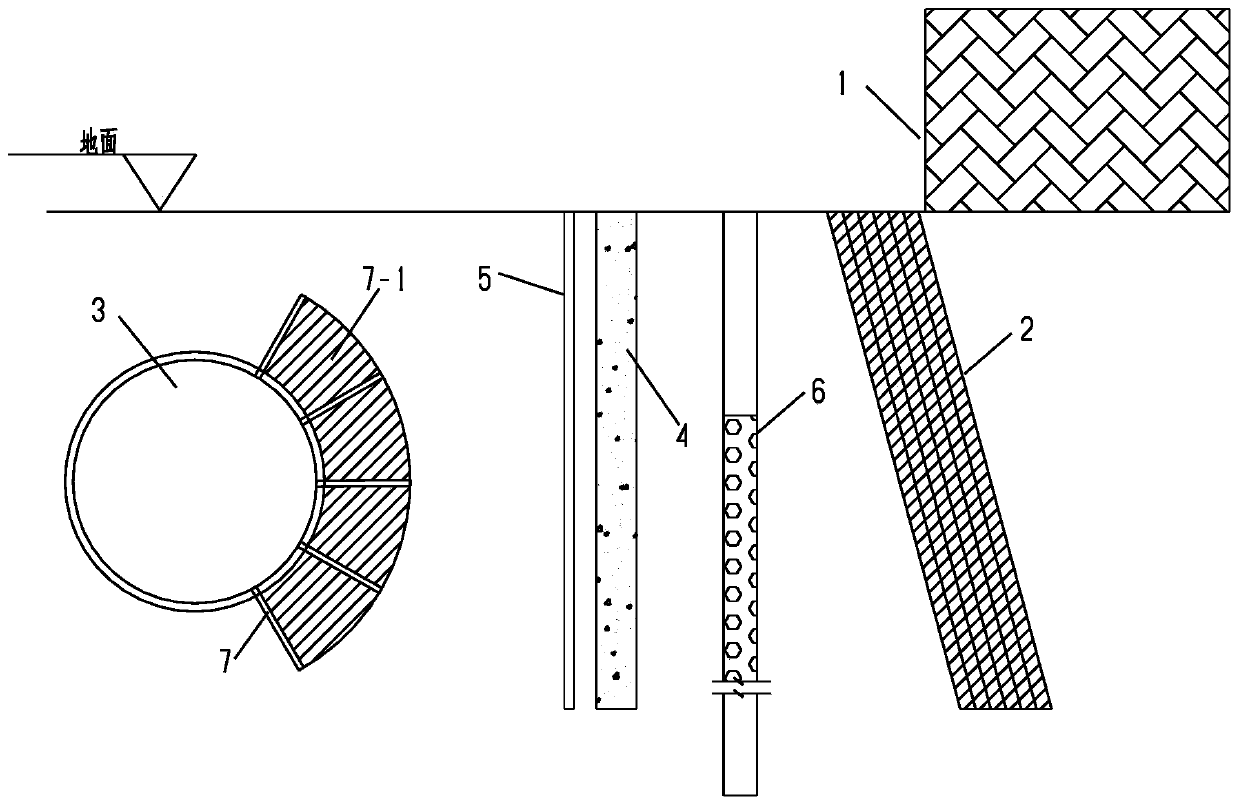

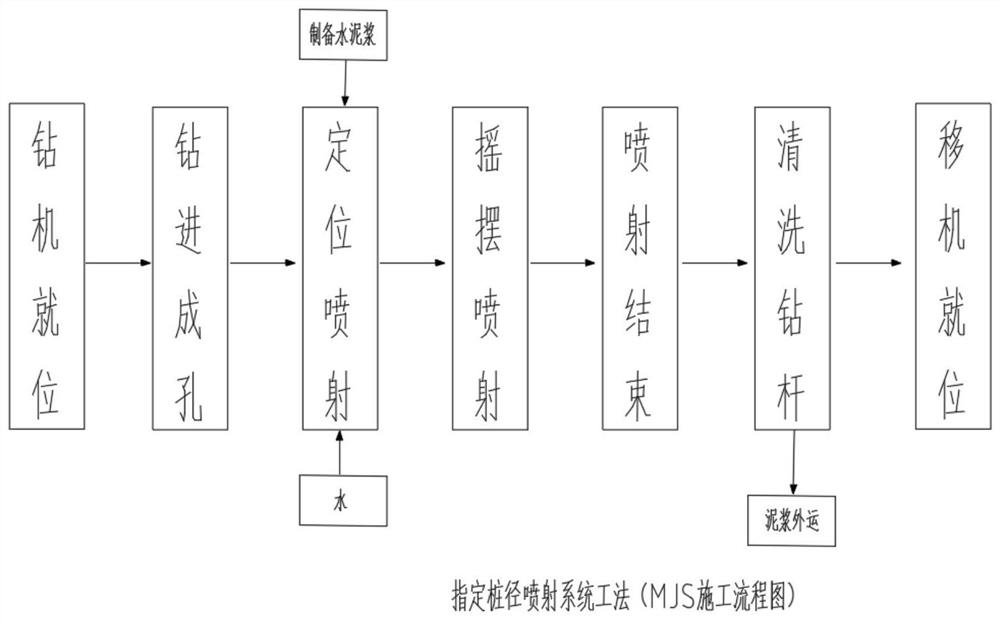

Construction method for lateral penetration of building by shield

PendingCN110359921AImprove pile qualityLarge pile diameterMining devicesUnderground chambersPrecipitationShield tunneling

The invention provides a construction method for lateral penetration of a building by a shield. The construction method specifically comprises the following steps: before the shield passes through, MJS construction method piles with angles of 15-30 degrees are constructed, a lower stratum of the building is reinforced, and plain concrete piles are adopted for isolation protection of a front area between the building and a tunnel; the middle of the plain concrete piles is drilled near the tunnel is drilled to embed sleeve valve pipes for isolation protection of un-engaged weak places of the plain piles; recharge wells are arranged around the building; water level, precipitation and inclination monitoring points are arranged around the building; in the shield tunneling process, shield parameters are controlled, and the monitoring points are used for monitoring; and after the tunnel is driven, small guide pipes are arranged in the tunnel near the building in a range of 120 degrees for grouting to prevent long-time accumulated influence on the building in later operation process. The construction method prevents the influence on the building by near-distance construction of the shielded tunnel, guarantees the structure stability of the building, and can effectively control the precipitation penetrating through the area.

Owner:URBAN MASS TRANSIT ENG CO LTD OF CHINA RAILWAY 11TH BUREAU GRP

Foundation reinforcing mode

The foundation reinforcing method for loose and soft soil includes depositing straight sunken tube into loose and soft soil through vibration or other process, throwing stuffing, such as sand and stone, mine refuse, clay, etc. mixed with cement and water, into the sunken tube, hammering to density and form piles, and final spreading stuffing cushion in the top of the piles to form composite foundation with high strength cement piles. The method is simple in construction and low in cost, and has wide application range and no environmental pollution.

Owner:王光明 +1

Porous pipe method large-diameter high-pressure jet grouting pile construction method

The invention relates to a porous pipe method large-diameter high-pressure jet grouting pile construction method. A high-pressure water conveying pipe, a high-pressure water compressed air conveying pipe and the like are arranged in a drill rod, the lower part of a drill bit is respectively provided with a high-pressure solidifying liquid and compressed air jet opening, a high-pressure water pipe jet opening and a compressed air water spraying opening, the positions of the high-pressure water pipe jet opening and the compressed air water spraying opening are positioned above the high-pressure solidifying liquid and compressed air jet opening, the bottom of the drill bit is provided with a high-pressure water jet opening, and the high-pressure water conveying pipe downwards jets water flow through the high-pressure water jet opening for cutting, so that the lower side of the drill pipe reaches the design pile bottom elevation, then, high-pressure water jet flow and compressed air jet flow are jetted from the high-pressure water pipe jet opening and the compressed air jet opening, high-pressure solidifying liquid and compressed air jet flow is jetted out from the high-pressure solidifying liquid and compressed air jet opening and is rotationally lifted along with the drill rod, and the peripheral soil bodies are subjected to secondary cutting, so that cement slurry and soil are stirred to be mixed into a pipe. Compared with an ordinary high-pressure jet grouting pile, the porous pipe method large-diameter high-pressure jet grouting pile has the advantage that the integral pile forming efficiency is improved by about 30 percent.

Owner:上海开普天岩土科技集团有限公司 +1

Construction process of floral tube dry filling piles

InactiveCN101713189AReduce labor intensityFew control parametersBulkheads/pilesResource utilizationWater table

The invention relates to a construction process of floral tube dry filling piles with obvious engineering effect, low economic cost, high technical content and high resource utilization by improving the inherent characteristics of cement, soil strata, materials and the like. The process comprises the following steps of: (1) pore-forming process: 1, using dry pore-forming process for pore-forming piles above underground water level; 2, positioning a pore opening machine and a drill for pore-forming piles below underground water level; drilling in at low stroke and high rotary speed with clean water; reaching a drilling-in depth; lifting to a pore opening at unified stroke and high rotary speed with clean water; drilling into a pore bottom at unified stroke and high rotary speed with clean water; rotating at high speed and filling with cement mortar; and lifting to the pore opening at high rotary speed and low stroke after cement mortar returns to the pore opening; moving the drill; (2) the process of installation and pile molding by filling: adopting the following steps for installing pile pores and filling dry cement above or below water level: installing floral tubes; correcting the pore position of the floral tubes; filling the dry cement; and filling the dry cement to an elevation required by the design.

Owner:HENAN UNIVERSITY

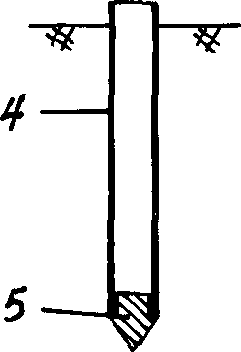

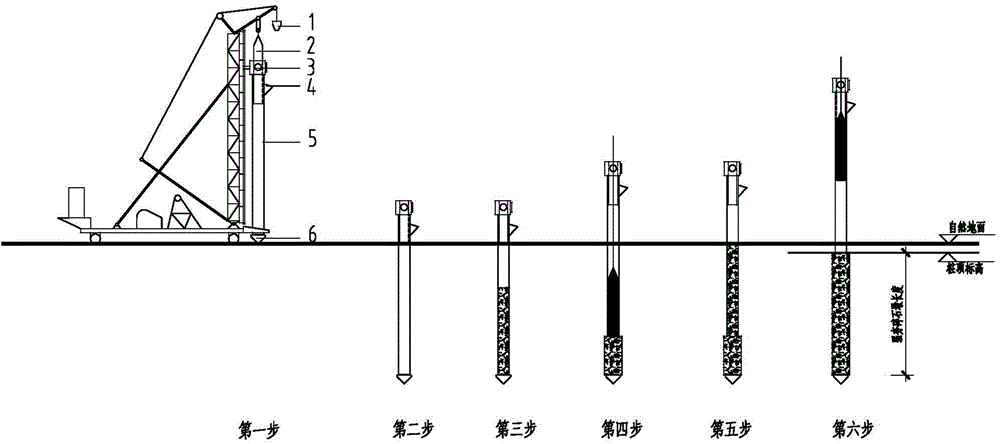

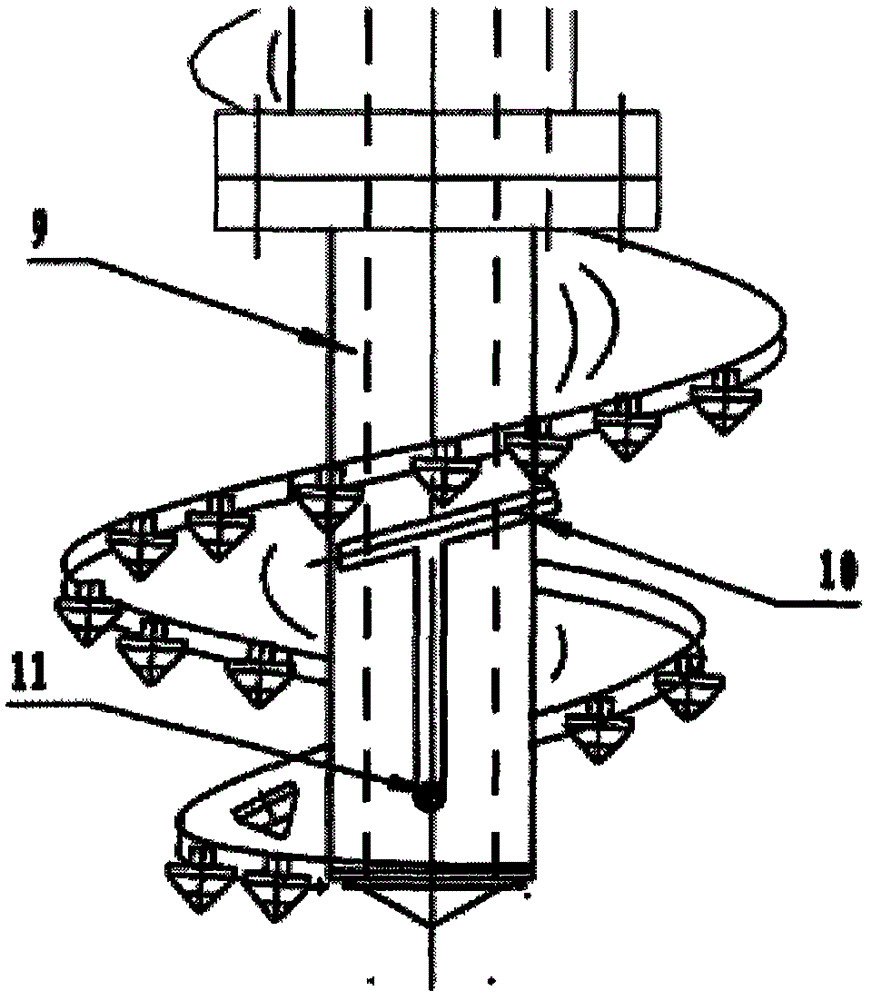

Deep replacement dynamic compaction gravel pile foundation reinforcement method

InactiveCN104947648ALarge pile diameterGood pile effectSoil preservationDynamic compactionEngineering

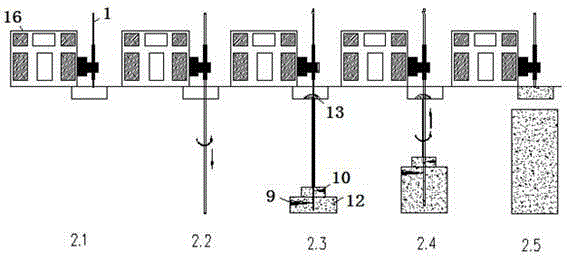

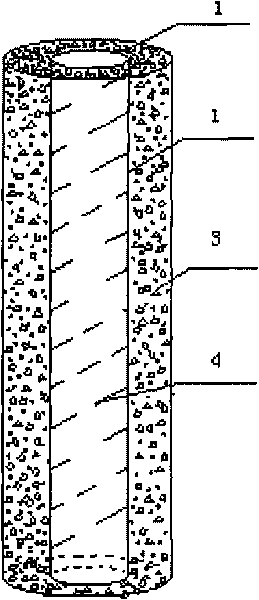

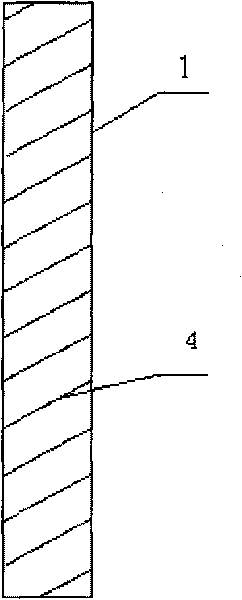

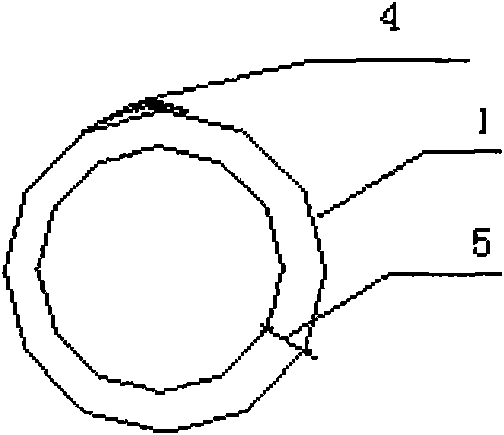

The invention discloses a deep replacement dynamic compaction gravel pile foundation reinforcement method. The method includes the following steps that firstly, a pile pipe (5) of a pile machine is aligned with a pile toe (6) in place at a pile position; secondly, a vibrating hammer (3) of the pile machine is started and vibrates to conduct countersinking operation downwards; thirdly, a hopper (1) of the pile machine is used for conducting filling for the first time from a feed port (4); fourthly, the pile pipe (5) of the pile machine ascends, dynamic compaction broaching is conducted, and a dynamic compaction gravel mound is formed; fifthly, the hopper (1) is used for conducting supplementary filling from the feed port (4); sixthly, the fourth step and the fifth step are repeated till the dynamic compaction gravel mound reaches pile tip elevation. Dynamic compaction energy can be effectively led to the foundation deep position through the pile pipe, the defects of the replacement dynamic compaction construction process and the vibration gravel pile process are overcome, quality is high, benefits are good, the construction period is short, and the foundation reinforcement effect is better.

Owner:SCEGC MECHANIZED CONSTR GRP COMPANY

Novel steel pipe pile foundation for preventing pile circumferential soil from being liquefied under action of waves

InactiveCN108708365ASignificant progressQuick resultsMachines/enginesEngine componentsSuction forcePore water pressure

The invention discloses a novel steel pipe pile foundation for preventing pile circumferential soil from being liquefied under an action of waves. The novel steel pipe pile foundation is characterizedin that a vacuum cavity is formed in a steel pipe pile below a seabed mud surface, the vacuum cavity is connected to a vacuum pump through a suction pipe, the vacuum pump is provided with a water outlet, drainage holes are distributed in the wall of the steel pipe pile corresponding to the vacuum cavity, water is permeated to the pile circumferential soil and enters the vacuum cavity through thedrainage holes, and then under the action of the vacuum pump, the pile circumferential soil is discharged to the vacuum pump through the suction pipe and then is discharged from the water outlet; andpreference is given, the device can further comprise a wave energy conversion section, a permeation layer expansion section and the like. According to the novel steel pipe pile foundation, the pore water pressure caused by the waves is reduced on the premise that the property of the pile circumferential soil is not changed, so that the liquefaction is prevented and the environment influence is small; the vacuum suction force is manufactured by utilizing the wave energy, and extra energy consumption is not needed; and the effect area of the pile soil is expanded by the permeation layer expansion section, so that the soil resistance is fully obtained so as to reduce the displacement response of the pile foundation under the action of the waves.

Owner:HOHAI UNIV

Perforated pipe method super-deep, fast, and super-large diameter high pressure chemical churning pile construction method

InactiveCN104612137AReduce the crowding effectLarge pile diameterDrill bitsDrilling rodsWater pipeEngineering

The invention relates to a perforated pipe method super-deep, fast, and super-large diameter high pressure chemical churning pile construction method. Two high pressure curing liquid and compressed air injection openings and a high pressure water pipe injection opening and compressed air water injection nozzle are arranged on the lower side of a drill, the position of the high pressure water pipe injection opening and compressed air water injection nozzle is above the position of the high pressure curing liquid and compressed air injection openings, and the two pressure curing liquid and compressed air injection openings are in the symmetric positions of the same flat surface; the high pressure water pipe injection opening downward injects water to conduct cutting, the lower side of a drill stem is higher than a bottom label of a designed pile, then the high pressure water pipe injection opening and compressed air injection nozzle injects a high pressure water pipe injection flow and compressed air injection flow, and the high pressure curing liquid and compressed air injection openings inject high pressure curing liquid and compressed air injection flow. With the drill stem rotating and lifting, adjacent soil body is conducted a secondary cutting, and cement paste and soil are mixed to a pile. Compared with the prior high pressure chemical churning pile, the overall pile formation efficiency is increase by almost 48%.

Owner:上海开普天岩土科技集团有限公司 +1

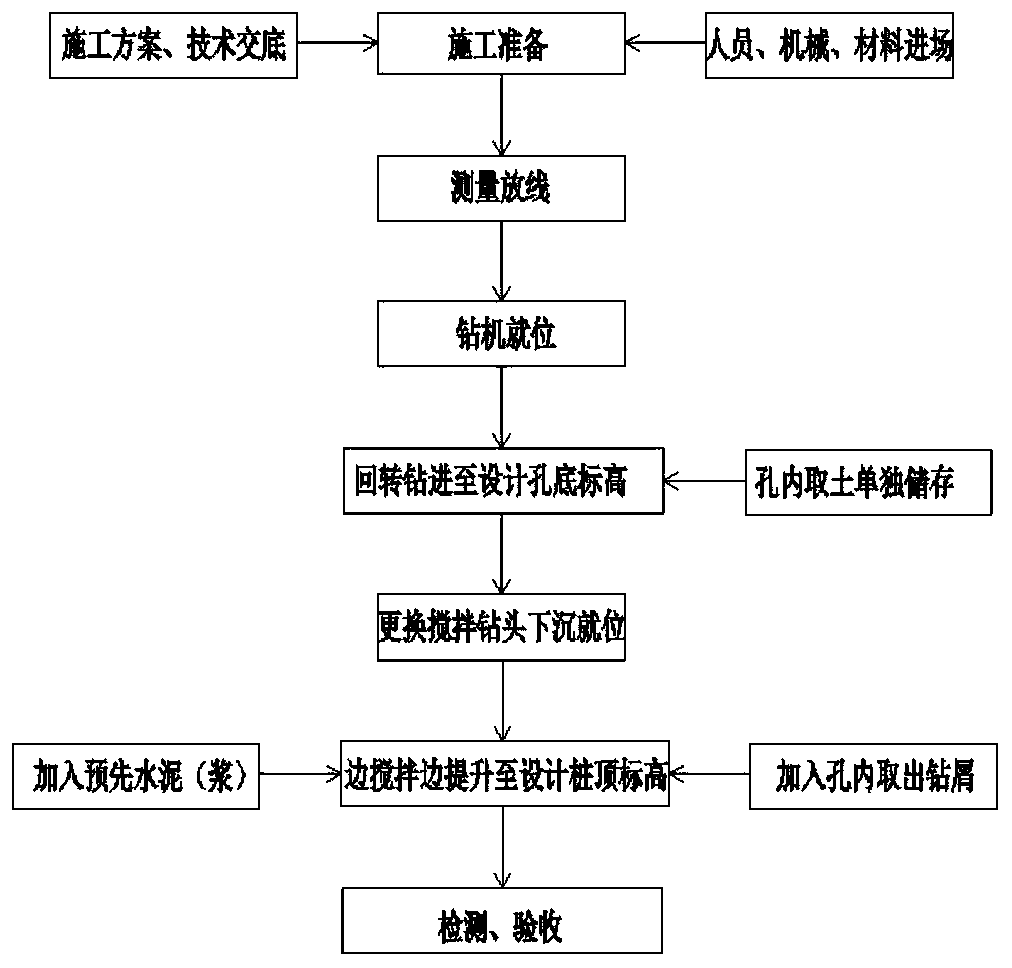

Large diameter cement soil pile construction method

InactiveCN110318392AImprove the difficulty of mixing evenlyPile type stabilityBulkheads/pilesDrill cuttingsSoil strength

The invention discloses a large diameter cement soil pile construction method. The large diameter cement soil pile construction method includes: using a rotary drilling machine for performing rotary soil fetching to form a hole, gradually performing the soil fetching for forming the hole and stopping drilling until reaching the designed pile bottom elevation, then injecting cement slurry into thebottom of the hole, replacing a drill bit of the rotary drilling machine with a stirring drill bit, placing the stirring drill bit at the bottom of the hole for stirring the bottom of the hole, then adding backfill materials in the hole in batches, lifting the stirring drill bit while rotating and stirring, and completely stirring the cement slurry and the backfill materials uniformly from the bottom up so as to solidify the cement slurry and the backfill materials into a pile. The large diameter cement soil pile construction method solves the puzzles that in a compact stratum, mechanical ability is restricted, stirring resistance is large, and construction efficiency is low by adopting the hole preforming technology, achieves substantial enlargement of the diameter of the pile, obtains astable pile shape, uses drilling cuttings as pile forming materials in the backfill materials, reduces environment pollution and resource waste, more easily stirs for mixing the materials uniformly, guarantees construction quality, can guarantee cement soil strength of the pile body by controlling a cement ratio, and facilitates guarantee for stirring uniformity of the pile body by placing the cement in the hole in advance.

Owner:成都四海岩土工程有限公司

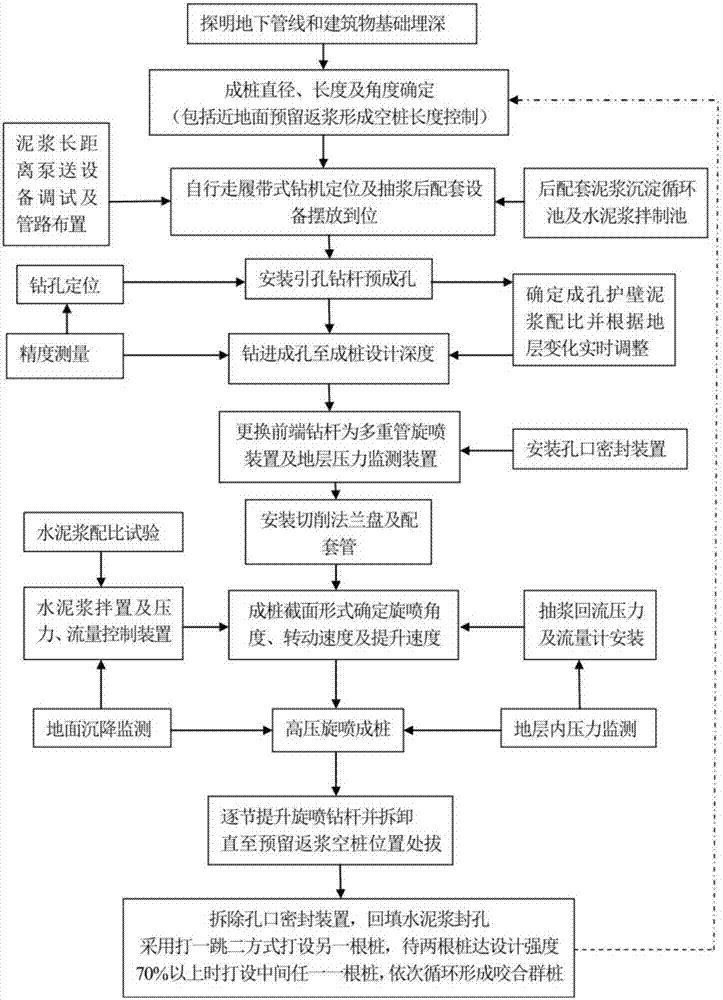

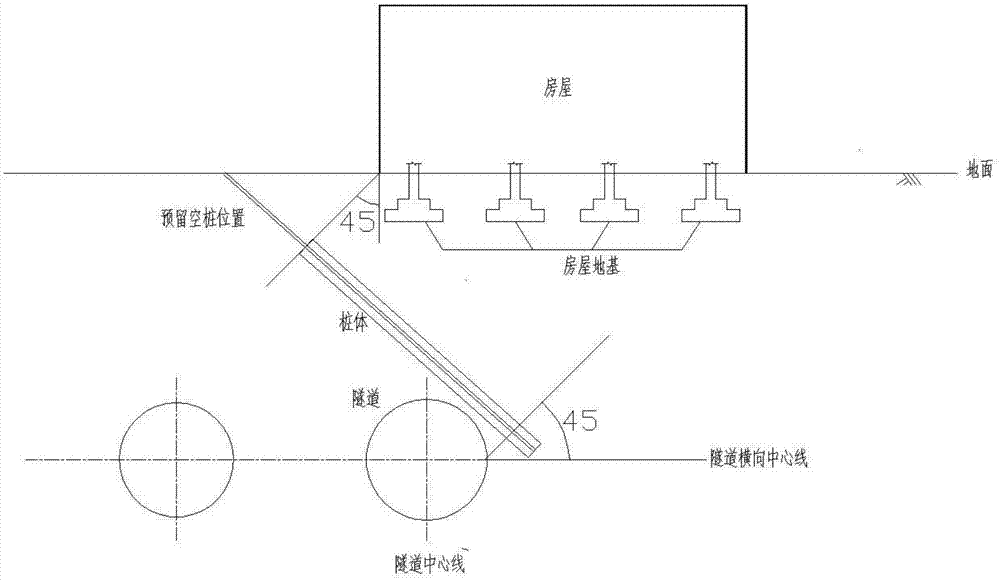

Weak perturbation inclined rotary jet group pile occlusion strengthening method used for shield passing underneath house

InactiveCN107152042ASolve the problem of uneven settlementProtection hysteresisFoundation repairBulkheads/pilesGround subsidenceSlurry

The invention discloses a weak perturbation inclined rotary jet group pile occlusion strengthening method used for a shield passing underneath a house. The method includes the steps that the driven position, the pile forming angle, the driven depth and the reserved empty pile position of a rotary jet pile are determined according to the position relationship of the house and a tunnel; the hole drilling parameter is determined, and an inclined hole is drilled; the ground initial height within a preset scope is detected; and the lower portion of a drilling rod is driven into the inclined hole for rotary jet pile construction, the drilling rod at least comprises one suction multiple pipe, the ground height is detected in real time in the work progress, if the rising amount of the ground height of any position within the preset scope is larger than a first threshold value, the suction multiple pipe is used for slurry pumping until the ground height does not rise any more, and if the falling amount of the ground height of any position within the preset scope is smaller than a second threshold value, the suction multiple pipe is used for injecting water or air until the ground height is not reduced any more. By means of the weak perturbation inclined rotary jet group pile occlusion strengthening method, stratum disturbance influences can be reduced to the maximum degree, the technological process is simple, and ground subsidence caused by the shield underneath pass house can be effectively reduced.

Owner:CCCC SECOND HARBOR ENG

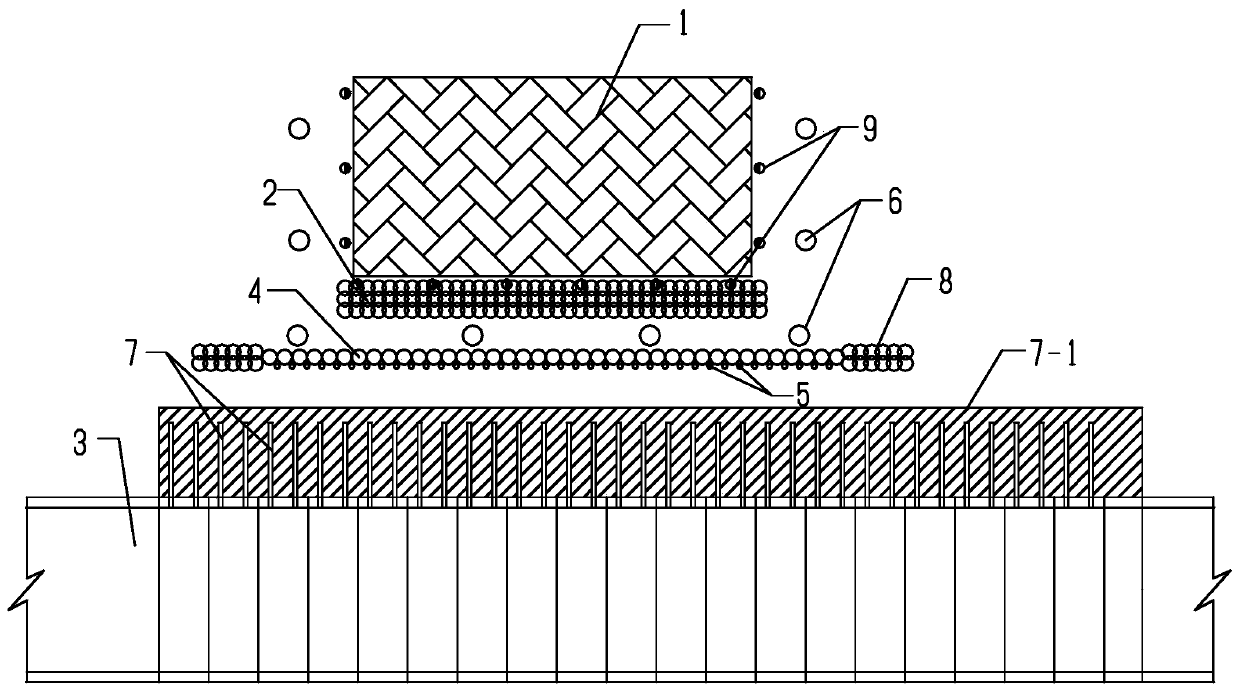

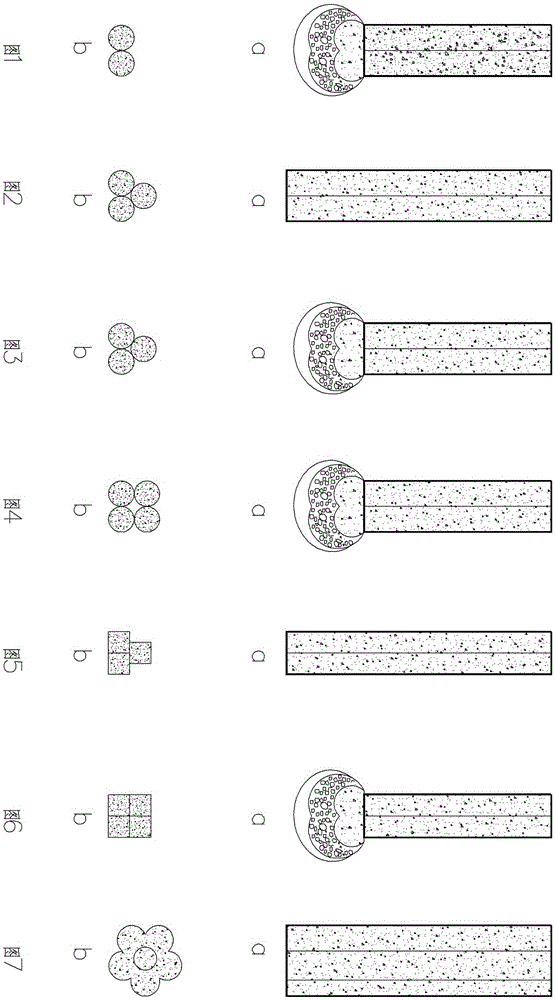

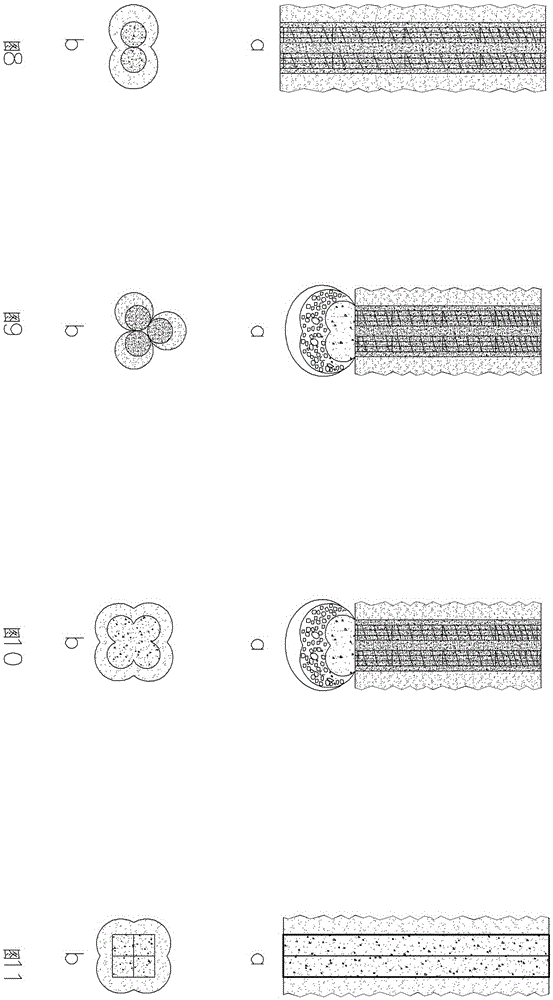

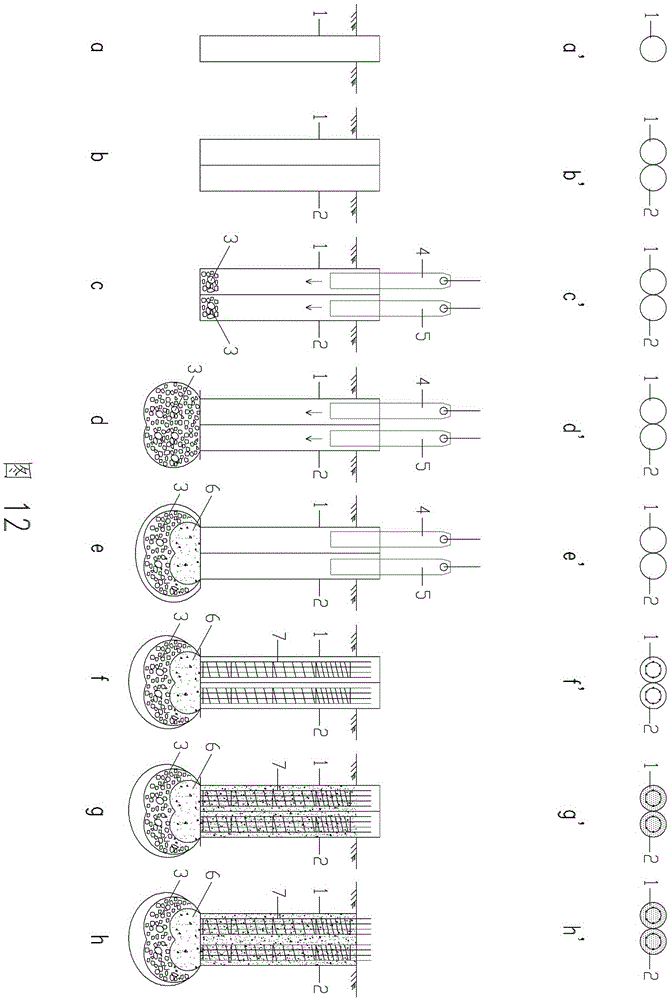

Small-diameter pile cluster used for pile foundation and construction method of small-diameter pile cluster

The invention aims at providing a pile foundation which can obtain large stress area and meanwhile is capable of saving cost, environment-friendly and free of pollution, and a construction method of the pile foundation and relates to a small-diameter pile cluster used for the pile foundation and a construction method of the small-diameter pile cluster. The small-diameter pile cluster is composed of two or more small-diameter piles, pile tops are in contact or engagement, and the diameter of the piles forming the pile cluster is smaller than 800 mm. Soil can be stirred on the peripheries of the piles of the pile cluster in advance, and cement slurry can be injected into soil bodies on the peripheries of the piles for curing; and the piles in the pile cluster can include pile end carriers. The construction method of the small-diameter pile cluster includes the steps that firstly, pile positions are reserved according to design requirements; and secondly, small-diameter pile construction is conducted on the pile positions at the same time or conducted on the pile positions in sequence, cemented soil piles can be formed in the soil bodies on the peripheries of the piles before the small-diameter piles are constructed, the diameter of the cemented soil piles which are finally formed is larger than or equal to the maximum diameter of the pile cluster, and small-diameter pile construction is conducted before the strength of the cemented soil piles meets the requirement for initial setting.

Owner:王继忠

Pile bottom post-grouting method

The invention discloses a method for post-grouting in the bottom of a pile, which comprises the following steps: in the process of constructing the pile by drilling holes, a grouting pipeline is prearranged in the bottom of the pile and grout is injected. The method has good grouting effect and high success rate of grouting.

Owner:JIANGSU NANTONG NO 2 CONSTR ENG GRP

Equipment and method for constructing high-pressure rotary jet stiffening pile by using ribbed drilling method

The invention relates to equipment and a method for constructing a high-pressure rotary jet stiffening pile by using a ribbed drilling method. The technical scheme is that: the equipment comprises an end bearing plate which is adjacent to a bearing; the bearing is provided with a protective cover; and a tapered propelling body is arranged on the non-bearing side of the end bearing plate. The equipment also comprises a vibroflot on one side, which is not provided with a drive drill pipe, of a power head. Due to the adoption of the technical scheme, the equipment and the method have the beneficial effects that the bearing is effectively protected; the protective cover is arranged outside the bearing, so that sand cannot enter the bearing; the sectional protective cover has a splicing surface which is a folding surface, and can be split through the splicing surface; the bearing can be replaced, and the sand and the like can be effectively prevented from entering the bearing through the folding surface; the tapered propelling body is arranged on the non-bearing side of the end bearing plate, so that obstacles on a propelling path can be effectively eliminated, and the end bearing plate can be smoothly propelled to finish construction; in addition, the vibroflot is arranged, so that the stratum on the propelling path can be effectively loosened, and the construction can be smoothly finished; and manpower and material resources are saved, work hours are reduced, complex procedures are eliminated, and pore-forming, rib insertion and grouting can be finished at one time.

Owner:王忠友

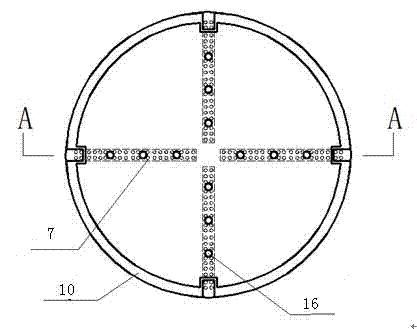

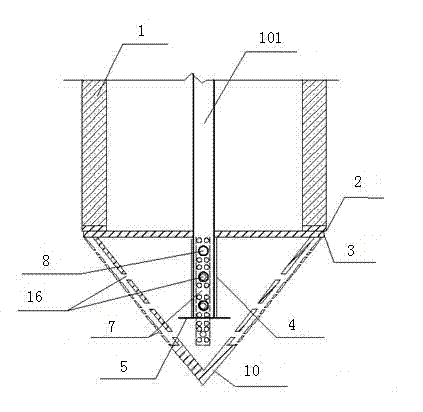

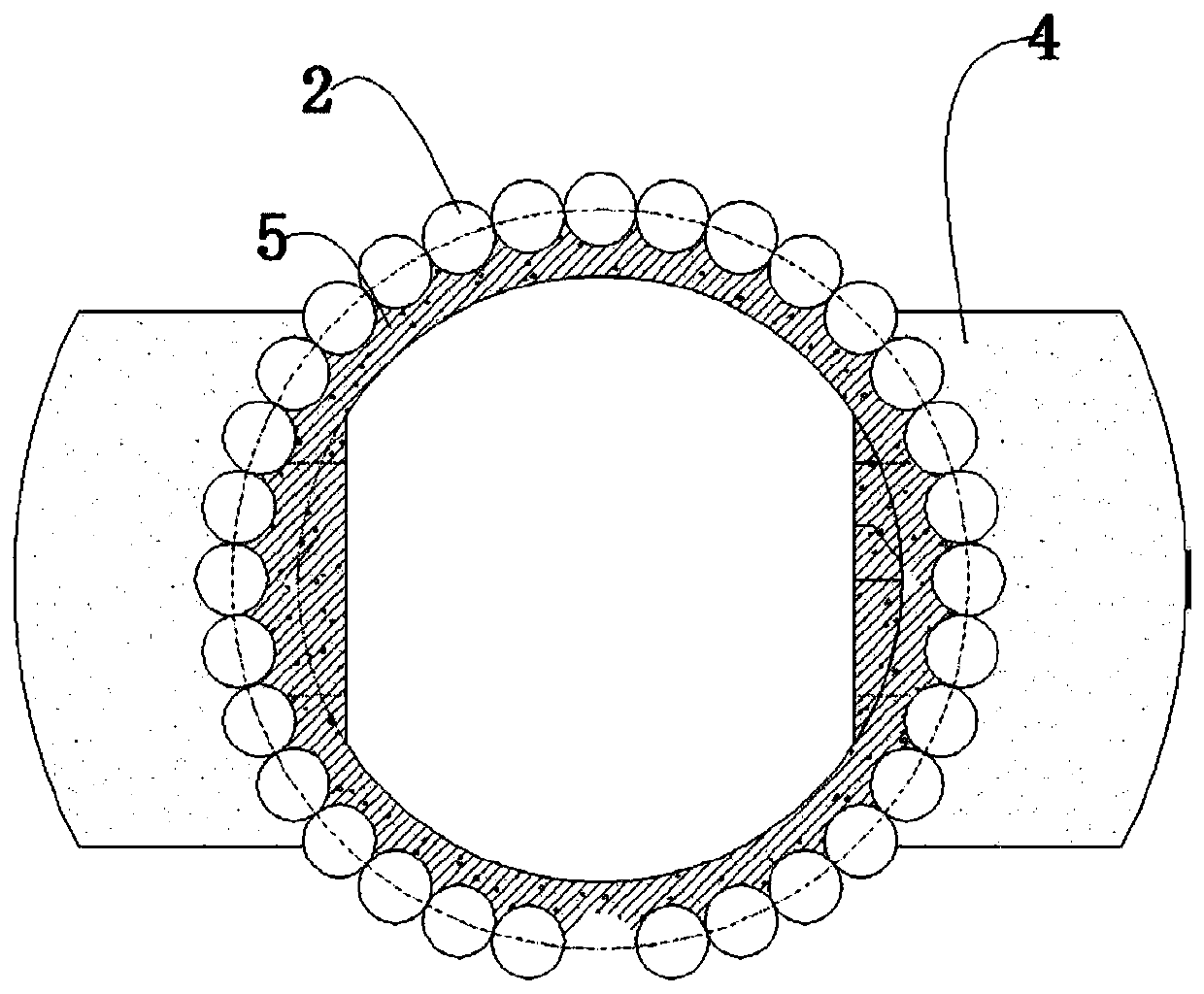

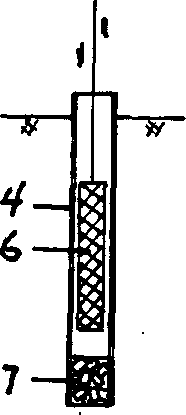

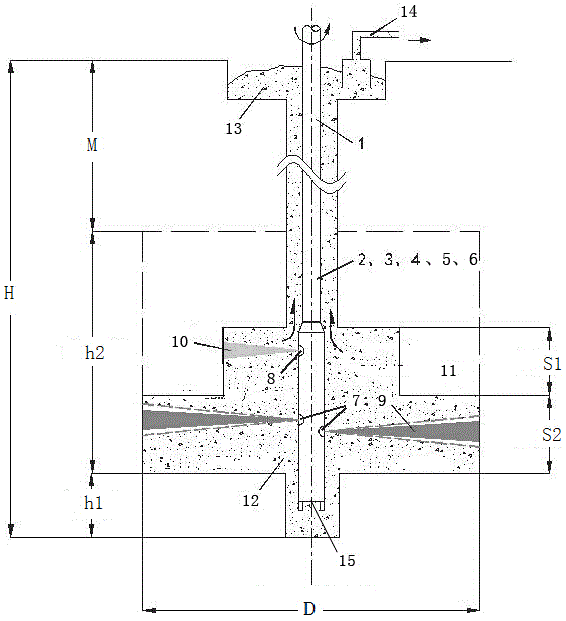

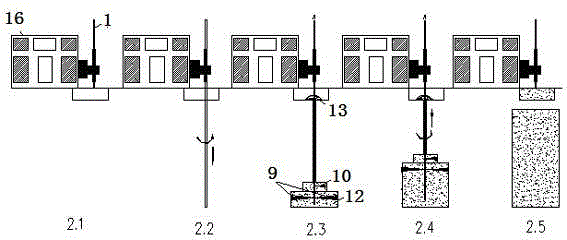

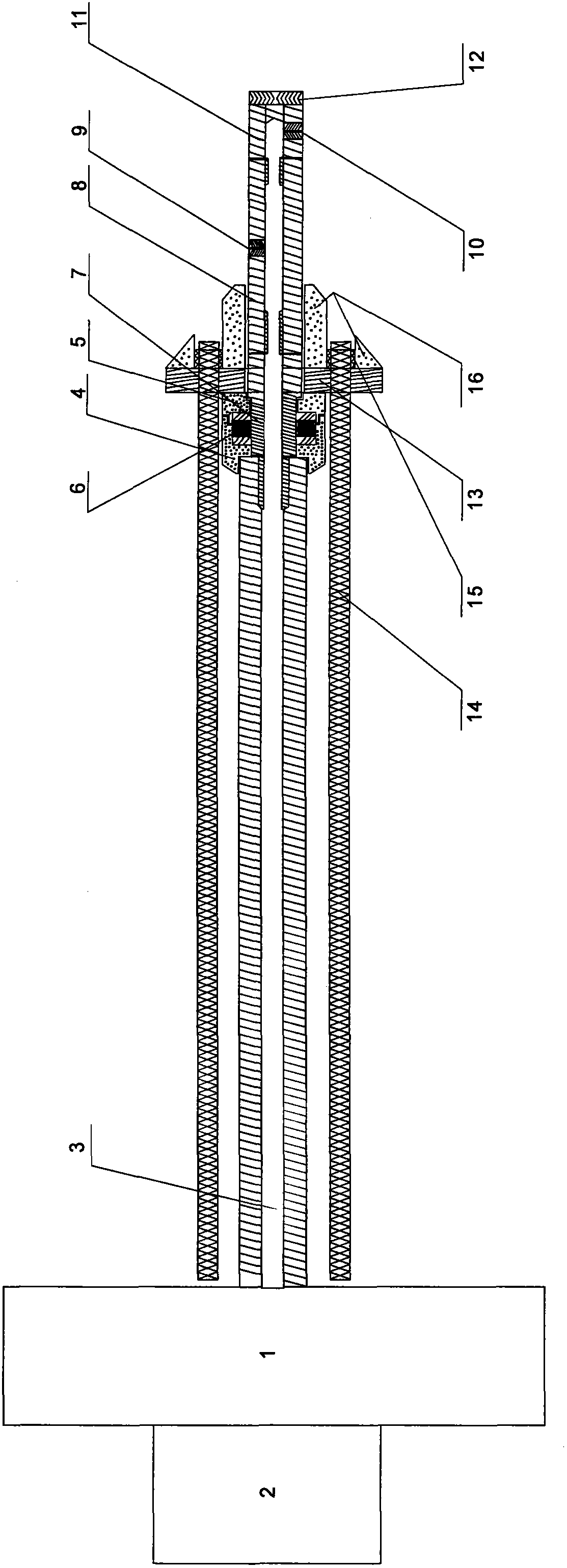

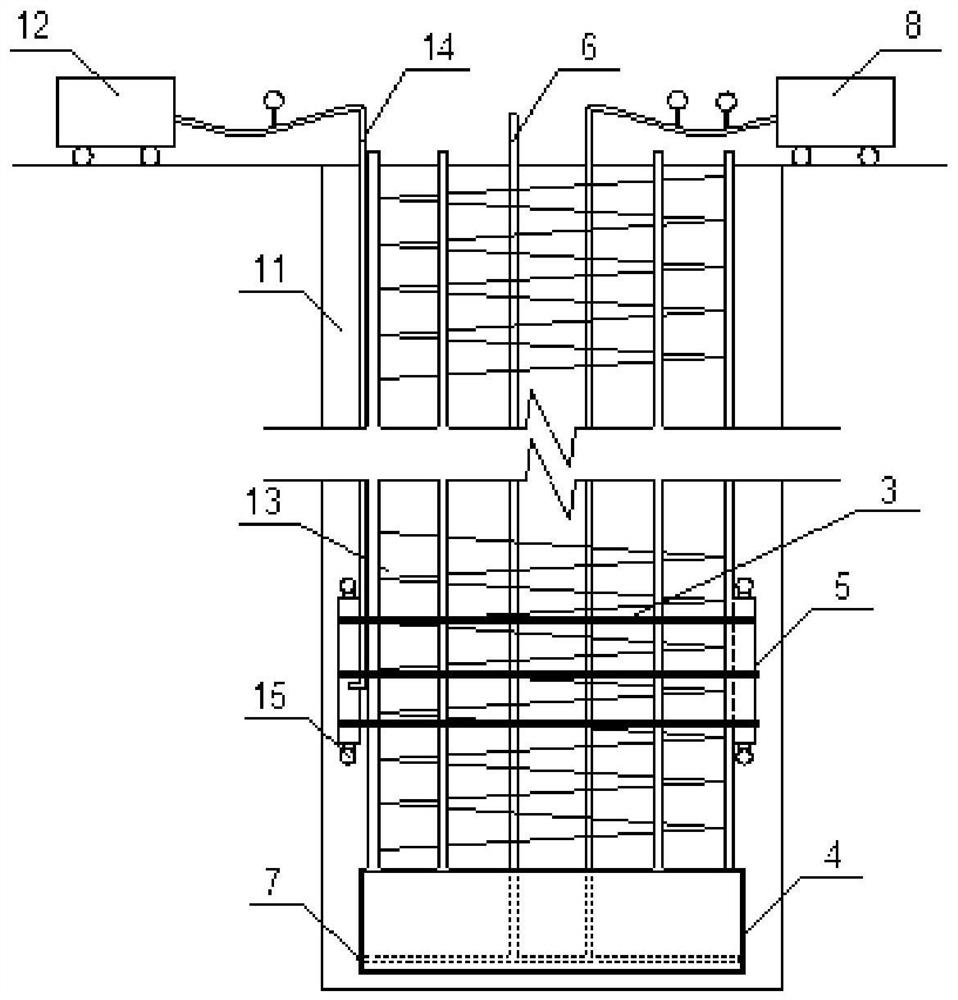

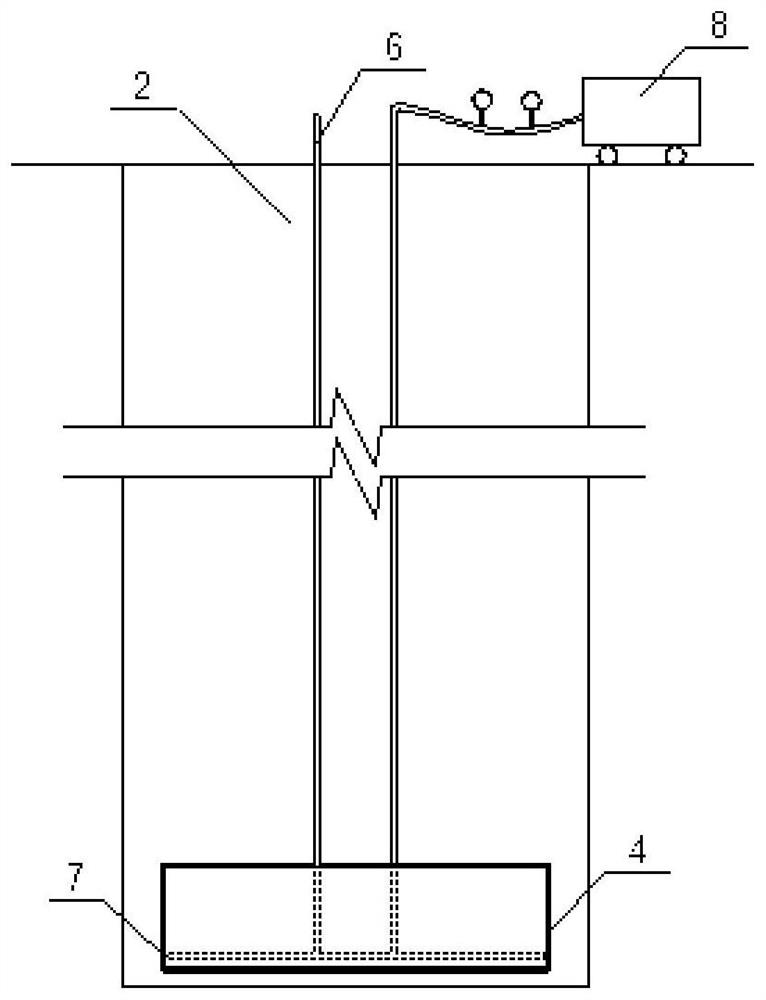

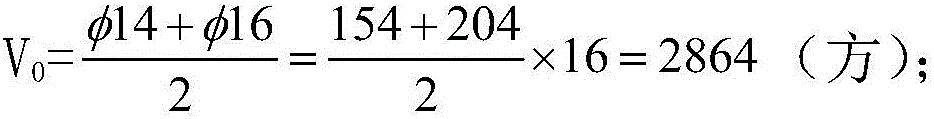

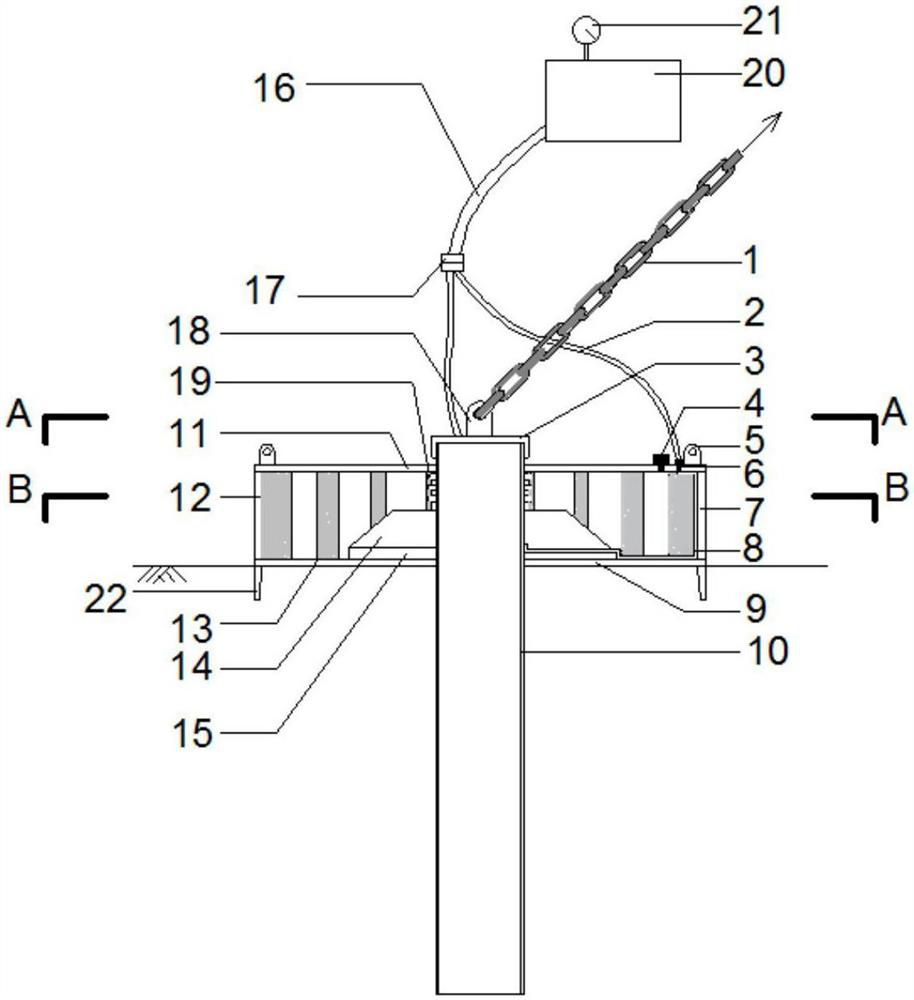

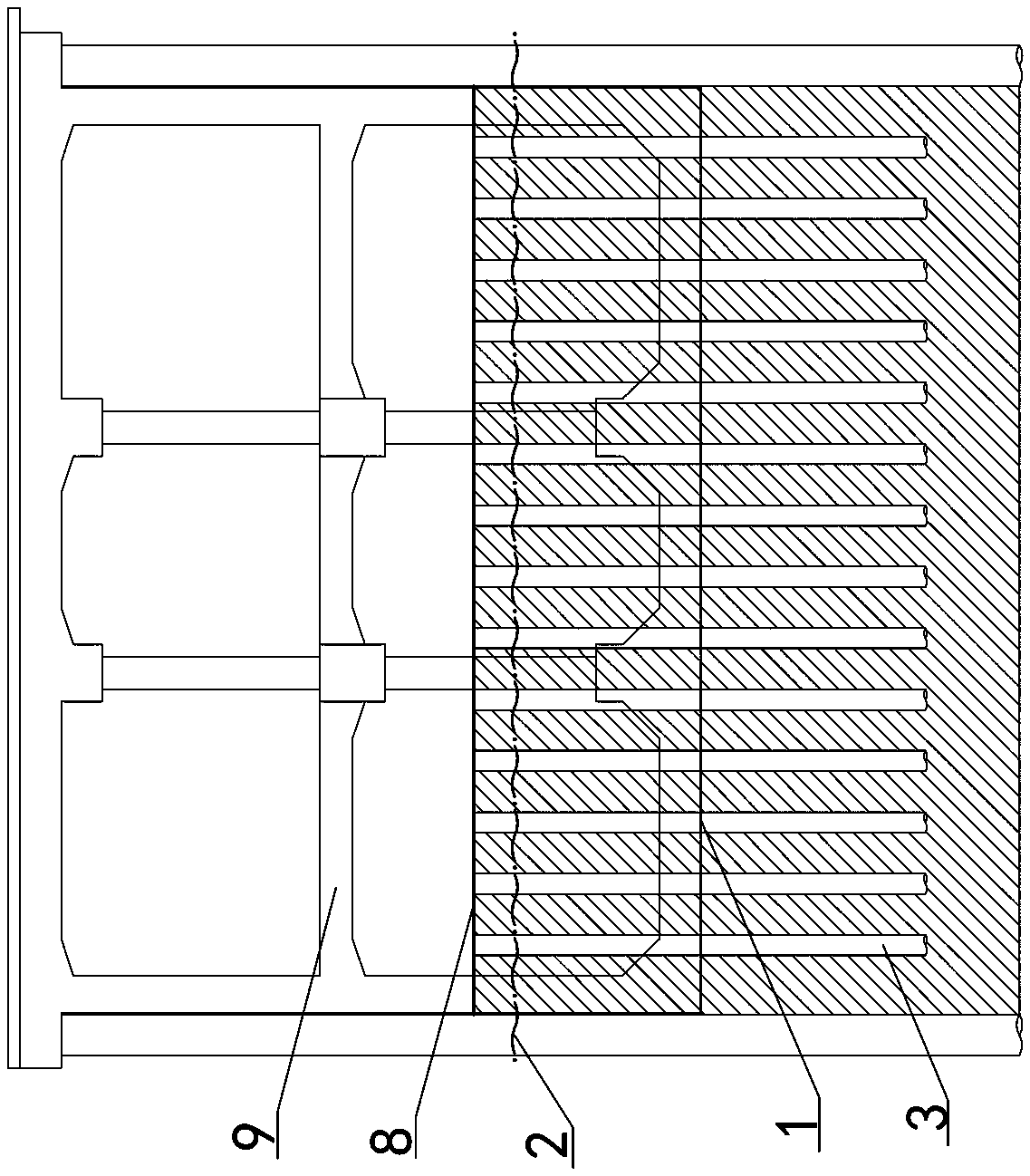

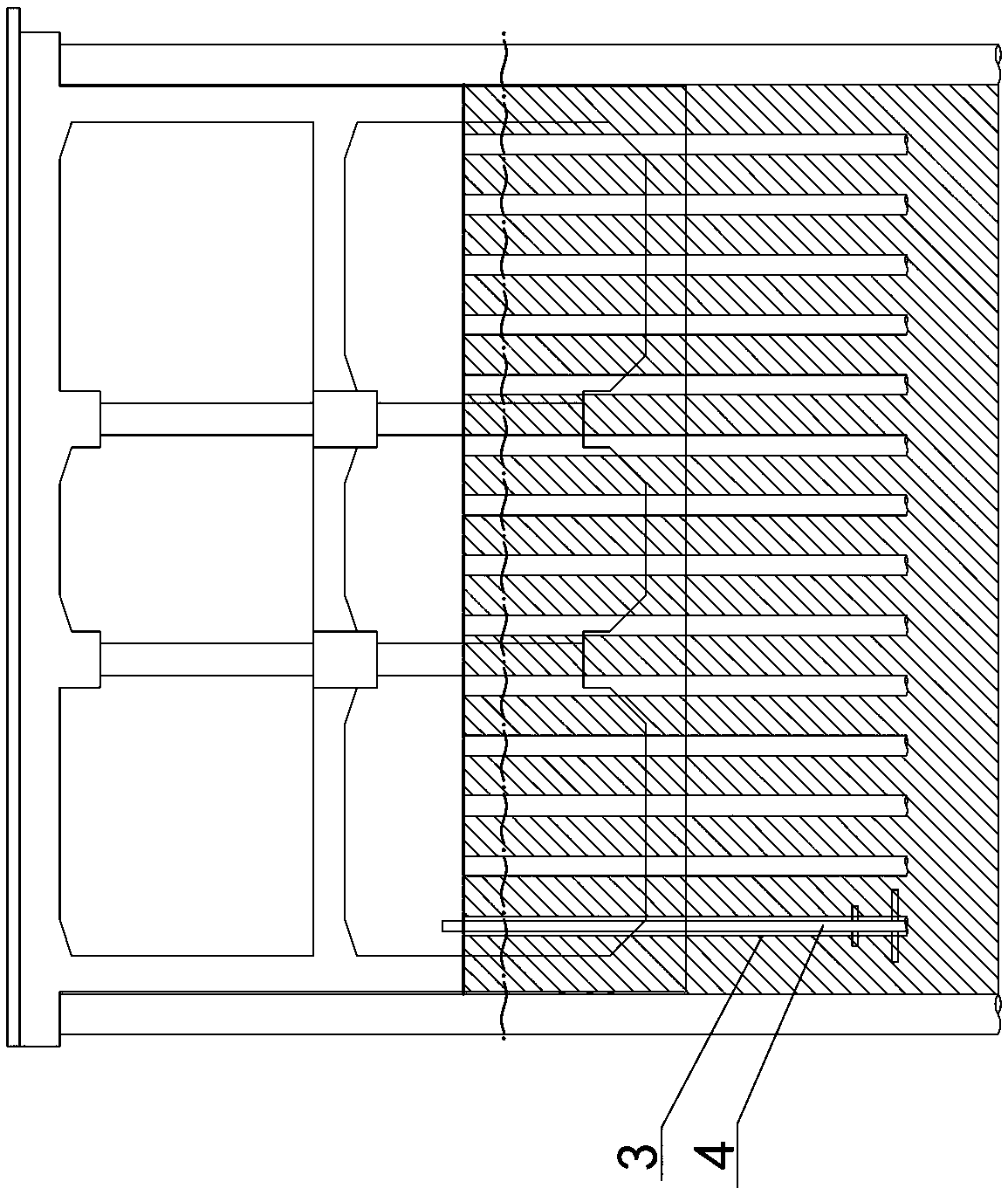

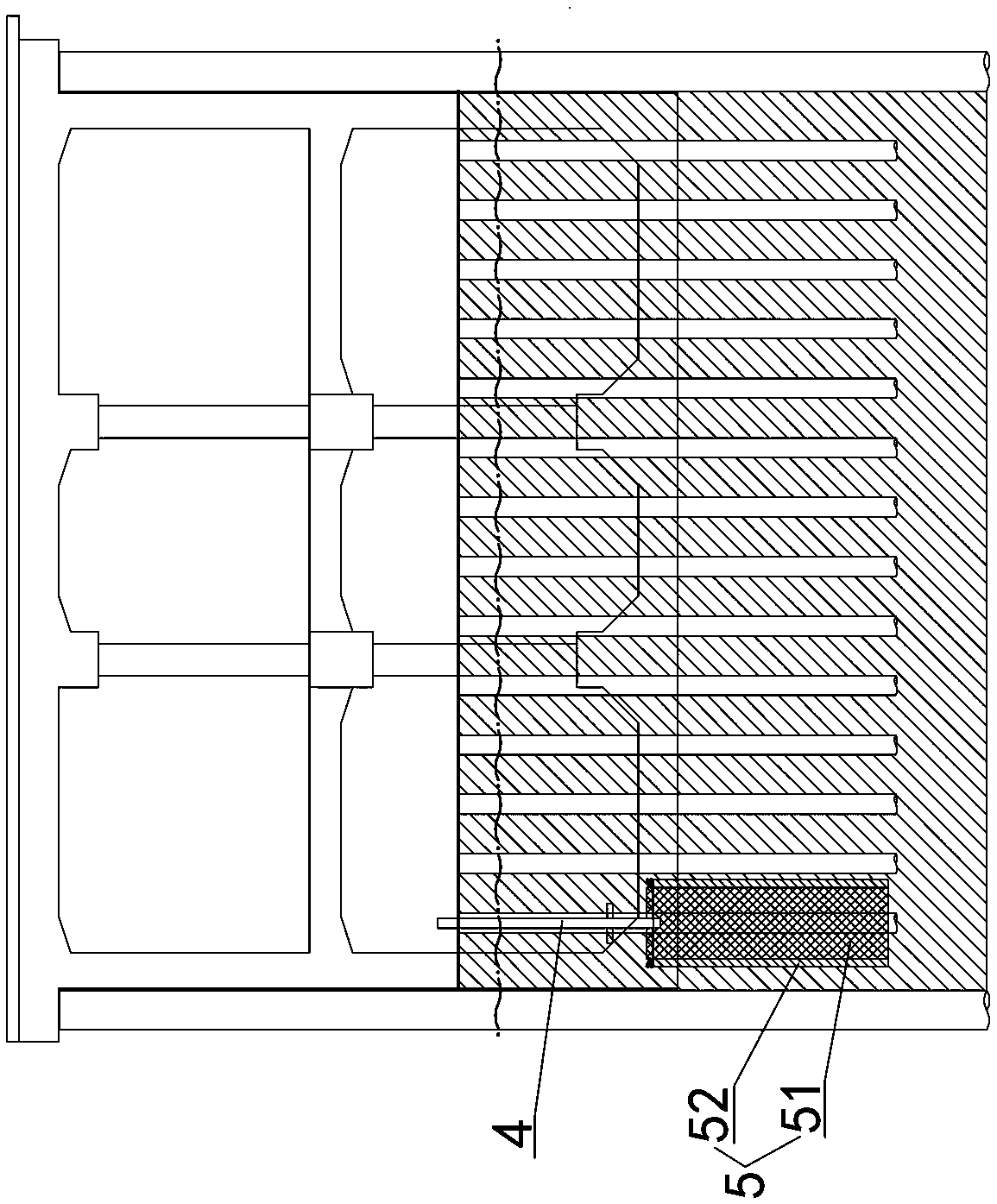

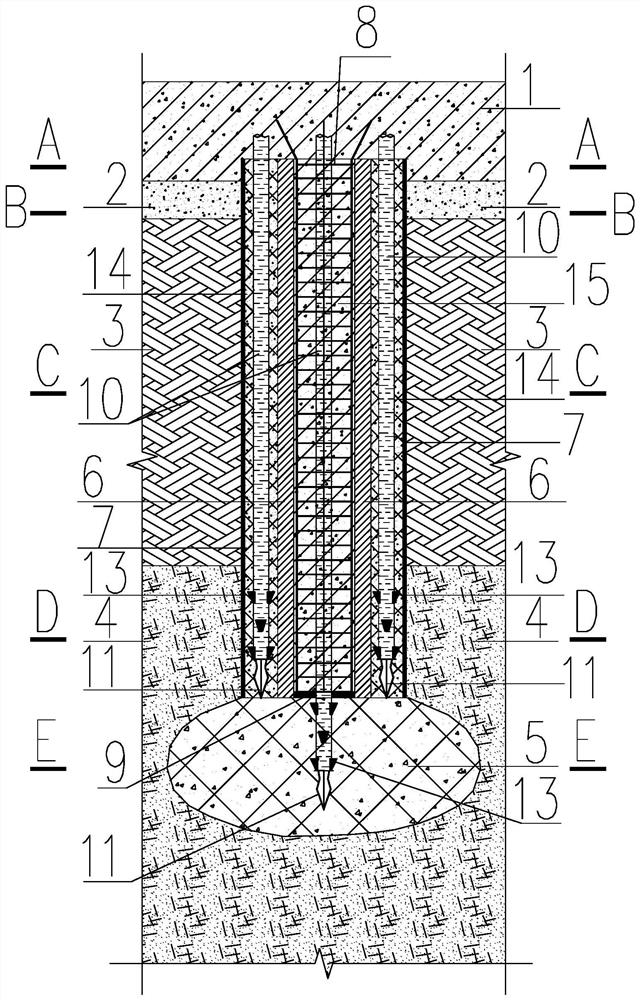

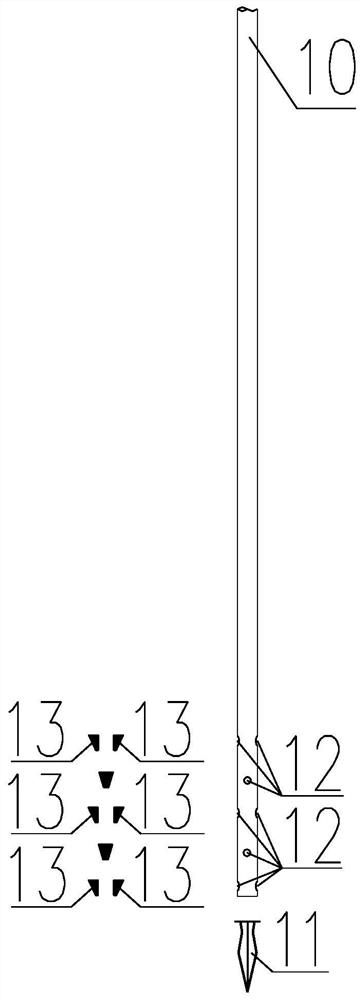

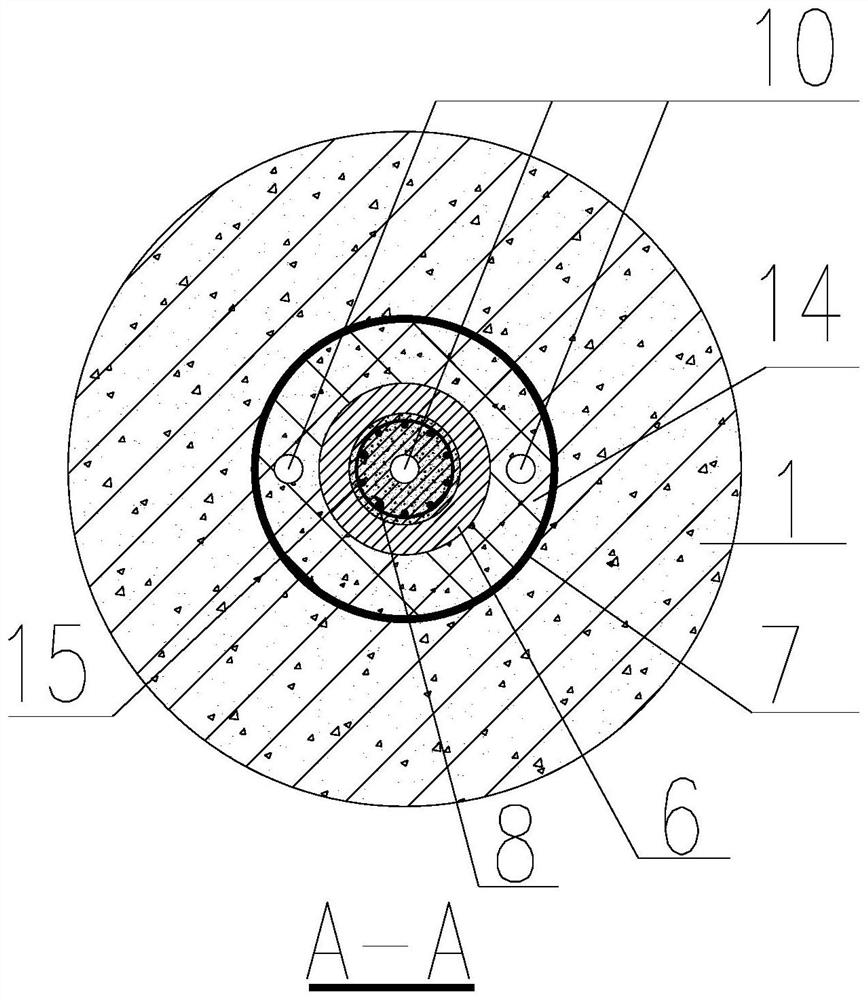

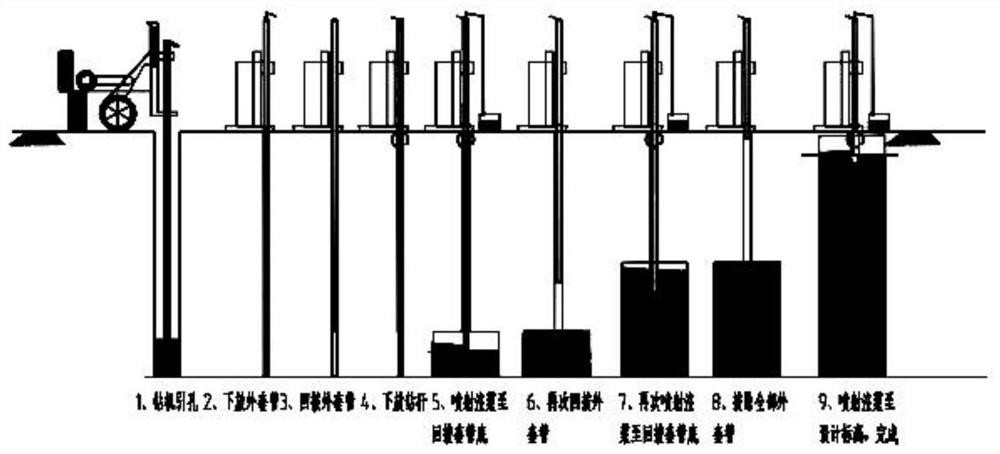

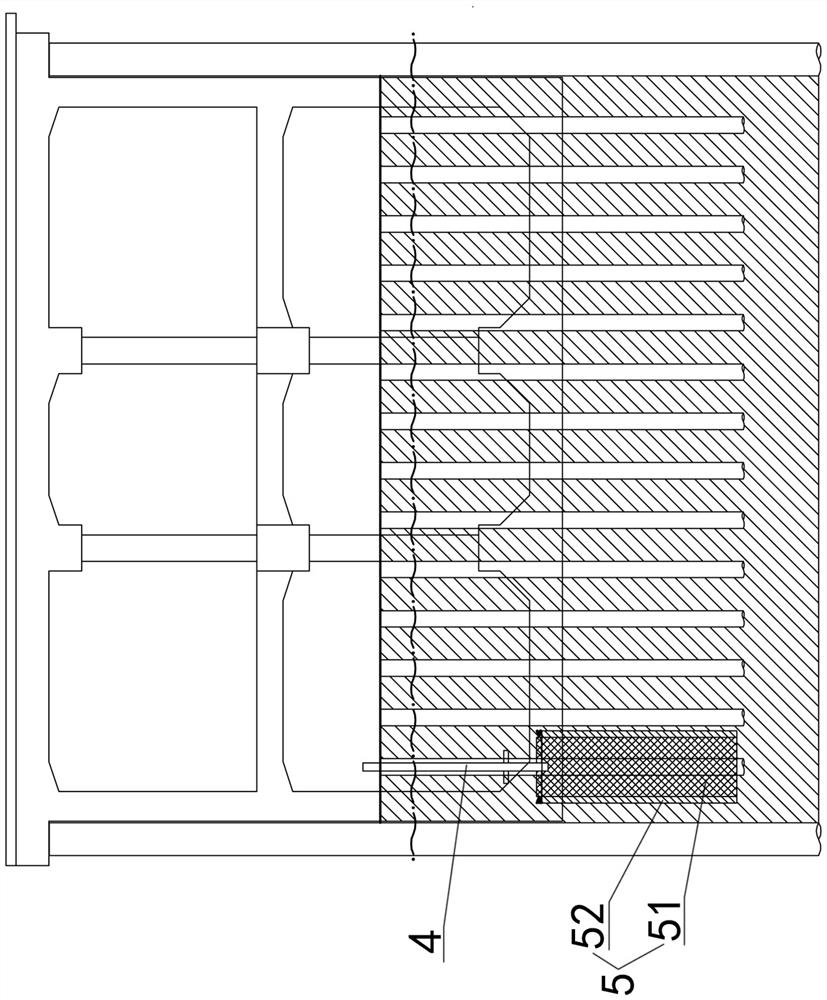

System for grouting pile side sealing and pile tip extrusion grouting of cast-in-place pile and construction method thereof

The invention relates to a cast-in-place pile side slurry sealing and pile end extrusion grouting system and a construction method thereof.The cast-in-place pile side slurry sealing and pile end extrusion grouting system comprises a pile side slurry sealing device and a pile end extrusion grouting device, and the pile side slurry sealing device is arranged on the outer side face of a reinforcement cage of a cast-in-place pile; the upper end face of the pile end extrusion grouting device is fixedly connected with the bottom end of the reinforcement cage, the lower end face of the pile end extrusion grouting device abuts against pile bottom sediment in the sinking process of the reinforcement cage, and the pile bottom sediment is axially and downwards pushed, compacted and compacted through the pile end extrusion grouting device; the pile side slurry sealing device forms a pile side slurry sealing section on the outer side of the reinforcement cage after slurry jacking, high-pressure grouting is conducted on the pile end of the cast-in-place pile and the pile side range below the pile side slurry sealing section through the pile end extrusion grouting device, and grouting reinforcing layers are formed on the pile bottom face and the pile side face. The method has the advantages that the construction process is simple, the flowing direction and the diffusion range of grout injected into the pile end and the pile side can be quantitatively and controllably controlled, then the single-pile bearing capacity of the cast-in-place pile can be greatly improved, and the settlement amount of a foundation pile is reduced.

Owner:浙江坤德创新岩土工程有限公司

Pile bottom post-grouting method

The invention discloses a method for post-grouting in the bottom of a pile, which comprises the following steps: in the process of constructing the pile by drilling holes, a grouting pipeline is prearranged in the bottom of the pile and grout is injected. The method has good grouting effect and high success rate of grouting.

Owner:JIANGSU NANTONG NO 2 CONSTR ENG GRP

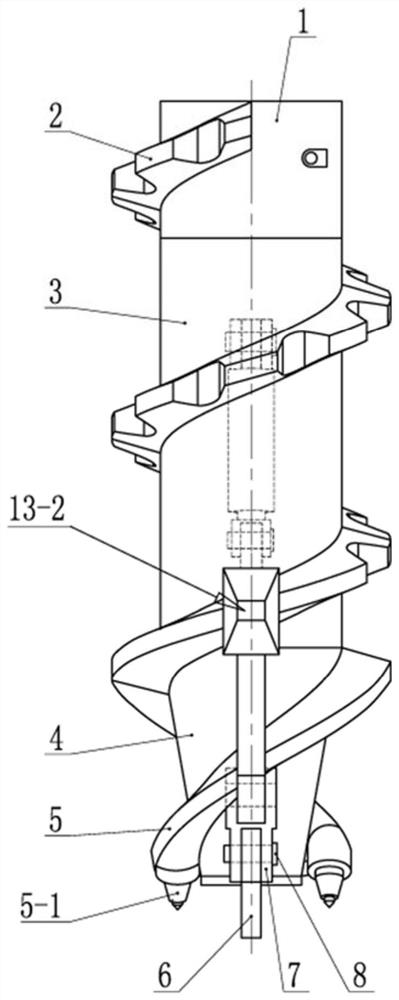

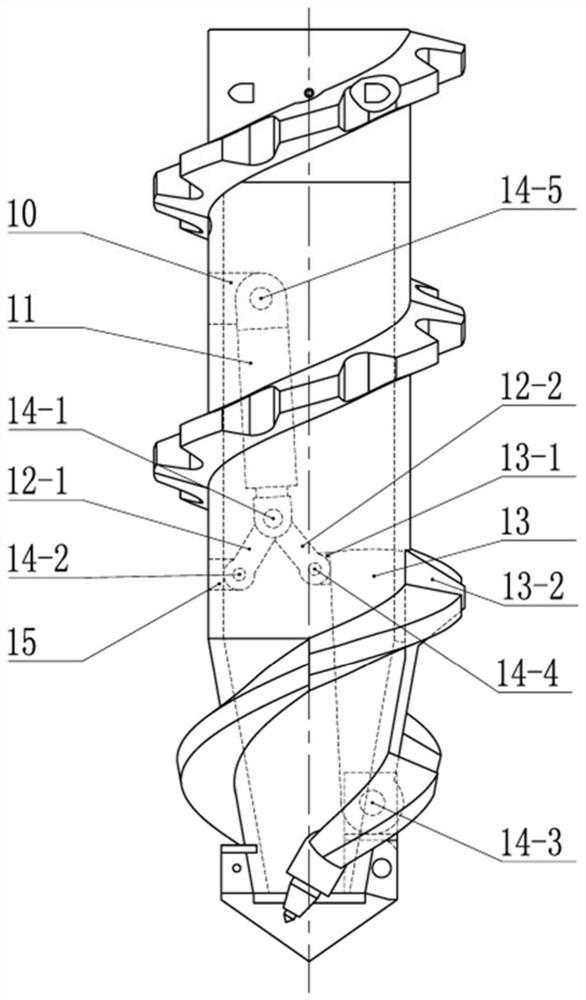

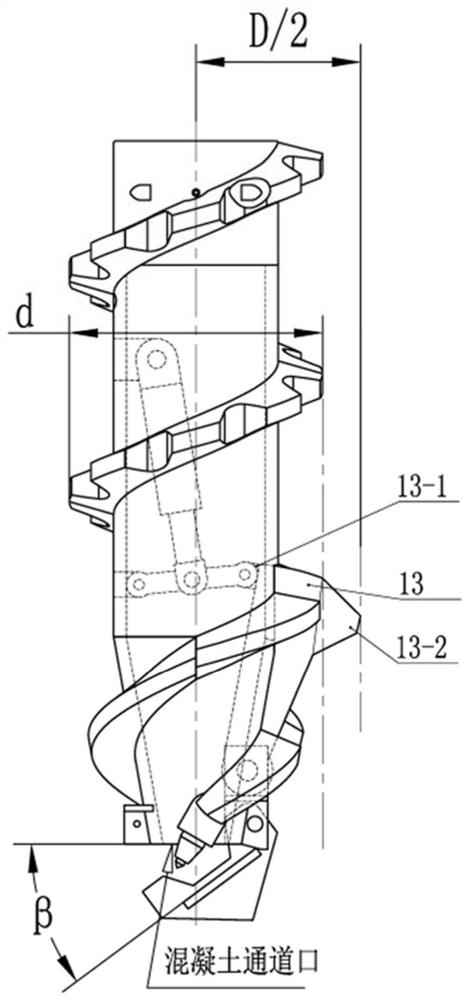

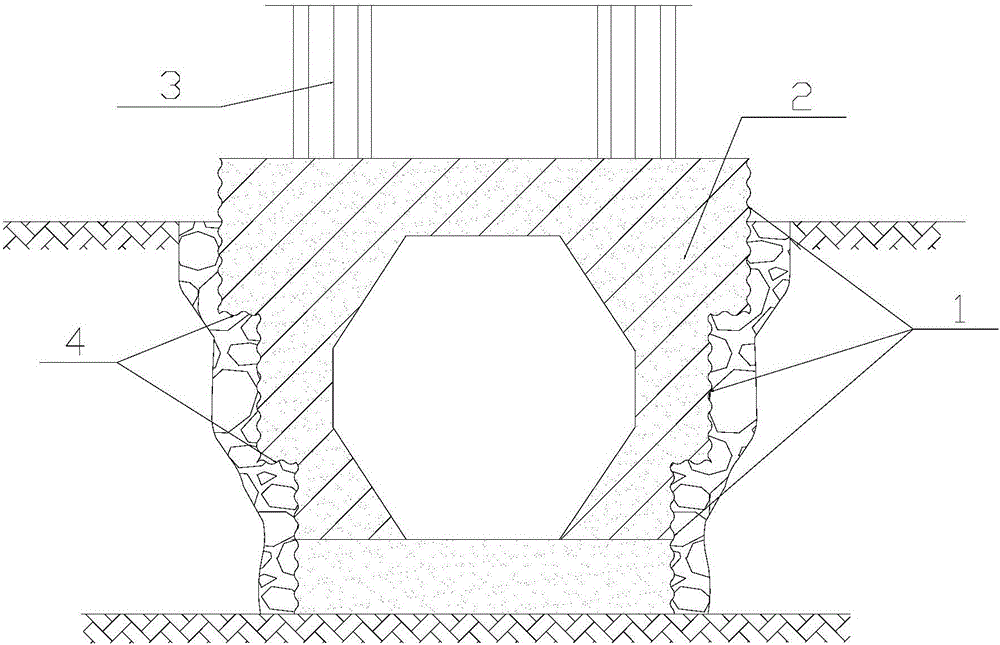

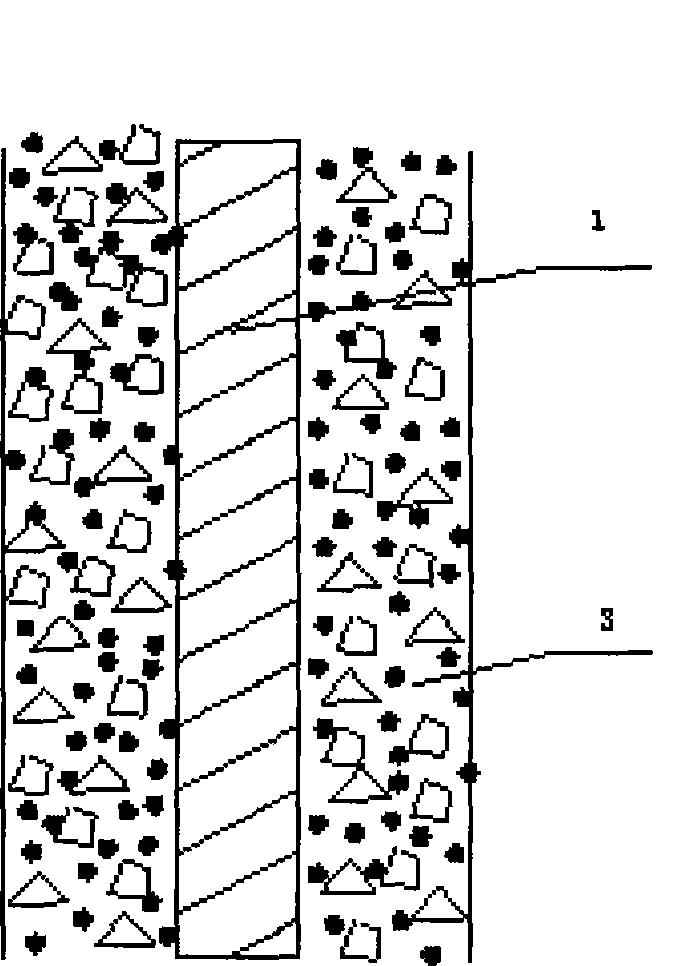

Cast-in-place concrete pile with mixing layer wrapped pile section, drill bit for pile forming and construction method

PendingCN112900424AImprove bearing capacityImprove carrying capacityDrill bitsSealing/packingResidual soilsDrill bit

The invention relates to a cast-in-place concrete pile with a mixing layer wrapped pile section, a drill bit for pile forming and a construction method. The cast-in-place concrete pile with the mixing layer wrapped pile section is composed of a pile body section and a pile bottom section; the pile body section at least comprises one mixing layer wrapped pile section; and the mixing layer wrapped pile section is arranged at the bottom end and / or the middle portion and / or the top end of the pile body section. According to the mixing layer wrapped pile section, the periphery of a pile body of a foundation pile section is wrapped by a mixing layer which has a certain thickness and is formed by a mixture formed by stirring and mixing pile side soil and concrete through an extruding and expanding protruding block of the drill bit, and the mixing layer wrapped pile section and the pile body of the foundation pile section are fixedly connected into the integrated pile section; the bearing capacity of the created pile is high, the controllability of the outer diameter of the mixing layer is good, the extruding and expanding protruding block in an expanding sliding block in the drill bit has the soil extruding effect during work, and threaded pile sections with different expanding diameters can be formed; and the drill bit for pile forming is simple in structure, has the soil extruding and hole forming functions, and is small in residual soil emission, easy to operate during pile forming construction, good in pile forming quality controllability, high in work efficiency and free of vibration and mud during construction.

Owner:刘守进 +1

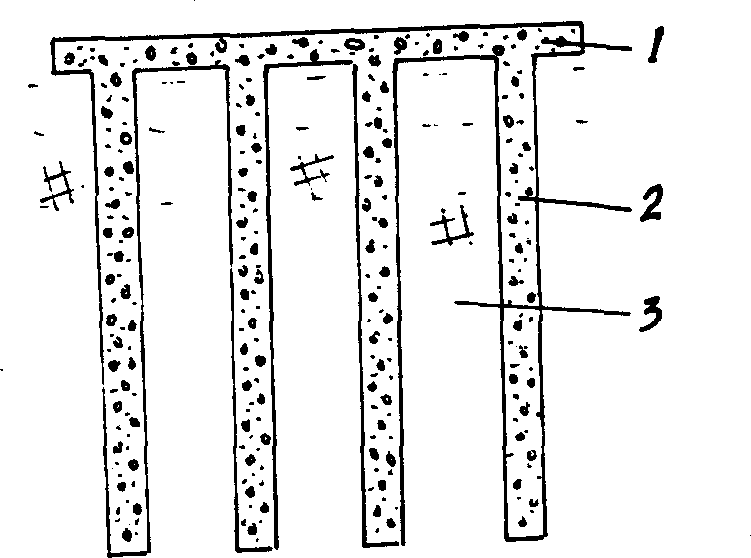

Corrugated steel cofferdam hollow digging pile and manufacturing technique thereof

The invention relates to a corrugated steel cofferdam hollow digging pile and a manufacturing technique thereof. The corrugated steel cofferdam hollow digging pile comprises a cofferdam, a steel bar concrete hollow pile body in the cofferdam, and a pier stud above the steel bar concrete hollow pile body. The cofferdam is provided with a plurality of circular corrugated steel wallboards arranged in a layered mode. The diameters of the circular corrugated steel wallboards arranged in the layered mode are decreased sequentially from top to bottom. A transverse corrugated steel connection plate is arranged in a gap between every two adjacent circular corrugated steel wallboards. The manufacturing technique of the corrugated steel cofferdam hollow digging pile comprises the steps that a hoisting excavator excavates the first section of pile hole, and the first layer of circular corrugated steel wallboard is arranged; the multiple layers of circular corrugated steel wallboards with the diameters decreasing from top to bottom are arranged through the same construction method; a hollow inner mold is mounted and perfected; pouring of all concrete of a pier foundation is completed; and finally the pier stud is embedded and connected with steel bars. According to the corrugated steel cofferdam hollow digging pile and the manufacturing technique thereof, the material consumption of the cofferdam is low, the frictional resistance of the pile wall is high, the diameter of the pile is large, the open excavation speed is higher than the drilling speed, the technique is easy and convenient to implement, and the economic benefits are good.

Owner:JSTI GRP CO LTD

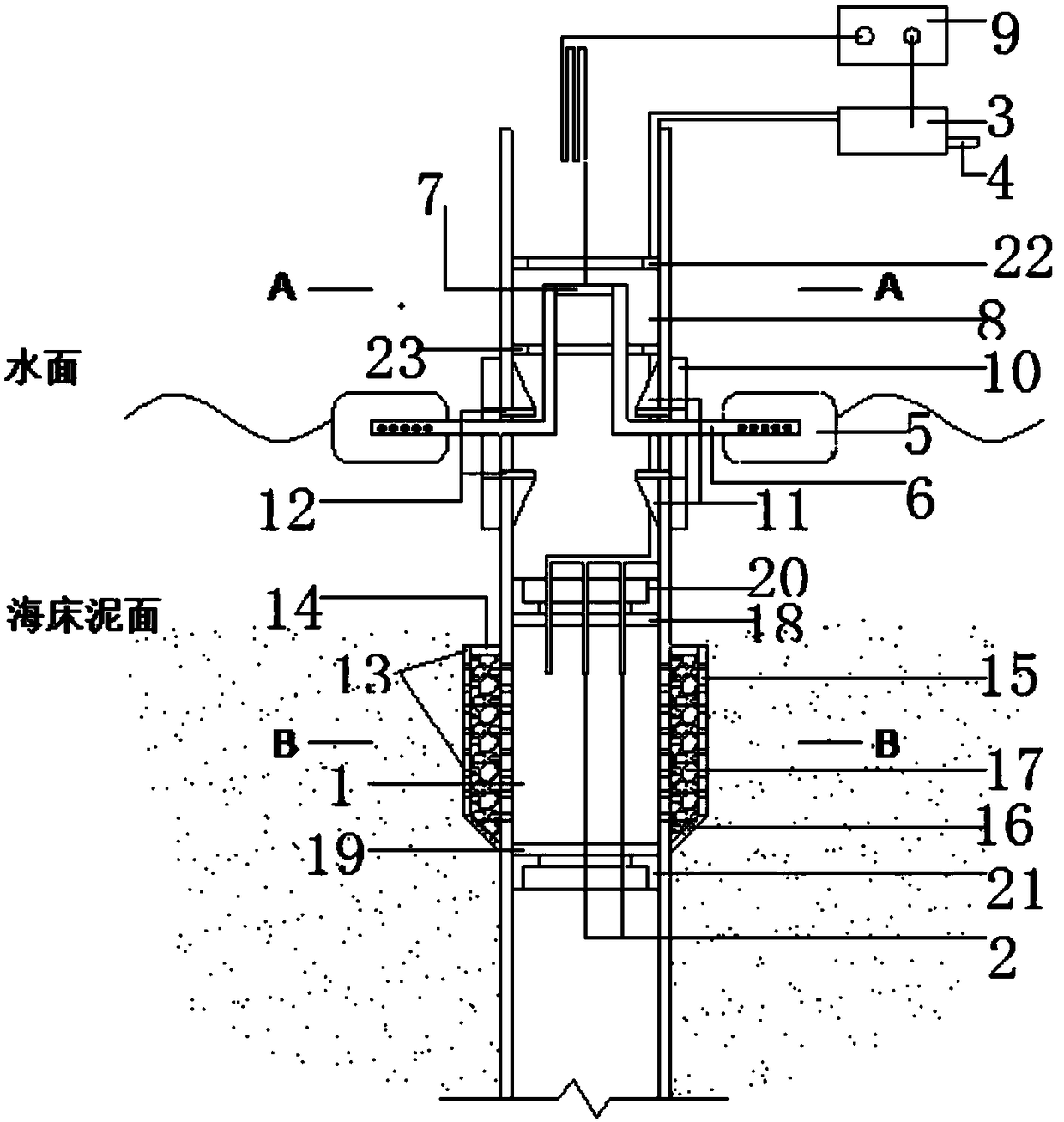

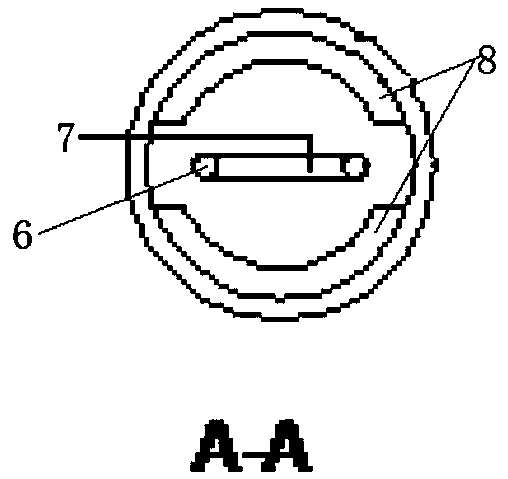

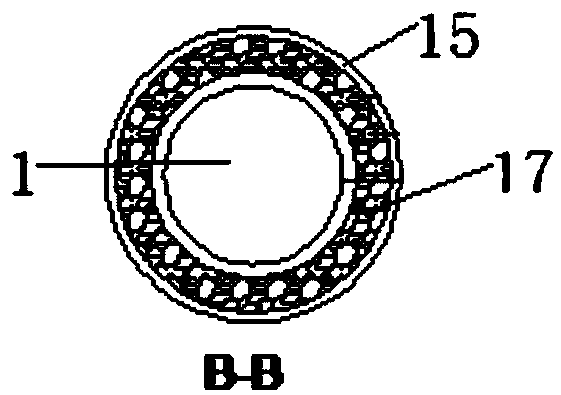

A Grouting Gravity Anchor Pile Foundation Suitable for Medium Water Depth

ActiveCN110080265BSignificant progressImprove vertical pull-out capacityFoundation engineeringPipeMooring line

The invention discloses a grouting type gravity anchor pile foundation suitable for medium water depth, which comprises a gravity chamber and steel pipe piles. The gravity chamber is located on the mud surface of the seabed, and a pile plate is arranged on the bottom surface of the gravity chamber. The steel pipe piles described above run through the entire gravity chamber and the pile plate, and are inserted deep into the seabed. Among them, the steel pipe piles located inside the gravity chamber are provided with several rows of shear keys distributed along the circumference of the steel pipe piles. The bottom is provided with a number of skirts, the skirts are inserted into the seabed, and the gravity chamber is provided with a grouting inner pipe, and the grouting inner pipe is connected with a grouting machine. The gravity chamber of the present invention can form an obvious additional self-weight section. By combining the grouting technology, the self-weight of the anchor pile foundation after the completion of the laying can be further increased, thereby effectively increasing the vertical pull-out bearing capacity and forming a full-angle anti-mooring The capacity of the cable load is improved, and the setting of the bottom apron further improves the horizontal bearing performance, and the device of the present invention can be prefabricated as a whole, which is convenient for construction.

Owner:HOHAI UNIV

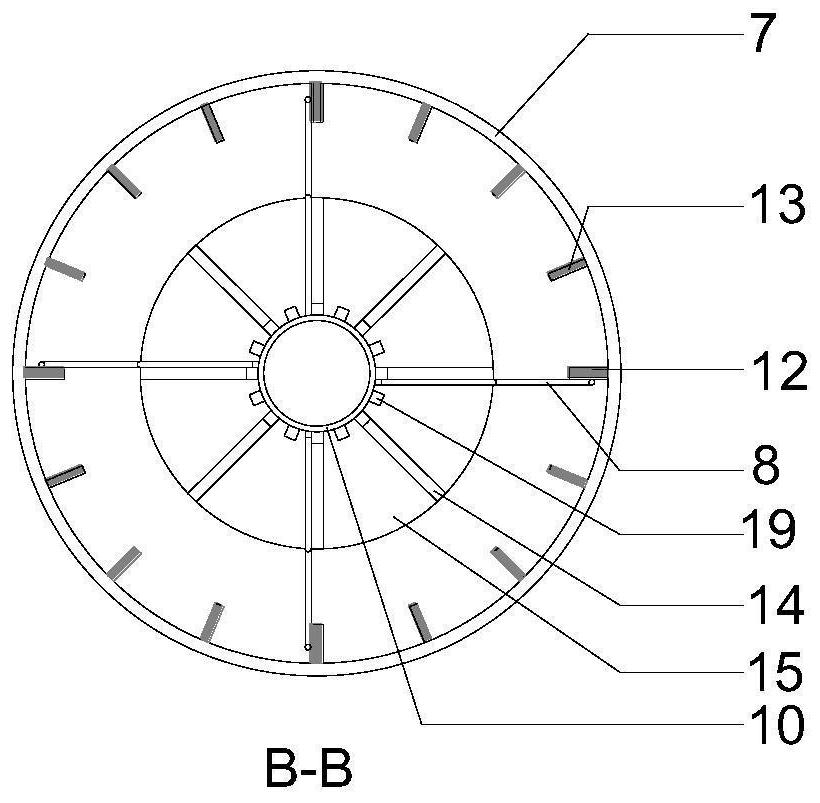

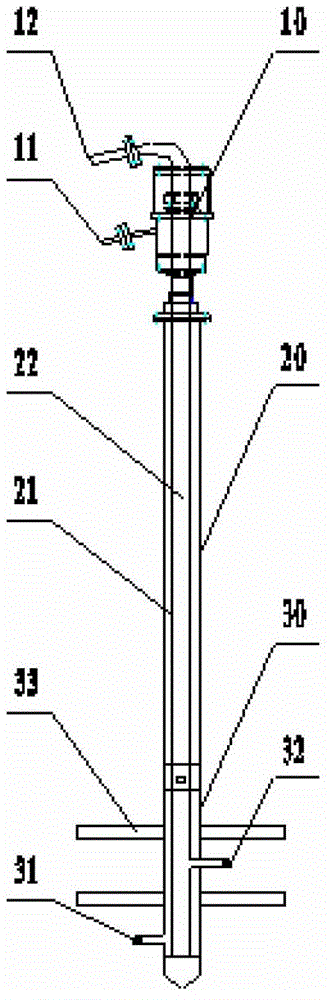

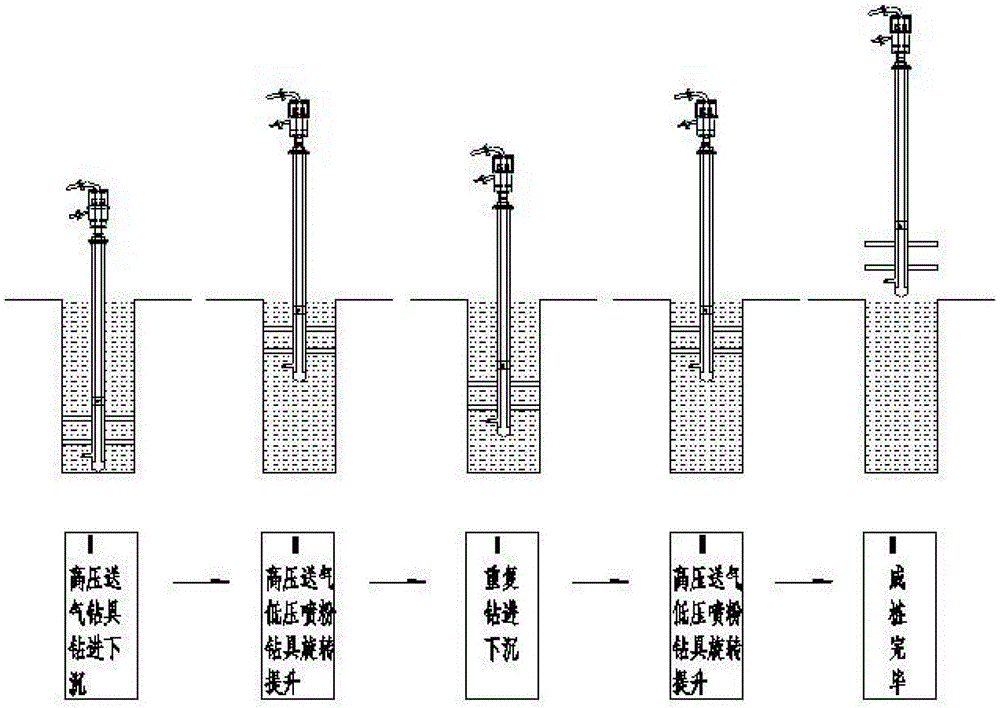

Double-tube dry-shotcrete cement soil pile-forming method

The invention discloses a double-tube dry-shotcrete cement soil pile-forming method which comprises a first step of conducting ventilation premixing sinking, a second step of conveying and lifting dry powder curing agent, and a third step of conducting repeated mixing and forming a pile. A high-pressure draft is jetted into the soil through air tubes, and the high-pressure draft has the functions of soil cutting and cement soil stirring. Therefore, construction of a power-spraying pile with a large diameter and a large depth can be achieved, and the efficiency of construction and the quality of the formed piles can be improved.

Owner:CHINA RAILWAY SCI & IND GRP RAIL TRANSPORTATION EQUIP LIMITED

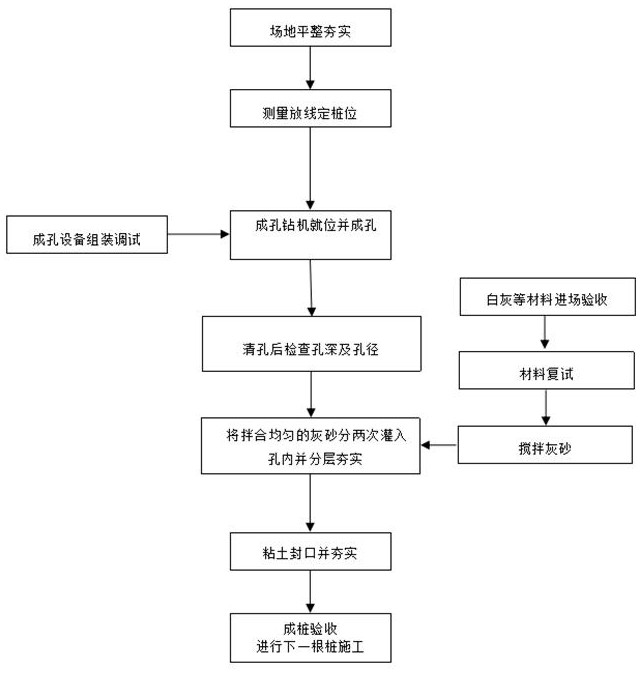

Construction method for enhancing earthwork compactness of small-span #-shaped beam inner lime sand pile

The invention belongs to the technical field of building construction, and particularly relates to a construction method for enhancing earthwork compactness of a small-span #-shaped beam inner lime sand pile. The construction method comprises the following steps that S100, site leveling and tamping are conducted; S200, surveying, setting out and positioning of the pile are conducted; S300, a hole forming drilling machine is in place, and hole forming work is conducted; S400, the hole depth and the hole diameter are checked after emptying is conducted; S500, evenly-mixed lime sand is poured into a hole in two times, and layered tamping is conducted; S600, clay sealing and tamping are conducted; and S700, pile forming acceptance is conducted, and construction of the next pile is conducted. According to the construction method, the manufacturing cost is low, the construction period is short, construction is convenient, and the effect is remarkable.

Owner:CHINA RAILWAY NO 3 GRP CO LTD

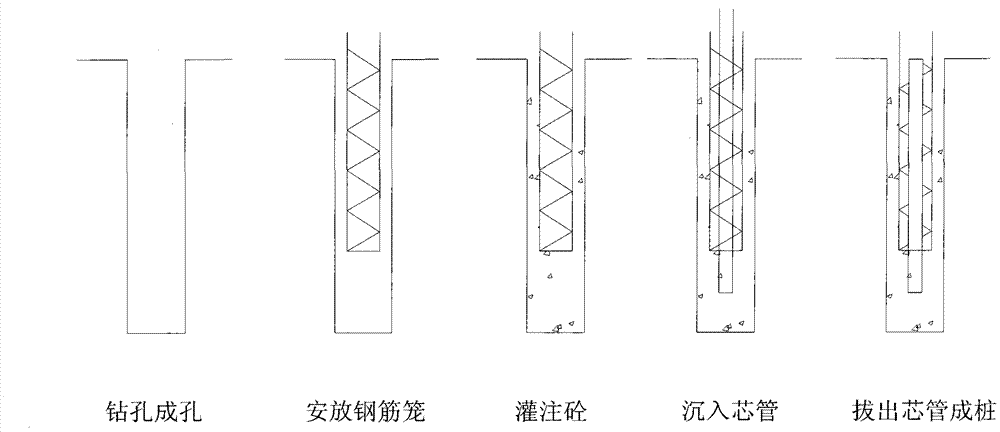

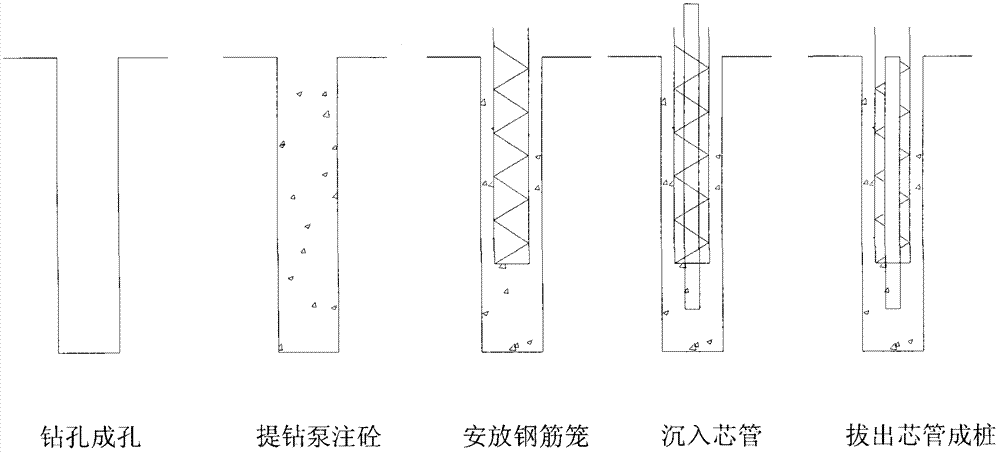

Method for drilling and filling concrete hollow pile

The invention provides a method for drilling and filling a concrete hollow pile. The method comprises the following steps: drilling by using a long spiral drilling machine; arranging a steel bar cage in a drilled hole; keeping a protection layer between the steel bar cage and a hole wall; filling concrete into the drilled hole; sinking an inner core pipe into the drilled hole and keeping for the first pre-set time; and pulling out the hollow core pipe after second pre-set time to form the concrete hollow pile. The method provided by the invention has the beneficial effects that the inner core pipe is sunk into a concrete pile so that a pile body of the concrete pile and a soil body beside the pile are compacted; meanwhile, the pile diameter of the concrete pile is increased so that the aim of improving the pile bearing force is achieved.

Owner:董相东 +1

Construction method for underground excavation station bottom part water-stopping

ActiveCN110485460ATo achieve water-stop effectSolve the water stop problemArtificial islandsUnderwater structuresSlurry wallPilot hole

The invention discloses a construction method for underground excavation station bottom part water-stopping. The construction method for underground excavation station bottom part water-stopping comprises the steps that construction preparation is conducted, pilot holes are constructed, chambering is conducted, mixing is conducted, a rotary jet grouting mixing pile is formed, a next rotary jet grouting mixing pile is constructed to be mutually occlusive to a pile body side part of the previous rotary jet grouting mixing pile, and a water-stop curtain is formed. An immersed tube method or a slurry wall protection method can be adopted in the construction of the pilot holes. The rotary jet grouting mixing pile at the previous pile position and the pilot hole at the next pile position can beconstructed simultaneously. According to the construction method for the underground excavation station bottom part water-stopping, the precipitation technology of a precipitation well is completely abandoned, groundwater resources are effectively protected, the problem of the station bottom part water-stopping in water-rich stratum is solved, at the same time, the construction method is simple and flexible, the construction period is short, the stratum is widely applicable, maneuverability is high, bearing capacity and anti-floating ability are extremely high, the construction impact is small, the underground environment is not harmed, and the construction method for underground excavation station bottom part water-stopping is of great engineering practical value for large-area and low-clearance underground excavation station construction with high underground water level.

Owner:BEIJING SHOUER ENG TECH

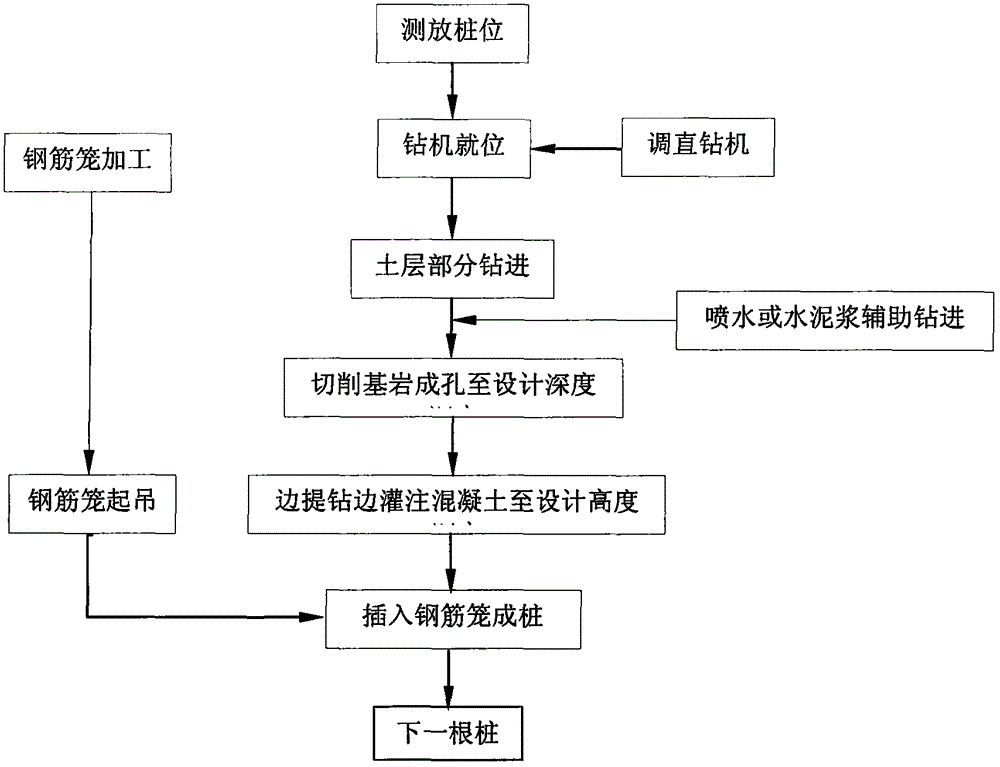

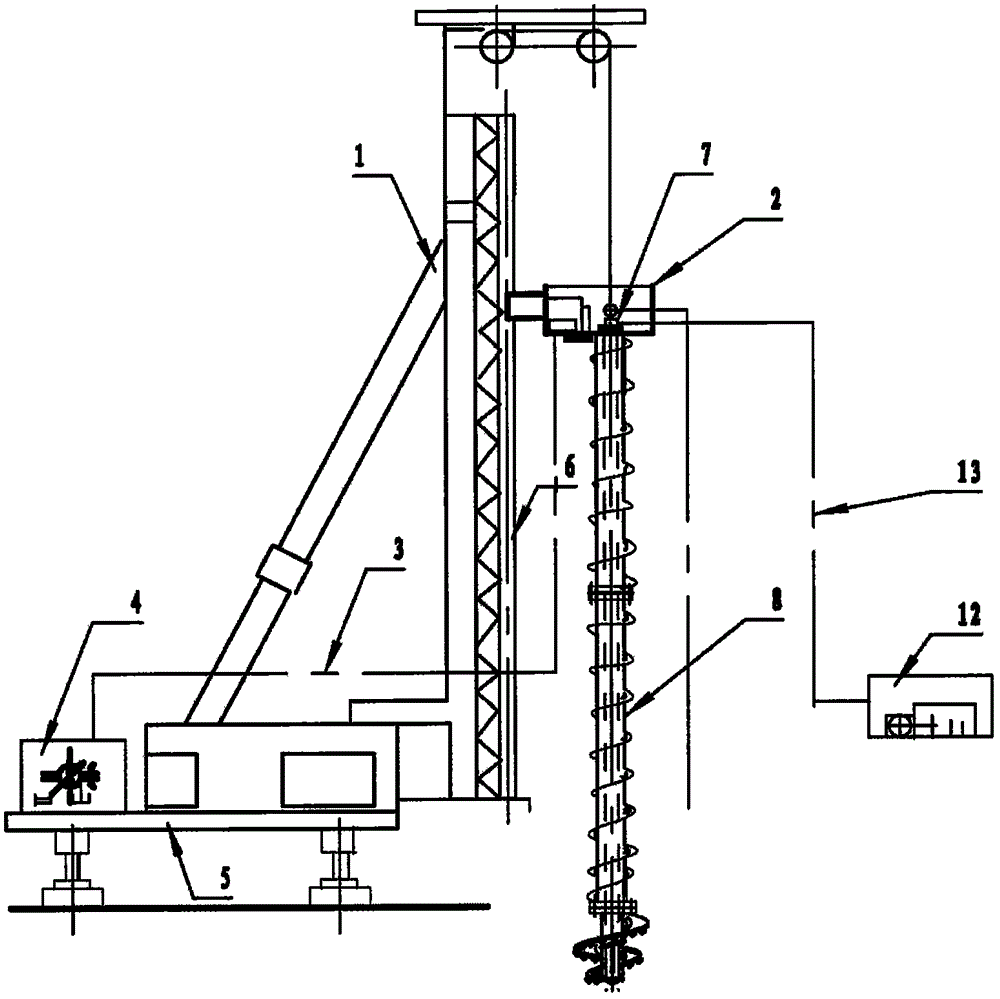

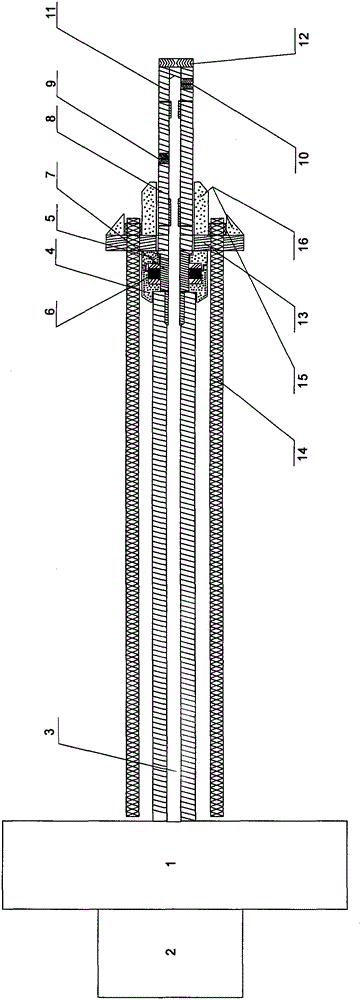

A kind of reinforced long spiral rock-socketed construction equipment and its technology

ActiveCN104329020BOutstanding construction abilityAdaptableDrill bitsDrilling rodsBedrockPower station

The invention relates to reinforced long-screw rock-socketed construction equipment. The reinforced long-screw rock-socketed construction equipment consists of a reinforced rack, a special power system, a drilling system and a cooling system, wherein the reinforced rack comprises a control console and a pile frame, the special power system comprises a power head, an oil pressure delivery pipe and a power station, the drilling system comprises a reinforced drill rod, a special drill bit and a multifunctional flange plate, and the cooling system consists of a grouting pump, a grouting pipe, a welded connecting pipe and a spray nozzle. A construction process adopting the reinforced long-screw rock-socketed construction equipment comprises the steps of pile position setting-out, construction equipment adjustment, drilling machine movement in position, soil layer drilling, cutting of bedrock for hole formation to design depth, grouting for pile formation, etc. The reinforced long-screw rock-socketed construction equipment and the process thereof have the advantages that the drilling ability is strong, the application scope is wide, the problems that a long-screw drilling machine cannot realize drilling, is get stuck and the like in dense large-grain-size gravel soil layers and decayed rock layers are solved, and a foundation is laid for widely applying long-screw hole drilling for pile grouting.

Owner:BEIJING ZHONGYAN DADI TECH CO LTD

Construction process of floral tube dry filling piles

InactiveCN101713189BReduce labor intensityFew control parametersBulkheads/pilesResource utilizationWater table

Owner:HENAN UNIVERSITY

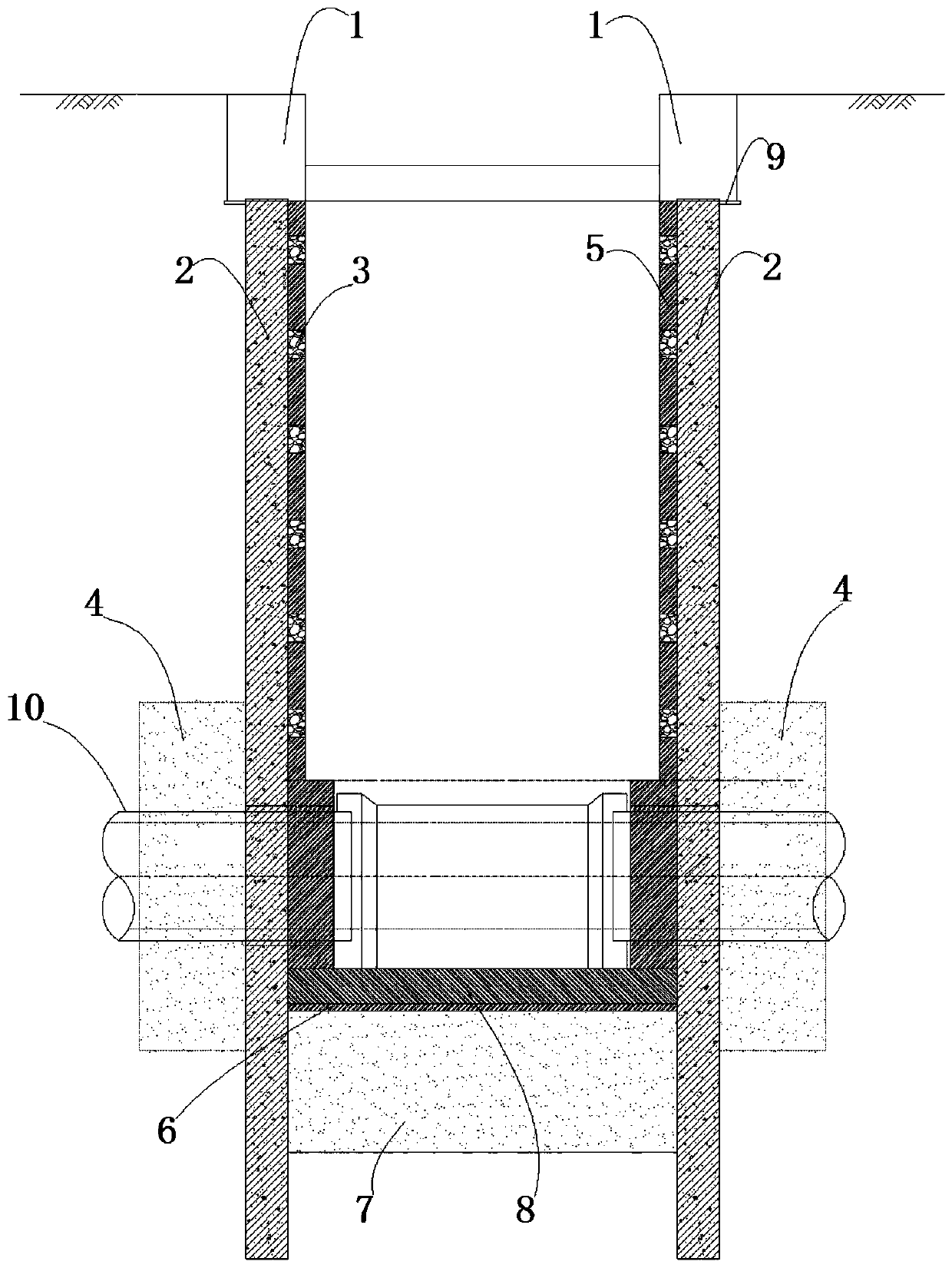

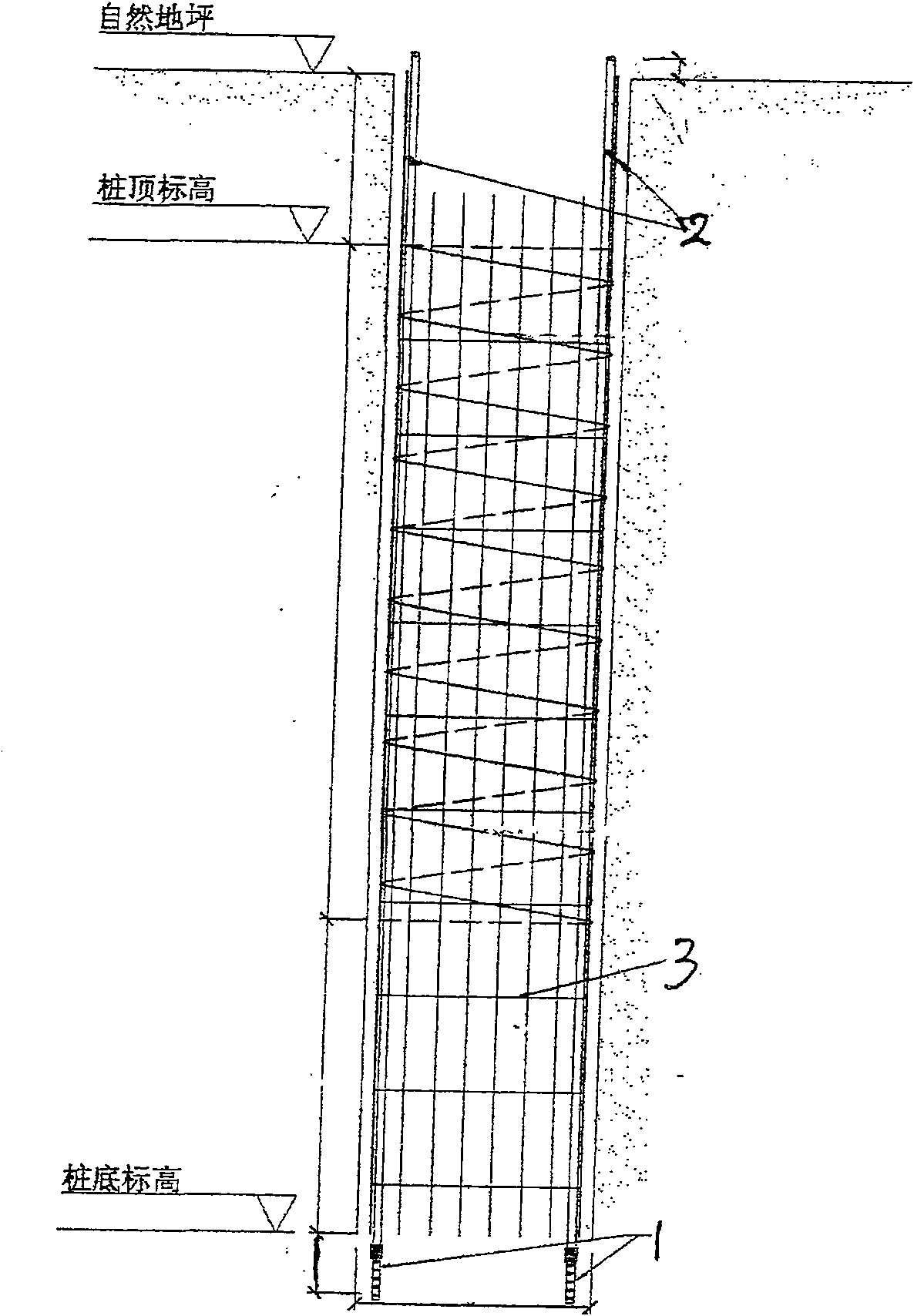

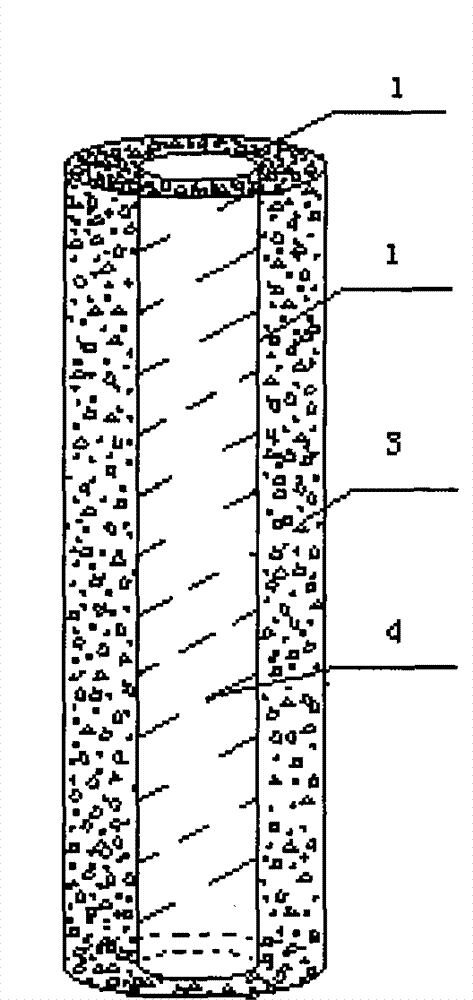

Construction method of combined pile foundation for reinforcing prestressed pipe pile

ActiveCN113250189AIncrease the cross-sectional areaHigh bonding strengthBulkheads/pilesSoil preservationPre stressCement paste

The invention discloses a construction method of a combined pile foundation for reinforcing a prestressed pipe pile. The construction method comprises the following steps that A1, firstly, the prestressed pipe pile (6) is constructed; A2, a steel pipe pile (7) is driven into the outer side of the prestressed pipe pile (6), the pile end of the steel pipe pile (7) extends into a bearing stratum soil body (4), and micro-expansive type polymer cement paste is injected to a position between the steel pipe pile (7) and the prestressed pipe pile (6) through two steel grouting floral tubes (10); A3, finally, soil in the prestressed pipe pile (6) is removed, a supporting plate (9) is placed, then a reinforcement cage (8) is put in, and fine aggregate concrete (15) is filled for pouring; and A4, then a garbage landfill layer (3) is leveled, a plain concrete cushion layer (2) is laid, finally, an upper structure foundation (1) is constructed on the plain concrete cushion layer (2), and the top end of the prestressed pipe pile (6) and the top end of the steel pipe pile (7) are anchored into the upper structure foundation (1). Therefore, the combined pile foundation is formed, and the purposes of improving compression resistance, shear resistance and stability are achieved.

Owner:郑州辉昂装饰设计工程有限公司

Method and apparatus for triple pipe rotary spray of reinforced concrete pile foundation

InactiveCN1109793CChange backward imageChange the problem of collapsing holes and hurting peopleBulkheads/pilesSoil preservationReinforced concreteCrushed stone

A technology for constructing the reinforced concrete pile foundation by three-pipe rotary spray includes drilling, cutting earth body, discharging earth, grouting and additional steps including opening surface earth, setting-up reinforcing bar cage, pouring broken stone as aggregate ,vibrating and curing. Its apparatus features that three pipes are collectively sealed, the inner cavity of water nozzle is composed of conic body and cylindrical body, and the inner cavity of air nozzle consists of conic barrel and cylindrical ring barrel. The grouting nozzle is under the water and air nozzle by a distance of 800-1200mm.

Owner:金怀娄 +1

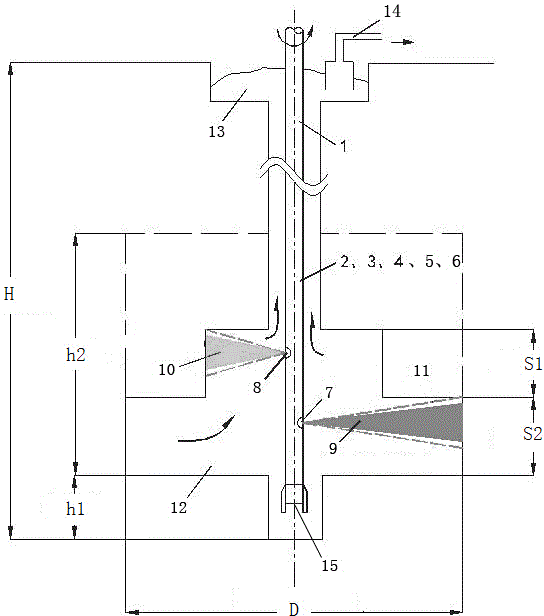

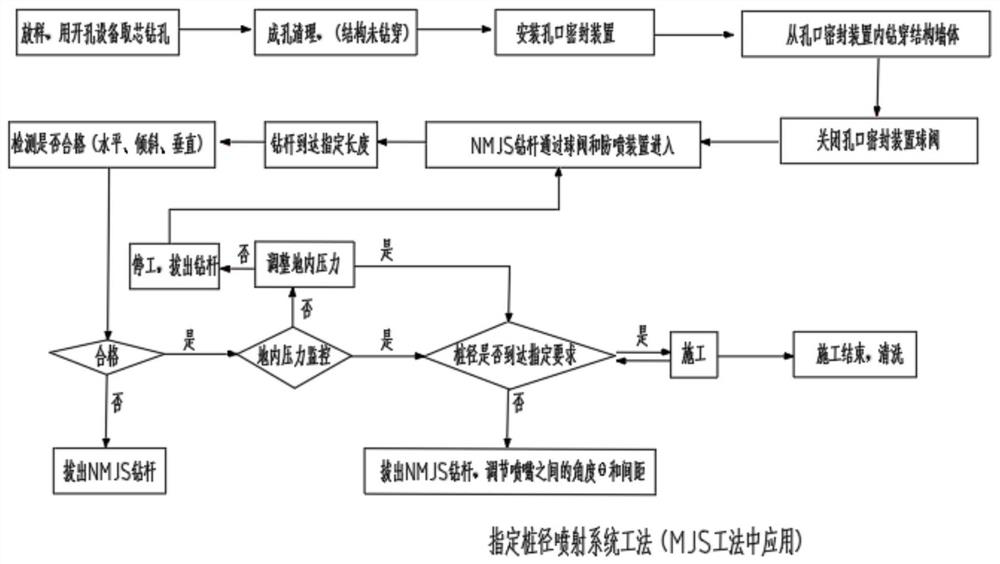

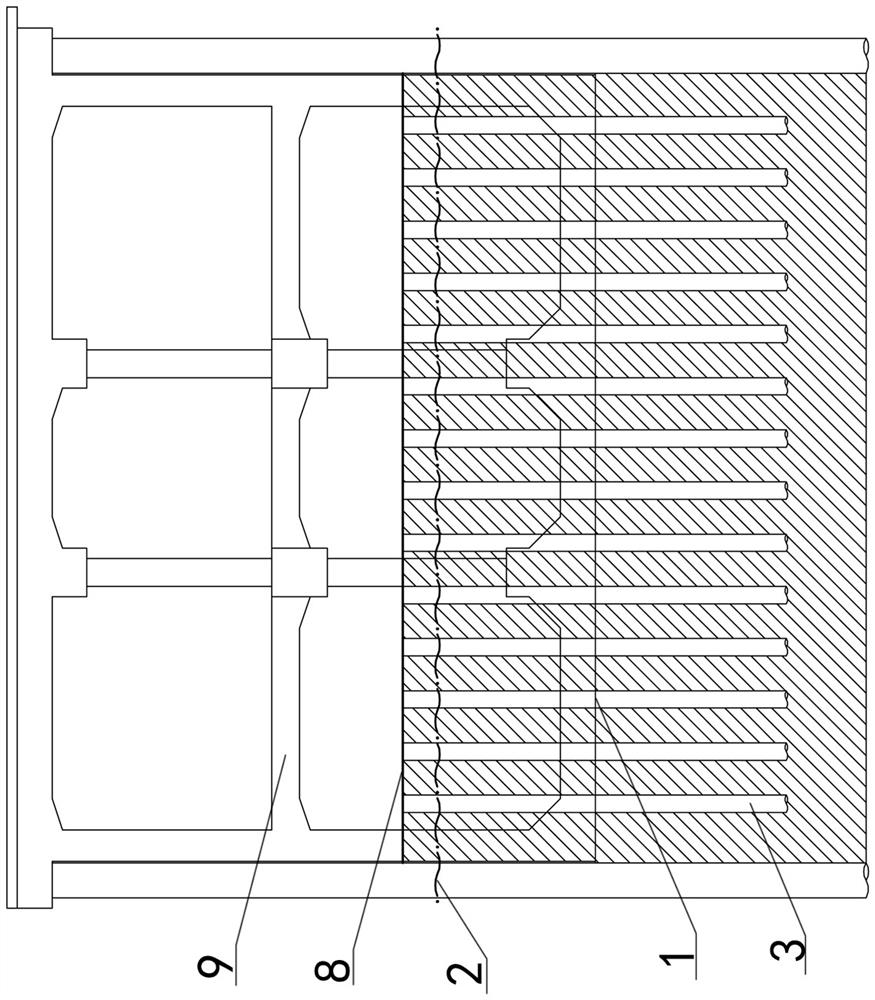

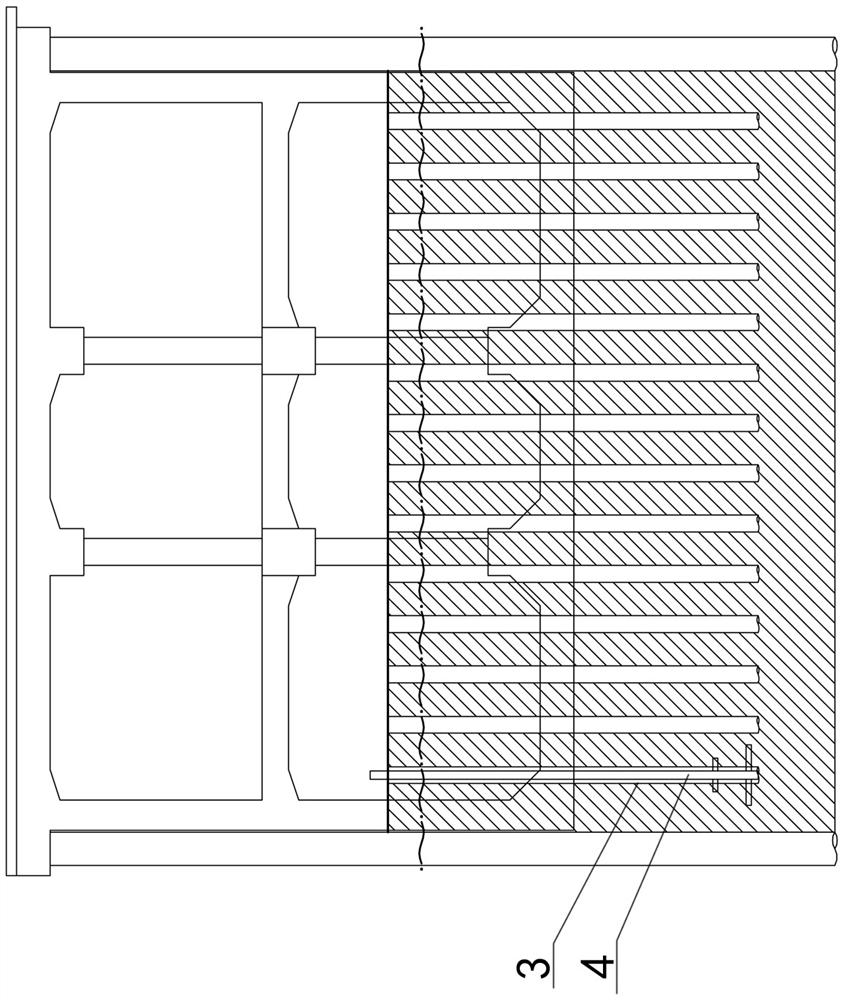

Underground grouting pile-forming multipurpose drill bit and designated pile diameter injection system construction method

InactiveCN113187399ALarge pile diameterLarge jet energySurveyLiquid/gas jet drillingSystem constructionGeotechnical engineering

The invention relates to an underground grouting pile-forming multi-purpose drill bit and a specified pile diameter injection system construction method in the technical field of rock and soil construction mechanical equipment, and adopts a novel underground grouting pile-forming multi-purpose drill bit shared by RJP and MJS processes on the basis of the existing RJP and MJS construction processes. The nozzle spacing of double main slurry nozzles (or multiple main slurry nozzles) is controlled through a specified pile diameter injection system construction method, and the specified pile diameter pile forming function is achieved in the injection mode that the injection angle is adjustable. The method has the advantages that the method is suitable for a large-flow and large-pile-diameter construction method, the pile diameter can be adjusted and controlled, and the pile forming effect is good.

Owner:上海煜铠智能科技有限公司

A Construction Method for Stopping Water at the Bottom of Underground Excavation Station

ActiveCN110485460BTo achieve water-stop effectSolve the water stop problemArtificial islandsUnderwater structuresWater stopPilot hole

A construction method for water stop at the bottom of underground excavation station, including construction preparation, construction pilot hole, hole expansion, stirring, rotary spraying, forming rotary spraying mixing pile, constructing the next rotary spraying mixing pile and the pile of previous rotary spraying mixing pile A step in which the sides of the body are occluded with each other to finally form a water-tight curtain. The construction of the pilot hole can adopt the immersed pipe method or the mud retaining wall method, etc. The rotary jet mixing pile at the previous pile position and the pilot hole at the next pile position can be carried out at the same time. The invention completely abandons the dewatering technology of the dewatering well, effectively protects the groundwater resources and solves the problem of water-stopping at the bottom of the station in the water-rich stratum. At the same time, the construction method is simple and flexible, the construction period is short, the stratum is widely applicable, and the controllability is strong. Strong bearing capacity and anti-floating capacity, small construction impact, harmless to the underground environment, and has strong engineering practical value for the construction of low-clearance submerged excavation stations with large areas and high groundwater levels.

Owner:BEIJING SHOUER ENG TECH

Equipment and method for constructing high-pressure rotary jet stiffening pile by using ribbed drilling method

ActiveCN102660944BImprove structural qualityDrilling speed reducedBulkheads/pilesMaterial resourcesHigh pressure

The invention relates to equipment and a method for constructing a high-pressure rotary jet stiffening pile by using a ribbed drilling method. The technical scheme is that: the equipment comprises an end bearing plate which is adjacent to a bearing; the bearing is provided with a protective cover; and a tapered propelling body is arranged on the non-bearing side of the end bearing plate. The equipment also comprises a vibroflot on one side, which is not provided with a drive drill pipe, of a power head. Due to the adoption of the technical scheme, the equipment and the method have the beneficial effects that the bearing is effectively protected; the protective cover is arranged outside the bearing, so that sand cannot enter the bearing; the sectional protective cover has a splicing surface which is a folding surface, and can be split through the splicing surface; the bearing can be replaced, and the sand and the like can be effectively prevented from entering the bearing through the folding surface; the tapered propelling body is arranged on the non-bearing side of the end bearing plate, so that obstacles on a propelling path can be effectively eliminated, and the end bearing plate can be smoothly propelled to finish construction; in addition, the vibroflot is arranged, so that the stratum on the propelling path can be effectively loosened, and the construction can be smoothly finished; and manpower and material resources are saved, work hours are reduced, complex procedures are eliminated, and pore-forming, rib insertion and grouting can be finished at one time.

Owner:王忠友

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com